Numerical simulation study on synergetic fire suppression of nitrogen/water-mist in aircraft cargo compartment

-

摘要:

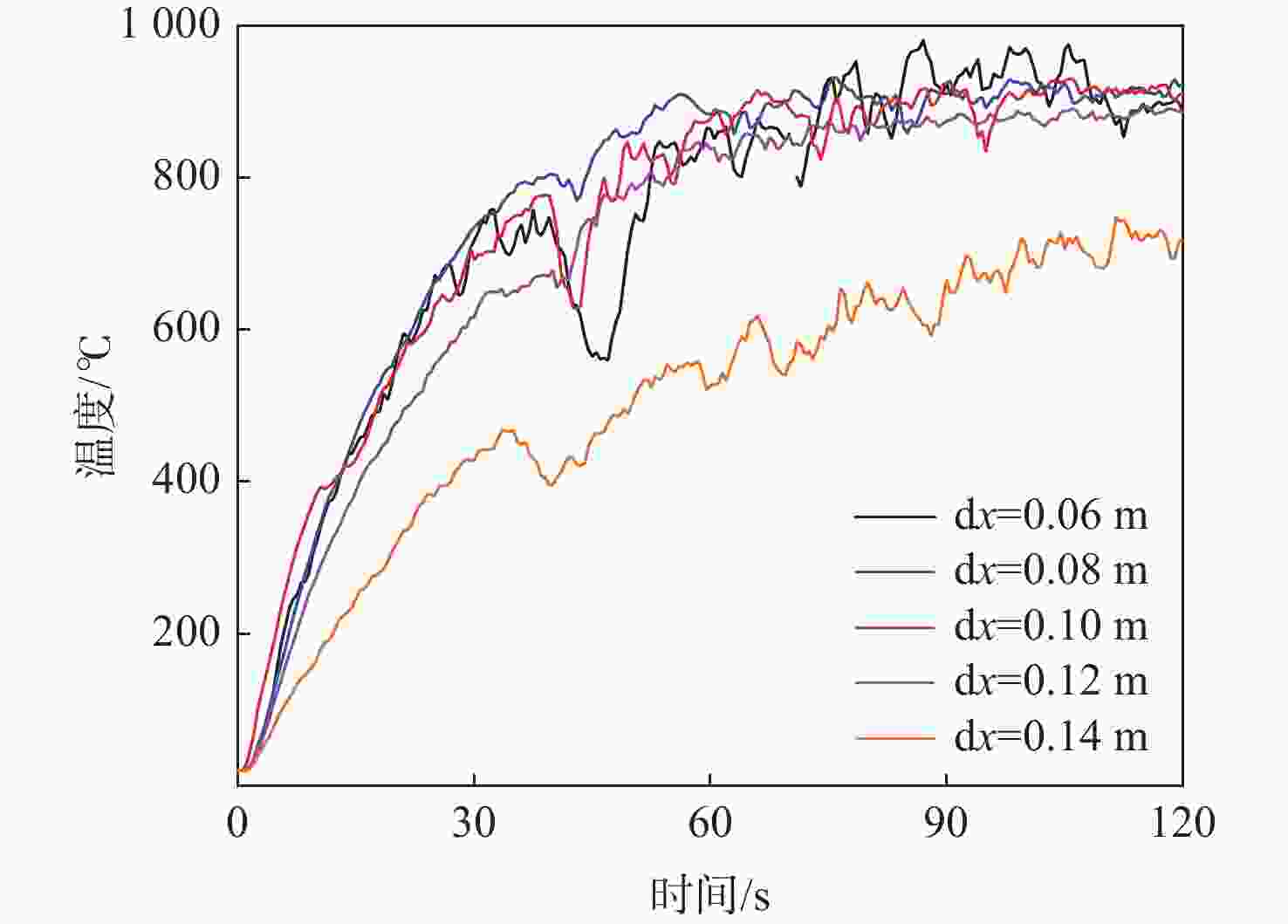

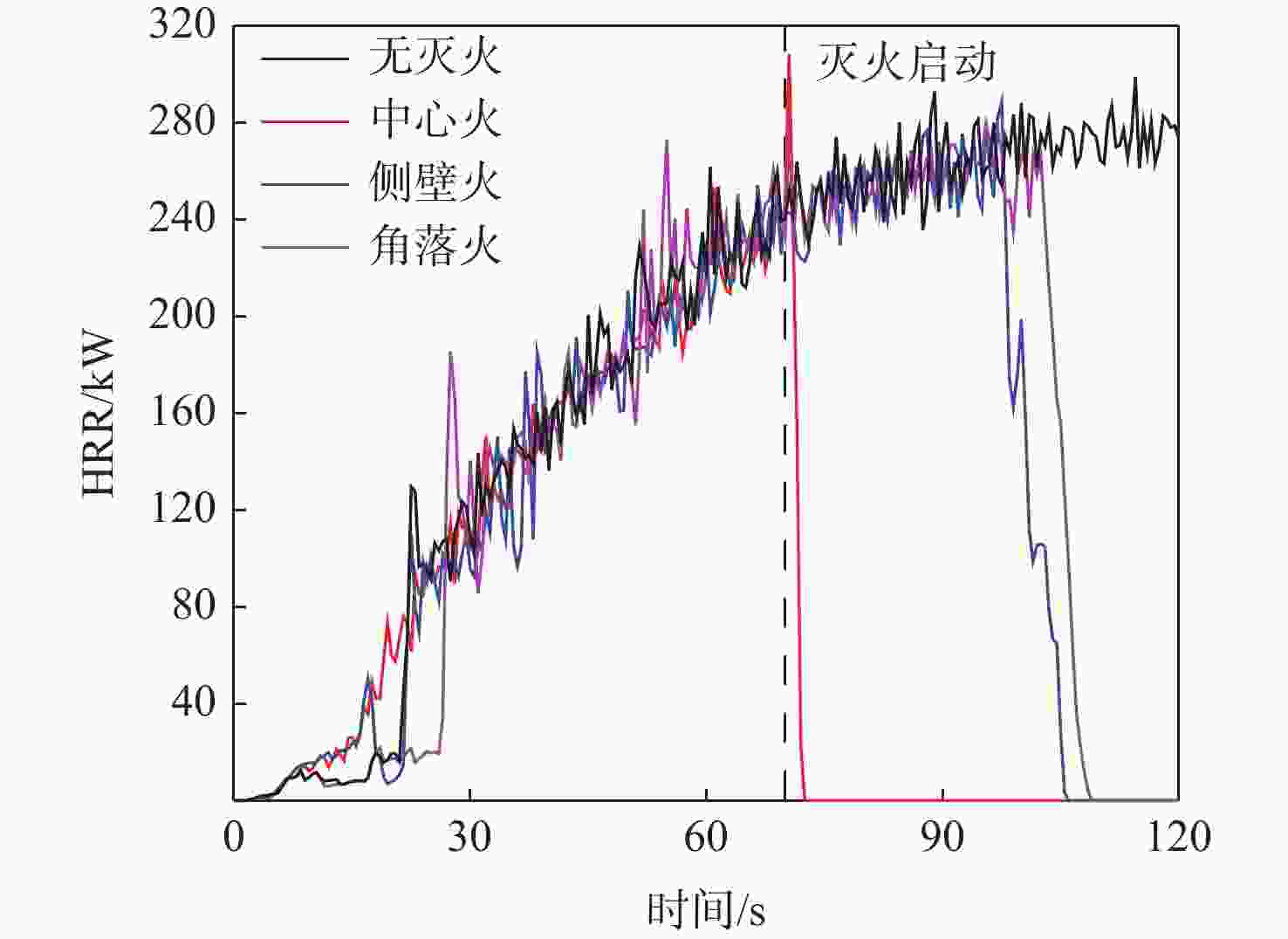

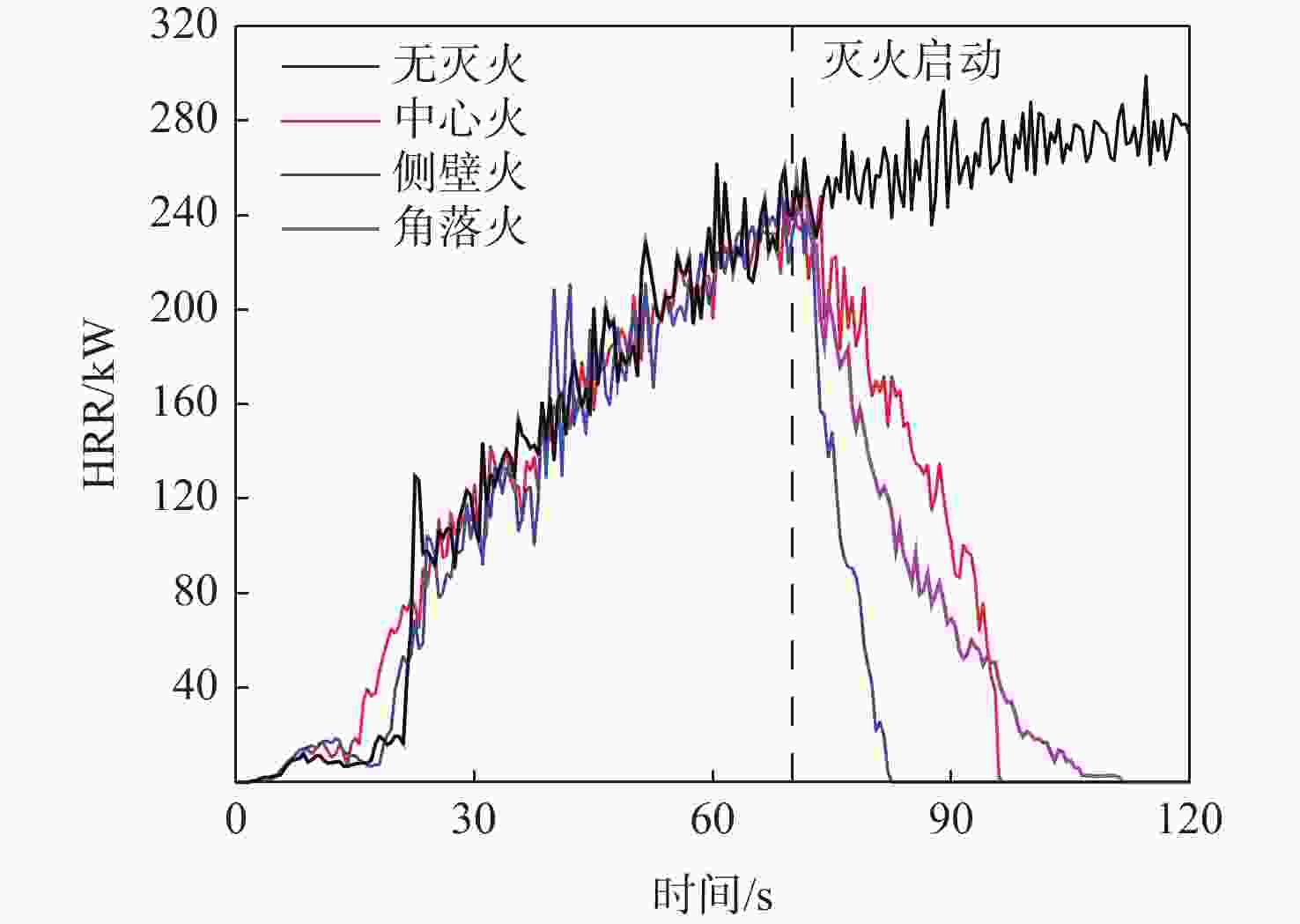

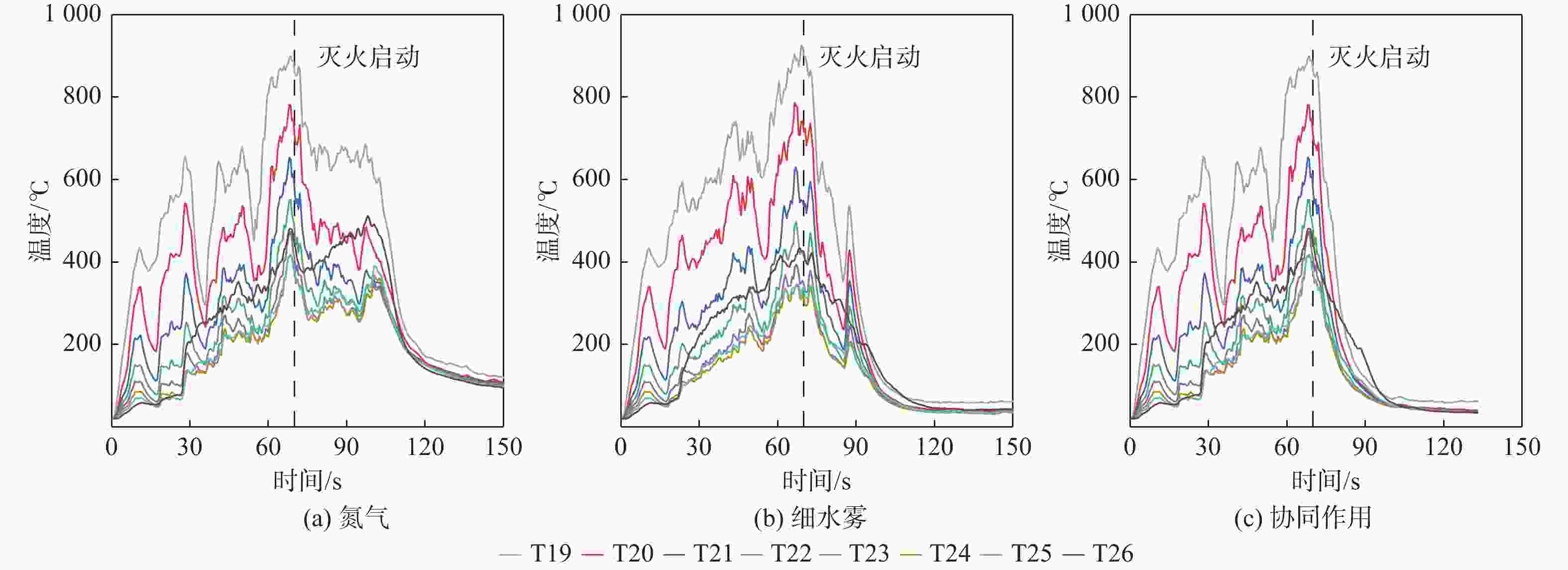

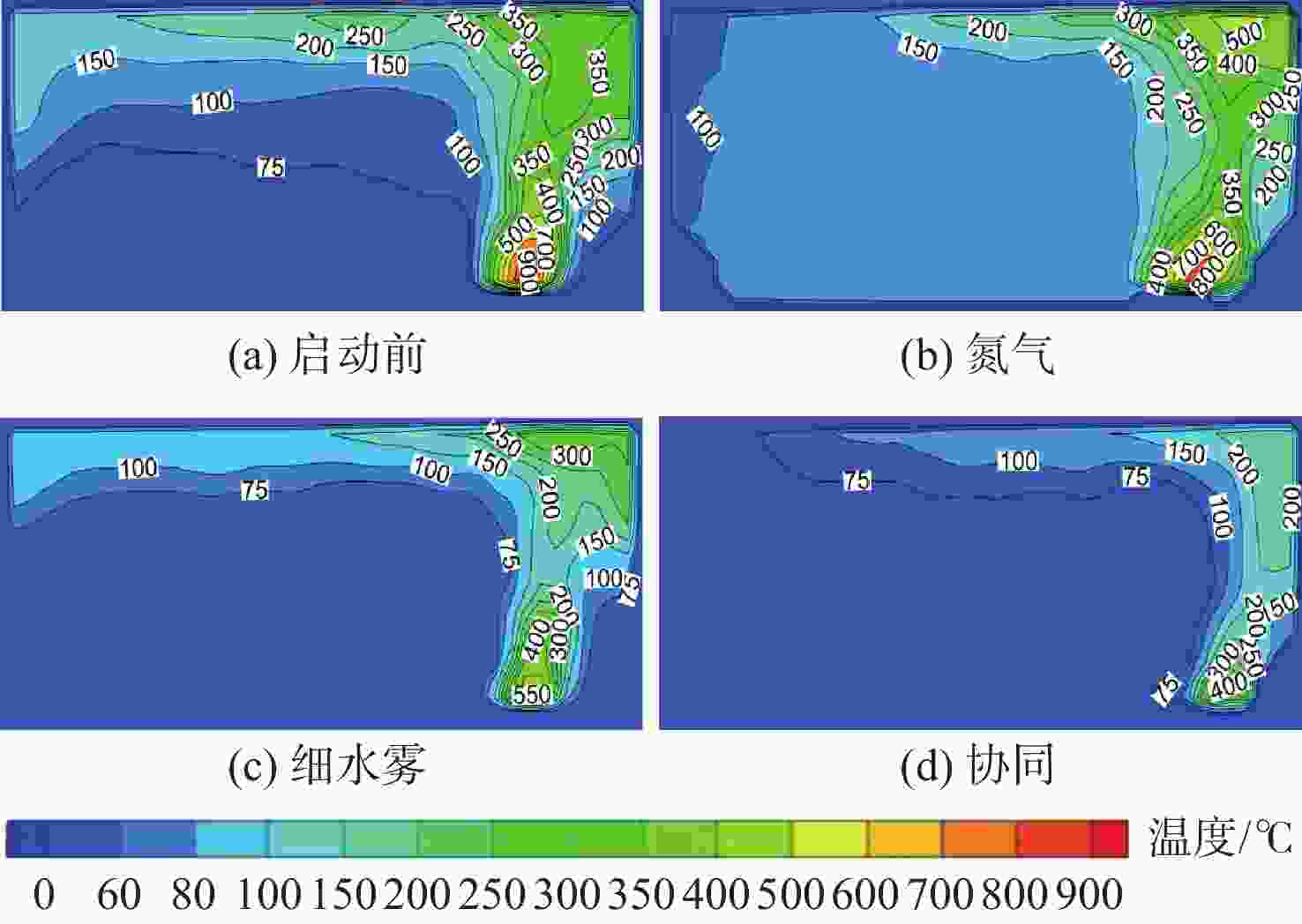

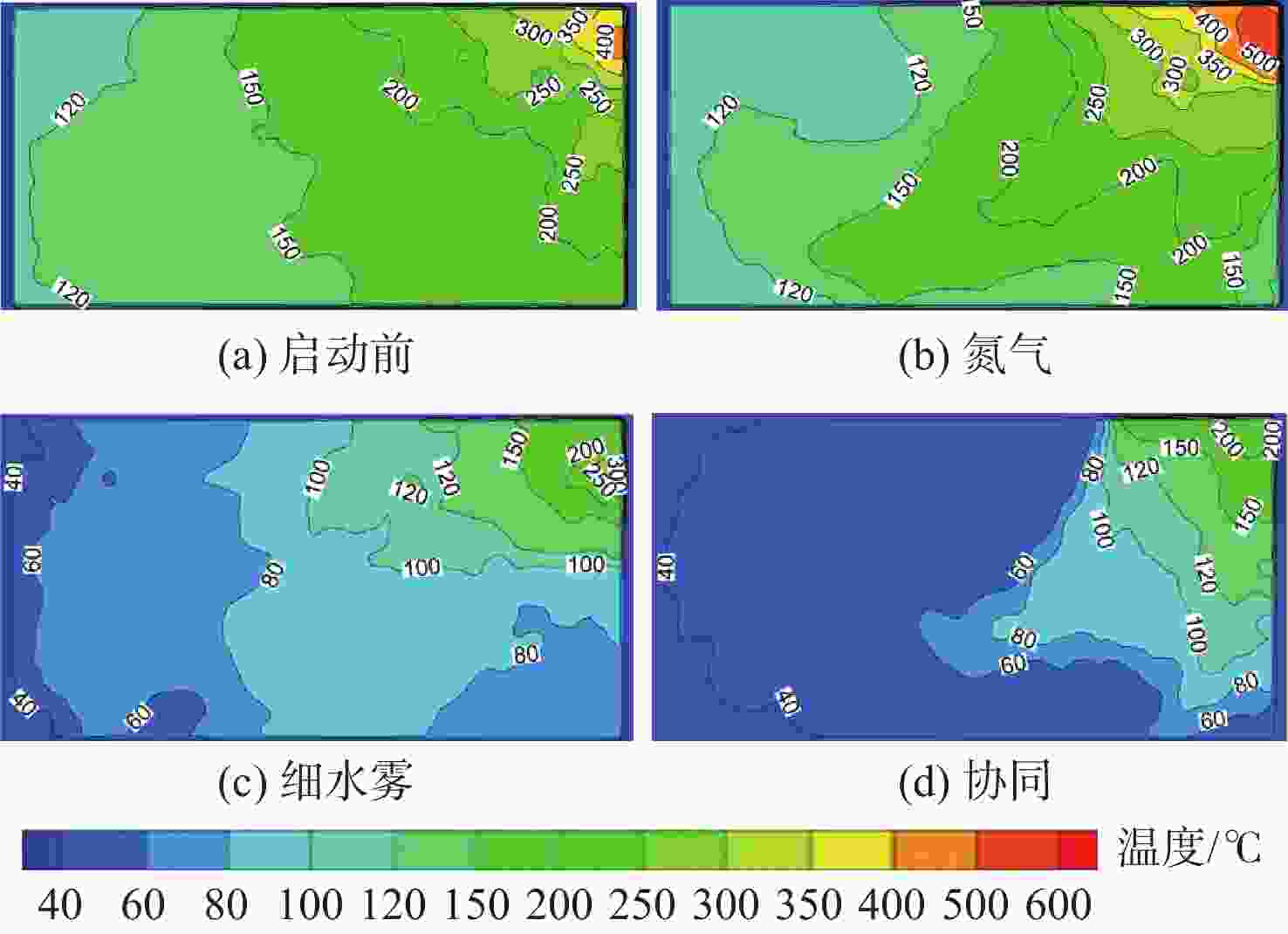

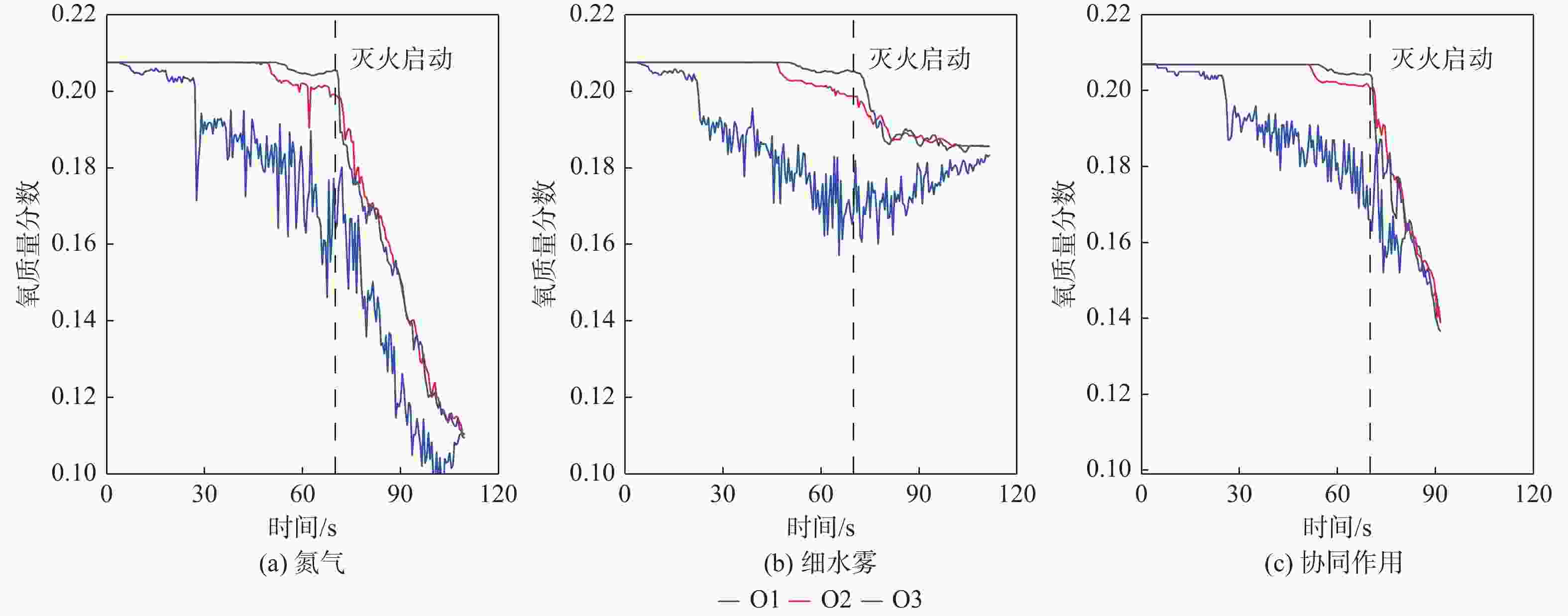

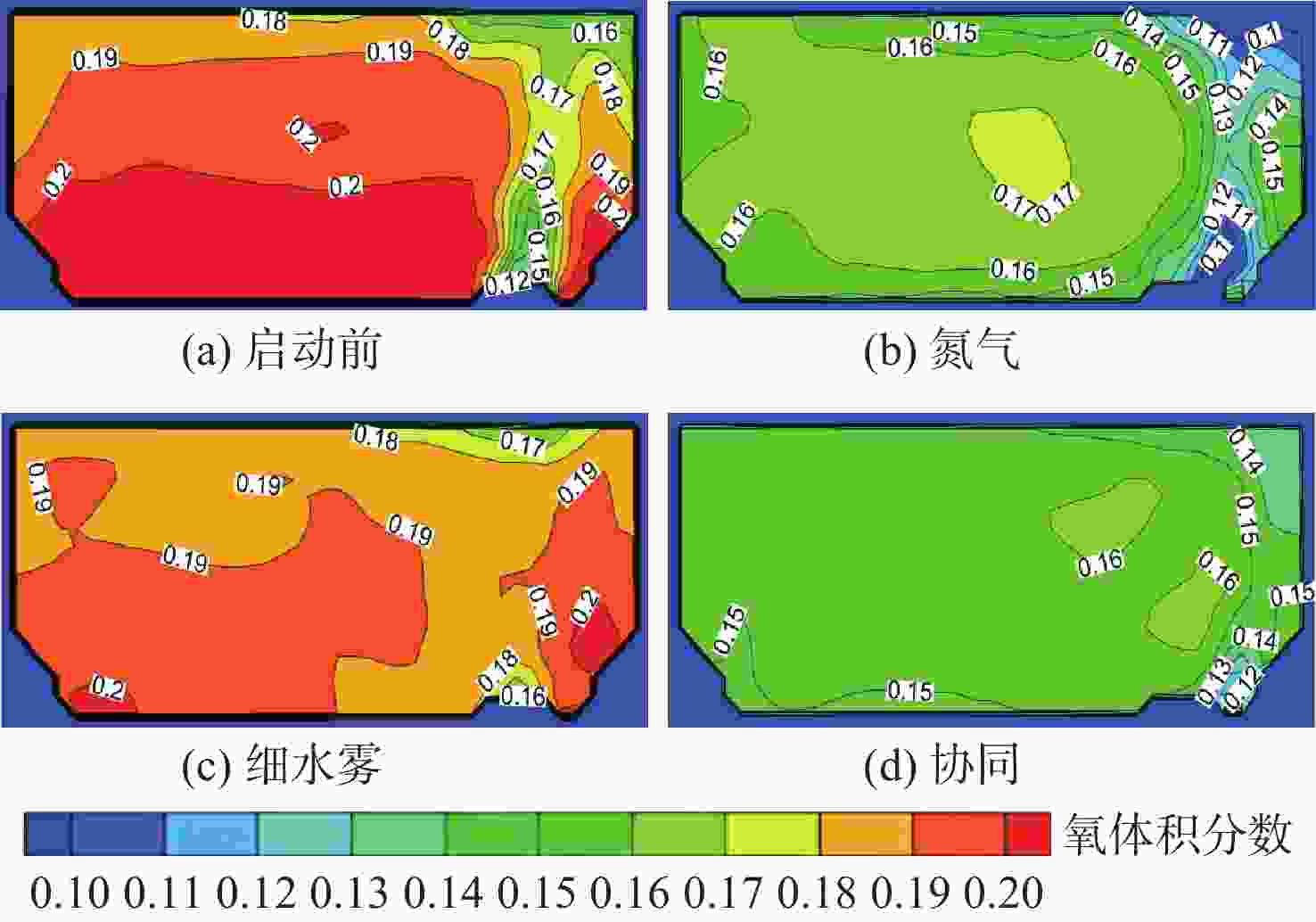

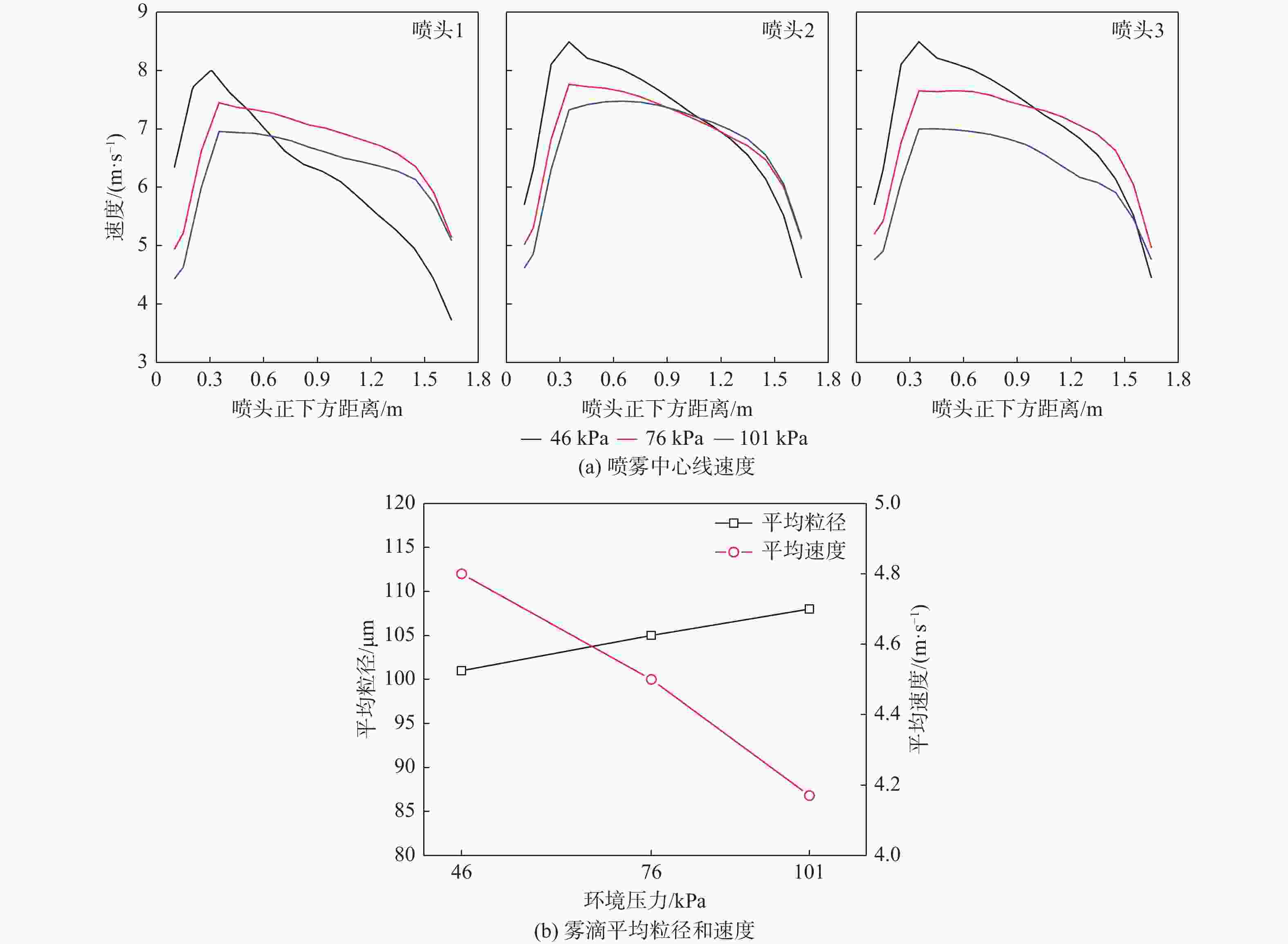

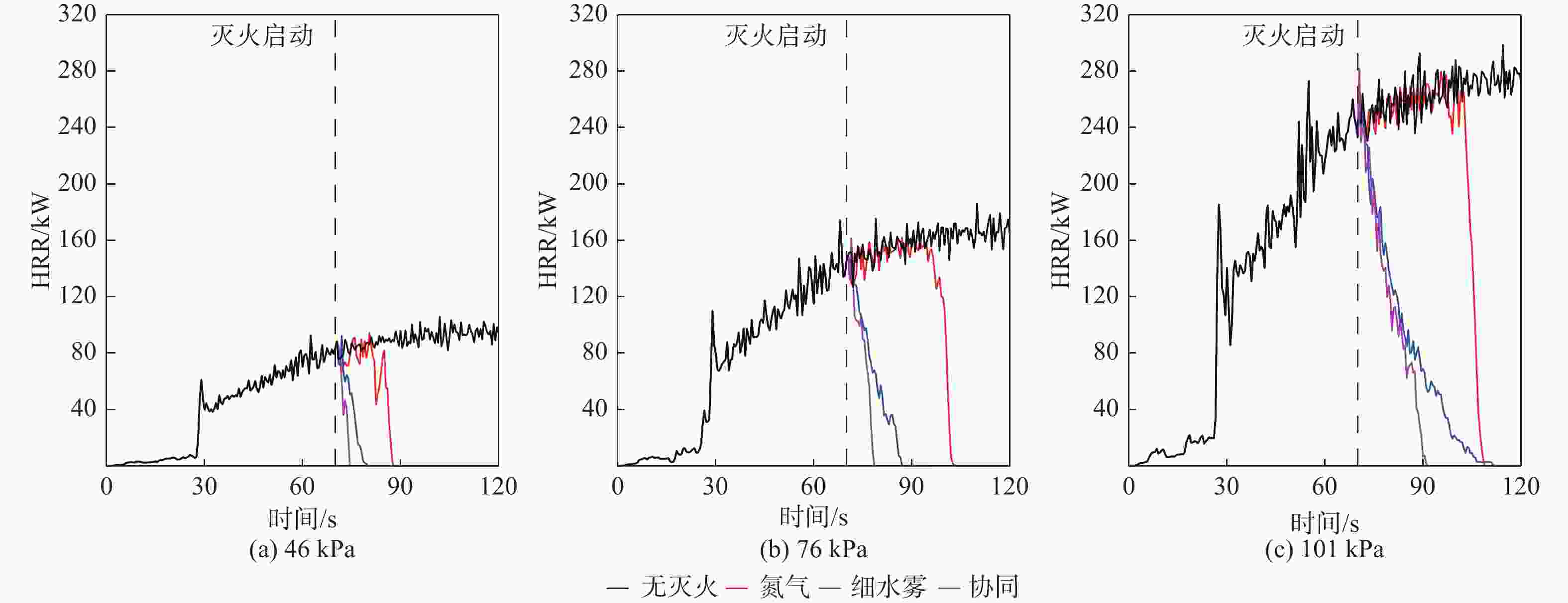

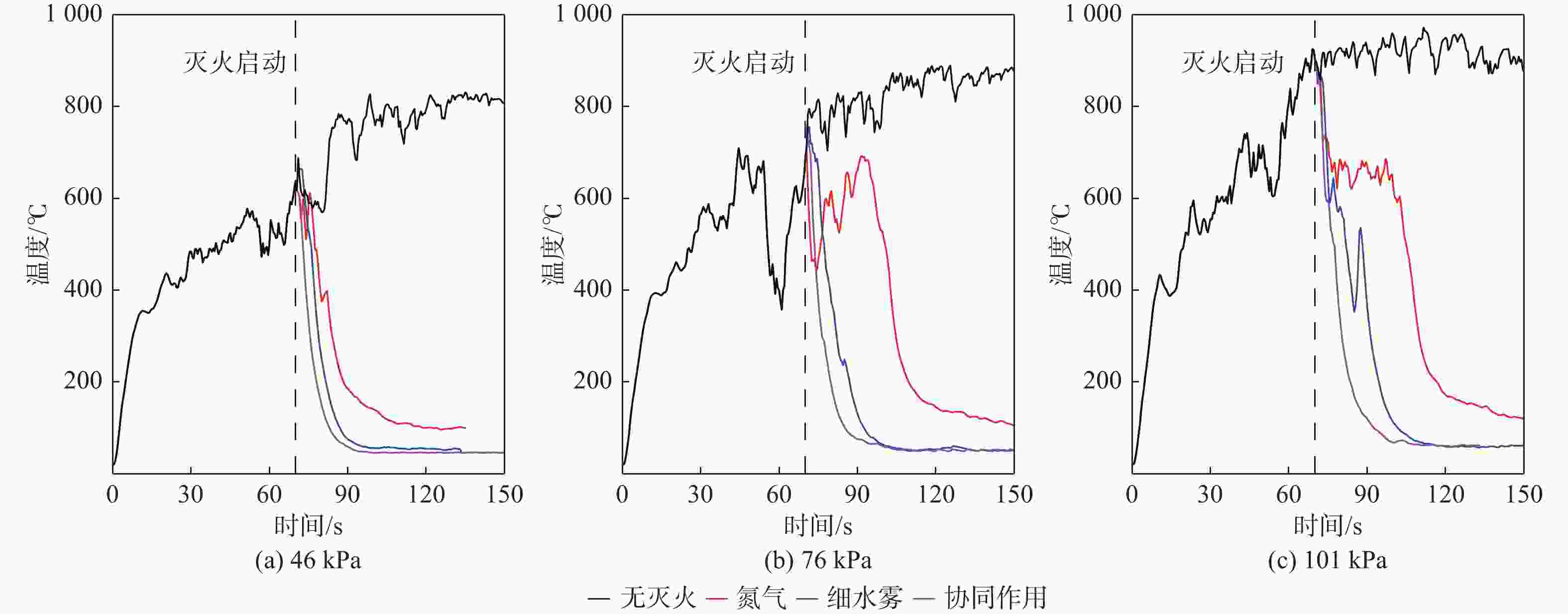

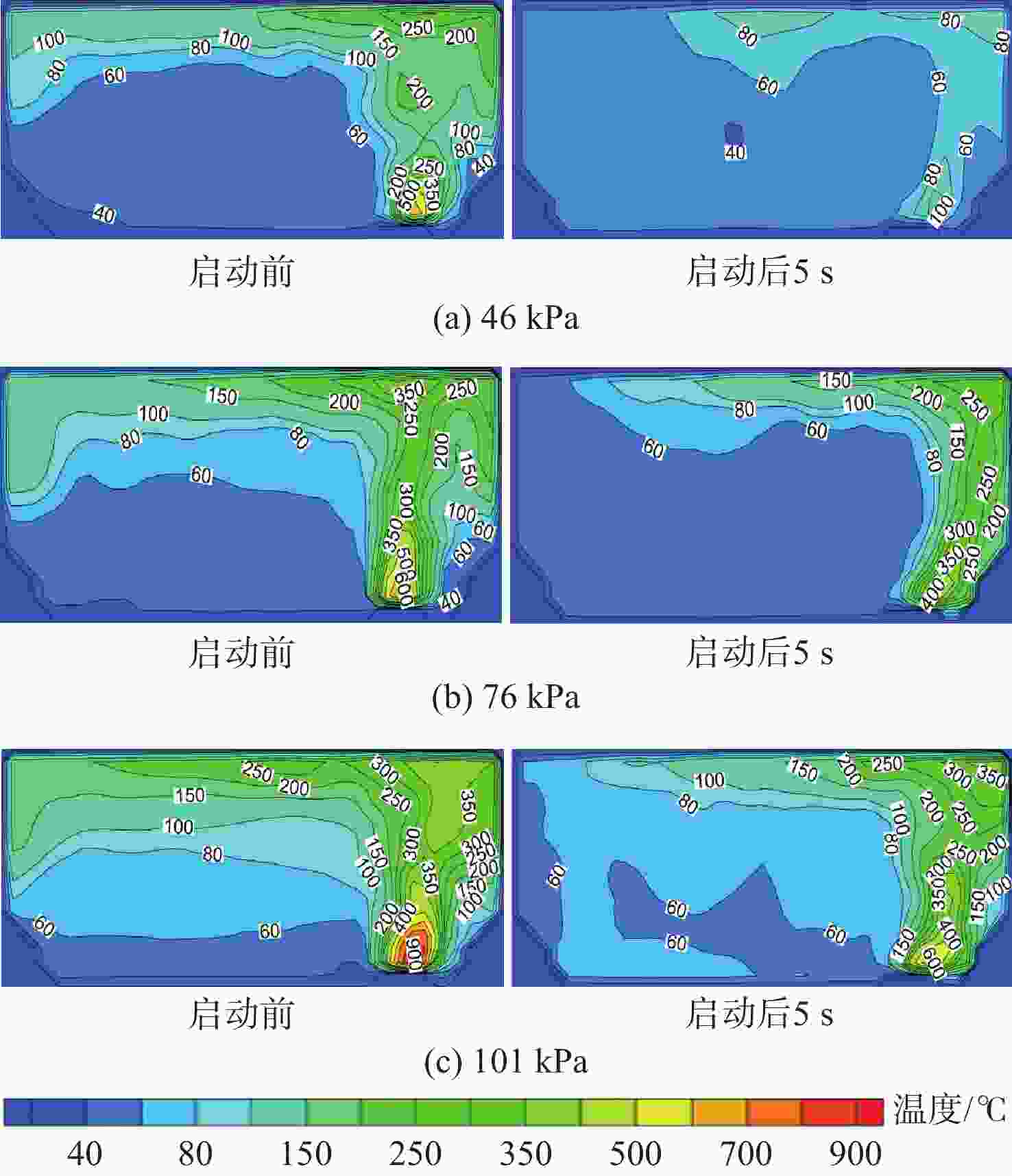

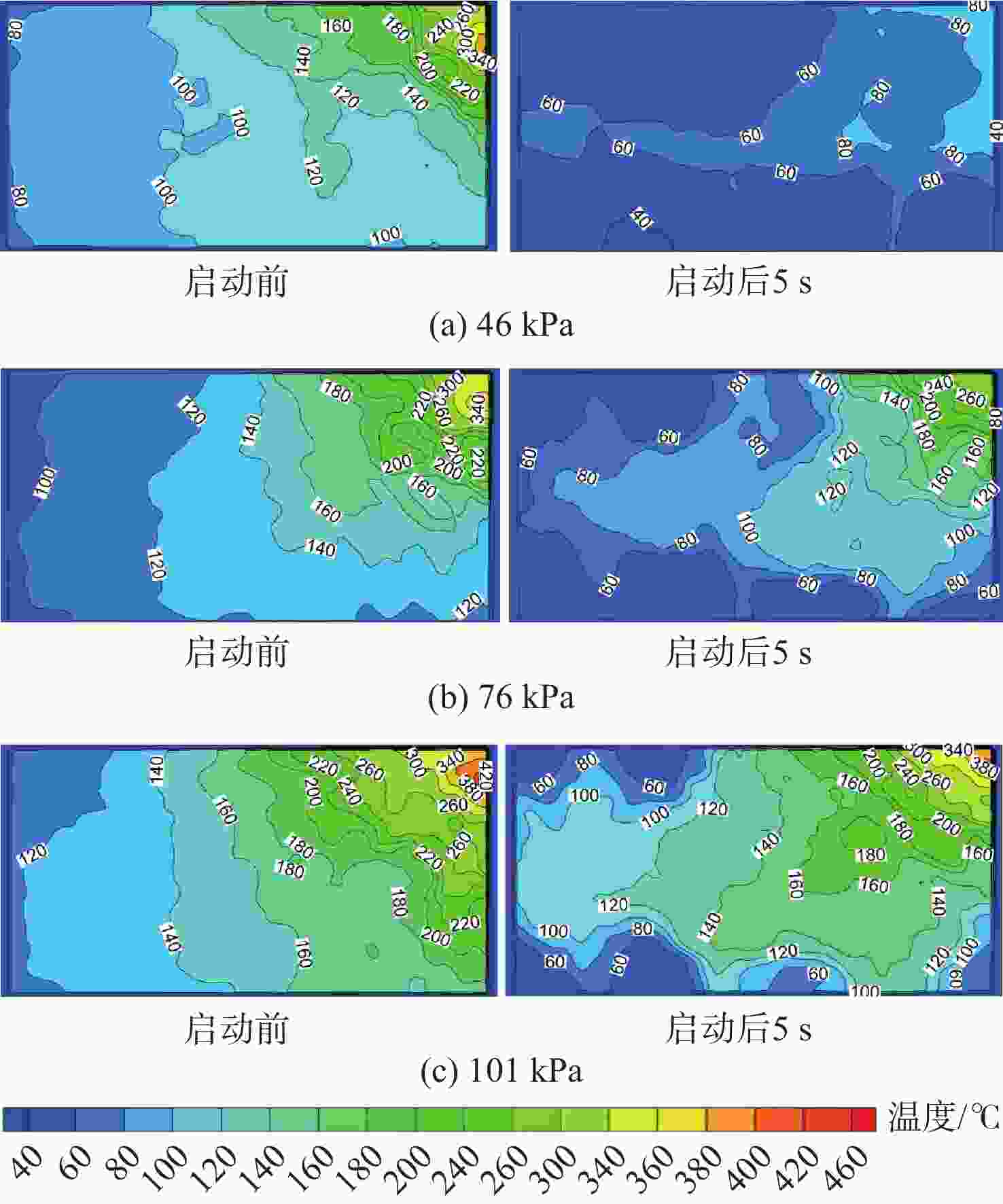

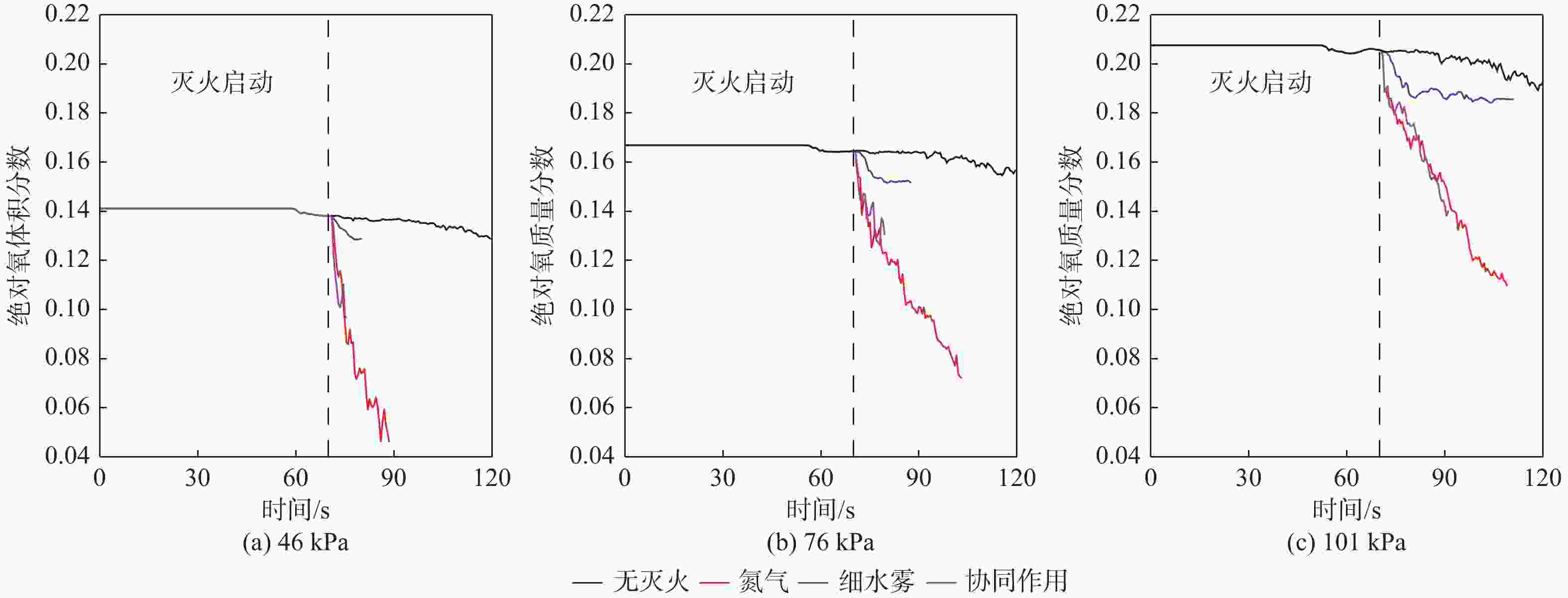

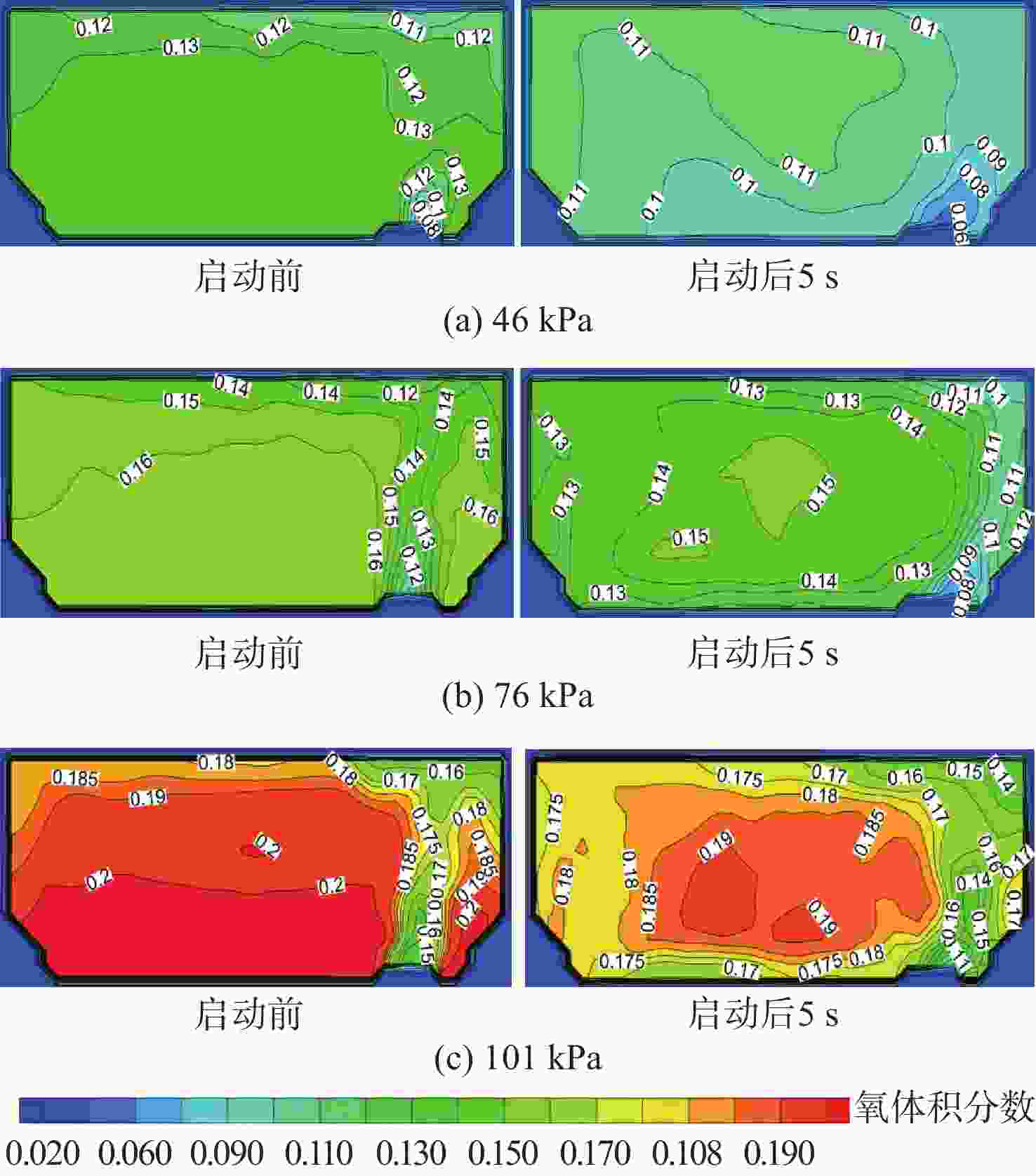

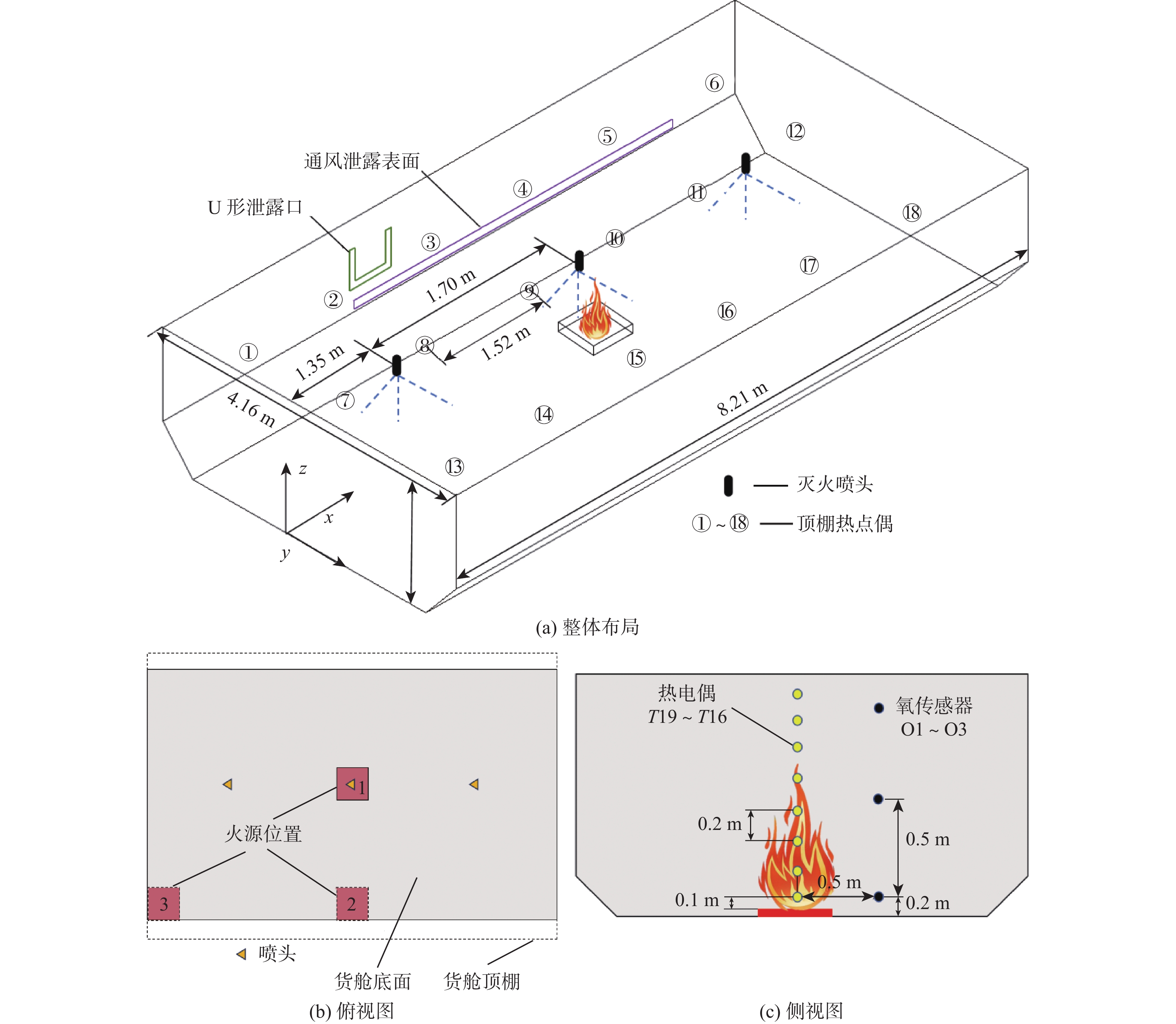

货舱火灾是民机运输安全的重要威胁之一。考虑不同火源位置和环境压力的影响,基于火灾动力学模拟(FDS)代码开展了全尺度飞机货舱氮气-细水雾协同熄灭航空煤油池火有效性评估研究。结果表明:货舱火源位置影响灭火效果,角落火最难扑灭;以角落火为例,氮气灭火初期对火源难以有效抑制,而细水雾启动后可快速衰减火源热释放率;在氮气和细水雾单喷头流量分别为0.222 kg/s和15 L/min时,与单独氮气和细水雾灭火相比,协同灭火时冷却降温和窒息效应均显著增强,灭火效率分别提高46.20%和48.80%,其中氮气的加入可使水消耗量减少48.78%;当灭火参数相同时,灭火剂释放速率增加可同时降低灭火时间和灭火剂消耗量,实际中应采用大流量快速释放的喷头结构设计;环境压力降低可显著降低灭火时间,环境压力从101 kPa 降低至46 kPa,协同灭火降温速率可提高约48.60%。

Abstract:The threat of fire in the cargo compartments of civil aircraft poses a considerable safety risk. The synergetic fire suppression effectiveness of nitrogen-water mist to extinguish aviation kerosene pool fire in a full-scale aircraft cargo compartment was studied using the Fire Dynamics Simulator (FDS) code, considering different fire source locations and ambient pressures. The results showed that the location of fire source affects the effectiveness of fire suppression, and the corner fire is the most difficult to extinguish. For corner fire, it is difficult to suppress by nitrogen at the initial stage, whereas water mist can rapidly reduce the heat release rate of fire. When the flow rates of nitrogen and water mist were set at 0.222 kg/s and 15 L/min, respectively, the synergetic suppression demonstrated significantly enhanced cooling and suffocation effects compared to using nitrogen or water mist alone. The suppression efficiency increased by 46.2% and 48.8% respectively, while nitrogen reduced water consumption by 48.87%. Increasing the release rate of extinguishing agents with constant suppression parameters could reduce both the suppression time and consumption. Therefore, it is recommended to design nozzles with high flow rates and rapid release. Furthermore, decreasing ambient pressure significantly reduced the suppression time. A decrease for ambient pressure from 101 kPa to 46 kPa increased the cooling rate by 48.60% during synergistic suppression.

-

Key words:

- civil aircraft cargo compartment /

- N2 /

- water mist /

- synergetic fire suppression /

- ambient pressure

-

表 1 不同灭火剂流量下灭火对比结果

Table 1. Comparative results of fire extinguishing under different flow rates of extinguishing agents

工况

序号灭火剂 灭火时间/s 消耗量/kg 氮气 细水雾 1 氮气(0.222 kg/s) 39 26.01 0 细水雾(15 L/min) 41 0 30.75 协同(氮气: 0.222 kg/s,水:15 L/min) 21 14.01 15.75 2 氮气(0.10 kg/s) 65 19.50 0 细水雾(10 L/min) 70 0 35.00 协同(氮气: 0.10 kg/s,水:10 L/min) 54 16.20 27.00 表 2 不同环境压力与灭火模式下灭火时间结果

Table 2. Fire extinguishing time data results under different ambient pressure and fire extinguishing mode

灭火剂 灭火时间/s 46 kPa 76 kPa 101 kPa 氮气 18 33 39 细水雾 10 17 41 协同 5 9 21 表 3 不同环境压力下协同灭火时降温速率数据

Table 3. Data of synergetic cooling rate under different ambient pressures

环境压力/ kPa 最高温度/℃ 达到常温时间/s 降温速率/(℃·s−1) 46 638 23 26.0 76 769 43 18.0 101 900 49 17.5 -

[1] CRAIG P L. “Environmental Control Systems” in the encyclopedia of aerospace engineering[M]. Hoboken: John Wiley & Sons, Ltd, 2010. [2] PROTOCOL M, DEPLETE O. Halons technical options committee assessment report[R]. Geneva: UN Environment, 2018. [3] 贺元骅, 张政, 伍毅. 低压环境下航空电缆材料燃烧特性的研究[J]. 塑料科技, 2020, 48(1): 71-74.HE Y H, ZHANG Z, WU Y. Experimental study on combustion characteristics of aviation cable materials under low pressure environment[J]. Plastics Science and Technology, 2020, 48(1): 71-74(in Chinese). [4] WANG W, WANG L, YANG R, et al. Investigation of the effect of low pressure on fire hazard in cargo compartment[J]. Applied Thermal Engineering, 2019, 158: 113775. doi: 10.1016/j.applthermaleng.2019.113775 [5] 刘全义, 朱博, 邓力, 等. 低压环境下不同直径油池火特征参量研究[J]. 中国安全科学学报, 2021, 31(4): 105-110.LIU Q Y, ZHU B, DENG L, et al. Study on characteristic parameters of oil pool fire of different diameters in low pressure environment[J]. China Safety Science Journal, 2021, 31(4): 105-110(in Chinese). [6] DINESH A, BENSON C M, HOLBORN P G, et al. Performance evaluation of nitrogen for fire safety application in aircraft[J]. Process Safety and Environmental Protection, 2020, 141: 110-122. doi: 10.1016/j.psep.2020.04.022 [7] HU X Q, KRAAIJEVELD A, LOG T. Numerical investigation of the required quantity of inert gas agents in fire suppression systems[J]. Energies, 2020, 13: 2536. doi: 10.3390/en13102536 [8] LEE J, MOON J. Numerical analysis of the effect of horizontal distance between a water mist nozzle and ignition source on reduction in heat release rate[J]. Annals of Nuclear Energy, 2020, 144: 107560. doi: 10.1016/j.anucene.2020.107560 [9] WANG Z, Wang W H, WANG Q S. Optimization of water mist droplet size by using CFD modeling for fire suppressions[J]. Journal of Loss Prevention in the Process Industries, 2016, 44: 626-632. doi: 10.1016/j.jlp.2016.04.010 [10] ZHANG T W, LIU H, SONG J W, et al. Synergistic inhibition effect on lithium-ion batteries during thermal runaway by N2-twin-fluid liquid mist[J]. Case Studies in Thermal Engineering, 2022, 37: 102269. doi: 10.1016/j.csite.2022.102269 [11] ZHANG B, ZHU Q, XU Y, et al. The effect of ambient pressure on gas jet diffusion in air: experimental and numerical study[J]. International Journal of Heat and Mass Transfer, 2019, 134: 392-403. [12] WANG X S, ZHU P, LI Y, et al. Effect of low ambient air pressure on spray characteristics of water mist[J]. Experimental Thermal and Fluid Science, 2015, 66: 7-12. doi: 10.1016/j.expthermflusci.2015.03.009 [13] ZHU P, WANG X S. Numerical study on the effects of ambient air pressure on water mist characteristics[J]. Energy Procedia, 2015, 66: 169-172. doi: 10.1016/j.egypro.2015.02.005 [14] 戴经天. 低压环境细水雾灭火有效性实验研究[D]. 广汉: 中国民用航空飞行学院, 2019: 13-48.DAI J T. Experimental study on fire extinguishing effectiveness of water mist in low pressure environment[D]. Guanghan: Civil Aviation Flight College of China, 2019: 13-48(in Chinese). [15] MA Q J, WAN M S, SHAO J C, et al. Pool fire suppression performance by twin-fluid water mist under low pressures in an altitude chamber[J]. Process Safety Progress, 2021, 40(1): e12155. doi: 10.1002/prs.12155 [16] REINHARDT J. Minimum performance standard for aircraft cargo compartment halon replacement fire suppression systems (2012 update[R]. Washington, D.C.: Federal Aviation Administration, 2012. [17] XIONG Y F, DIAKOSTEFANIS M, DINESH A, et al. Numerical assessment for aircraft cargo compartment fire suppression system safety[J]. Journal of Fire Sciences, 2021, 39(3): 240-261. doi: 10.1177/07349041211003208 [18] MARKER T R, REINHARDT J. Water spray as a fire suppression agent for aircraft cargo compartment Fires: DOT/FAA/AR-TN01/1[R]. Virginia: National Technical Information Service, 2001. [19] REINHARDT J. The evaluation of water mist with and without nitrogen as an aircraft cargo compartment fire suppression system: DOT/FAA/AR-01/121[R]. Virginia: National Technical Information Service, 2002. [20] 吕志豪. 民机货舱细水雾雾场特性及抑灭火有效性研究[D]. 广汉: 中国民用航空飞行学院, 2020: 37-79.LV Z H. Study on characteristics of water mist field and effectiveness of fire suppression in Civil aircraft cargo Hold[D]. Guanghan: Civil Aviation Flight College of China, 2020: 37-79(in Chinese). [21] 朱培, 罗圣峰, 刘全义, 等. 货舱低压环境下细水雾抑灭航空煤油池火有效性[J]. 清华大学学报(自然科学版), 2022, 62(1): 21-32.ZHU P, LUO S F, LIU Q Y, et al. Effectiveness of aviation kerosene pool fire suppression by water mist in a cargo compartment with low-pressure environment[J]. Journal of Tsinghua University (Science and Technology), 2022, 62(1): 21-32(in Chinese). [22] KEVIN M G, SIMO H, RANDALL M D, et al. Fire dynamics simulator user’s guide[M]. Gaithersburg: National Institute of Standards and Technology, 2019. [23] KEVIN M G, SIMO H, RANDALL M D, et al. Fire dynamics simulator technical reference guide volume 1: mathematical mode[M]. Gaithersburg: National Institute of Standards and Technology, 2019. [24] Klein RA. SFPE handbook of fire protection engineering[M]. 5th ed. New York; Springer, 2015. -

下载:

下载: