Unexpected electric breakdown control and thermal characteristics of ion thruster shell

-

摘要:

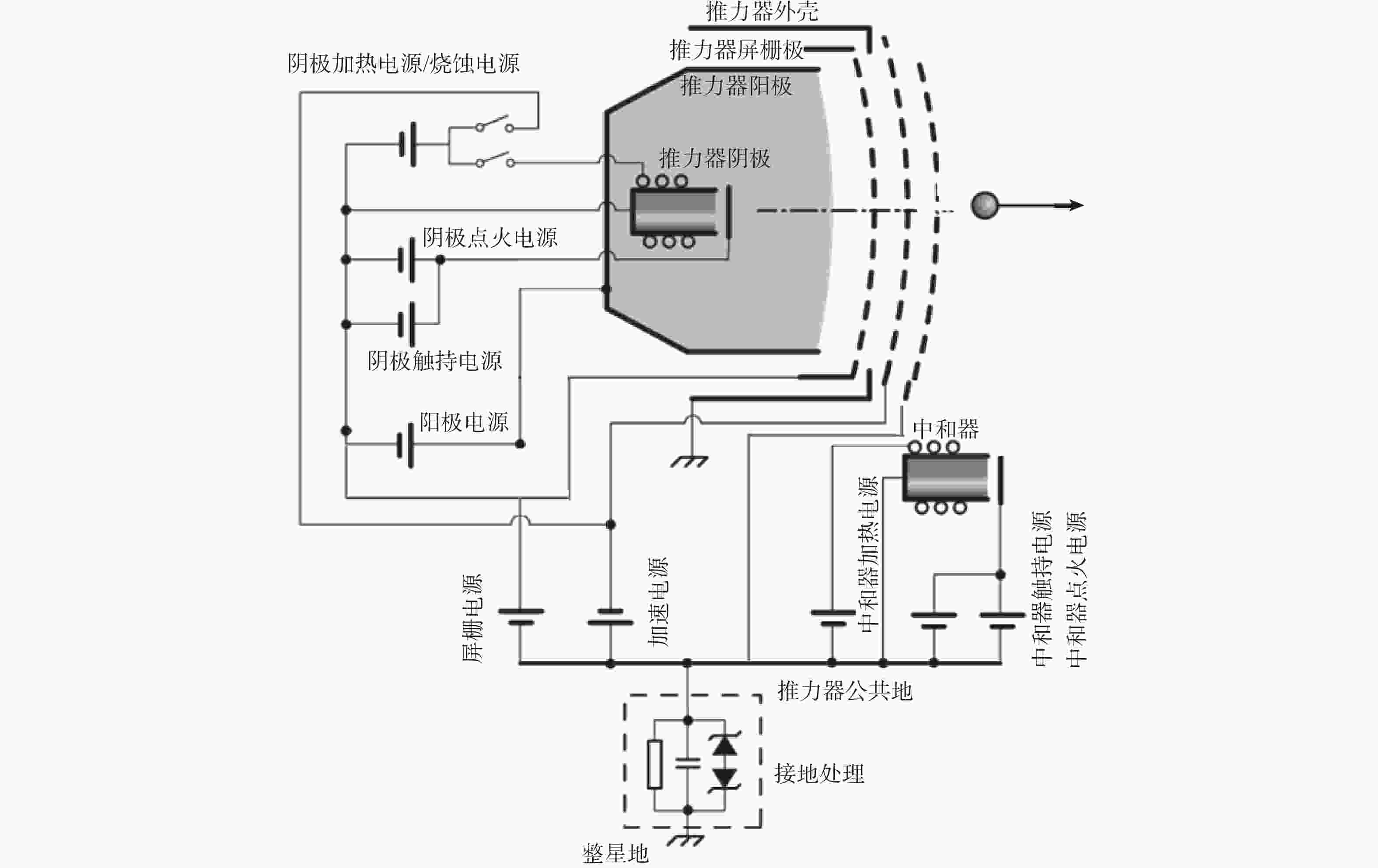

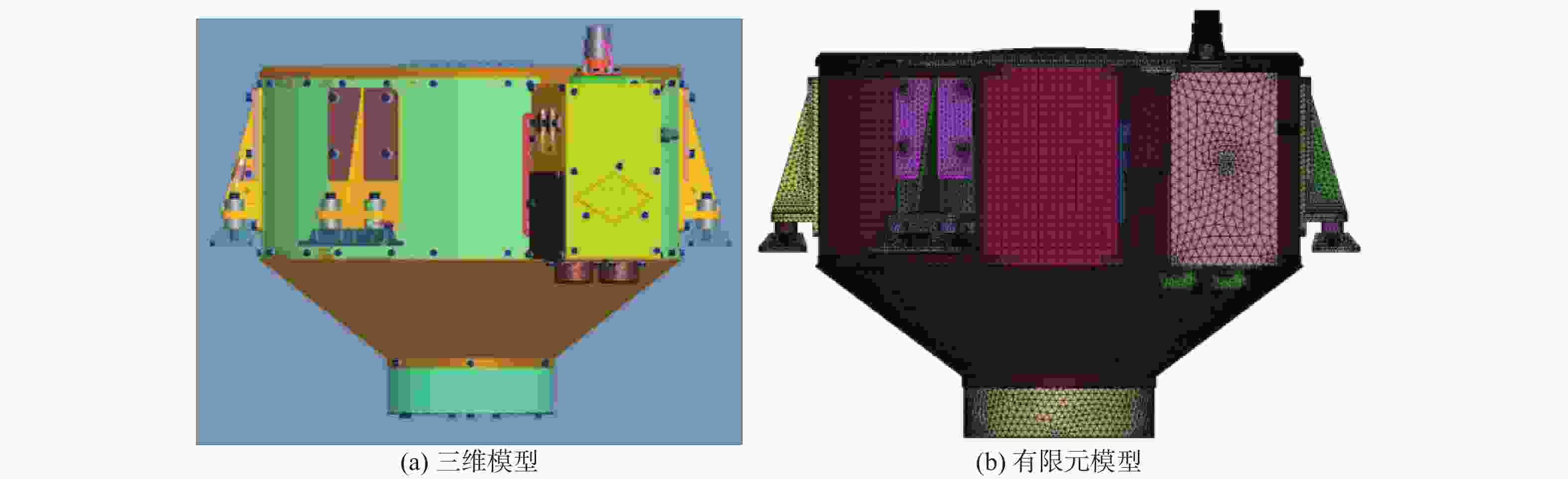

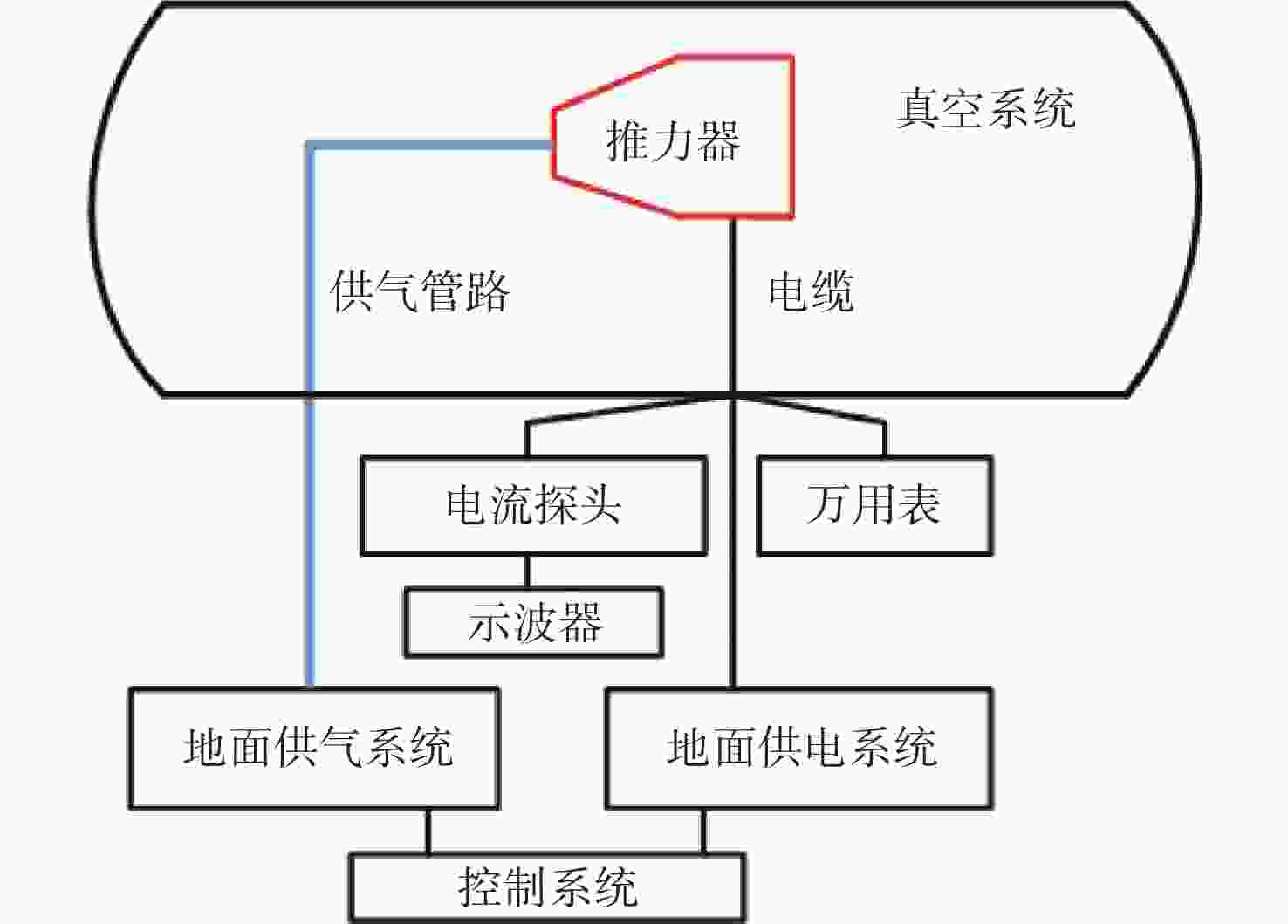

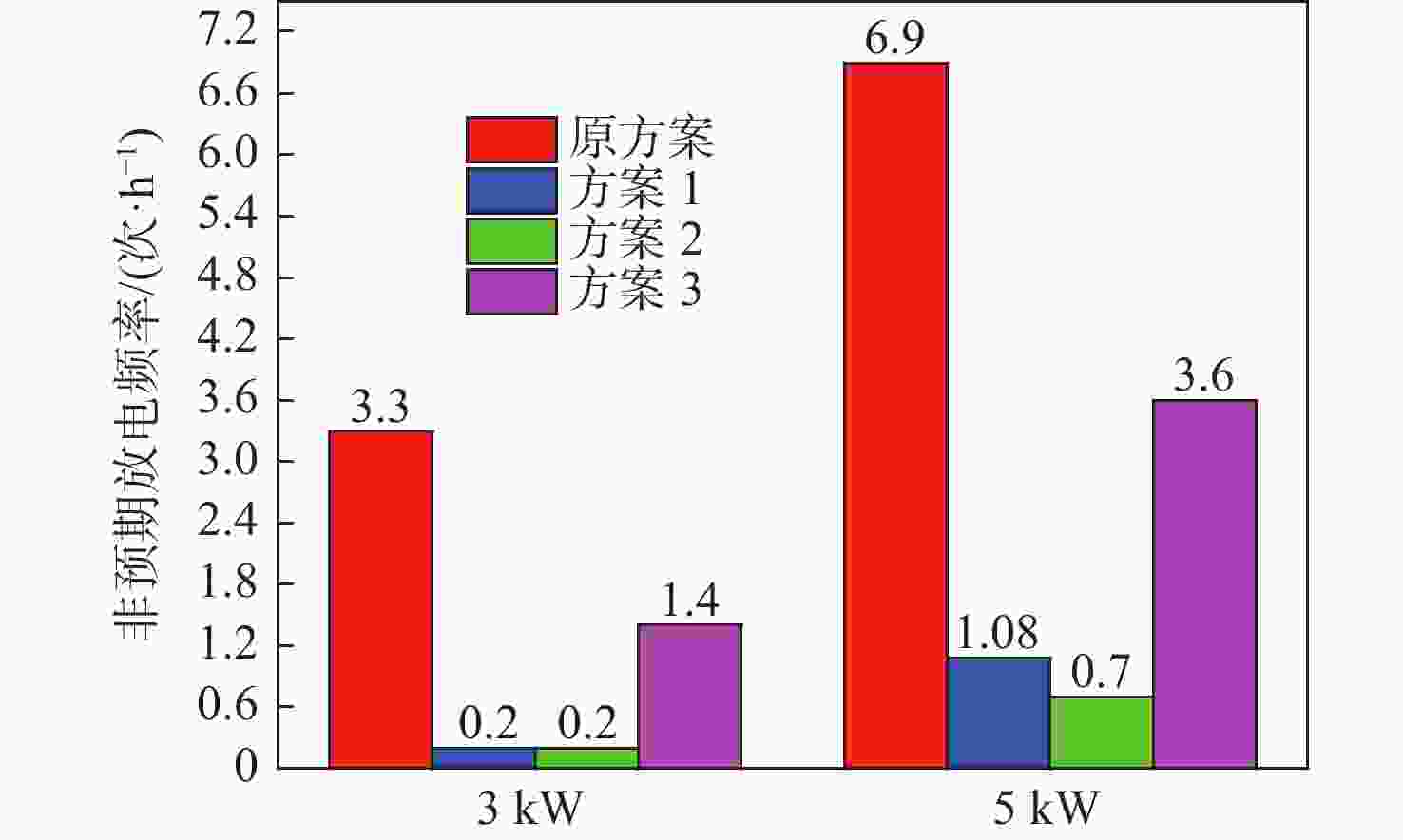

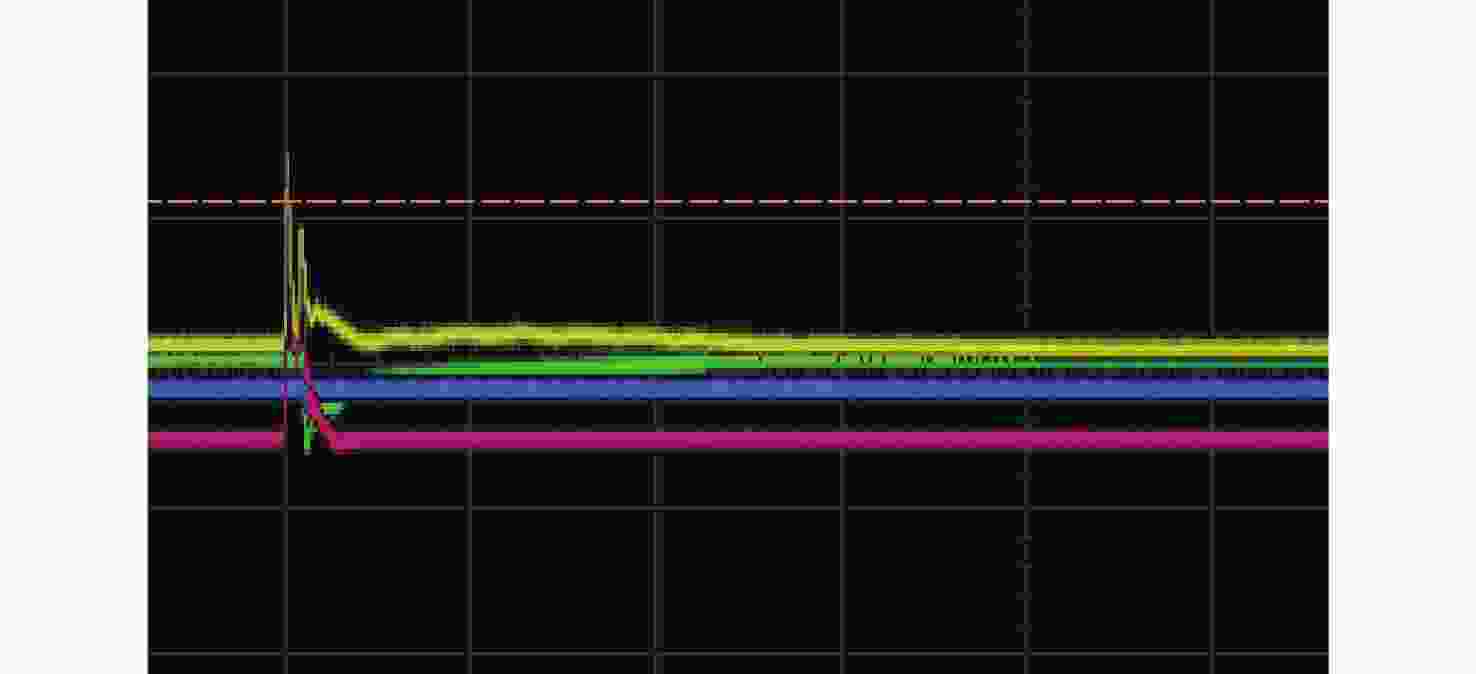

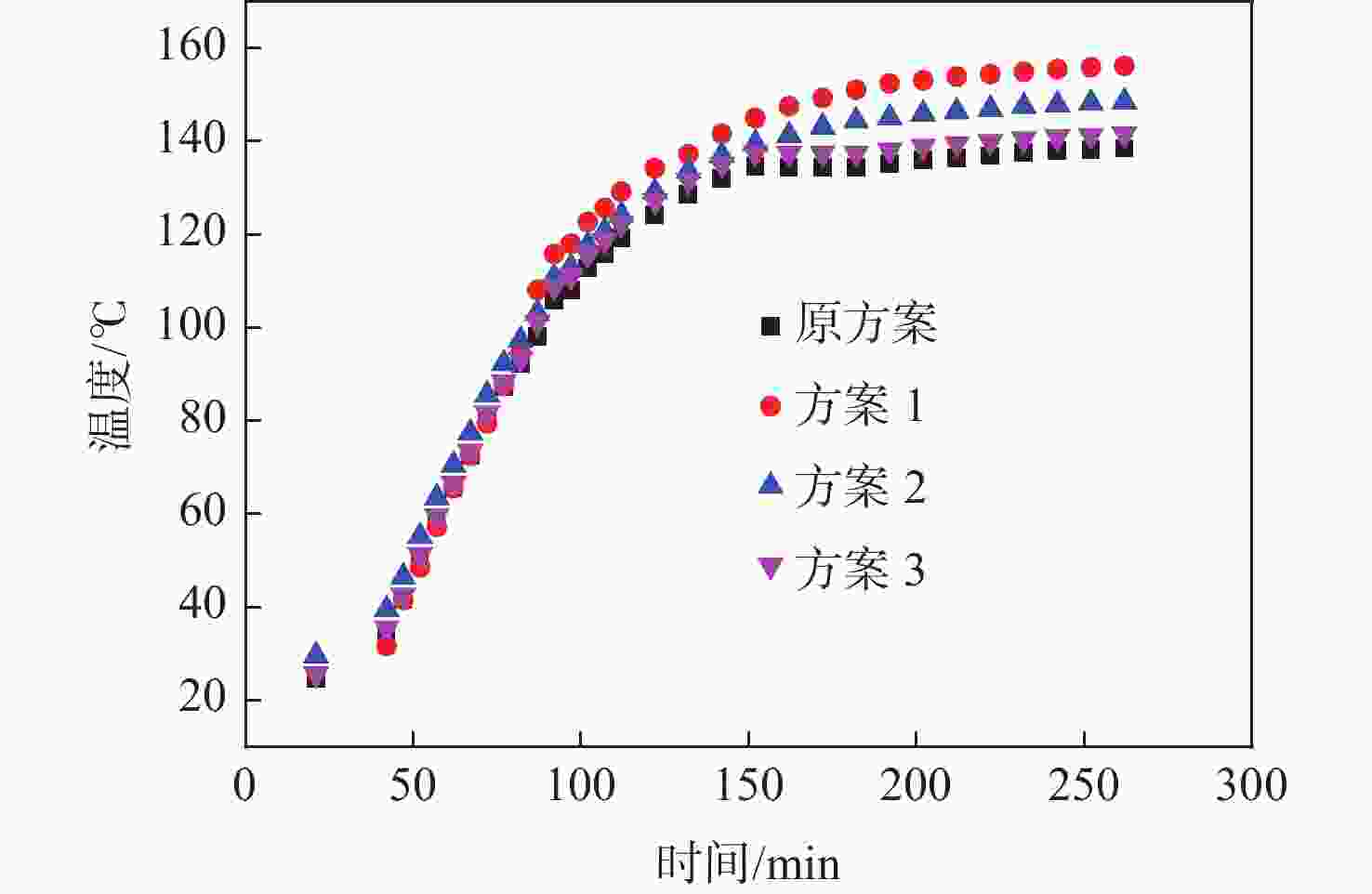

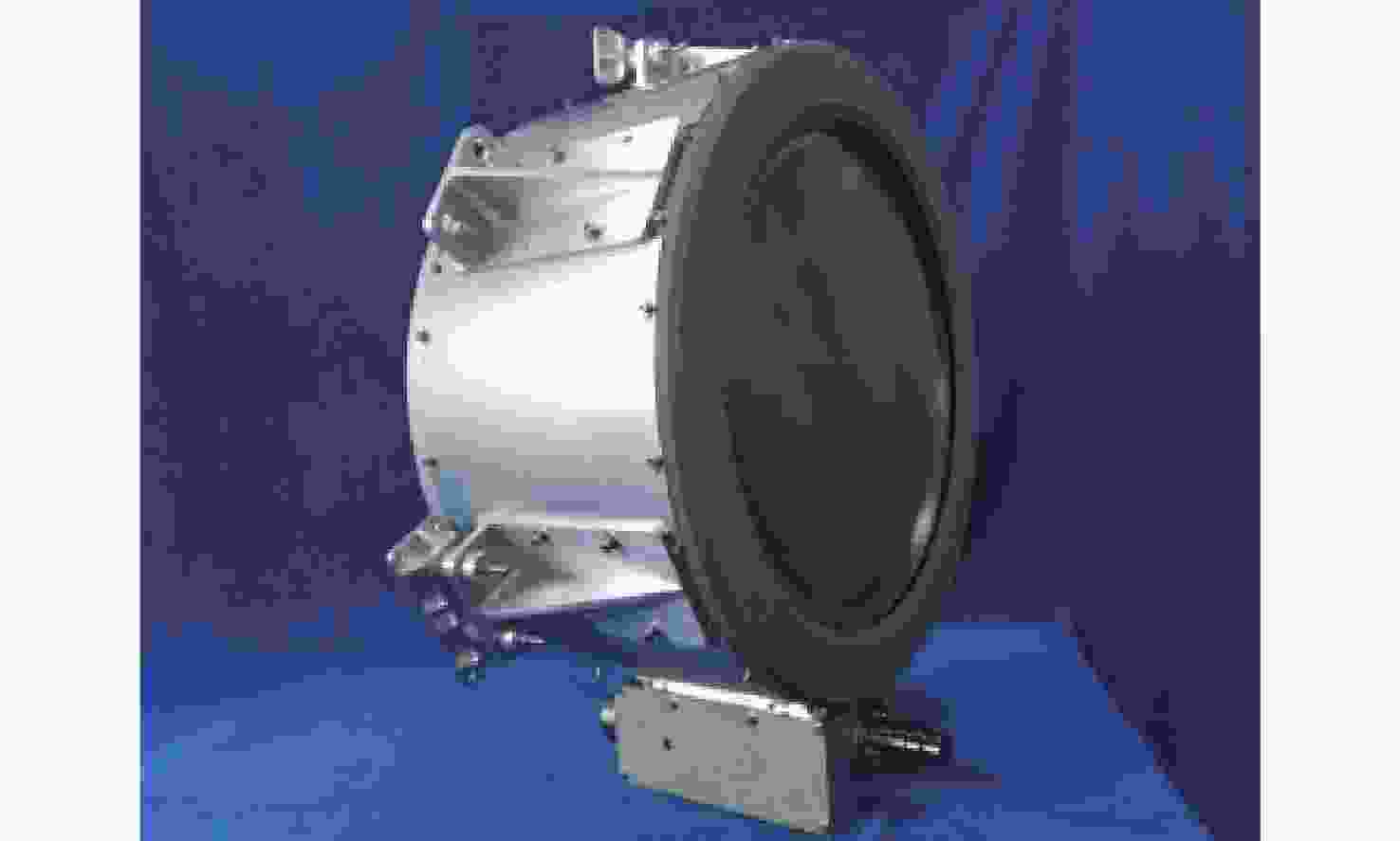

离子推力器非预期放电直接影响其工程应用可靠性,为降低推力器外壳与屏栅间的非预期放电频率,通过理论分析和试验的方法明确了非预期放电机制,综合考虑降低非预期放电频率和热设计开展了3种方案的外壳优化设计及热特性分析,搭建了外壳验证及热平衡试验系统。结果表明:高功率下非预期放电频率明显高于低功率,采用单面本色阳极化外壳方案后,5 kW工况下,推力器非预期放电频率从优化前6.90次/h降低到0.70次/h,3 kW工况下,从优化前的3.3次/h降低到0.20次/h,电连接器处测温最高温度为148.5 ℃,满足使用要求,不同外壳方案对热敏感性强的栅极组件温度影响较小,温差范围为5 ℃,推力器温度测试和热分析最大误差小于10 ℃。

Abstract:Unexpected breakdowns of ion thrusters affect their reliability in engineering applications. In order to reduce the frequency of unexpected electric breakdown between shell and screen grid of the thruster, the unexpected breakdown mechanism was clarified through theoretical analysis and experimental methods. By considering the thermal design and the elimination of unexpected electric breakdowns, the shell optimization design and thermal characteristic analysis of three schemes were carried out. A shell scheme verification and heat balance test system was built. The results show that the frequency of unexpected electric breakdowns is significantly higher at high power than at low power. After the single-sided anodized shell on the inner surface is adopted, the frequency of unexpected electric breakdowns of the thruster is reduced from 6.90 times/h before optimization to 0.70 times/h under 5 kW working condition and from 3.3 times/h before optimization to 0.20 times/h under 3 kW working condition. The maximum temperature measured at the electrical connector is 148.5 ℃, meeting the application requirements. The effect of different shell schemes on the temperature change of the thermally sensitive assembly is small, with a temperature difference within 5 ℃, and the maximum error of the thruster temperature test and thermal analysis is less than 10 ℃.

-

Key words:

- ion thruster /

- shell /

- unexpected electric breakdown /

- control /

- thermal design

-

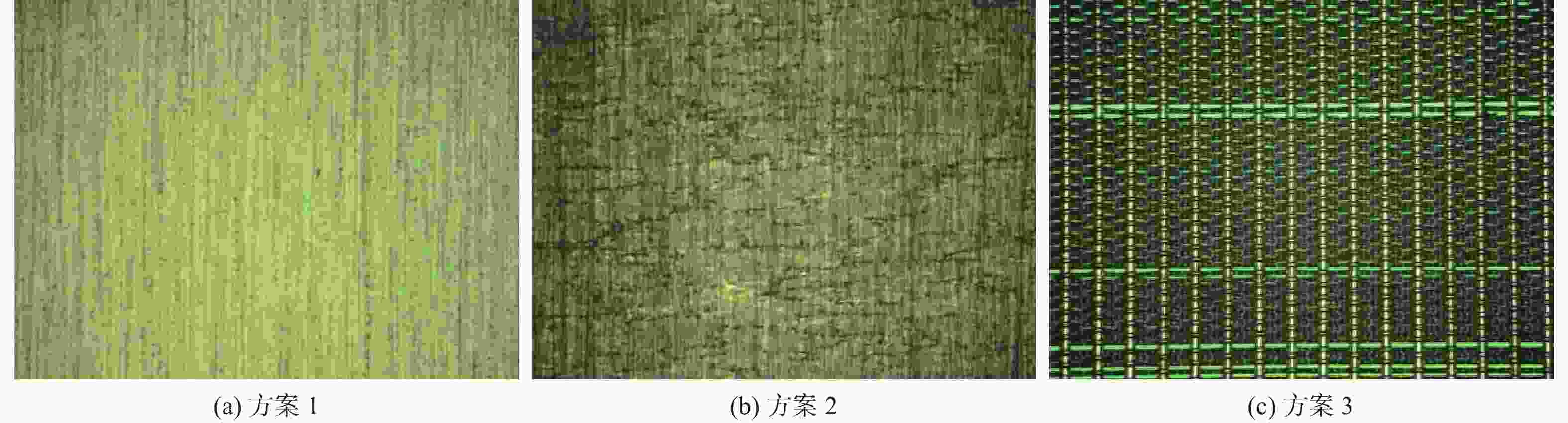

表 1 离子推力器不同外壳设计方案

Table 1. Different shell design schemes of ion thruster

方案 材料 表面处理 质量/kg 厚度/mm 原方案 2A12铝 双面本色阳极化 0.26 0.5 方案1 2A12铝 不处理 0.26 0.5 方案2 2A12铝 单面本色阳极化 0.26 0.5 方案3 不锈钢网 不处理 0.36 0.3 表 2 离子推力器主要性能参数

Table 2. Main performance parameters of ion thruster

推力/mN 比冲/s 流率/(mg·s−1) 束电压/V 束电流/A 放电电压/V 放电电流/A 功率/kW 200 3400 2.551 1450 3.68 29.0 24.4 5 表 3 离子推力器热分布

Table 3. Heat distribution of ion thruster

阳极

热耗/W主阴极

触持热耗/W屏栅

热耗/W加速栅

热耗/W主阴极

发射体温度/ ℃中和器

触持热耗/W中和器

发射体温度/ ℃494 29.8 133 29 1776 32 1400 表 4 离子推力器不同外壳方案发射率吸收率

Table 4. Emissivity and absorptivity for different shell schemes of ion thruster

方案 外表面发射率 内表面发射率 外表面吸收率 内表面吸收率 原方案 0.67 0.68 0.88 0.87 方案1 0.03 0.03 0.19 0.19 方案2 0.75 0.07 0.35 0.15 方案3 0.26 0.26 0.31 0.34 表 5 离子推力器在5 kW工况下热分析仿真结果

Table 5. Thermal analysis simulation results of ion thruster under 5 kW working condition

℃ 方案 屏栅温度 加速栅温度 减速栅温度 中和器盒温度 后外壳温度 柱段外壳温度 支撑环温度 阳极温度 原方案 447.1 355.8 246.8 131.4 163.8 155.6 100.8 325.4 方案1 448.2 362.5 263.5 169.5 210.5 196.6 145.5 352.4 方案2 449.8 359.1 252.1 153.18 197.8 176.9 129.5 354.7 方案3 448.1 355.9 249.1 147.2 193.6 176.2 128.8 346.5 表 6 离子推力器电连接器热平衡后最高温度

Table 6. Maximum temperature of electrical connector of ion thruster after heat balance

℃ 方案 实验温度 仿真温度 原方案 138.2 131.40 方案1 156.2 165.50 方案2 148.5 153.18 方案3 141.8 147.20 -

[1] 李建鹏, 张天平, 赵以德, 等. 阳极电流和屏栅电压对5kW离子推力器性能的影响[J]. 推进技术, 2021, 42(6): 1435-1440.LI J P, ZHANG T P, ZHAO Y D, et al. Effects of anode current and screen grid voltage on performance of 5kW ion thruster[J]. Journal of Propulsion Technology, 2021, 42(6): 1435-1440(in Chinese). [2] GOEBEL D M, KATZ I. Fundamentals of electric propulsion ion and Hall thrusters[M]. Hoboken: Wiley, 2008. [3] AHMED L N, CROFTON M W. Surface modification measurements in the T5 ion thruster plume[J]. Journal of Propulsion and Power, 1998, 14(3): 336-347. doi: 10.2514/2.5302 [4] RAWLIN V, SOVEY J, HAMLEY J, et al. An ion propulsion system for NASA’s deep space missions[C]// Space Technology Conference and Exposition. Reston: AIAA, 1999. [5] PATTERSON M J, VERHEY T R. A 5kW xenon ion thruster lifetest[C]//International Electric Propulsion Conference Florida. Reston: AIAA, 1990. [6] OHMICHI W, KUNINAKA H. Performance degradation of a spacecraft electron cyclotron resonance neutralizer and its mitigation[J]. Journal of Propulsion and Power, 2014, 30(5): 1368-1372. doi: 10.2514/1.B35062 [7] HERMAN D, SOULAS G, PATTERSON M. Performance evaluation of the prototype-model NEXT ion thruster[C]//Proceedings of the 43rd AIAA/ASME/SAE/ASEE Joint Propulsion Conference & Exhibit. Reston: AIAA, 2007. [8] MARTINEZ R A, WILLIAMS J D. Electric field breakdown characteristics of carbon-based ion optics[C]//Proceedings of the 29th International Electric Propulsion Conference. Reston: AIAA, 2005. [9] 李建鹏, 靳伍银, 赵以德, 等. 离子推力器外壳非预期放电抑制实验研究[J]. 推进技术, 2023, 44(4): 264-271.LI J P, JIN W Y, ZHAO Y D, et al. Experimental study of unexpected breakdown reduction of ion thruster housings[J]. Journal of Propulsion Technology, 2023, 44(4): 264-271(in Chinese). [10] SHASTRY R,HERMAN D A, SOULAS G C, et al. Status of NASA’s Evolutionary Xenon Thruster(NEXT) long duration test as of 50000 h and 900 kg throughput: IEPC 2013-121[R]. Washington, D.C.: NASA, 2013-10-06.[11] VAN NOORD J L. Lifetime assessment of the next ion thruster[C]//Proceedings of the 43rd AIAA/ASME/SAE/ASEE Joint Propulsion Conference & Exhibit. Reston: AIAA, 2007. [12] WALLACE N, MUNDY D, FEARN D, et al. Evaluation of the performance of the T6 ion thruster[C]//Proceedings of the 35th Joint Propulsion Conference and Exhibit. Reston: AIAA, 1999. [13] CLARK S, RANDALL P, LEWIS R, et al. Bepicolombo-solar electric propulsion system test and qualification approach[C]//Proceedings of the 36th International Electric Propulsion Conference. Reston: AIAA, 2019. [14] KUNINAKA H, SHIMIZU Y, YAMADA T, et al. Flight report during two years on HAYABUSA explorer propelled by microwave discharge ion engines[C]//Proceedings of the 41st AIAA/ASME/SAE/ASEE Joint Propulsion Conference & Exhibit. Reston: AIAA, 2005. [15] KUNINAKA H, NISHIYAMA K, FUNAKI I, et al. Powered flight of HAYABUSA in deep space[C]//Proceedings of the 42nd AIAA/ASME/SAE/ASEE Joint Propulsion Conference & Exhibit. Reston: AIAA, 2006. [16] MARTINEZ R, WILLIAMS J, GOEBEL D. Electric field breakdown properties of materials used in ion optics systems[C]//Proceedings of the 42nd AIAA/ASME/SAE/ASEE Joint Propulsion Conference & Exhibit. Reston: AIAA, 2006. [17] SCHWIRZKE F R. Vacuum breakdown on metal surfaces[J]. IEEE Transactions on Plasma Science, 2002, 19(5): 690-696. [18] SILI E, CAMBRONNE J P, KOLIATENE F. Temperature dependence of electrical breakdown mechanism on the left of the paschen minimum[J]. IEEE Transactions on Plasma Science, 2011, 39(11): 3173-3179. doi: 10.1109/TPS.2011.2165969 [19] PEJOVIC M M, RISTIC G S, KARAMARKOVIC J P. Electrical breakdown in low pressure gases[J]. Journal of Physics D: Applied Physics, 2002, 35(10): R91-R103. doi: 10.1088/0022-3727/35/10/201 [20] ANDERS A. Breakdown of the high-voltage sheath in metal plasma immersion ion implantation[J]. Applied Physics Letters, 2000, 76(1): 28-30. doi: 10.1063/1.125645 [21] 李宗良, 高俊, 刘国西, 等. 小行星探测电推进系统方案研究[J]. 深空探测学报, 2018, 5(4): 347-353.LI Z L, GAO J, LIU G X, et al. Study on the electric propulsion system for asteroid detection[J]. Journal of Deep Space Exploration, 2018, 5(4): 347-353(in Chinese). [22] 李建鹏, 靳伍银, 赵以德. 加速电压和阳极流率对离子推力器性能的影响[J]. 物理学报, 2022, 71(1): 172-179.LI J P, JIN W Y, ZHAO Y D. Influence of acceleration grid voltage and anode flow rate on performance of ion thruster[J]. Acta Physica Sinica, 2022, 71(1): 172-179(in Chinese). [23] 孙明明, 张天平, 陈娟娟, 等. LIPS-200离子推力器热特性模拟分析研究[J]. 强激光与粒子束, 2014, 26(8): 252-257.SUN M M, ZHANG T P, CHEN J J, et al. Thermal analysis of LIPS-200 ion thruster[J]. High Power Laser and Particle Beams, 2014, 26(8): 252-257(in Chinese). -

下载:

下载: