-

摘要:

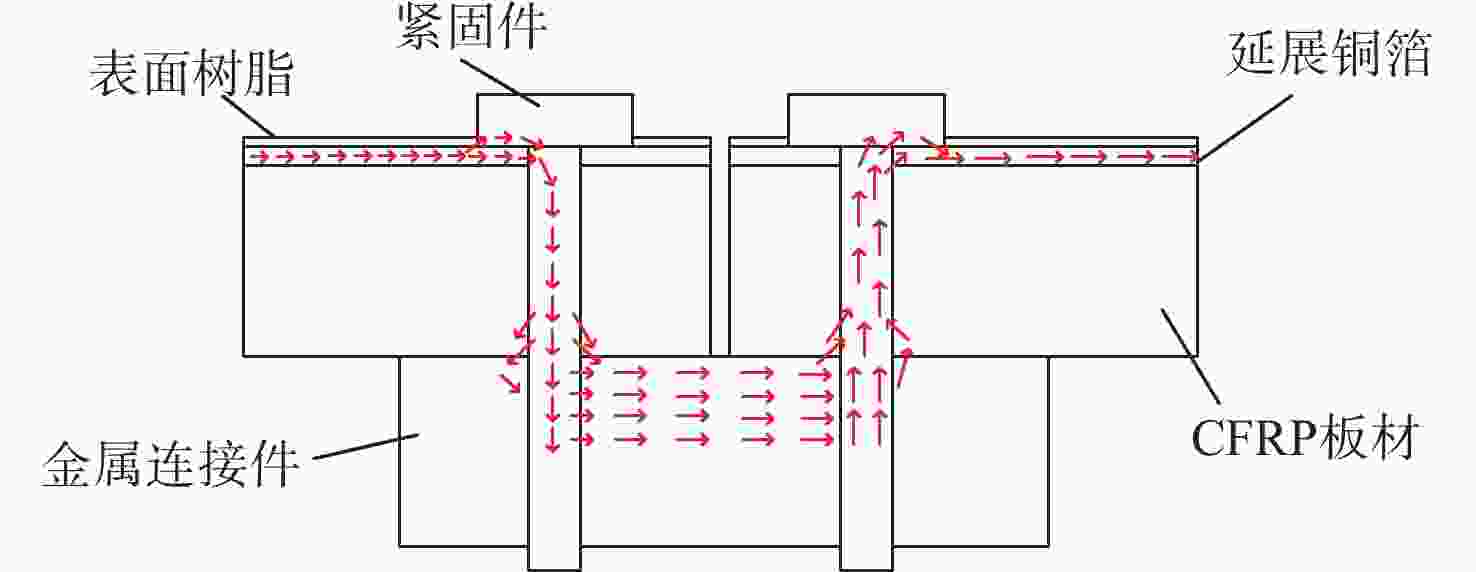

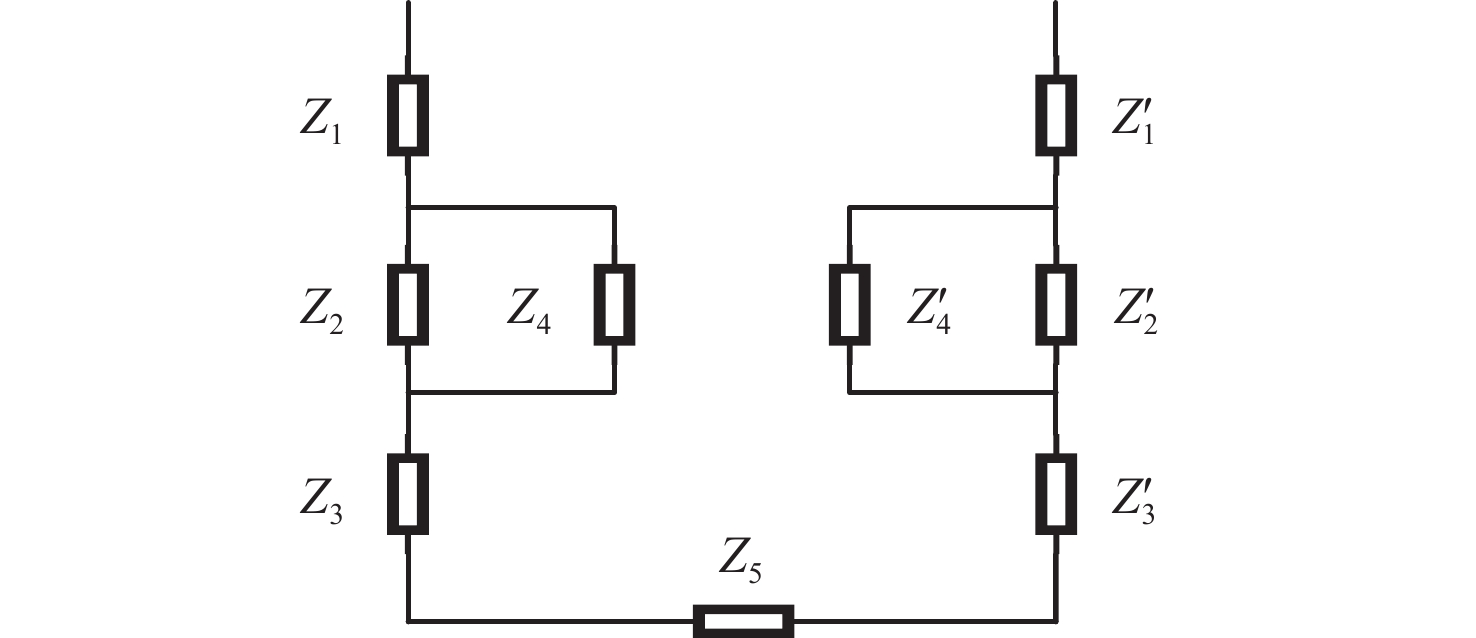

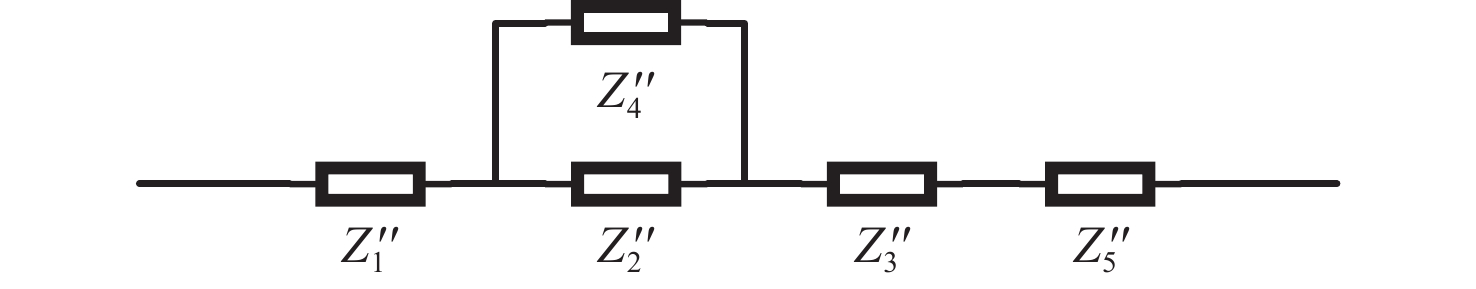

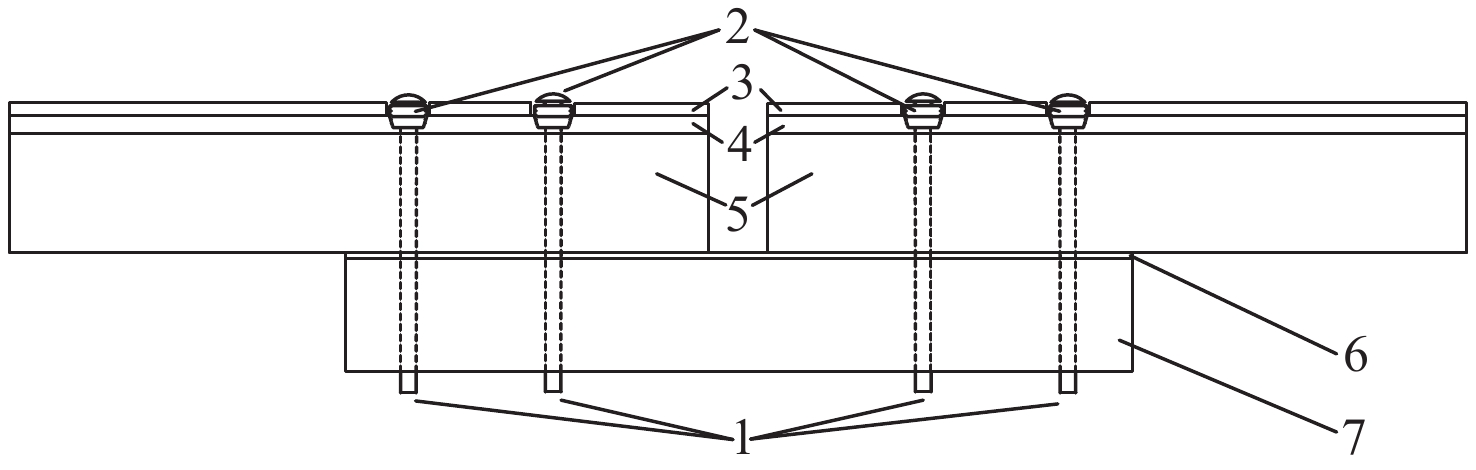

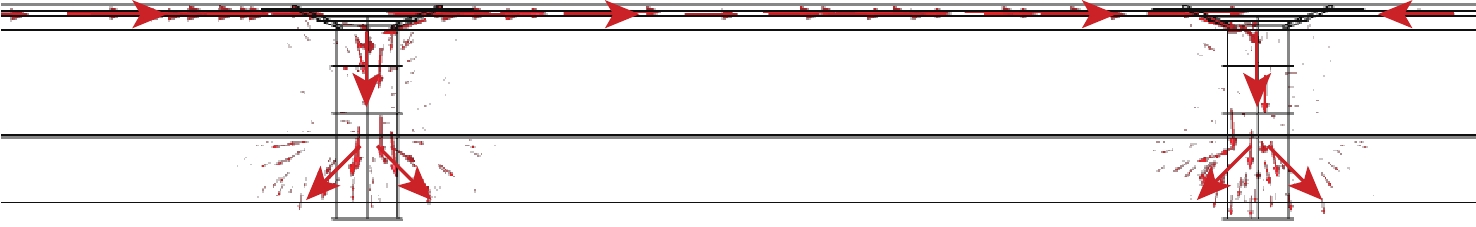

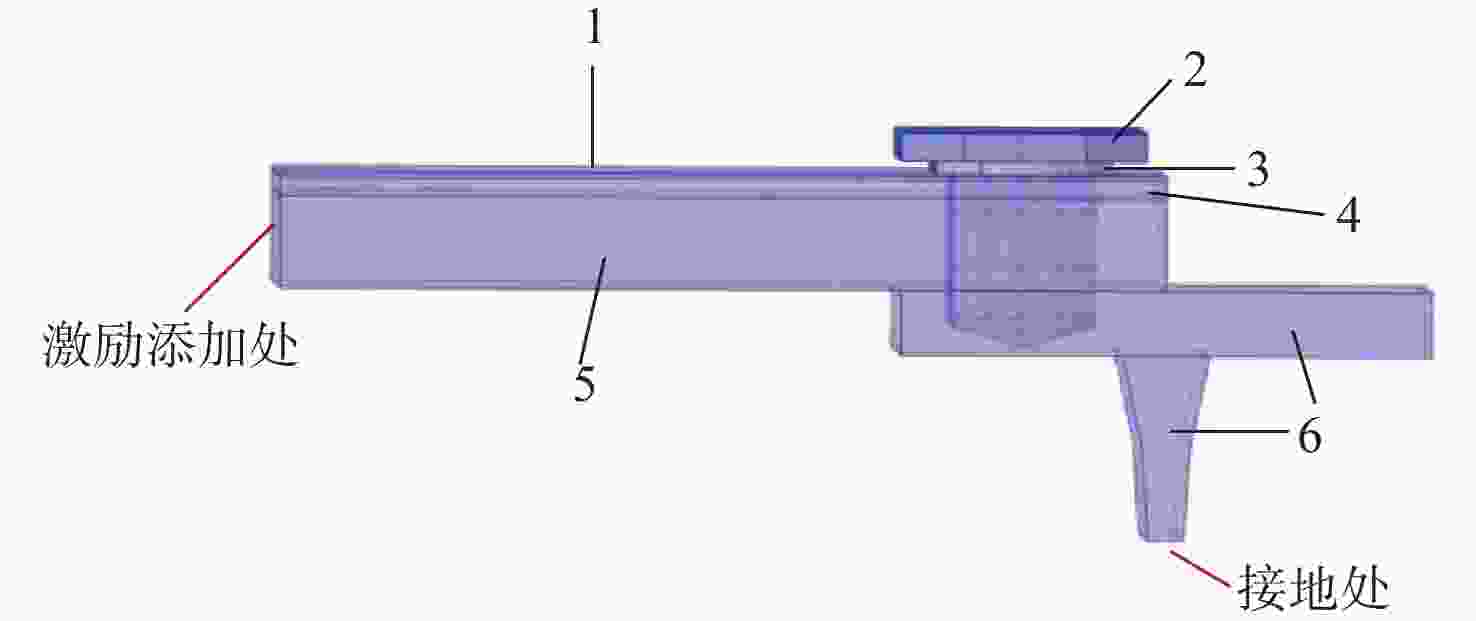

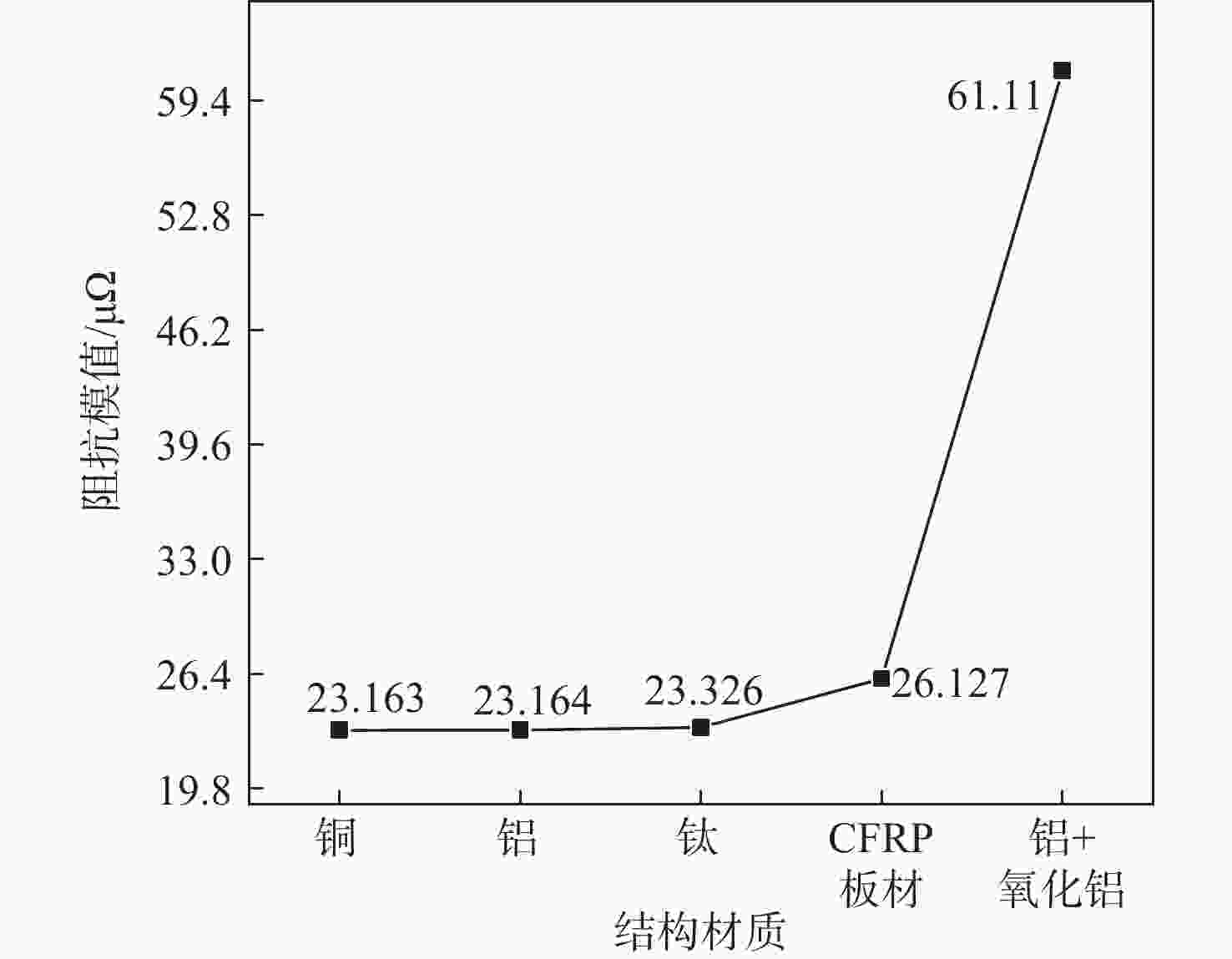

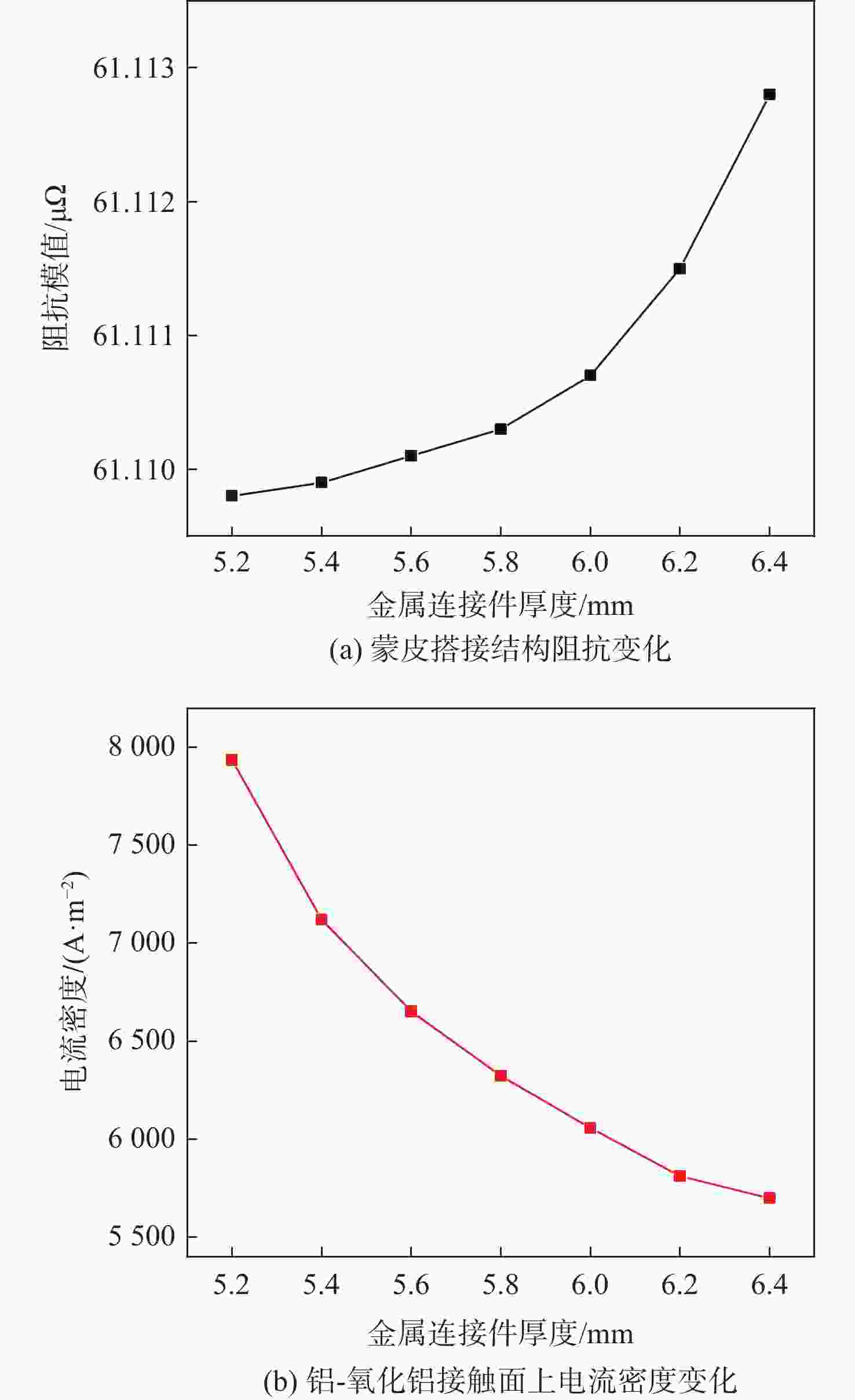

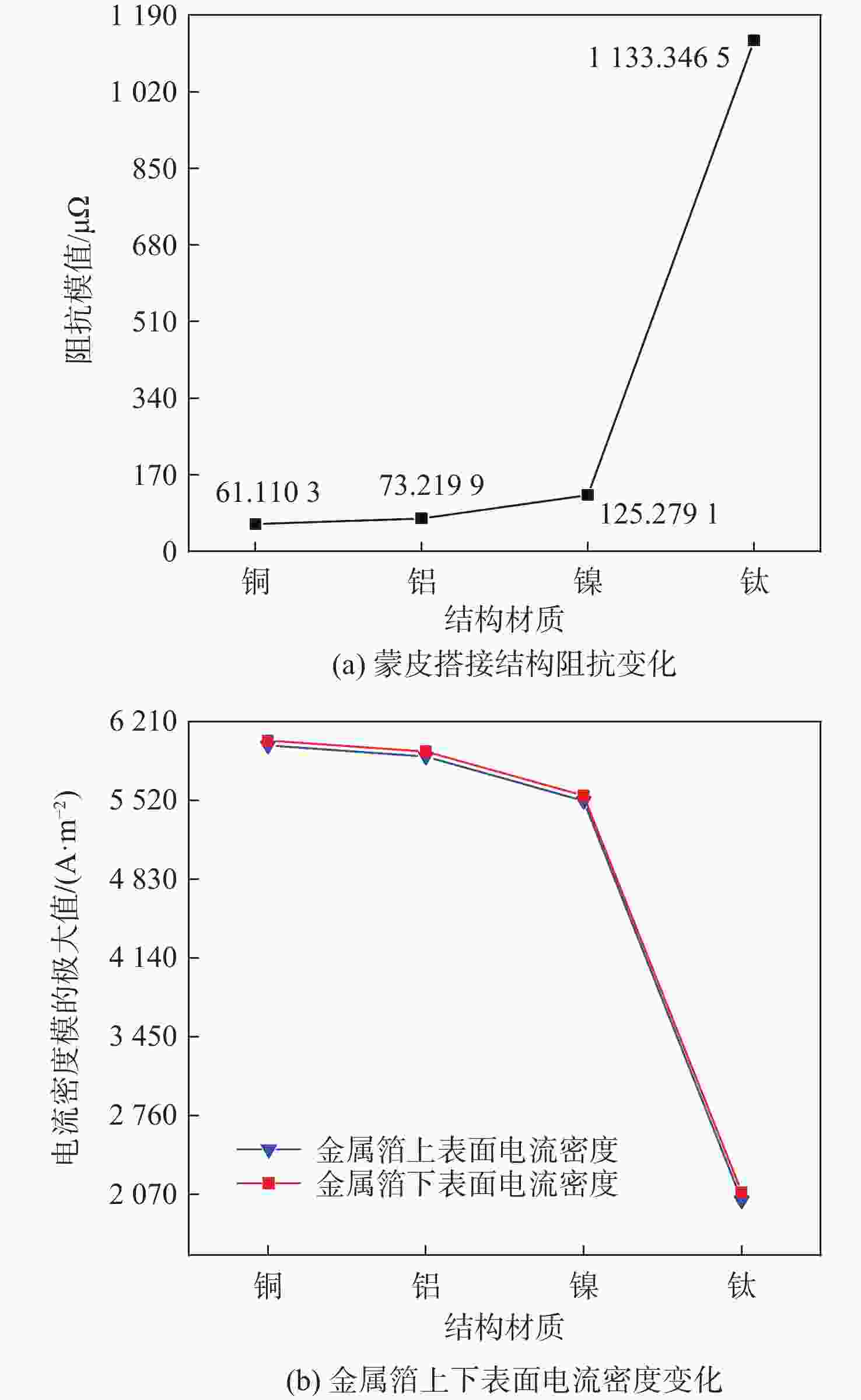

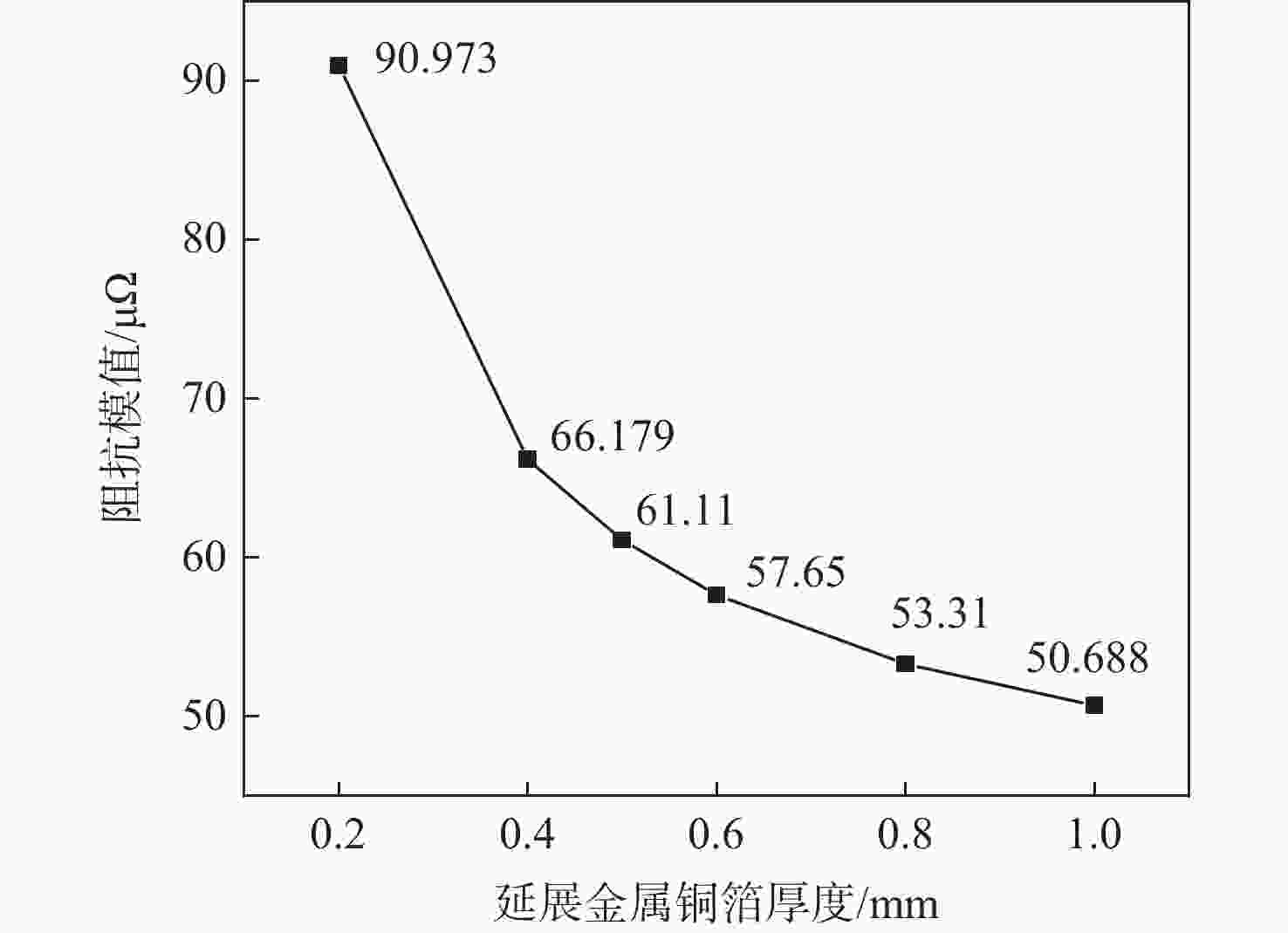

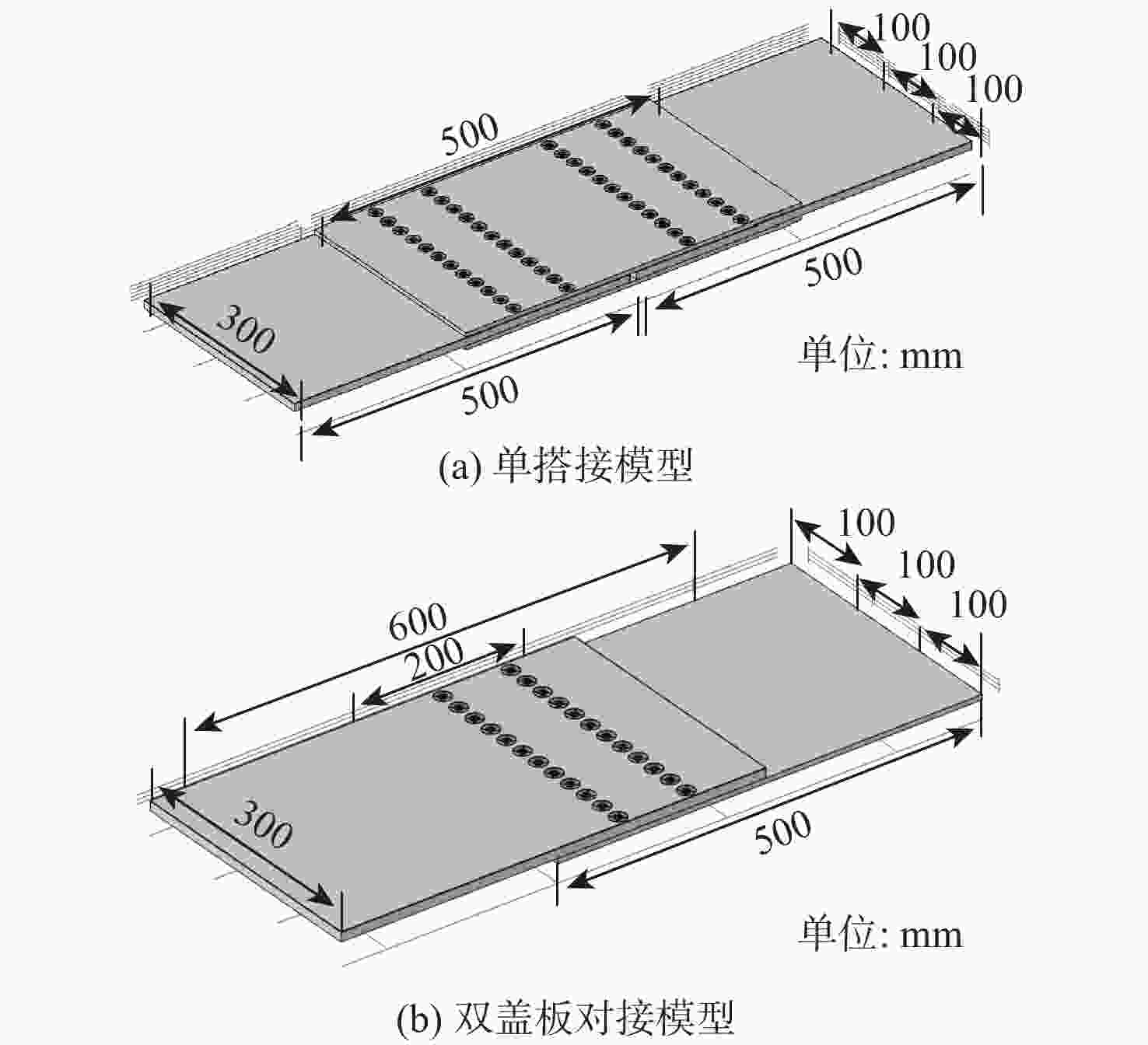

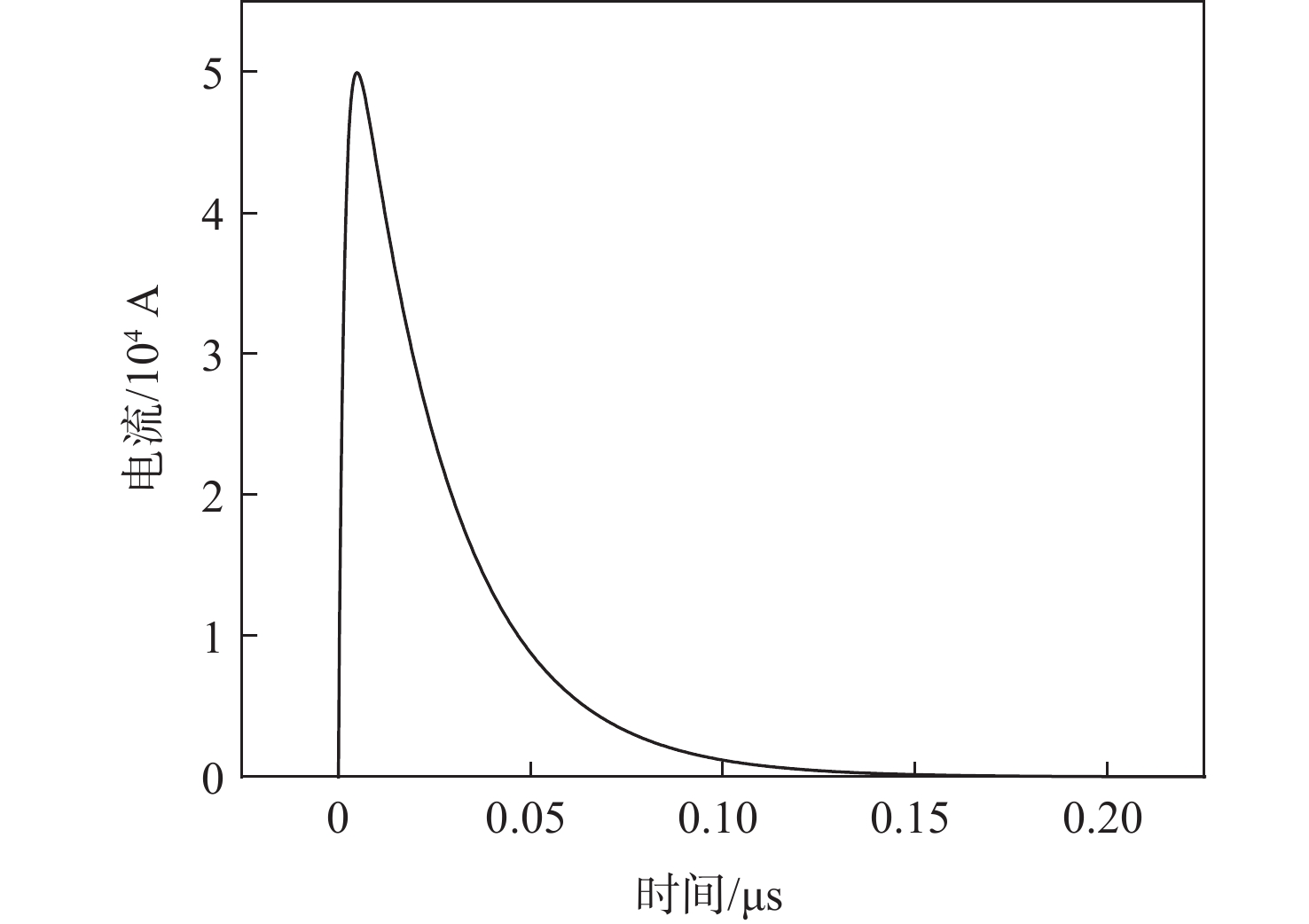

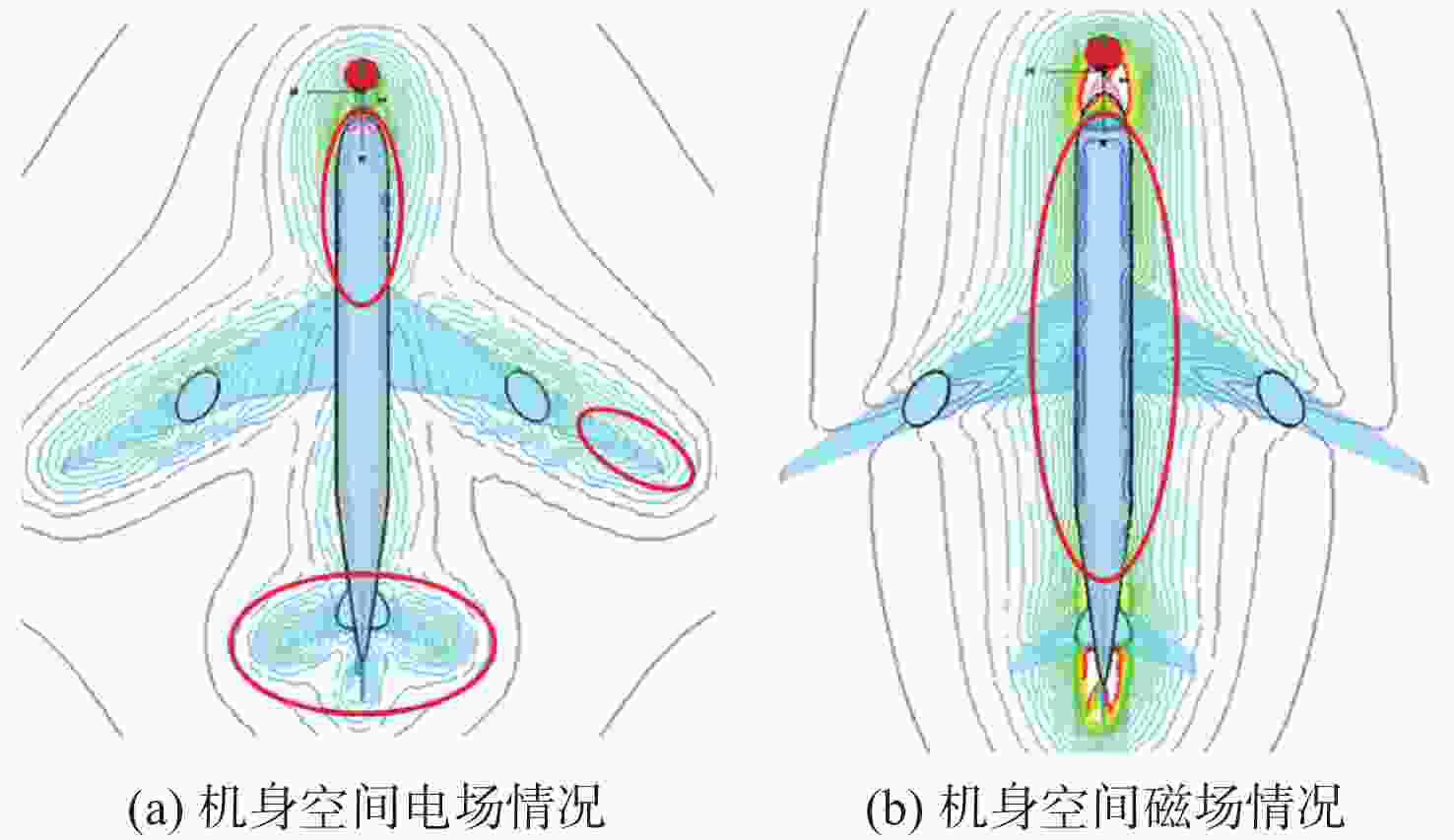

现代商业飞机中复合材料的使用率逐步上升,然而较低的电导率限制了其在蒙皮结构中的应用,一般还需搭接额外的导电结构以增强蒙皮内电流的导通性能。为分析复合材料飞机蒙皮电气特性及其影响因素,对蒙皮结构之间的搭接进行建模,并通过建立等效电路分析搭接结构电气特性影响机理。基于所构建的复合材料飞机蒙皮典型搭接结构模型,计算结构件类型、搭接方式对蒙皮电气特性的影响,并分析不同搭接方式受雷电间接效应的影响情况。计算及仿真结果表明:结构件的材质、形状及尺寸对蒙皮电气性能有一定影响,采取恰当的搭接方式可有效减小蒙皮结构阻抗、提升飞机雷电间接效应屏蔽性能。

Abstract:The use of composite materials in modern commercial aircraft is gradually increasing. However, their low electrical conductivity limits their application in skin structures. To enhance the conductivity of current within the skin, additional conductive structures are often bonded. This study modeled the bonding structures of composite aircraft skins and analyzed the electrical properties and influencing factors by establishing equivalent circuits. Using a typical bonding structure model for composite aircraft skin, the effects of structural types and bonding modes on the electrical properties were calculated, and the impact of lightning indirect effects on different bonding modes was analyzed. The results of calculations and simulations show that the material, shape, and size of structural components affect the electrical properties of the skin. Adopting appropriate bonding modes can effectively reduce structural impedance and enhance the shielding performance against lightning indirect effects.

-

Key words:

- composite material /

- aircraft skin /

- bonding mode /

- electrical properties /

- lightning indirect effect

-

表 1 螺栓与凹形垫圈尺寸

Table 1. Bolt and concave washer size

参数 数值 参数 数值 沉头螺栓总长度/mm 18 凹形垫圈高度/mm 2.2 沉头螺杆直径/mm 6.4 凹形垫圈内径/mm 6.45 沉头螺栓头直径/mm 9 凹形垫圈外径/mm 19 沉头螺栓头厚度/mm 0.5 凹形垫圈厚度/mm 0.4 表 2 结构件材质及其电导率

Table 2. Materials of structural parts and their electrical conductivity

结构件名称 材质 延展金属箔 铜 CFRP板材 CFRP 金属氧化膜 氧化铝 金属连接件 铝 沉头螺栓 钢 凹形垫圈 钛 表 3 单搭接模型紧固件尺寸

Table 3. Single lap model fastener size

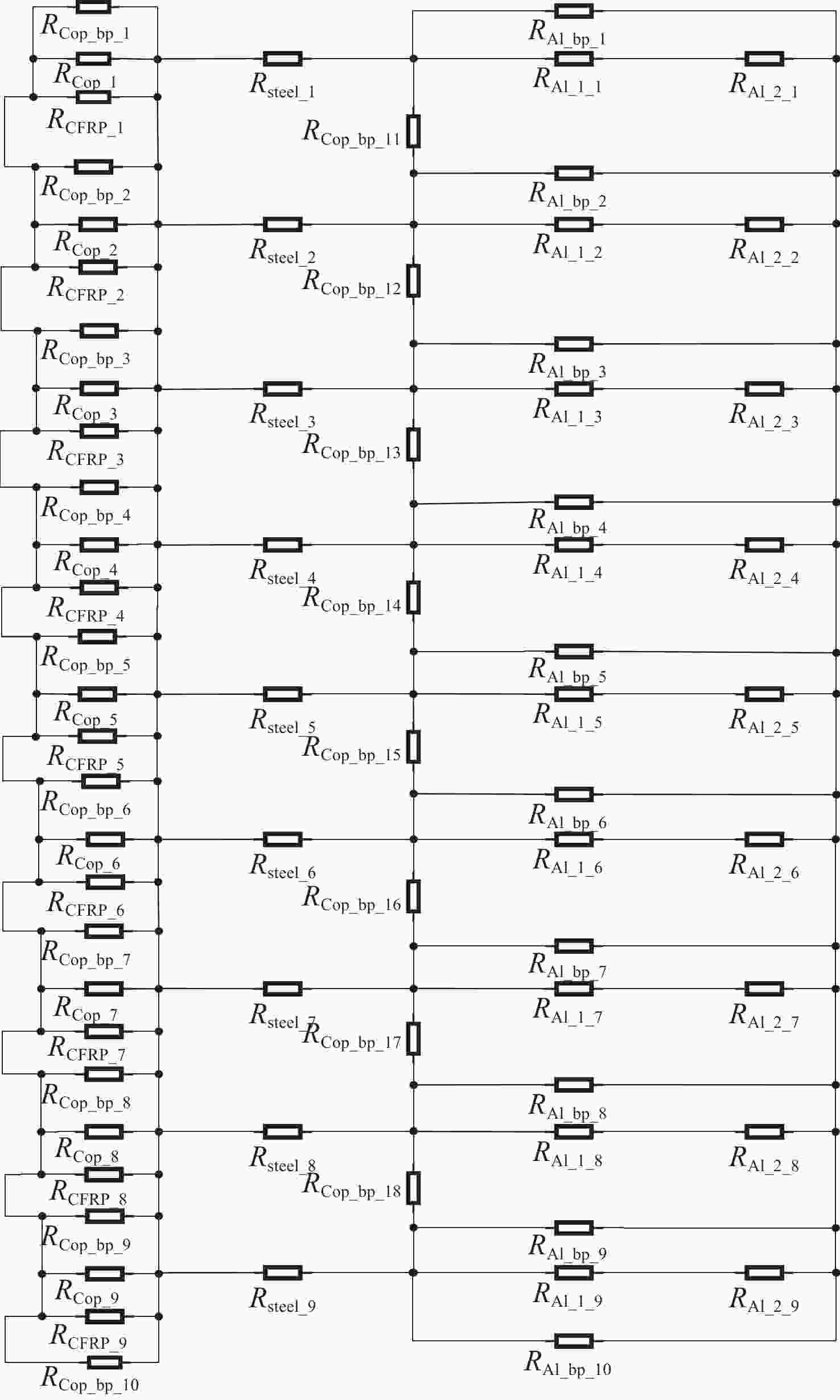

参数 数值 参数 数值 螺栓总长度/mm 23.14 垫圈高度/mm 1.5 螺杆直径/mm 16 垫圈内径/mm 16 螺栓头边长/mm 13.86 垫圈外径/mm 20 螺栓头厚度/mm 3 垫圈厚度/mm 1.5 表 4 单搭接模型等效阻值情况

Table 4. Equivalent resistance of single lap model

参数 阻值/Ω 参数 阻值/Ω Rcop 3.96×10−5 RAl_1 1.10×10−5 Rcop_by_1~Rcop_by_10 1.58×10−5 RAl_by_1~RAl_by_10 1.89×10−5 RCFRP 3.17×10−2 RAl_2 5.96×10−6 Rcop_by_2~ Rcop_by_9 3.96×10−5 RAl_by_2~ RAl_by_9 4.72×10−6 Rsteel 2.04×10−5 Rcop_by_11~ Rcop_by_18 1.25×10−5 表 5 金属连接件材质及对应电导率

Table 5. Metal connector material and corresponding conductivity

材质 电导率/(S·m−1) 铜 5.998×107 铝 3.03×107 氧化铝 0.01 钛 7.41×105 表 6 金属箔材质及对应电导率

Table 6. Metal foil material and corresponding conductivity

材质 电导率/(S·m−1) 铜 5.998×107 铝 3.03×107 镍 1.43×107 钛 7.41×105 表 7 搭接方式对蒙皮电气性能的影响

Table 7. Effect of lap method on electrical performance of skin

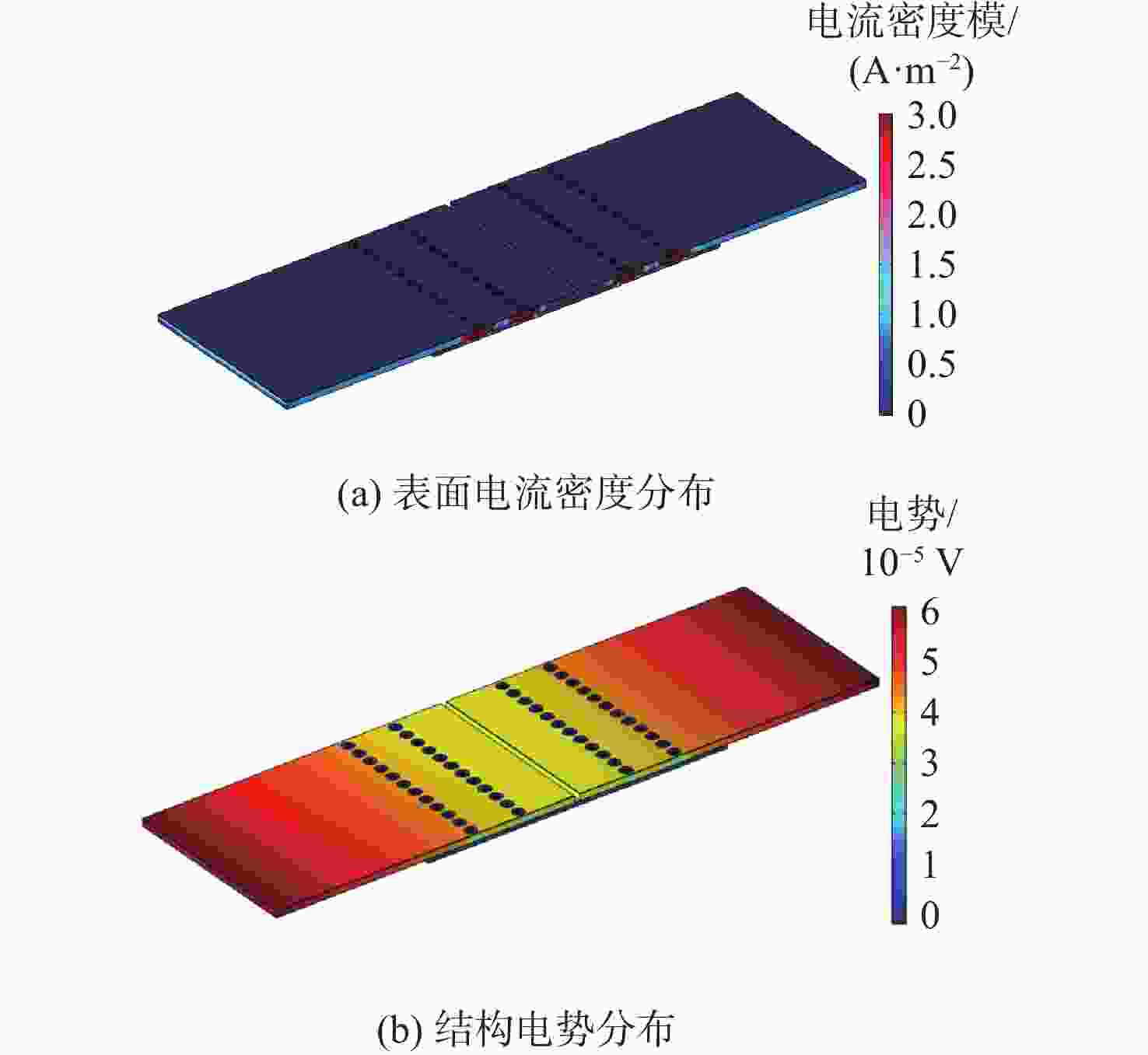

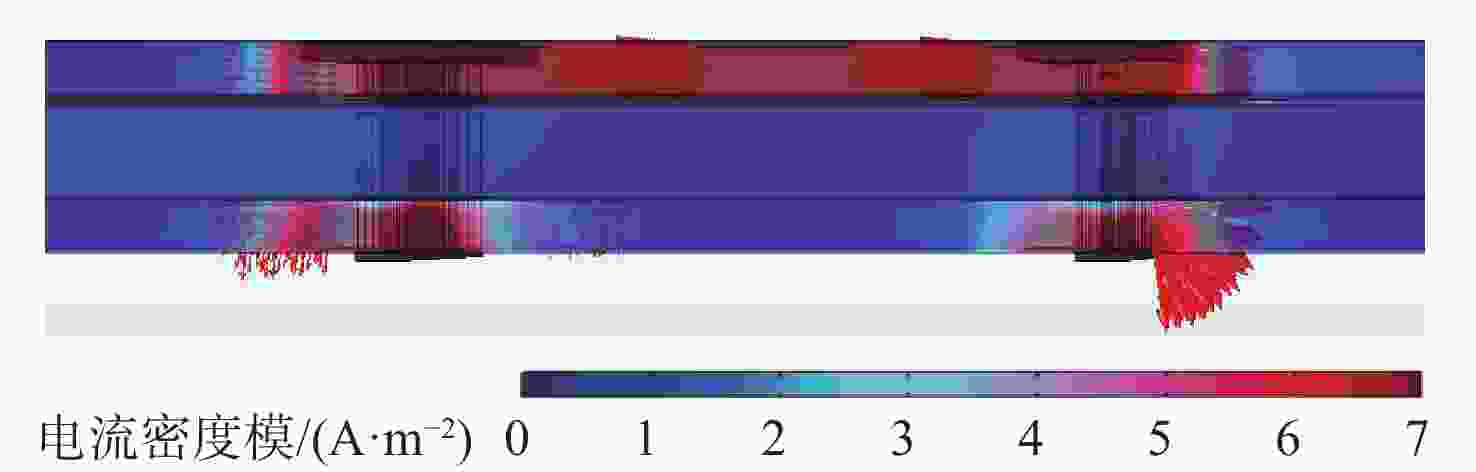

搭接方式 蒙皮整体搭接

结构阻抗/μΩ表面电流密度模的

极大值/(A·m−2)电场模的

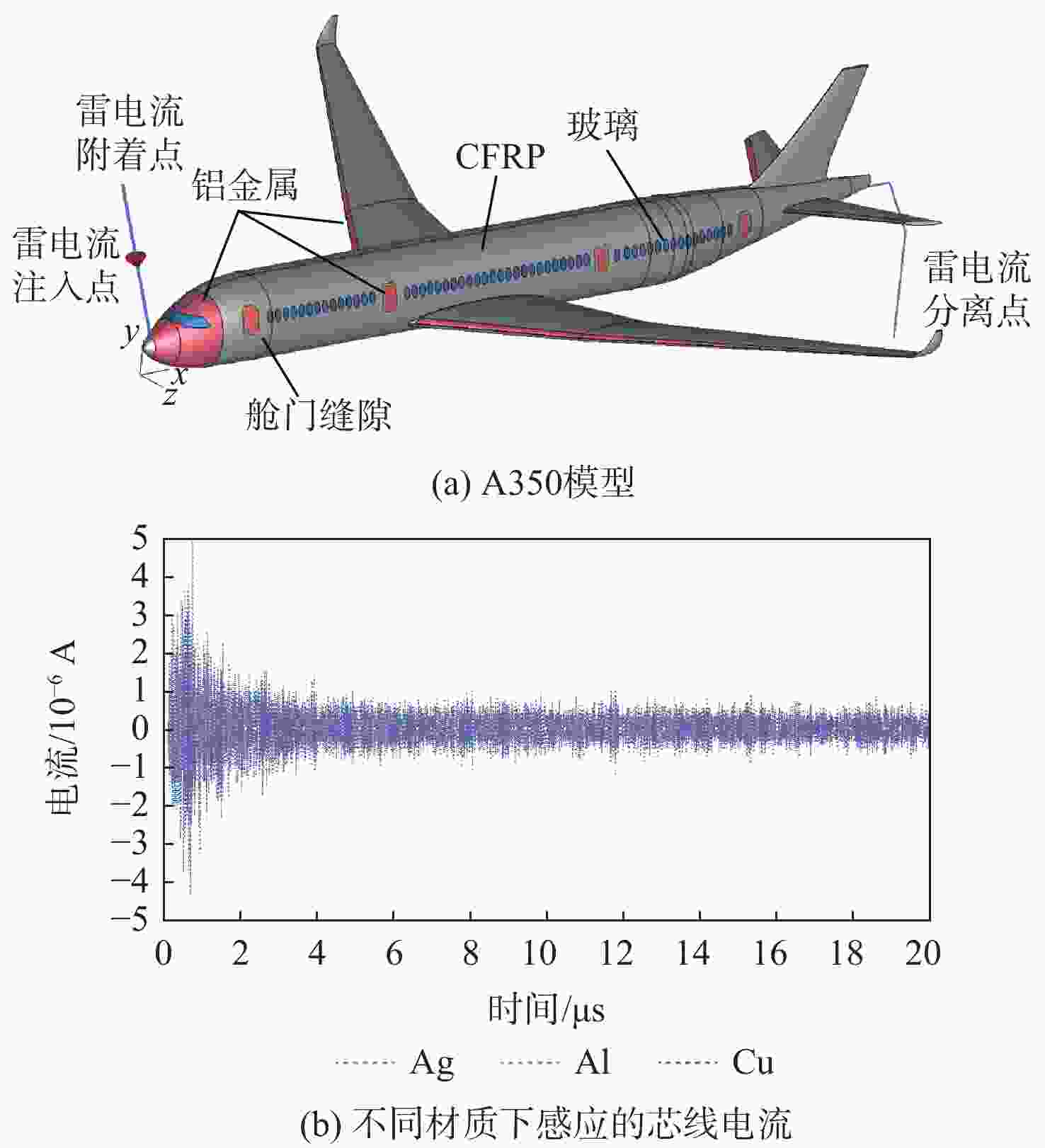

极大值/(V·m−1)单搭接 122.216 30750 0.705 单盖板对接 61.114 12650 0.396 双盖板对接 20.935 13870 0.034 表 8 不同材质屏蔽层下芯线电流情况

Table 8. Core current under different shield materials

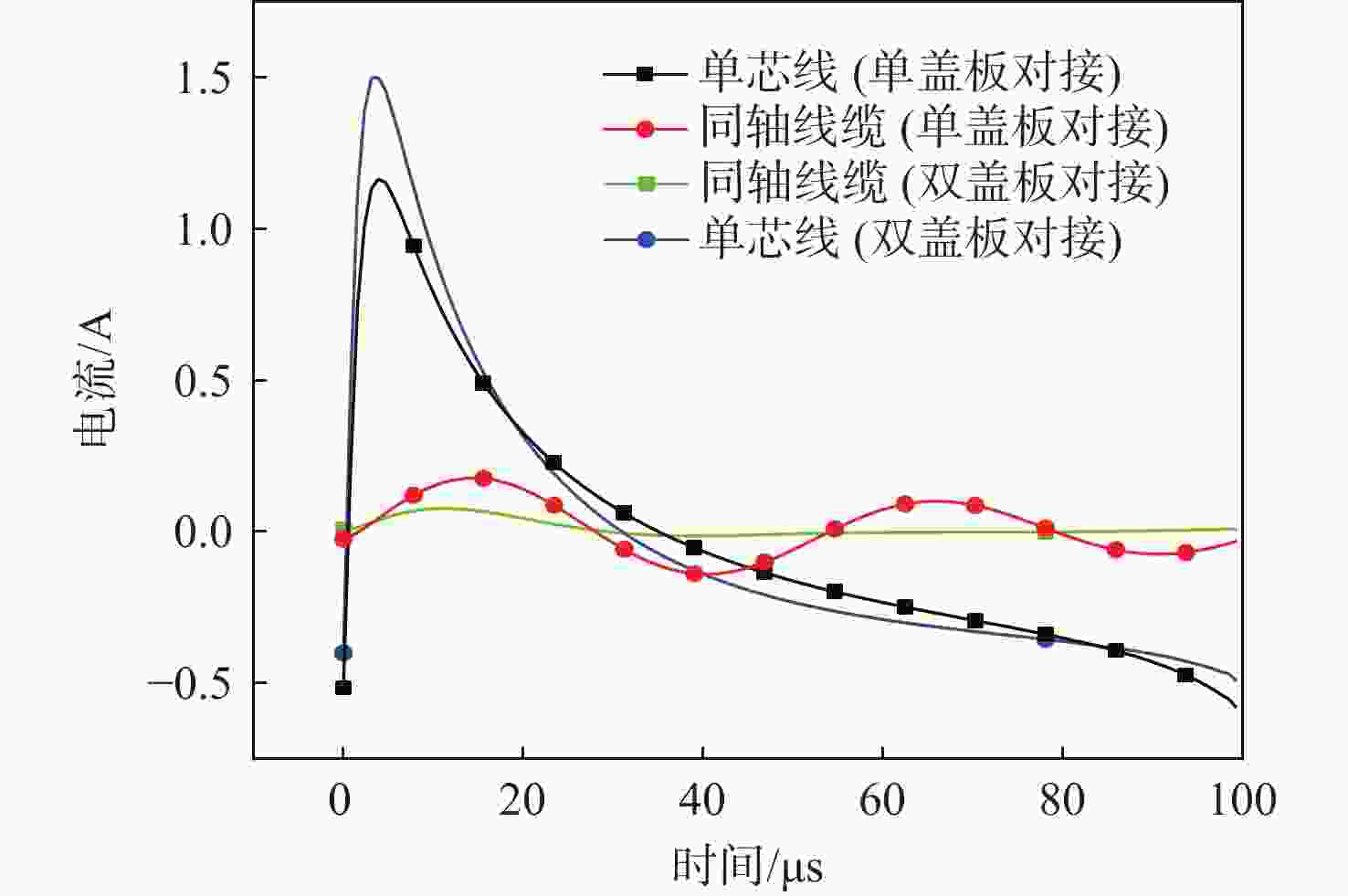

材质 电流/10−6 A 铜 4.777 铝 2.647 银 3.436 表 9 搭接方式对线缆感应电流和紧固件电流的影响

Table 9. Effect of lap splice method on cable-induced current and fastener current

搭接方式 同轴线缆感应

电流峰值/mA紧固件电流密度

峰值/(dBA·m−1)双盖板对接 76.519 80.938 单盖板对接 177.062 88.414 -

[1] JOSÉ A, T G F, BENTO S D M, et al. An innovative approach for integrated airline network and aircraft family optimization[J]. Chinese Journal of Aeronautics, 2020, 33(2): 634-663. doi: 10.1016/j.cja.2019.10.004 [2] JAWAID M, THARIQ M. Sustainable composites for aerospace applications[M]. Cambridge: Woodhead Publishing, 2018: 1-18. [3] PARVEEZ B, KITTUR M I, BADRUDDIN I A, et al. Scientific advancements in composite materials for aircraft applications: a review[J]. Polymers, 2022, 14(22): 5007. doi: 10.3390/polym14225007 [4] JONES C E, SZTYKIEL M, PENA-ALZOLA R, et al. Correction: grounding topologies for resilient, integrated composite electrical power systems for future aircraft applications[C]//Proceedings of the AIAA Propulsion and Energy Forum. Reston: AIAA, 2019. [5] 赵中杰. 结构-导电复合材料的制备及其导电性能研究[D]. 哈尔滨: 哈尔滨工业大学, 2019.ZHAO Z J. Preparation and conductivity of structure-conductive composites[D]. Harbin: Harbin Institute of Technology, 2019(in Chinese). [6] CALADO E A, LEITE M, SILVA A. Selecting composite materials considering cost and environmental impact in the early phases of aircraft structure design[J]. Journal of Cleaner Production, 2018, 186: 113-122. doi: 10.1016/j.jclepro.2018.02.048 [7] AMAN F, CHERAGHI S H, KRISHNAN K K, et al. Study of the impact of riveting sequence, rivet pitch, and gap between sheets on the quality of riveted lap joints using finite element method[J]. The International Journal of Advanced Manufacturing Technology, 2013, 67(1): 545-562. [8] 康永刚, 李春生, 陈希多, 等. 航空大壁板装配连接局部变形数值建模与仿真分析[J]. 航空制造技术, 2020, 63(3): 45-52.KANG Y G, LI C S, CHEN X D, et al. Numerical modeling and simulation analysis of local deformation for aircraft large-walled panel assembly connection[J]. Aeronautical Manufacturing Technology, 2020, 63(3): 45-52(in Chinese). [9] JONES C E, NORMAN P J, GALLOWAY S J, et al. Electrical model of carbon fibre reinforced polymers for the development of electrical protection systems for more-electric aircraft[C]//Proceedings of the 18th European Conference on Power Electronics and Applications. Piscataway: IEEE Press, 2016: 1-10. [10] 刘国春, 郭荣辉, 秦文峰. 民用飞机复合材料结构制造与维修[M]. 北京: 清华大学出版社, 2020: 19.LIU G C, GUO R H, QIN W F. Manufacture and maintenance of composite structure of civil aircraft[M]. Beijing: Tsinghua University Press, 2020: 19(in Chinese). [11] MALINOWSKI P H, WANDOWSKI T, OSTACHOWICZ W M. Characterisation of CFRP adhesive bonds by electromechanical impedance[C]//Proceedings of the Health Monitoring of Structural and Biological Systems. Belingham: SPIE, 2014: 906415. [12] MALINOWSKI P H, OSTACHOWICZ W M, BRUNE K, et al. Study of electromechanical impedance changes caused by modifications of CFRP adhesive bonds[J]. Fatigue & Fracture of Engineering Materials & Structures, 2017, 40(10): 1592-1600. [13] REVEL I, PICHE A, PERES G, et al. Modeling strategy for functional current return in large CFRP structures for aircraft applications[C]//Proceedings of the International Symposium on Electromagnetic Compatibility-EMC Europe. Piscataway: IEEE Press, 2008: 1-5. [14] BANDINELLI M, MORI A, GALGANI G, et al. A surface PEEC formulation for high-fidelity analysis of the current return networks in composite aircrafts[J]. IEEE Transactions on Electromagnetic Compatibility, 2015, 57(5): 1027-1036. doi: 10.1109/TEMC.2015.2422672 [15] GOLEANU A L, DUNAND M, GUICHON J M, et al. Towards the conception and optimisation of the current return path in a composite aircraft[C]//Proceedings of the IEEE International Systems Conference. Piscataway: IEEE Press, 2010: 466-471. [16] GOLEANU A L, GUICHON J M, DUNAND M, et al. Design and optimization techniques for the current return path in a composite aircraft[C]//Proceedings of the 14th European Conference on Power Electronics and Applications. Piscataway: IEEE Press, 2011: 1-10. [17] 刘建英, 隋政, 张起浩, 等. 复合材料飞机接地回流网络建模与阻抗分析[J]. 北京麻豆精品秘 国产传媒学报, 2021, 47(5): 885-893.LIU J Y, SUI Z, ZHANG Q H, et al. Modeling and impedance analysis of composite material aircraft grounded return network[J]. Journal of Beijing University of Aeronautics and Astronautics, 2021, 47(5): 885-893(in Chinese). [18] 杨占刚, 隋政, 张起浩, 等. 复合材料飞机接地回流网络网内压降分析[J]. 航空学报, 2022, 43(1): 324859.YANG Z G, SUI Z, ZHANG Q H, et al. Voltage drop in composite aircraft grounding and current return network[J]. Acta Aeronautica et Astronautica Sinica, 2022, 43(1): 324859(in Chinese). [19] HEPPE A J. Computation of potential at surface above an energized grid or other electrode, allowing for non-uniform current distribution[J]. IEEE Transactions on Power Apparatus and Systems, 1979, 98(6): 1978-1989. [20] KOUTEYNIKOFF P. Numerical computation of the grounding resistance of substations and towers[J]. IEEE Transactions on Power Apparatus and Systems, 1980, 99(3): 957-965. [21] MOUPFOUMA F, TSE W, JALALI M. More about lightning induced effects on systems in a composite aircraft[C]//Proceedings of the SAE Technical Paper Series. Warrendale: SAE International, 2013: 151-162. [22] 龙奕, 胡皓全, 赵家升, 等. 电磁屏蔽效能分析与实例计算[C]//第17届全国电磁兼容学术会议论文集. 广州: 中国通信学会, 2007: 68-73.LONG Y, HU H Q, ZHAO J S, et al. Electromagnetic shielding effectiveness analysis and example calculation[C]//Proceedings of the 17th National Conference on Electromagnetic Compatibility. Guangzhou: China Institute of Communications, 2007: 68-73(in Chinese). [23] 周秦汉. 复合材料飞机雷电间接效应仿真研究[D]. 南京: 南京麻豆精品秘 国产传媒, 2019.ZHOU Q H. Simulation study on lightning indirect effect of composite aircraft[D]. Nanjing: Nanjing University of Aeronautics and Astronautics, 2019(in Chinese). [24] United States of America Department of Defense. Electromagnetics environmental effects requirements for systems: MIL-STD-464A[S]. Washington, D. C.: United States of America Department of Defense, 2002. -

下载:

下载: