Detection method for complex dark spots on plastic gears based on U-Net++ and feature fusion

-

摘要:

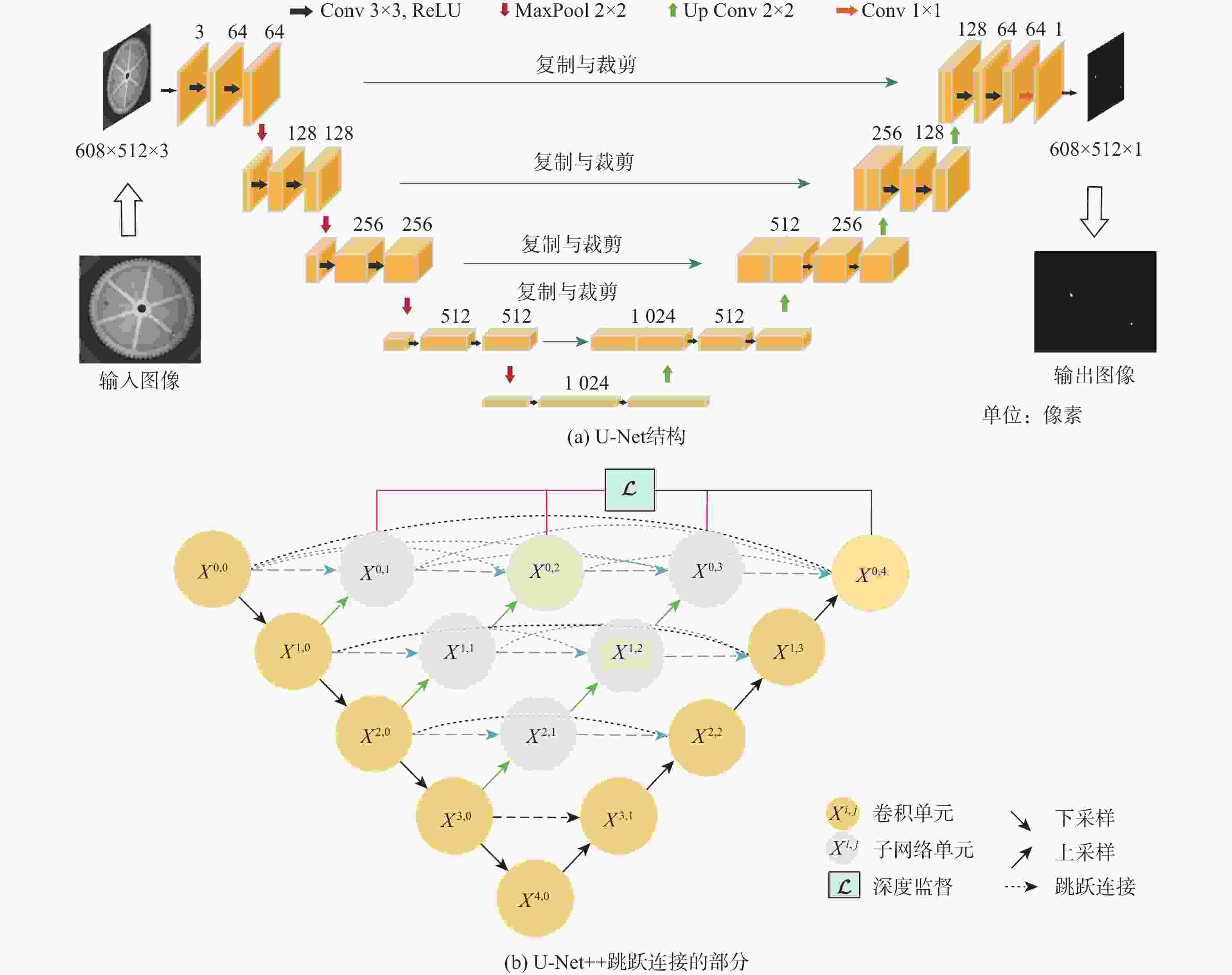

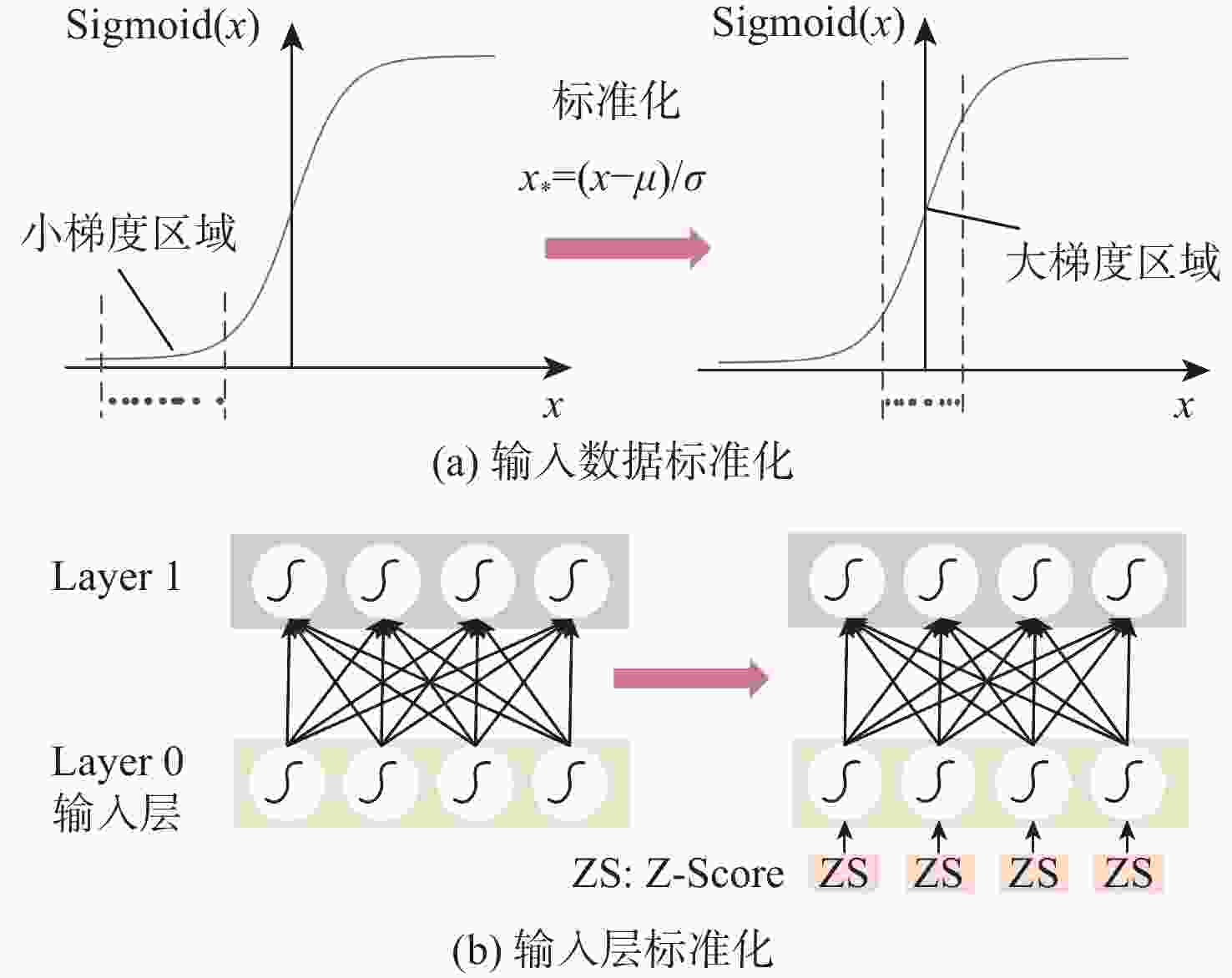

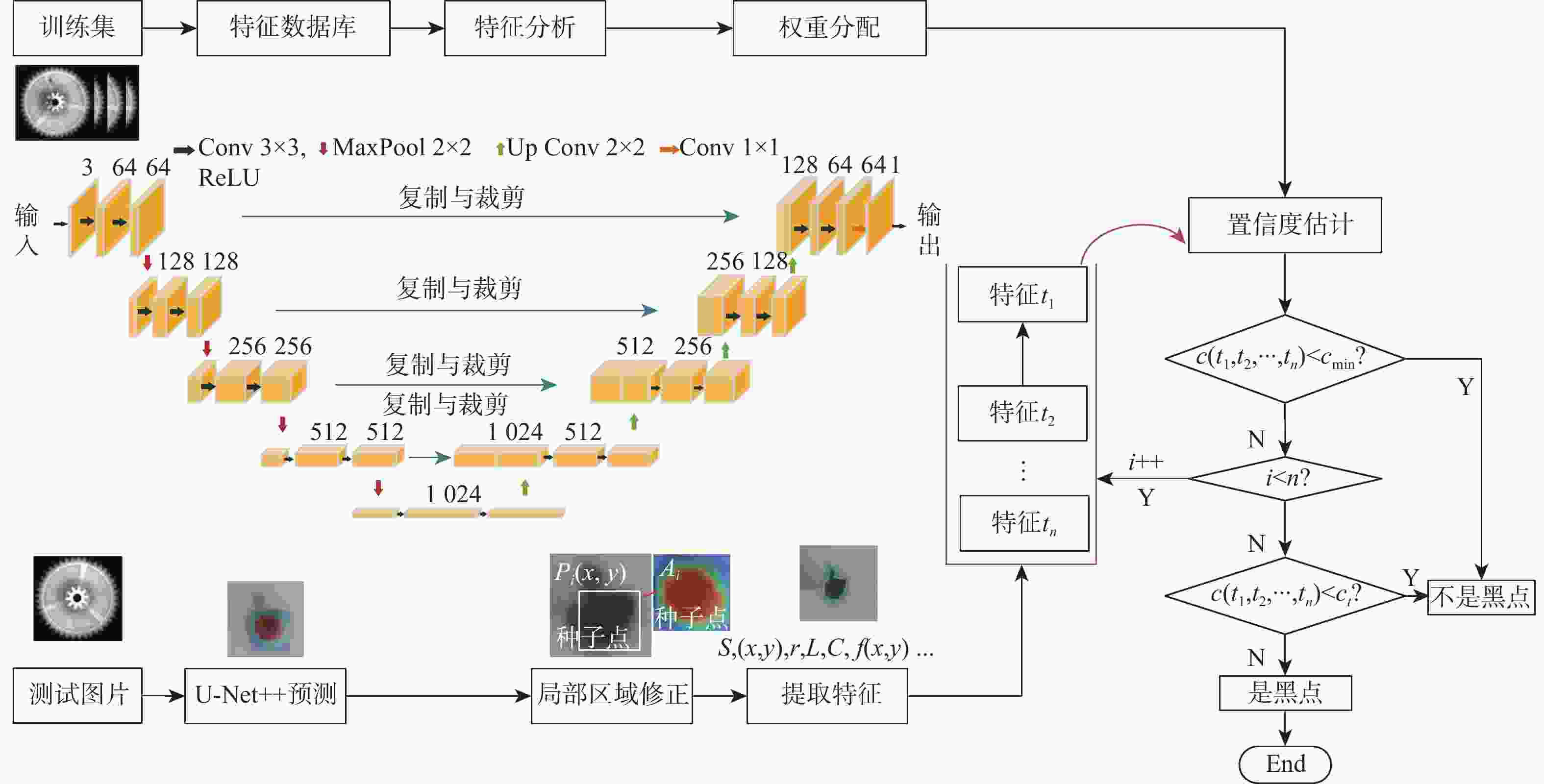

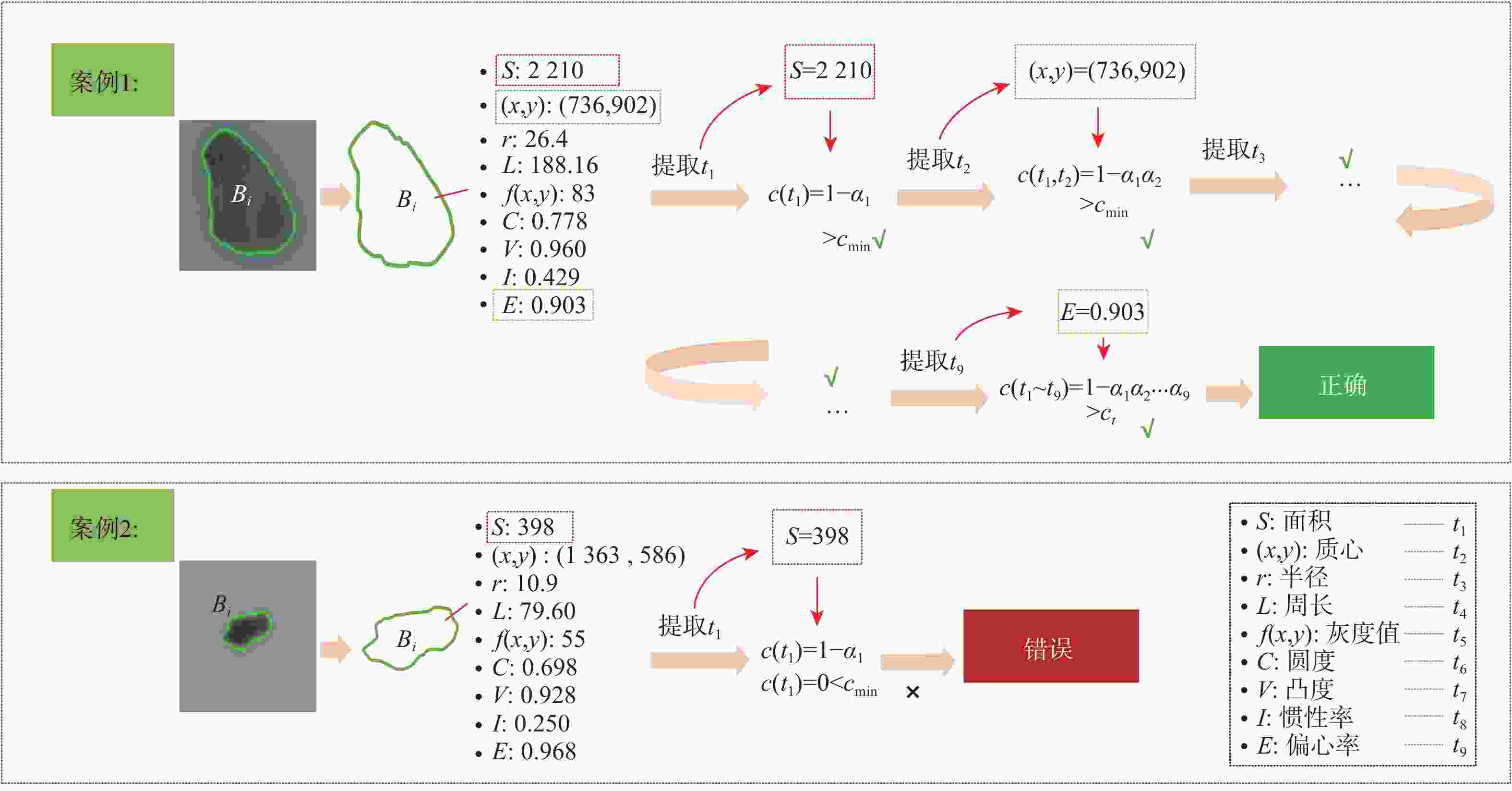

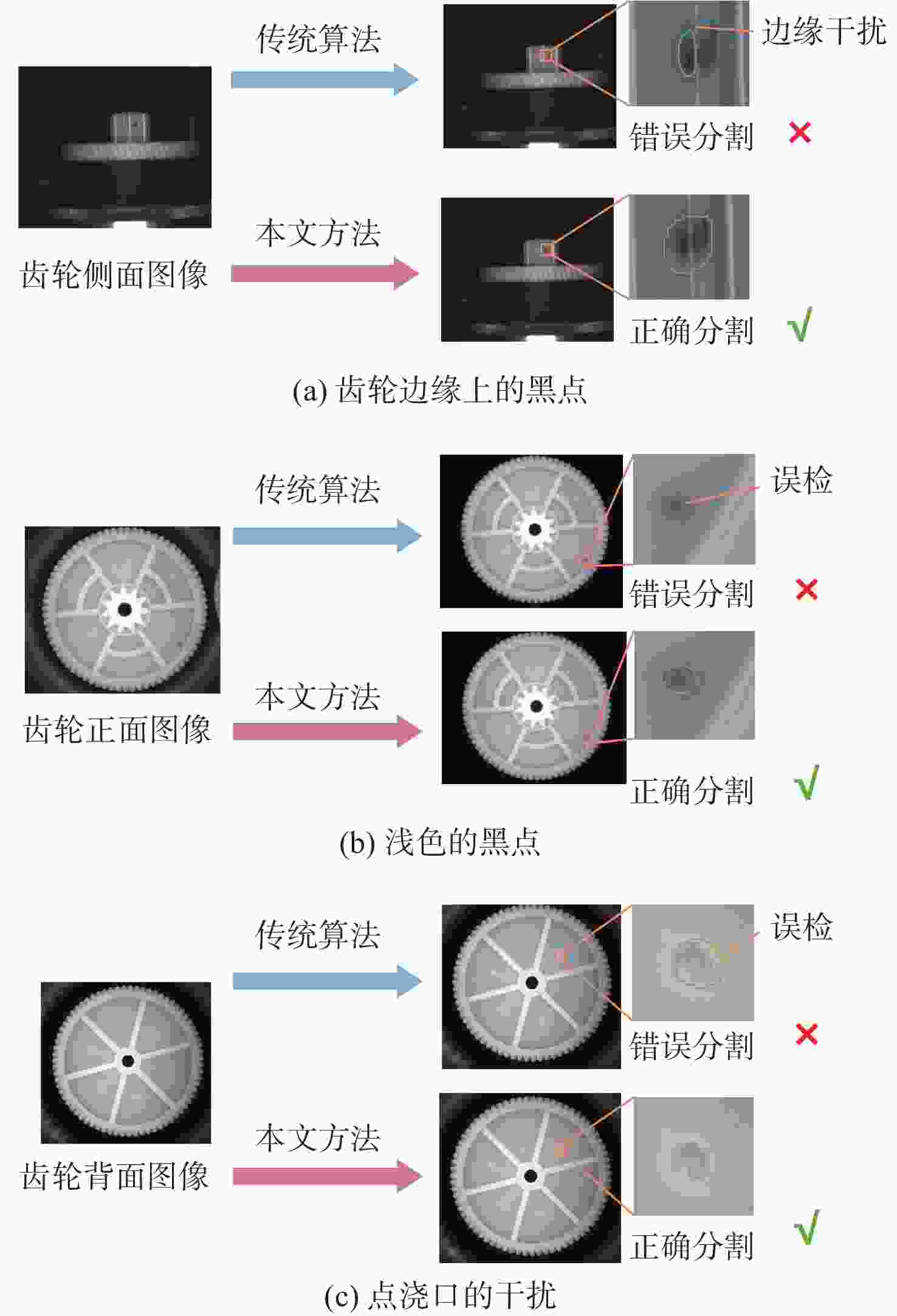

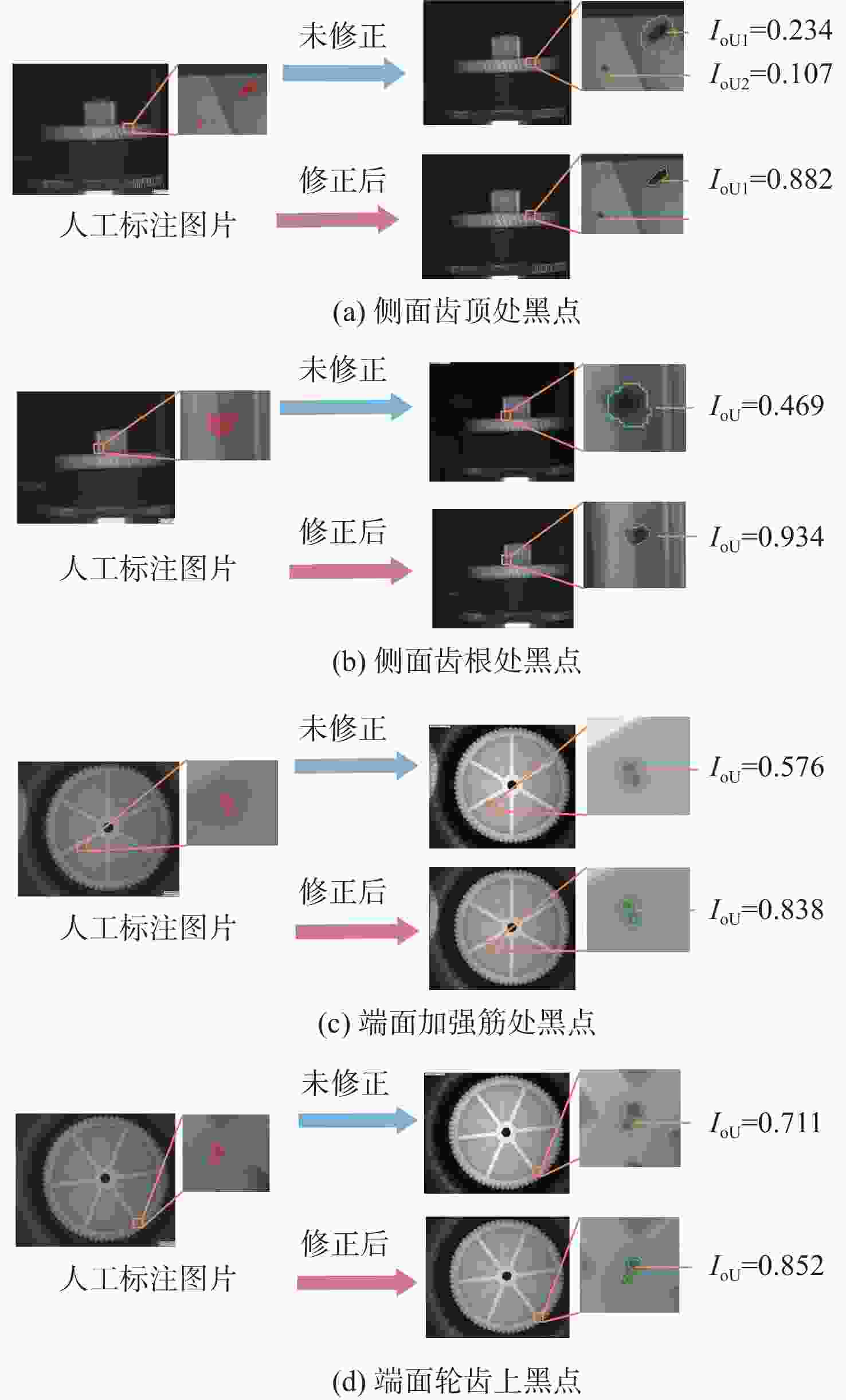

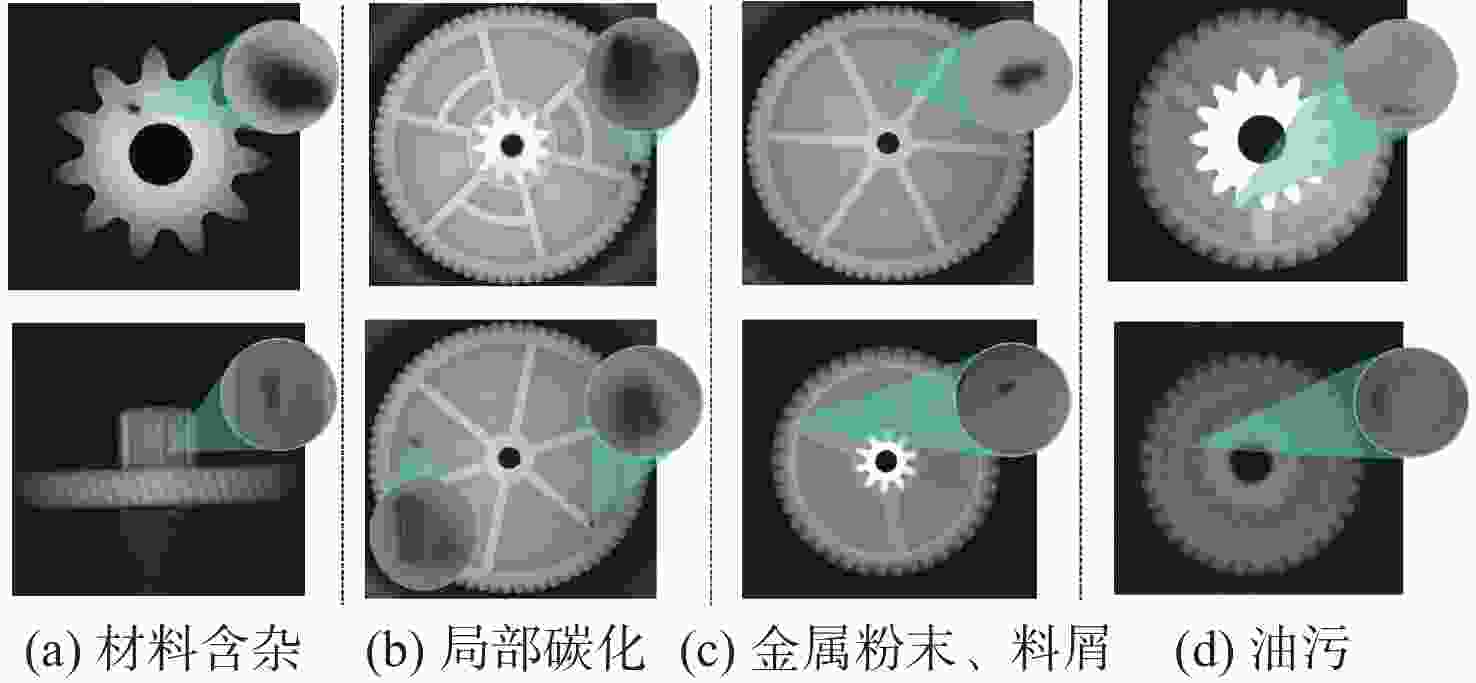

传统的缺陷检测算法在检测塑料齿轮表面复杂黑点时效果不佳,主要问题是对齿轮边缘上黑点的大小和位置判别不准确、对浅色黑点的漏检率高、易将点浇口误判为黑点。为此,提出一种基于U-Net++和特征融合的塑料齿轮复杂黑点检测方法。所提方法通过U-Net++预测黑点区域;根据梯度特征对黑点区域进行修正;结合多特征融合分析给出最终判定结果,提高了对复杂黑点检测的准确性和稳定性。测试结果表明:所提方法表征检测结果准确性的

P c值达到了98.93%,表征分割结果准确性的交并比平均值达到了0.864,相比传统的缺陷检测算法和未做修正的深度学习算法,交并比的平均值分别提高了0.478和0.309。Abstract:Traditional defect detection algorithms exhibit poor performance in accurately detecting complex dark spots on the surface of plastic gears. There are three primary issues: firstly, inaccurately distinguishing the size and position of dark spots on the gear edge; secondly, a high rate of missed detection for light dark spots; thirdly, a tendency to misjudge the point gate as dark spots. This paper proposed an improved detection method for complex dark spots on plastic gears based on U-Net++ and feature fusion. The dark spot area was predicted through U-Net++ and corrected depending on gradient features. Multi-feature fusion analysis was utilized to provide the final judgment result, thus improving the accuracy and stability of complex dark spot detection. The test results demonstrate that the

P c value, which represents the accuracy of the detection results, is as high as 98.93%, and the average value of IoU, representing the accuracy of the segmentation results, reaches 0.864. In comparison to traditional defect detection algorithms and uncorrected deep learning algorithms, the proposed method increases the average value of IoU by 0.478 and 0.309, respectively.-

Key words:

- plastic gear defects /

- deep learning /

- U-Net++ /

- multi-feature fusion /

- local area correction

-

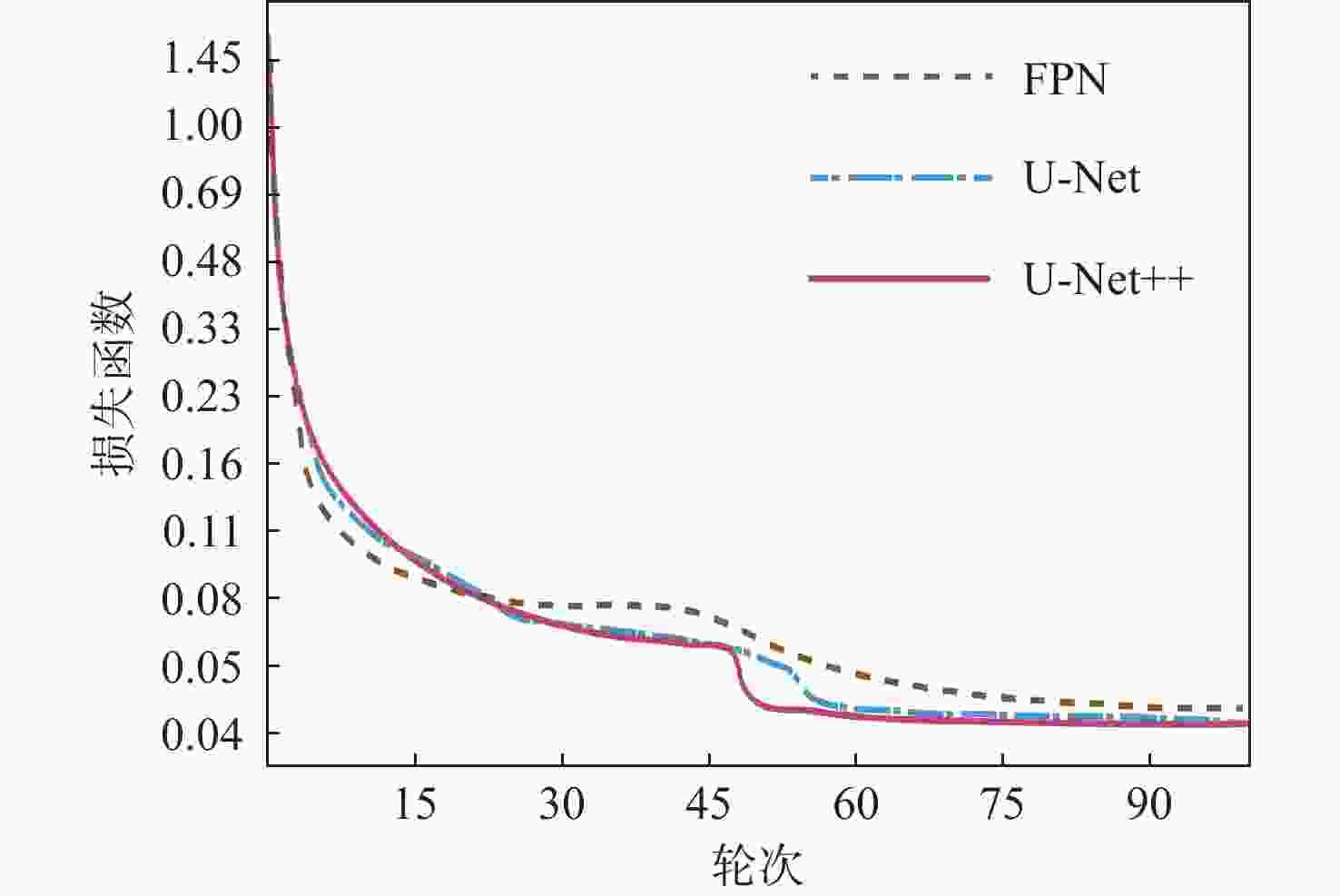

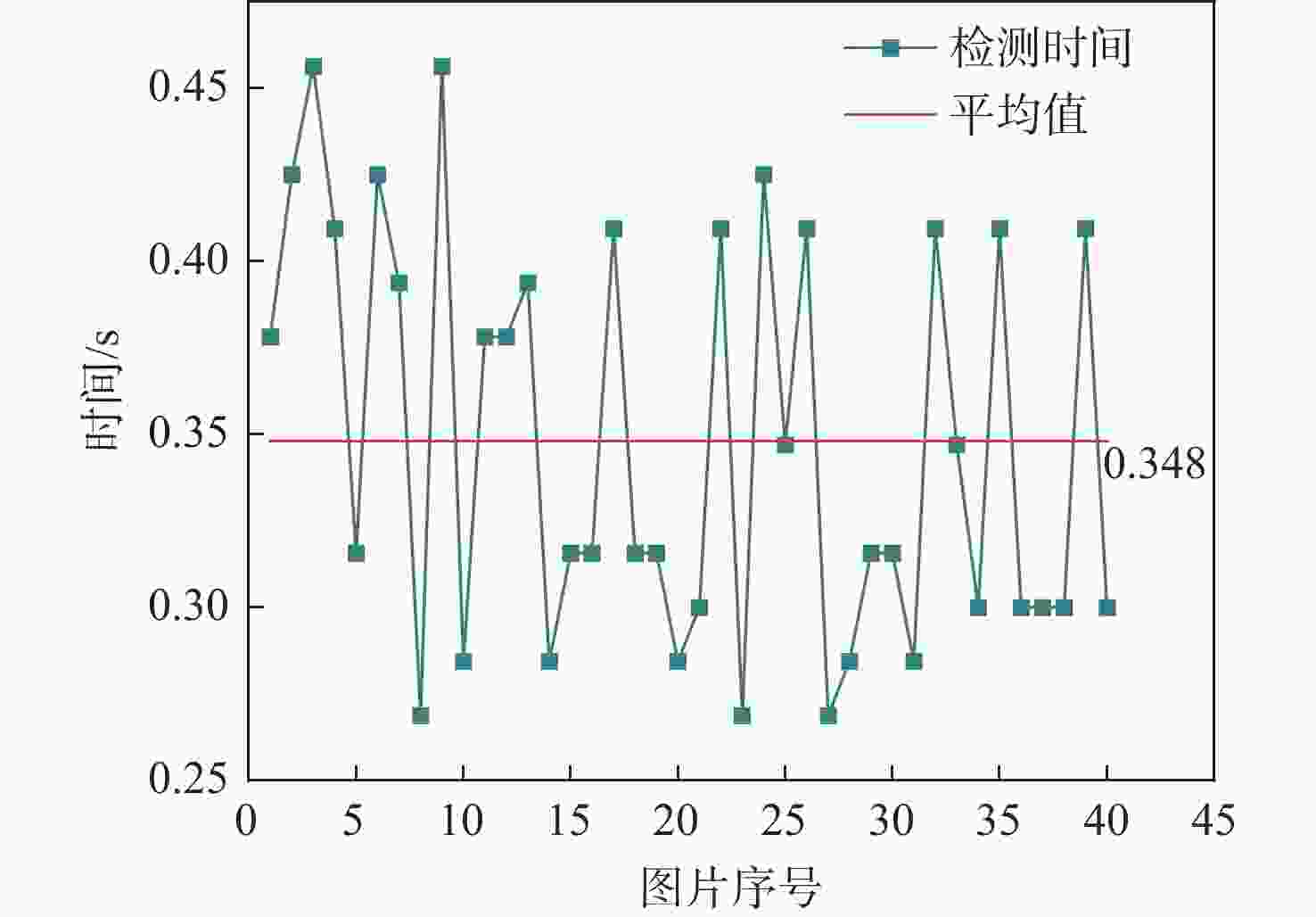

表 1 3种模型比较

Table 1. Comparison of three models

模型 编码器 图像数量 平均处理时间/s IoU平均值 Pc/% FPN resnet18 201 0.192 0.45 97.87 resnet34 0.200 0.48 97.99 efficientnet-b1 0.204 0.44 97.53 U-Net resnet18 201 0.196 0.48 98.02 resnet34 0.202 0.51 98.52 efficientnet-b1 0.227 0.42 97.81 U-Net++ resnet18 201 0.263 0.52 98.32 resnet34 0.298 0.60 98.93 efficientnet-b1 0.246 0.54 98.58 表 2 不同检测方法对塑料齿轮黑点缺陷数据集的检测效果对比

Table 2. Comparison of detection effects among different methods on dataset of plastic gears with dark spot defects

方法 IoU平均值 Pc值/% 传统缺陷检测算法

(基于局部极值的分水岭算法)0.386 55.60 U-Net++(未做修正) 0.555 98.93 本文方法 0.864 98.93 -

[1] 石照耀, 方一鸣, 王笑一. 齿轮视觉检测仪器与技术研究进展[J]. 激光与光电子学进展, 2022, 59(14): 1415006.SHI Z Y, FANG Y M, WANG X Y. Research progress in gear machine vision inspection instrument and technology[J]. Laser & Optoelectronics Progress, 2022, 59(14): 1415006(in Chinese). [2] 欧阳志喜, 石照耀. 塑料齿轮设计与制造[M]. 北京: 化学工业出版社, 2011: 271-276.OUYANG Z X, SHI Z Y. Design and manufacturing of plastic gears[M]. Beijing: Chemical Industry Press, 2011: 271-276(in Chinese) . [3] HAN K T M, UYYANONVARA B. A survey of blob detection algorithms for biomedical images[C]//Proceedings of the 7th International Conference of Information and Communication Technology for Embedded Systems. Piscataway: IEEE Press, 2016: 57-60. [4] 杨亚, 陶红艳, 余成波. SURF与灰度差分在小模数塑料齿轮缺陷检测中的研究与应用[J]. 机械传动, 2018, 42(5): 156-160.YANG Y, TAO H Y, YU C B. Research and application of SURF and gray difference in detection of small modulus plastic gear defect[J]. Journal of Mechanical Transmission, 2018, 42(5): 156-160(in Chinese). [5] 李江波, 彭彦昆, 黄文倩, 等. 桃子表面缺陷分水岭分割方法研究[J]. 农业机械学报, 2014, 45(8): 288-293. doi: 10.6041/j.issn.1000-1298.2014.08.046LI J B, PENG Y K, HUANG W Q, et al. Watershed segmentation method for segmenting defects on peach fruit surface[J]. Transactions of the Chinese Society for Agricultural Machinery, 2014, 45(8): 288-293(in Chinese). doi: 10.6041/j.issn.1000-1298.2014.08.046 [6] 韦玉科, 陈玉, 田洪金. 基于计算机视觉的焊点缺陷检测系统的设计[J]. 测控技术, 2015, 34(1): 138-141. doi: 10.3969/j.issn.1000-8829.2015.01.038WEI Y K, CHEN Y, TIAN H J. Design of solder joint defect detection based on machine vision[J]. Measurement & Control Technology, 2015, 34(1): 138-141(in Chinese). doi: 10.3969/j.issn.1000-8829.2015.01.038 [7] 陶显, 侯伟, 徐德. 基于深度学习的表面缺陷检测方法综述[J]. 自动化学报, 2021, 47(5): 1017-1034.TAO X, HOU W, XU D. A survey of surface defect detection methods based on deep learning[J]. Acta Automatica Sinica, 2021, 47(5): 1017-1034(in Chinese). [8] SU Y T, YAN P. A defect detection method of gear end-face based on modified YOLO-V3[C]//Proceedings of the 10th Institute of Electrical and Electronics Engineers International Conference on Cyber Technology in Automation, Control, and Intelligent Systems. Piscataway: IEEE Press, 2020: 283-288. [9] 张广世, 葛广英, 朱荣华, 等. 基于改进YOLOv3网络的齿轮缺陷检测[J]. 激光与光电子学进展, 2020, 57(12): 121009.ZHANG G S, GE G Y, ZHU R H, et al. Gear defect detection based on the improved YOLOv3 network[J]. Laser & Optoelectronics Progress, 2020, 57(12): 121009(in Chinese). [10] 刘悦, 黄新波. 基于YOLOv4和改进分水岭算法的绝缘子爆裂检测定位研究[J]. 电网与清洁能源, 2021, 37(7): 51-57. doi: 10.3969/j.issn.1674-3814.2021.07.007LIU Y, HUANG X B. Research on insulator burst fault identification based on YOLOv4 and improved watershed algorithm[J]. Power System and Clean Energy, 2021, 37(7): 51-57(in Chinese). doi: 10.3969/j.issn.1674-3814.2021.07.007 [11] RONNEBERGER O, FISCHER P, BROX T. U-Net: convolutional networks for biomedical image segmentation[C]//Proceedings of the Medical Image Computing and Computer-Assisted Intervention. Berlin: Springer, 2015: 234-241. [12] ZHOU Z W, RAHMAN SIDDIQUEE M M, TAJBAKHSH N, et al. U-Net++: a nested U-Net architecture for medical image segmentation[C]//Proceedings of the Deep Learning in Medical Image Analysis and Multimodal Learning for Clinical Decision Support. Berlin: Springer, 2018: 3-11. [13] SHELHAMER E, LONG J, DARRELL T. Fully convolutional networks for semantic segmentation[C]//Proceedings of the IEEE Transactions on Pattern Analysis and Machine Intelligence. Piscataway: IEEE Press, 2017: 640-651. [14] VON GIOI R G, JAKUBOWICZ J, MOREL J M, et al. LSD: a line segment detector[J]. Image Processing on Line, 2012, 2: 35-55. doi: 10.5201/ipol.2012.gjmr-lsd [15] ZHOU J, HUANG X H, PENG G. Recognition of airplanes using multi-feature fusion[J]. Journal of Huazhong University of Science and Technology, 2009, 37(1): 38-41. [16] LIN T Y, DOLLÁR P, GIRSHICK R, et al. Feature pyramid networks for object detection[C]//Proceedings of the IEEE Conference on Computer Vision and Pattern Recognition. Piscataway: IEEE Press, 2017: 936-944. [17] DUCHI J, HAZAN E, SINGER Y. Adaptive subgradient methods for online learning and stochastic optimization[J]. The Journal of Machine Learning Research, 2011, 12: 2121-2159. [18] RUDER S. An overview of gradient descent optimization algorithms[EB/OL]. (2017-06-15)[2023-02-01]. http://arxiv.org/abs/1609.04747v2. -

下载:

下载: