An efficient analysis method of helicopter fuselage bullet damage based on bullet penetration theory

-

摘要:

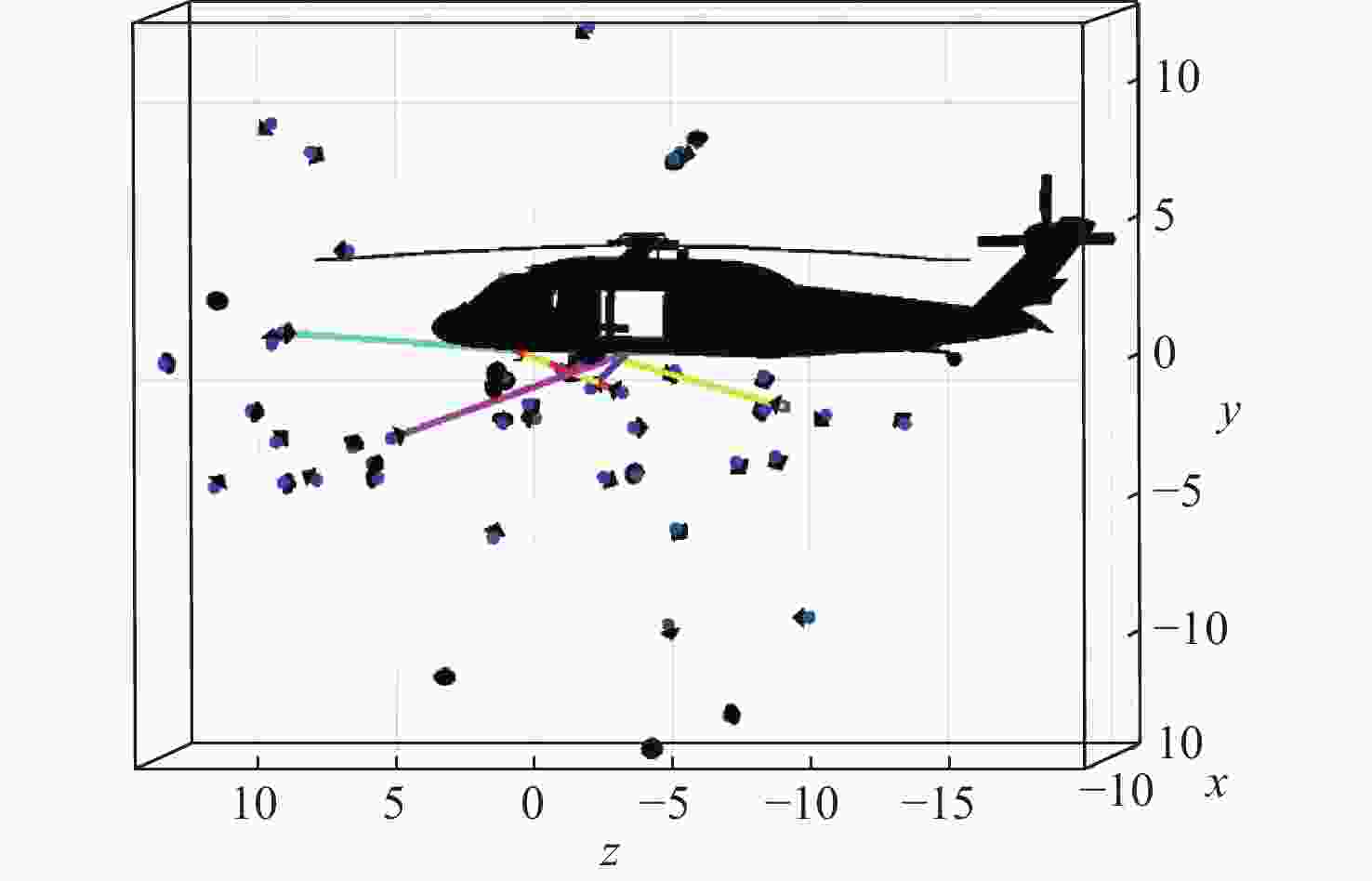

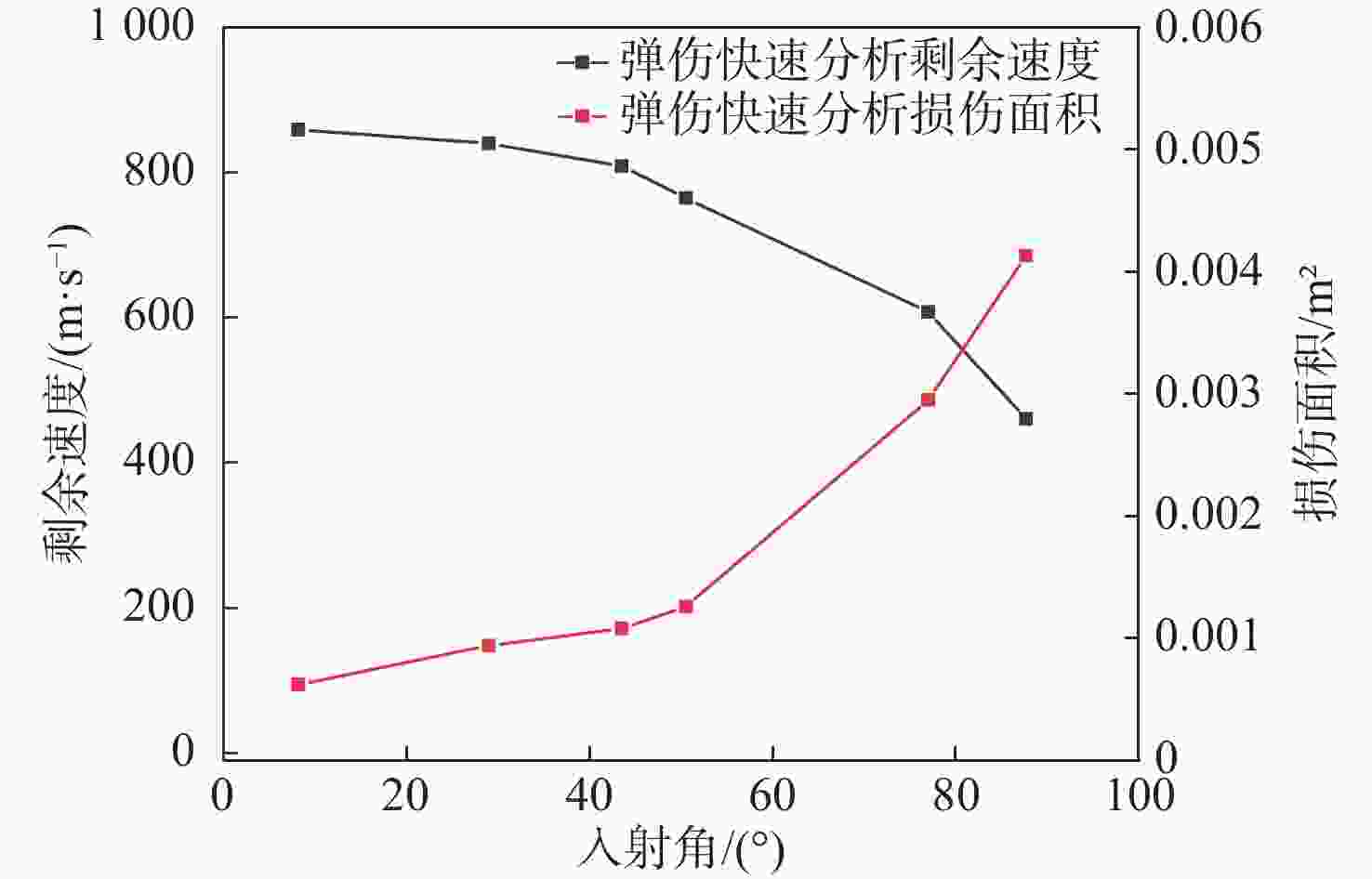

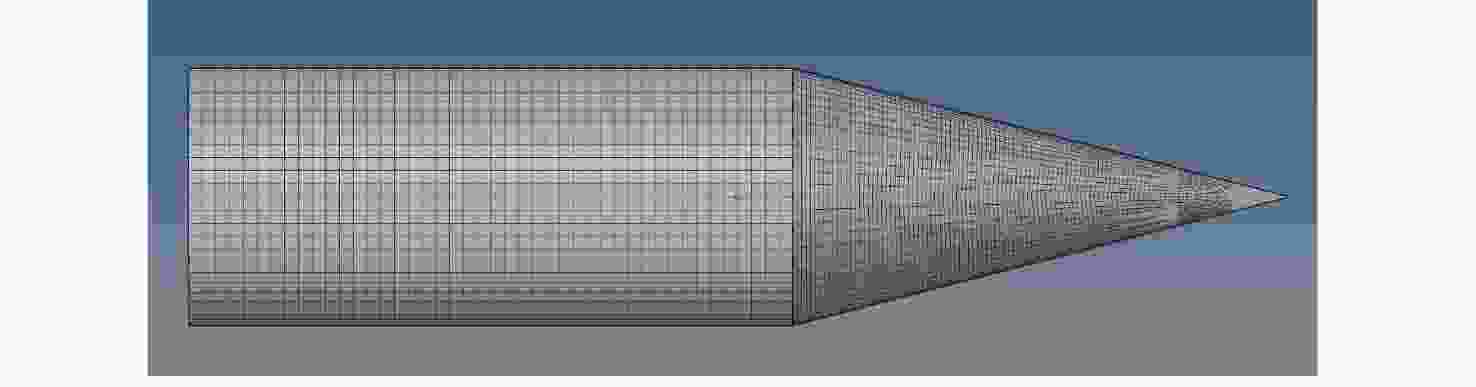

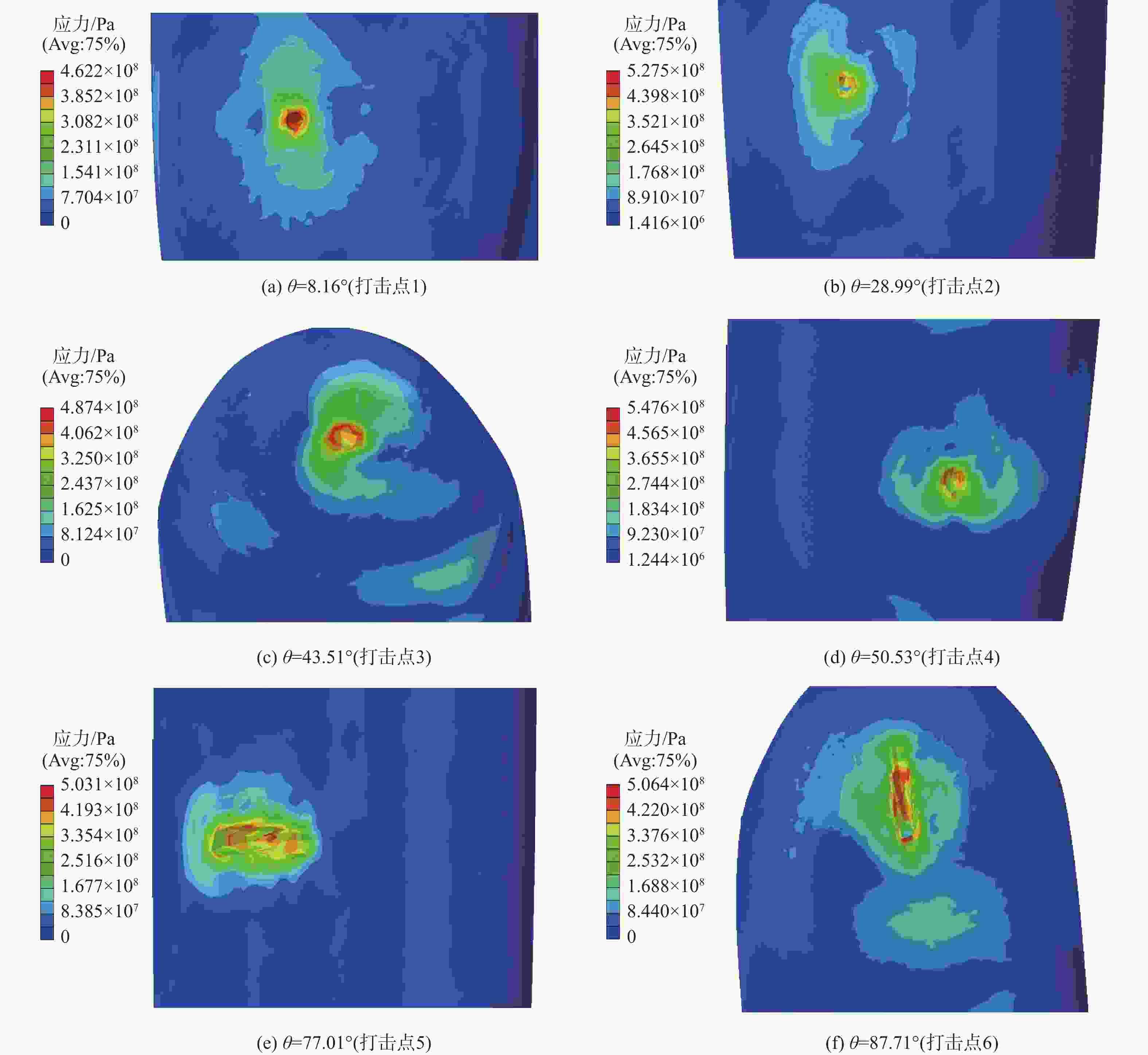

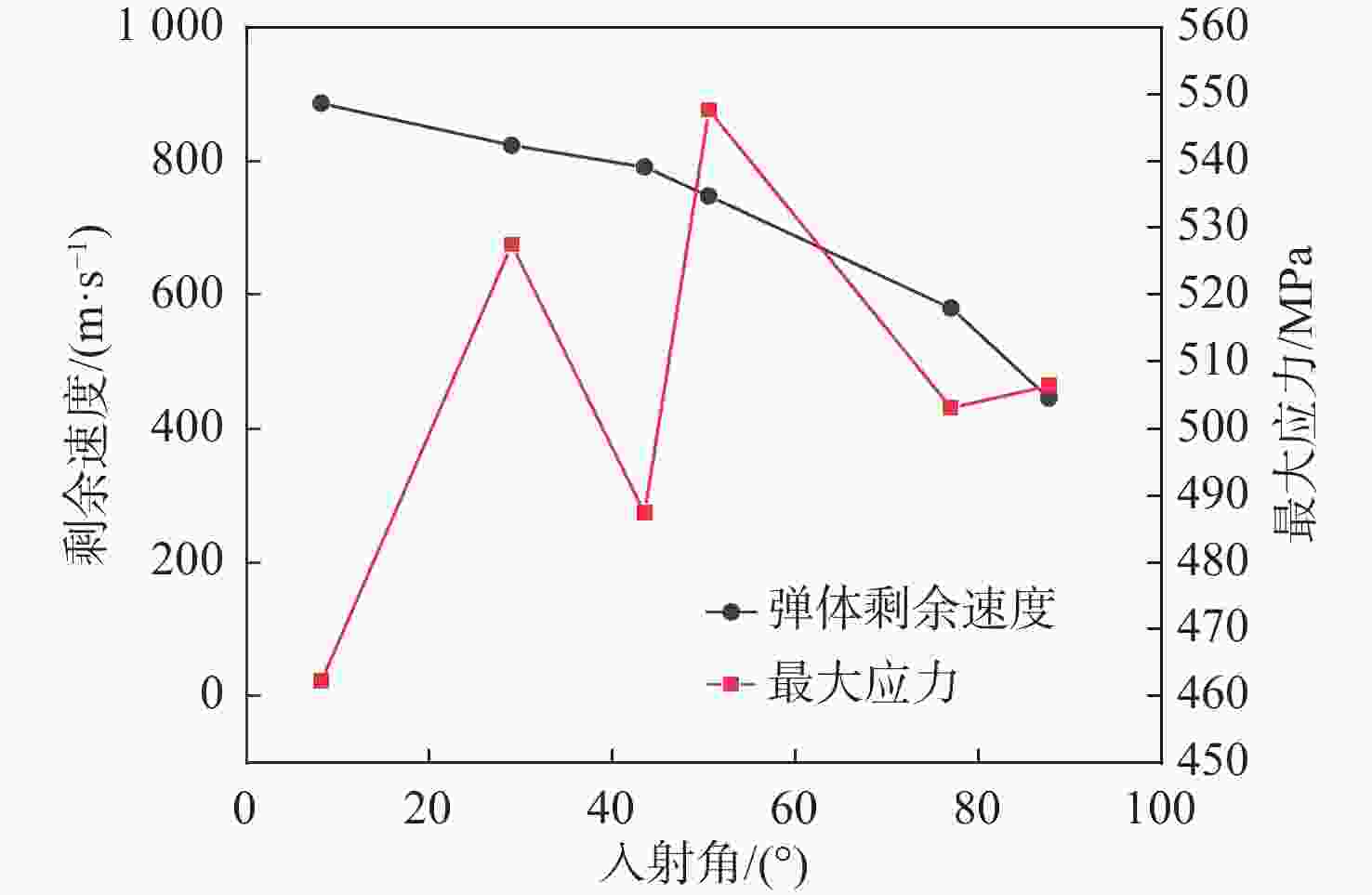

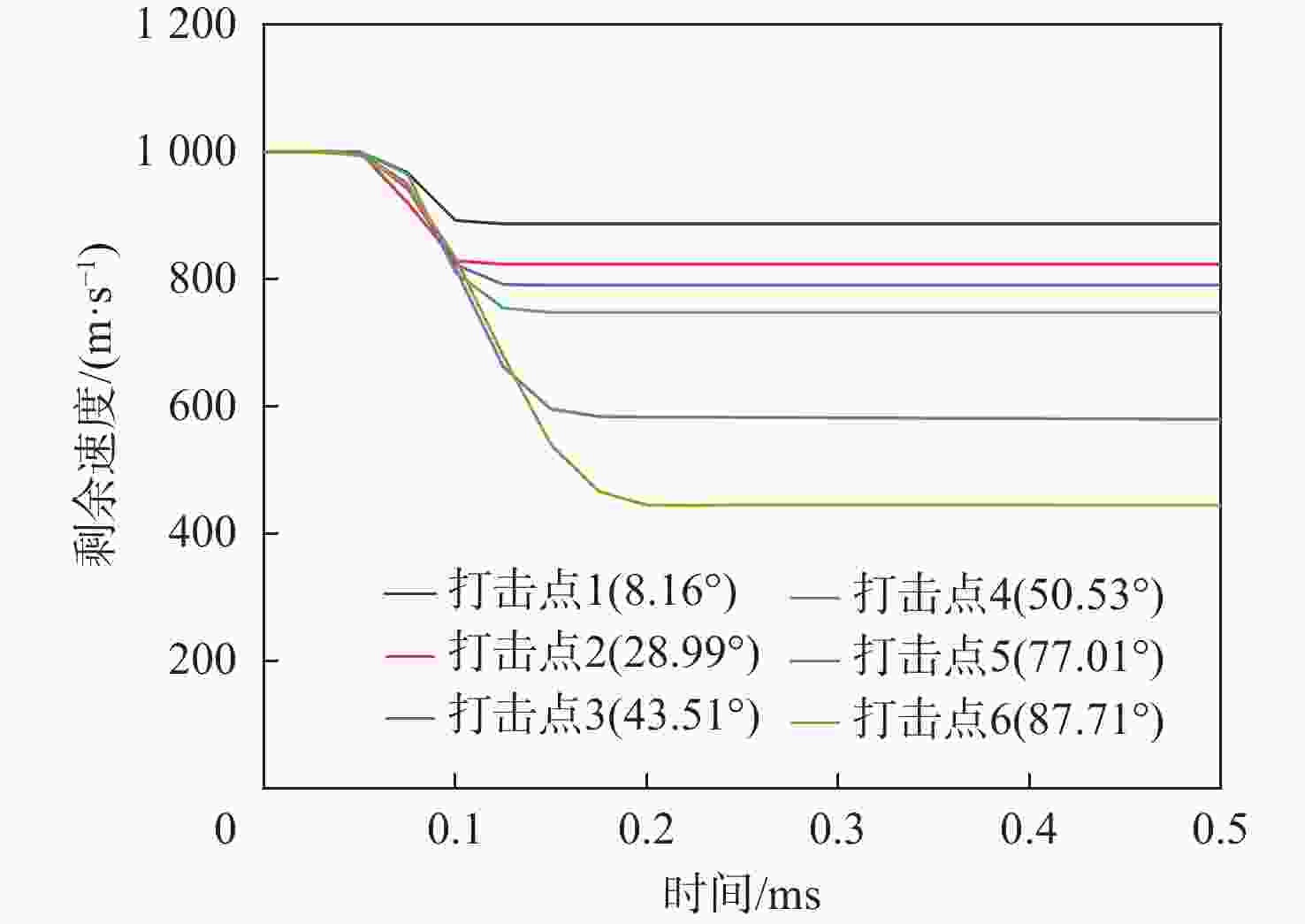

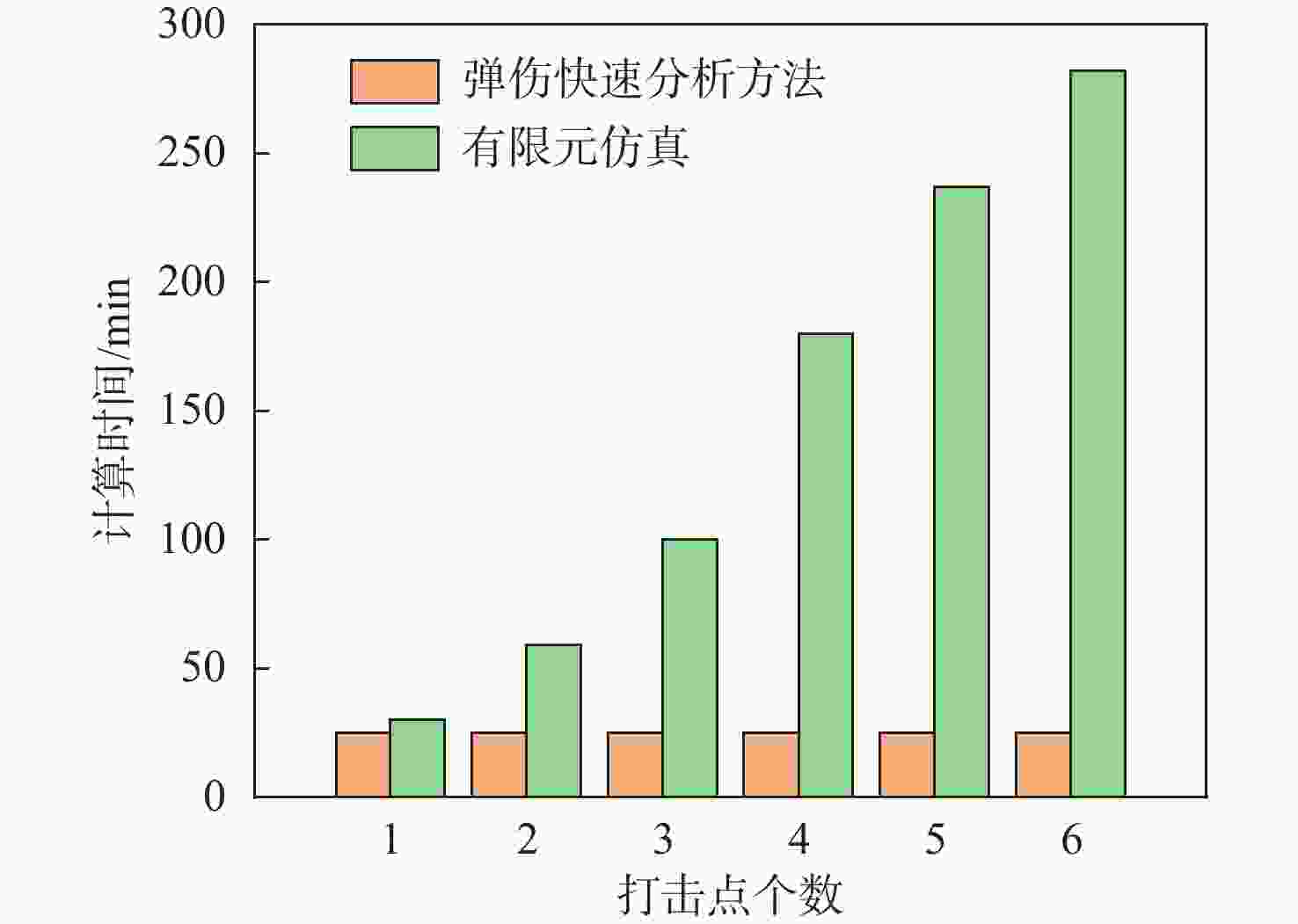

直升机机身外形与结构复杂,基于有限元方法的直升机机身弹伤数值仿真分析计算量大、周期长,难于适合复杂多弹环境的直升机机身弹伤快速分析评估。为此,耦合子弹击穿理论和弹击碰撞计算模型,建立直升机机身弹伤快速分析方法,并通过与试验结果、有限元数值仿真结果对比,验证快速分析方法的准确性。随后研究多弹打击的直升机机身弹击坐标、剩余速度以及机身损伤面积。研究表明:快速分析方法计算的剩余速度与试验结果相吻合;相比有限元弹伤数值仿真,快速分析方法计算的弹体剩余速度最大误差为4.7%,机身损伤面积最大误差为9.56%,计算时间减少92.1%,计算效率显著提高。随着弹体入射角增大,剩余速度减小,损伤面积增大;当弹体入射角过大,弹体无法穿透机身表面,产生水槽状滑擦损伤,造成较大面积损伤。

Abstract:The shape and structure of helicopter fuselage are complicated. Finite element simulation of helicopter fuselage bullet damage has a high computing burden and is time-consuming, which makes it difficult to be applied in rapid analysis and evaluation of helicopter fuselage bullet damage in complex multi-bullet environments. In view of this, an efficient analysis method of helicopter fuselage bullet damage was proposed by coupling the bullet penetration theory and the model of projectile impact. The results obtained from the method were compared with those of experiment and finite element simulation to validate its accuracy. Then, the helicopter fuselage impact coordinate, residual velocity, and fuselage damage area under multi-bullet attack were studied. The results show that the residual velocity calculated by the efficient analysis method is in agreement with the experimental result. The maximum error of the residual velocity of the projectile body and the maximum error of the fuselage damage area are 4.7% and 9.56%, respectively for the proposed method compared with the finite element simulation of bullet damage. Additionally, the efficiency of the present method is obviously improved as the computational time is reduced by 92.1%. With the increase of the incidence angle of the projectile body, the residual velocity decreases, and the damage area increases. When the incidence angle is too large, the projectile body cannot penetrate the surface of the fuselage, which results in flume-like skid damage and a large area of damage.

-

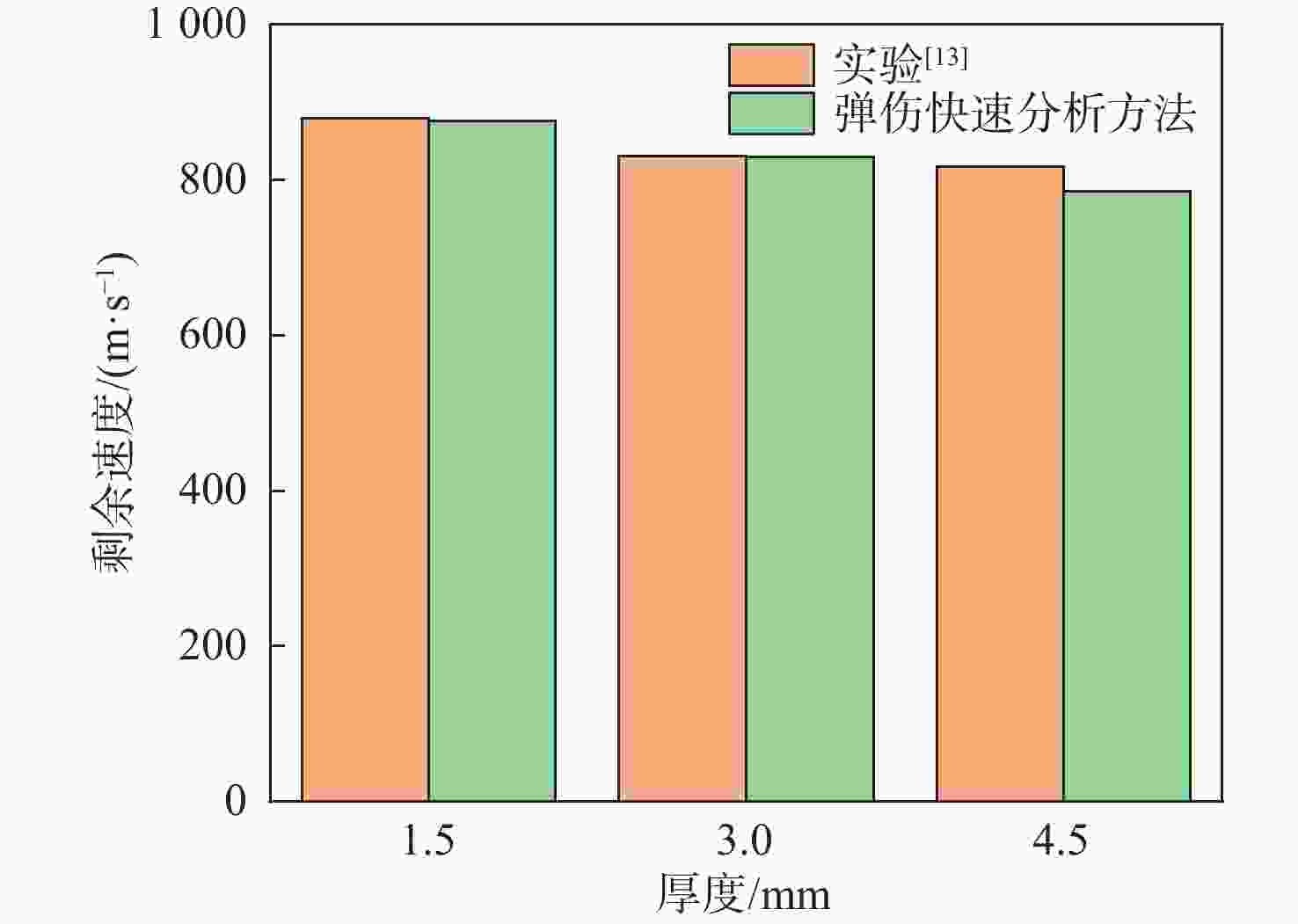

材料 密度ρ/(kg·m−2) 弹性模量E/MPa 泊松比μ 钢 7 800 200 000 0.3 表 2 弹体剩余速度实验与弹伤快速分析数值计算对比

Table 2. Comparison of residual velocity experiment on projectile body and efficient analysis method of bullet damage

金属板 序号 板厚/mm 射入

角度/(°)剩余速度/(m·s−1) 误差/% 实验 本文 钢板 1 1.5 0 878.73 875.65 0.3 钢板 2 3 0 830.37 829.35 0.12 钢板 3 4.5 0 816.99 785.67 3.8 表 3 靶板材料常用参数及失效参数[14]

Table 3. Common parameters and failure parameters of target plate materials[14]

材料 密度ρ/

(g·m−2)弹性模量

E/MPa泊松

比μ屈服强度

σ/MPaA/Pa B/Pa n 钢 7 800 200000 0.3 235 506 320 0.28 材料 m C D1 D2 D3 D4 D5 钢 1.06 0.064 0.1 0.76 1.57 0.005 −0.84 注:A为初始屈服应力;B为硬化常数;n为硬化指数;m为热软化指数;C为应变速率常数;D1-D5为材料参数。 表 4 剩余速度对比

Table 4. Residual velocity comparison

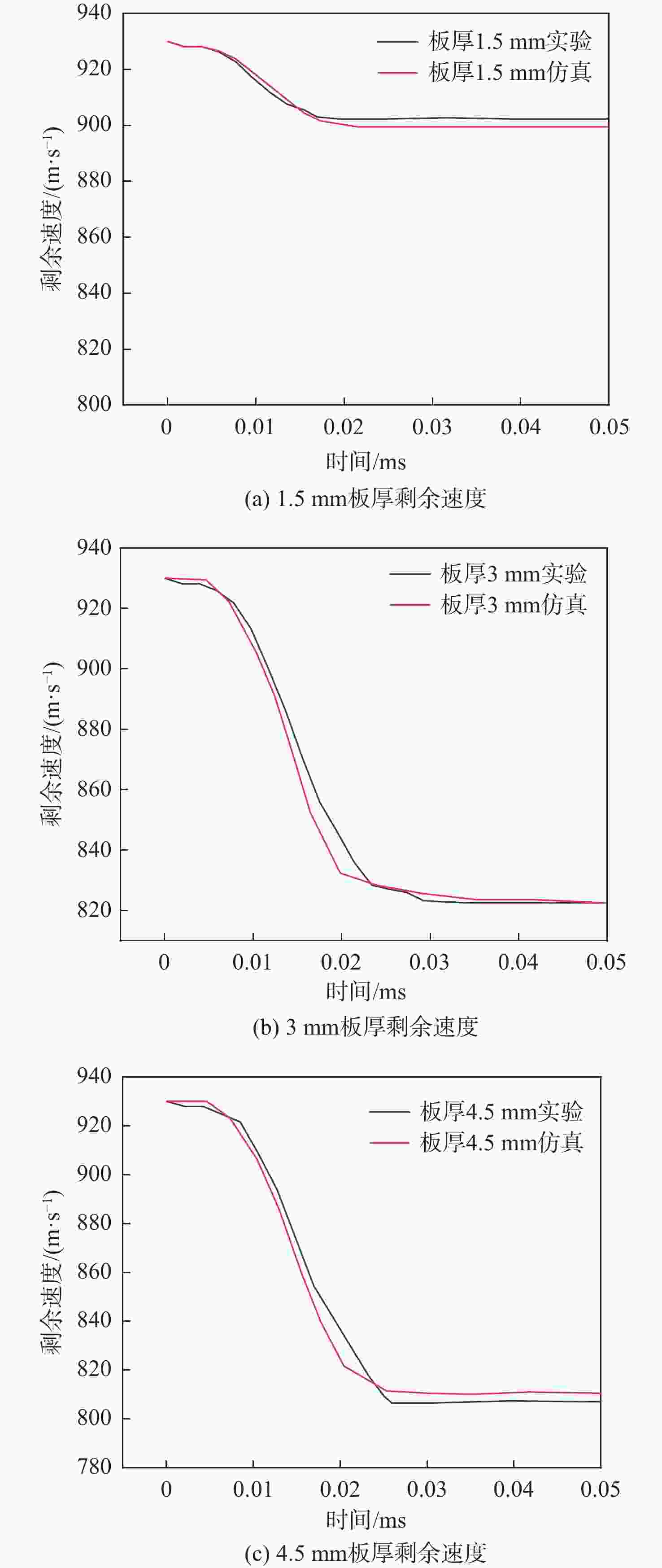

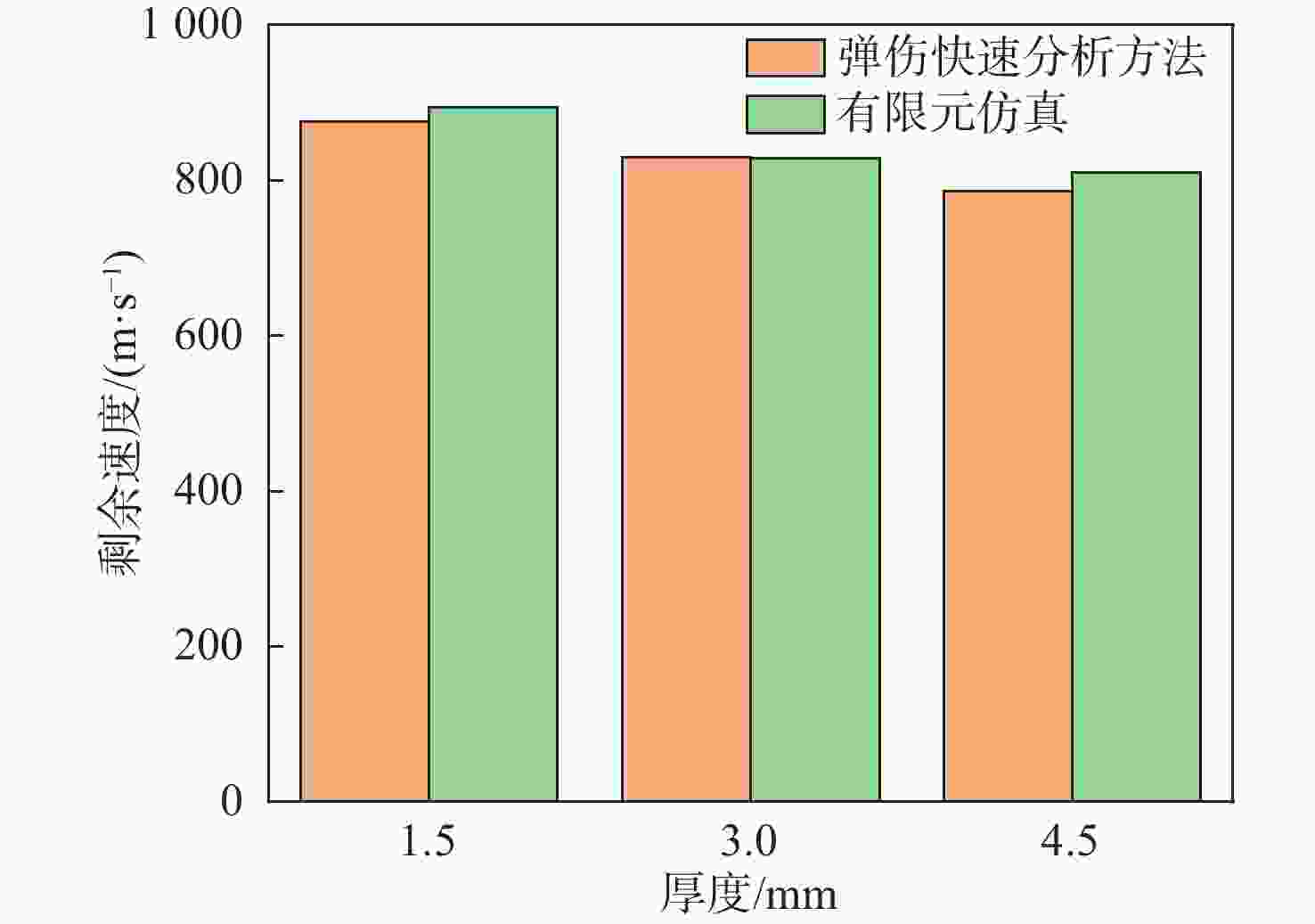

金属板 板厚/mm 剩余速度/(m·s−1) 误差/% 时间/s 实验 仿真 本文 仿真 本文 仿真 本文 钢板 1.5 878.73 893.09 875.65 1.63 0.3 45 0.032 3 830.37 828.27 829.35 0.78 0.12 55 0.025 4.5 816.99 810.17 785.67 0.83 3.8 62 0.021 表 5 直升机机身弹伤快速分析方法结果

Table 5. Results of efficient analysis method of helicopter fuselage bullet damage

打击点 材料 入射角/

(°)初速度/

(m·s−1)剩余速度/

(m·s−1)损伤

面积/m2计算

时间/min1 铝合金 8.16 1 000 858.8 6.21×10−4 25 2 铝合金 28.99 1 000 840.1 9.41×10−4 25 3 铝合金 43.51 1 000 808.6 1.08×10−3 25 4 铝合金 50.53 1 000 764.6 1.26×10−3 25 5 铝合金 77.01 1 000 607.5 2.95×10−3 25 6 铝合金 87.71 1 000 460.2 4.13×10−3 25 表 6 铝合金2A50材料参数及Johnson-Cook模型失效参数[20]

Table 6. Aluminum alloy 2A50 material parameters and failure parameters of Johnson-Cook model[20]

材料 密度/

(kg·m−3)弹性模

E/MPa泊松比μ A/Pa B/Pa 铝合金 2750 70000 0.3 324.1 113.8 材料 n m C $ D_{1} $ $ D_{2} $ $ D_{3} $ $ D_{4} $ $ D_{5} $ 铝合金 0.42 1.7 0.008 0.77 1.45 0.47 0.007 0 表 7 直升机机身弹伤快速分析计算与有限元仿真计算数据对比

Table 7. Comparison of data between efficient analysis and finite element simulation of helicopter fuselage bullet damage

打击点

入射角/(°)本文剩余

速度/(m·s−1)有限元剩余

速度/(m·s−1)本文损伤

面积/m2有限元损伤

面积/m28.16 858.8 886.4 6.21×10−4 5.75×10−4 28.99 840.1 823.6 9.41×10−4 8.96×10−4 43.51 808.6 790.8 1.08×10−3 1.02×10−3 50.53 764.6 747.7 1.26×10−3 1.15×10−3 77.01 607.5 580.3 2.95×10−3 2.82×10−3 87.71 460.2 445.1 4.13×10−3 3.84×10−3 -

[1] WADAGBALKAR P, LIU G R. Real-time prediction of projectile penetration to laminates by training machine learning models with finite element solver as the trainer[J]. Defence Technology, 2021, 17(1): 147-160. doi: 10.1016/j.dt.2020.04.011 [2] PETRUDI A M, VAHEDI K, RAHMANI M. Numerical and analytical simulation of ballistic projectile penetration due to high velocity impact on ceramic target[J]. Fracture and Structural Integrity, 2020, 14(54): 226-248. doi: 10.3221/IGF-ESIS.54.17 [3] 惠旭龙, 刘小川, 王计真, 等. TC4钛合金平板高速撞击损伤及弹道极限特性[J]. 科学技术与工程, 2017, 17(11): 1-8. doi: 10.3969/j.issn.1671-1815.2017.11.001HUI X L, LIU X C, WANG J Z, et al. High velocity impact failure and ballistic performance of TC4 plate[J]. Science Technology and Engineering, 2017, 17(11): 1-8(in Chinese). doi: 10.3969/j.issn.1671-1815.2017.11.001 [4] SINGH P K, LUMAR M. Hypervelocity impact behavior of projectile penetration on spacecraft structure: a review[J]. Materials Today: Proceedings, 2022, 62: 3167-3171. doi: 10.1016/j.matpr.2022.03.437 [5] 程玉, 陈智刚, 杨芮, 等. 无量纲参数对破片弹道极限速度的影响[J]. 弹道学报, 2022, 34(4): 8-14,51.CHENG Y, CHEN Z G, YANG R, et al. Influence of dimensionless parameters on ballistic limit velocity of fragments[J]. Journal of Ballistics, 2022, 34(4): 8-14,51(in Chinese). [6] 刘铁磊, 徐豫新, 王晓锋, 等. 钨合金球形破片侵彻低碳钢的弹道极限速度计算模型[J]. 兵工学报, 2022, 43(4): 768-779.LIU T L, XU Y X, WANG X F, et al. Ballistic limit calculation model of tungsten alloy spherical fragments penetrating into low carbon steel plate[J]. Acta Armamentarii, 2022, 43(4): 768-779(in Chinese). [7] 高润芳, 韩峰, 马晓青, 等. 几种钨合金破片垂直侵彻装甲钢板极限穿透速度研究[J]. 弹箭与制导学报, 2005, 25(4): 57-59,62. doi: 10.3969/j.issn.1673-9728.2005.04.020GAO R F, HAN F, MA X Q, et al. Investigation of tungsten fragments of different shape penetrating armour plate[J]. Journal of Projectiles, Rockets, Missiles and Guidance, 2005, 25(4): 57-59,62(in Chinese). doi: 10.3969/j.issn.1673-9728.2005.04.020 [8] 赵丽俊, 焦志刚, 李晓婕, 等. 预制破片侵彻均质装甲钢的极限穿透速度[J]. 爆炸与冲击, 2018, 38(1): 183-190. doi: 10.11883/bzycj-2016-0116ZHAO L J, JIAO Z G, LI X J, et al. Critical penetration velocity of prefabricated fragment in penetrating homogeneous armor steel plate[J]. Explosion and Shock Waves, 2018, 38(1): 183-190(in Chinese). doi: 10.11883/bzycj-2016-0116 [9] 胡静, 吕瑜晗. 斜撞击角度对铝合金薄板失效特性影响研究[J]. 机械强度, 2022, 44(5): 1119-1127.HU J, LÜ Y H. Study on the effect of oblique impact angle on the failure characteristics of aluminum alloy sheet[J]. Journal of Mechanical Strength, 2022, 44(5): 1119-1127(in Chinese). [10] Ball R E. The fundamentals of aircraft combat survivability analysis and design[M]. Second edition. Monterey: American Institute of Aeronautics and Astronautics, Inc, 2003: 739-778. [11] PEI Y, SONG B F, HAN Q. A generic calculation model for aircraft single-hit vulnerability assessment based on equivalent target[J]. Chinese Journal of Aeronautics, 2006, 19(3): 183-189. doi: 10.1016/S1000-9361(11)60343-9 [12] 宋笔锋, 韩庆. 飞行器易损性指标计算的基本理论与方法(Ⅰ)[J]. 现代防御技术, 1999, 27(4): 39-47.SONG B F, HAN Q. Basic theory and method of aircraft vulnerability index calculation (Ⅰ)[J]. Modern Defence Technology, 1999, 27(4): 39-47(in Chinese). [13] 陈刚, 陈小伟, 陈忠富, 等. A3钢钝头弹撞击45钢板破坏模式的数值分析[J]. 爆炸与冲击, 2007, 27(5): 390-397. doi: 10.3321/j.issn:1001-1455.2007.05.002CHEN G, CHEN X W, CHEN Z F, et al. Simulations of A3 steel blunt projectiles impacting 45 steel plates[J]. Explosion and Shock Waves, 2007, 27(5): 390-397(in Chinese). doi: 10.3321/j.issn:1001-1455.2007.05.002 [14] 张铁纯, 田璐, 邓云飞, 等. 2A12铝合金薄板抗叶片形弹体撞击的数值仿真研究[J]. 机械强度, 2019, 41(3): 734-738.ZHANG T C, TIAN L, DENG Y F, et al. Numerical simulation research on the aluminum alloy thin plate impacted by blade projectile[J]. Journal of Mechanical Strength, 2019, 41(3): 734-738(in Chinese). [15] 李金福. Q235叠层靶抗破片侵彻性能的研究[D]. 太原: 中北大学, 2021: 10-12.LI J F. Study on resistance of Q235 laminated target to fragment penetration[D]. Taiyuan: North University of China, 2021: 10-12(in Chinese). [16] 周卿, 黄松, 赵鹏铎, 等. 平头破片侵彻中厚Q235靶板的破坏模式研究[J]. 兵器装备工程学报, 2020, 41(7): 69-74. doi: 10.11809/bqzbgcxb2020.07.015ZHOU Q, HUANG S, ZHAO P D, et al. Study on failure mode of flat-headed projectile penetrating medium-thick Q235 target[J]. Journal of Ordnance Equipment Engineering, 2020, 41(7): 69-74(in Chinese). doi: 10.11809/bqzbgcxb2020.07.015 [17] 何降润. 穿燃含能破片侵彻靶板后的毁伤效能[D]. 太原: 中北大学, 2021: 12-20.HE J R. Study on the damage effectiveness of energy-containi-ng fragments penetrating a target plate through combustion[D]. Taiyuan: North University of China, 2021: 12-20(in Chinese). [18] 张钰龙, 郑宾, 郭华玲, 等. 球形钨破片侵彻钢靶毁伤效应研究[J]. 兵器装备工程学报, 2020, 41(5): 32-36. doi: 10.11809/bqzbgcxb2020.05.007ZHANG Y L, ZHENG B, GUO H L, et al. Study on damage effect of spherical tungsten fragments penetrating steel targets[J]. Journal of Ordnance Equipment Engineering, 2020, 41(5): 32-36(in Chinese). doi: 10.11809/bqzbgcxb2020.05.007 [19] 舒张忆南, 梁争峰, 阮喜军, 等. 多种因素影响下钨合金破片的穿甲深度研究[J]. 兵器装备工程学报, 2022, 43(4): 25-30. doi: 10.11809/bqzbgcxb2022.04.005SHU Z Y N, LIANG Z F, RUAN X J, et al. Research on penetration depth of tungsten alloy fragments under influence of many factors[J]. Journal of Ordnance Equipment Engineering, 2022, 43(4): 25-30(in Chinese). doi: 10.11809/bqzbgcxb2022.04.005 [20] 李亚, 任杰, 马大为, 等. 多角度高速侵彻金属靶的有限元模拟和实验研究[J]. 兵器材料科学与工程, 2017, 40(5): 72-77.LI Y, REN J, MA D W, et al. FEM simulation and experimental study of multiangular high velocity penetration of metallic targets[J]. Ordnance Material Science and Engineering, 2017, 40(5): 72-77(in Chinese). -

下载:

下载: