Flexible crystalline silicon heterojunction solar cells for near-space applications

-

摘要:

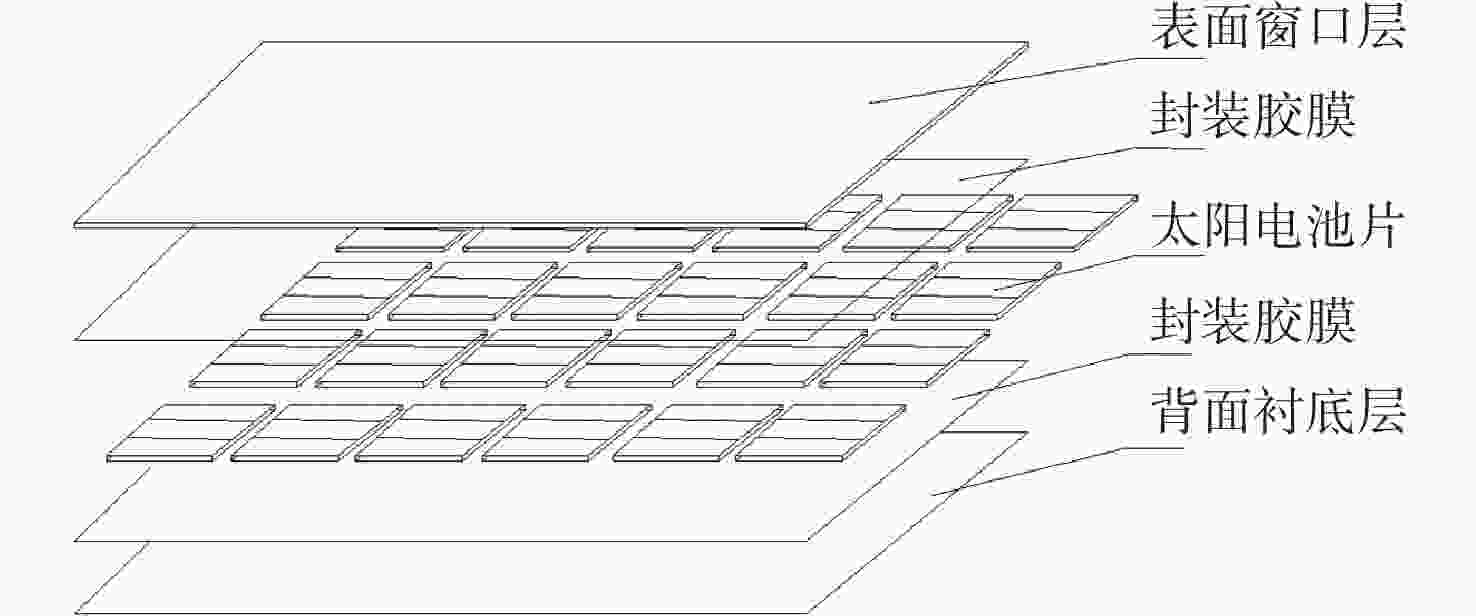

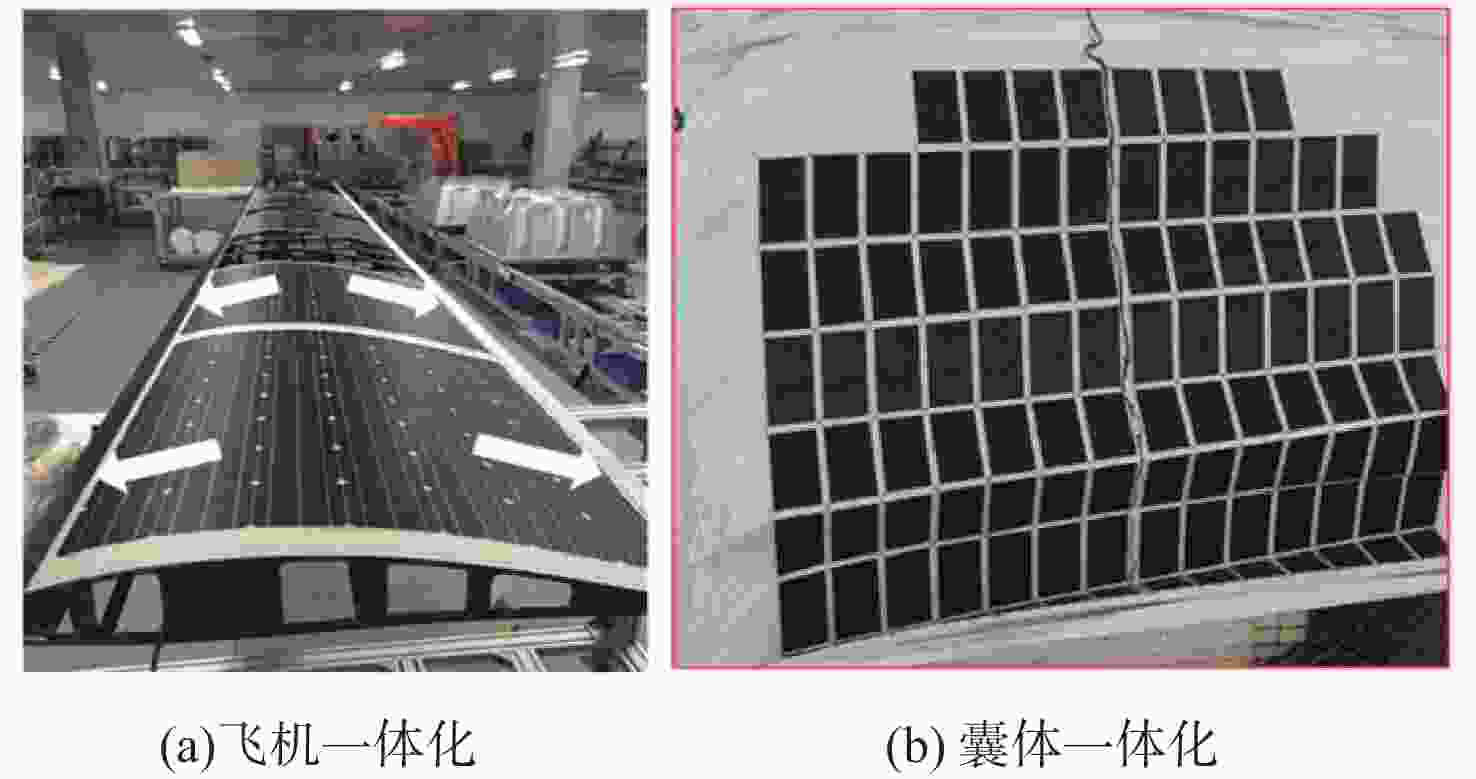

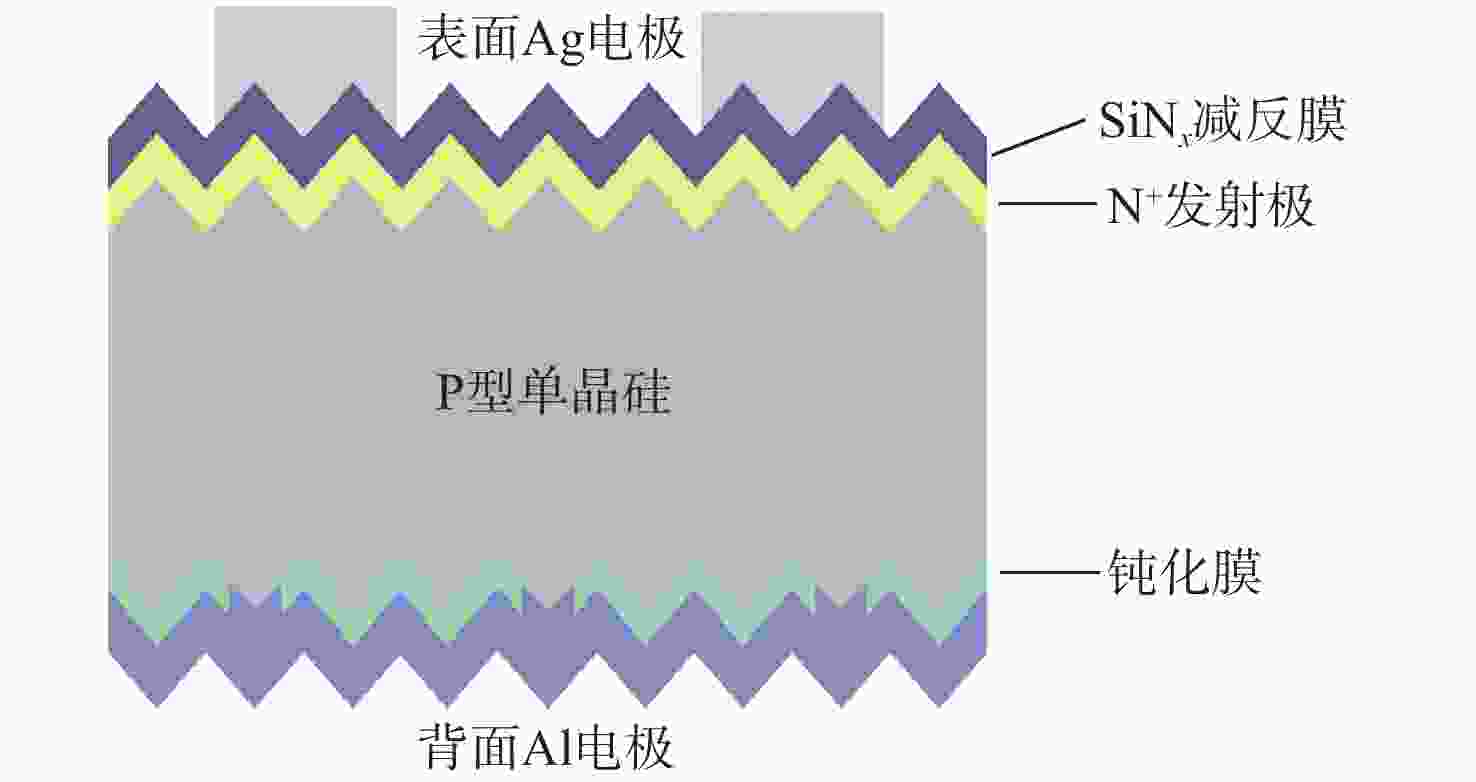

针对临近空间飞行器能源系统对太阳电池性能的需求,利用硅异质结(SHJ)太阳电池的双面对称结构和低温工艺特点,开发厚度小于100 µm的超薄柔性SHJ太阳电池。针对飞行器对太阳电池组件在力学、热学、电学的要求,开展柔性SHJ太阳电池组件封装材料的研究和优化,确定组件的封装结构和工艺,开发适用于临近空间飞行器的柔性高效率SHJ太阳电池组件。针对临近空间环境适应性要求对其可靠性进行研究,确立高耐候性、高稳定性柔性SHJ组件,大批量应用于高空无人机和平流层飞艇。同时,针对不同的应用环境,设计开发新一代高效率柔性组件,并对组件性能进行对比研究。结果表明:获得转换效率达到20.75%的太阳电池组件,经环境可靠性测试后几乎没有衰减,完全适用复杂多变的临近空间环境。

Abstract:Aiming at the urgent demand for energy-system for high-altitude spacecraft in near-space, an ultra-thin flexible silicon heterojunction (SHJ) solar cell with a thickness of less than 100 μm was developed based on the double-sided symmetrical structure and the characteristics of the low-temperature process. By examining, evaluating, and contrasting the mechanical, thermal, and electrical characteristics of the flexible modules' packaging materials, the encapsulation structure and technology of the modules were established, and silicon heterojunction photovoltaic modules that are both flexible and efficient and appropriate for high-altitude aircraft in near space were created. The dependability of SHJ high weather resistance and high stability flexible modules, which were extensively used in high-altitude UAVs and stratospheric airships, was investigated in accordance with the needs of environmental adaptation in near space. At the same time, according to different application environments, new components are designed and their performance is compared. The solar cell modules with a conversion efficiency of 20.75% show almost no degradation after environmental reliability testing, making them completely suitable for the complex and variable near-space environment.

-

表 1 3种空间常用太阳电池的综合对比

Table 1. Comprehensive performance comparison of three types of solar cells used in space

表 2 窗口层综合性能对比

Table 2. Comprehensive performance comparison of window layer

层 透光率(50 μm)/% 熔化温度/℃ 连续工作

温度/℃线性热膨胀

系数/C−1收缩率

(150 ℃×30 min)/%撕裂强度/

(g·25 μm−1)抗拉强度/

MPa水汽吸收率/% 湿气渗透(25 μm)/

(g·(m2·24 h)−1)ETFE 93 260 −100~150 5.9×10−4 −2~1 1400 ~2400 69 0.03 6 PVF 89.2 203 −70~100 9×10−4 −5~8 15~60 44 ≤0.5 30 表 3 封装胶膜综合性能对比

Table 3. Comprehensive performance comparison of foamed materials

胶膜 透光率/% 拉伸强度/MPa 黏结强度/(N·cm−1) 交联度/% 收缩率/% 水汽透过率/

(g·(m2·24 h)−1)紫外截止波长/nm 1 000 h紫外照射后黏结

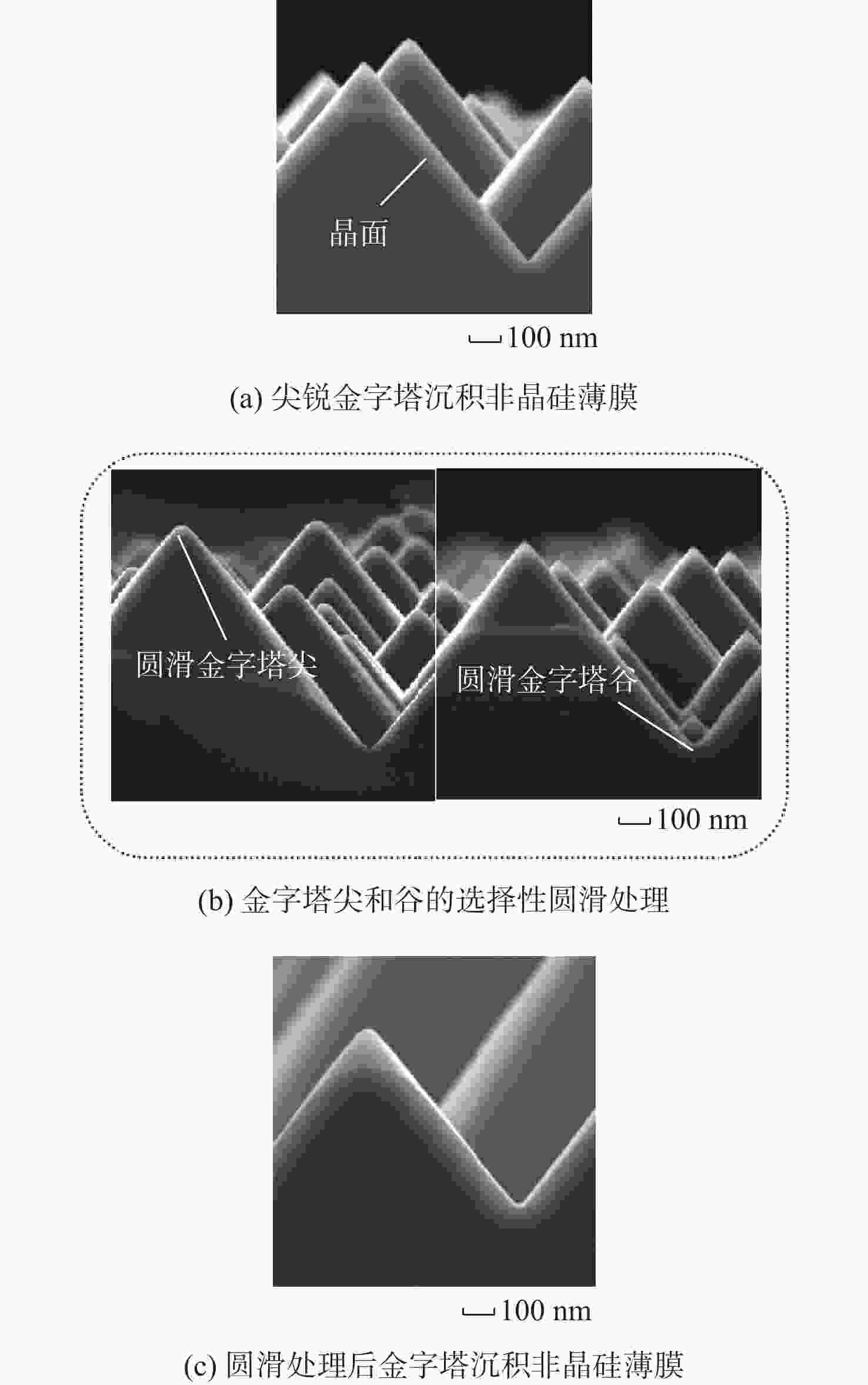

强度保持率/%POE 91.3 >15 >60 70.6 1 ≤2 300/360 40 EVA 91.5 >15 >100 85 2 20~30 360 25 表 4 柔性太阳电池组件在地面AM1.5标准测试条件下的电性能

Table 4. Electrical properties of flexible photovoltaic module under 1 sun AM1.5 illumination

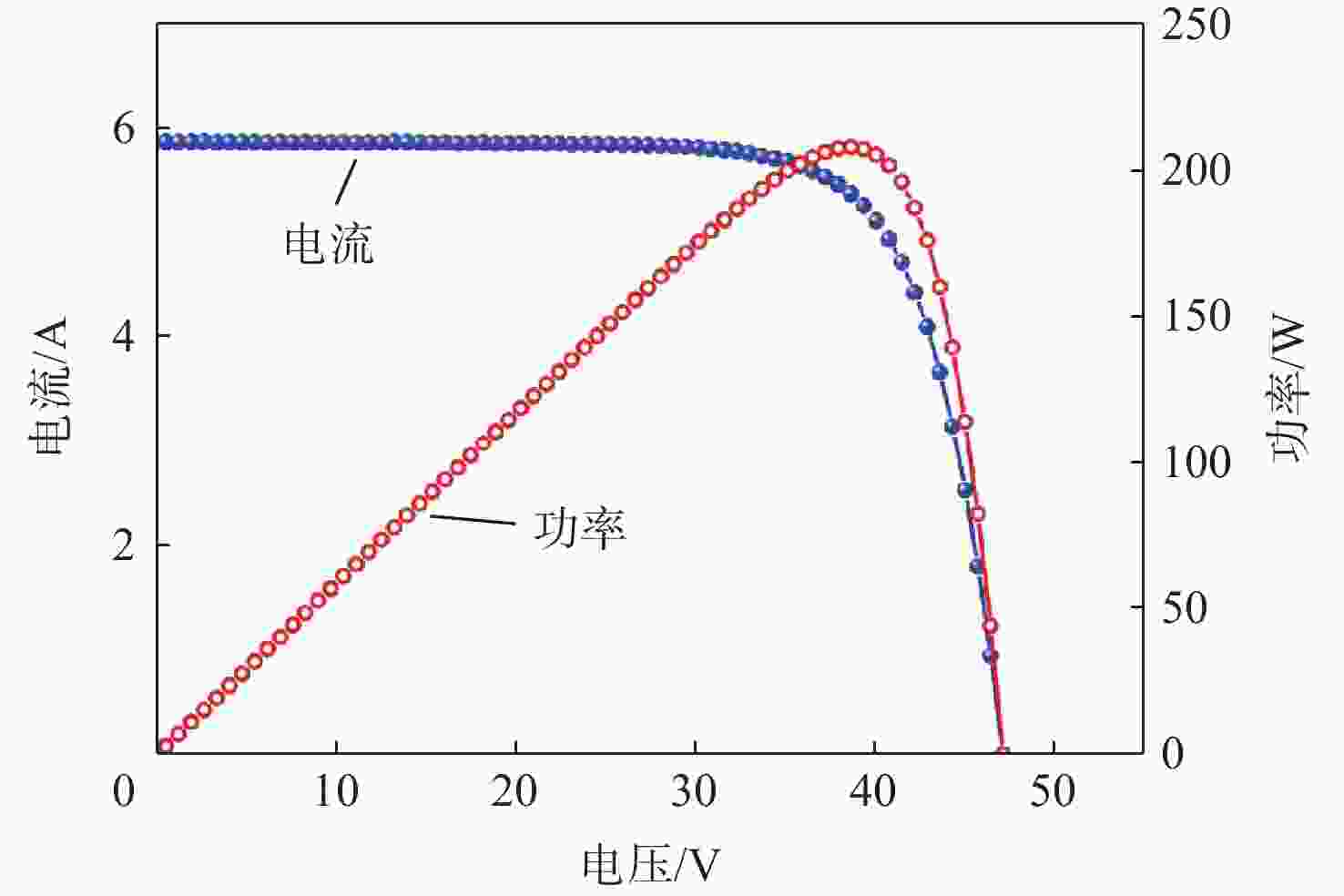

开路电压/V 短路电流/A 填充因子/% 功率/W 转换效率/% 47.19 5.86 75.10 207.71 20.75 表 5 柔性太阳电池组件在地面AM1.5和临近空间实际应用条件下的电性能

Table 5. Electrical properties of flexible photovoltaic module under ground AM1.5 illumination and near-space application conditions

组号 测试方式 最大功率点

输出电流 /A最大功率点

输出电压/V最大功率点

输出功率 /W1 地面AM1.5标准 5.21 39.70 207.02 临近空间实测 5.06 37.42 189.35 2 地面AM1.5标准 5.43 38.32 208.15 临近空间实测 7.65 33.95 259.72 表 6 临近空间用柔性太阳电池组件湿热测试

Table 6. Damp heat test of photovoltaic module for near space

序号 Pmax/W η/% η变化率 /% 湿热试验前 湿热试验后 湿热试验前 湿热试验后 1 53.205 52.804 20.82 20.66 0.77 2 53.205 52.964 20.86 20.77 0.43 表 7 临近空间用柔性太阳电池组件高低温循环测试

Table 7. Temperature cycle test of photovoltaic module for near-space

序号 Pmax/W η/% η变化率 /% 高低温循

环试验前高低温循

环试验后高低温循

环试验前高低温循

环试验后1 53.107 53.207 20.78 20.82 −0.19 2 53.029 53.222 20.75 20.83 −0.38 表 8 临近空间用柔性太阳电池组件低气压测试

Table 8. Low air pressure test of photovoltaic module for near space

序号 Pmax/W η/% η变化率 /% 低气压

试验前低气压

试验后低气压

试验前低气压

试验后1 50.855 50.717 20.50 20.45 0.24 2 50.719 50.412 20.45 20.32 0.64 表 9 临近空间用柔性太阳电池组件紫外测试

Table 9. Ultraviolet test of photovoltaic module for near space

序号 Pmax/W η/% η变化率/% 紫外试验前 紫外试验后 紫外试验前 紫外试验后 1 51.47 51.35 20.30 20.26 0.20 2 51.78 51.76 20.47 20.46 0.05 表 10 临近空间用柔性太阳电池组件弯曲测试

Table 10. Bending test of photovoltaic module for near space

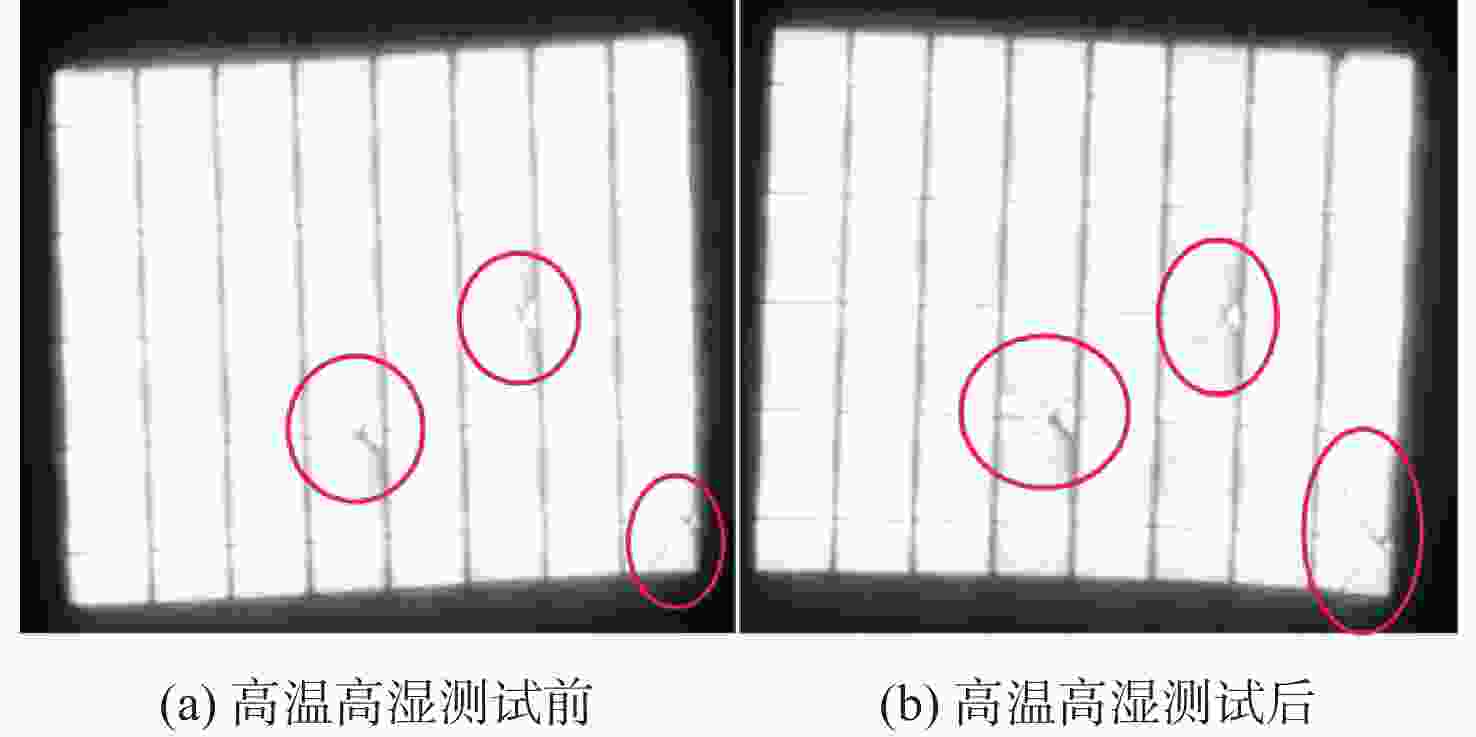

序号 Pmax/W η/% η变化率/% 弯曲试验前 弯曲试验后 弯曲试验前 弯曲试验后 1 51.40 51.34 20.36 20.33 0.15 2 51.67 51.38 20.46 20.35 0.54 表 11 含有裂纹的临近空间用柔性太阳电池组件高温高湿试验

Table 11. Damp heat test of flexible photovoltaic module for near-space containing cracks

序号 Pmax/W η/% η变化率/% 高温高湿

试验前高温高湿

试验后高温高湿

试验前高温高湿

试验后1 7.04 7.00 20.33 20.21 0.53 2 12.89 12.81 20.42 20.29 0.67 表 12 4种太阳电池组件在电性能及高低温循环、弯曲度可靠性上的对比

Table 12. Comparison of electrical performance, temperature cycling and bending reliability of four photovoltaic modules

组件类型 组件规格/m3 组件质量/g 组件面积/m2 有效面积/m2 面密度/(g·m−2) 功率/W 质量比功率/(W·kg−1) 高低温循环

衰减百分比/%弯曲适应性

衰减百分比/%常规串焊 555×558×2 175.2 0.3097 0.2556 565.71 48.09 274.48 −0.19 0.15 导电胶 690×570×2 230.6 0.3933 0.3194 586.32 62.60 271.46 0.02 0.12 叠瓦 690×540×1 228.6 0.3726 0.3024 613.52 63.02 273.55 −0.64 0.22 SWCT 600×585×1 236.9 0.351 0.2556 674.92 51.33 216.67 0.18 −0.42 -

[1] WANG W Q, CAI J Y, PENG Q C. Near-space microwave radar remote sensing: potentials and challenge analysis[J]. Remote Sensing, 2010, 2(3): 717-739. doi: 10.3390/rs2030717 [2] WANG W Q. Near-space vehicles: supply a gap between satellites and airplanes for remote sensing[J]. IEEE Aerospace and Electronic Systems Magazine, 2011, 26(4): 4-9. doi: 10.1109/MAES.2011.5763337 [3] XU Y M, ZHU W Y, LI J, et al. Improvement of endurance performance for high-altitude solar-powered airships: a review[J]. Acta Astronautica, 2020, 167: 245-259. doi: 10.1016/j.actaastro.2019.11.021 [4] YIN S, ZHU M, LIANG H Q. Multi-disciplinary design optimization with variable complexity modeling for a stratosphere airship[J]. Chinese Journal of Aeronautics, 2019, 32(5): 1244-1255. doi: 10.1016/j.cja.2019.03.003 [5] 曲鹏, 王寅. 太阳能无人机电源系统的发展现状与展望[J]. 电源技术, 2015, 39(4): 864-866. doi: 10.3969/j.issn.1002-087X.2015.04.083QU P, WANG Y. Development status and prospect of solar power systems for UAVs[J]. Chinese Journal of Power Sources, 2015, 39(4): 864-866(in Chinese). doi: 10.3969/j.issn.1002-087X.2015.04.083 [6] 潘振, 呼文韬, 王寅, 等. 适用于太阳能飞行器的单晶硅太阳电池[J]. 电源技术, 2016, 40(8): 1722-1725. doi: 10.3969/j.issn.1002-087X.2016.08.059PAN Z, HU W T, WANG Y, et al. Monocrystalline Si solar cells suitable for solar aerial vehicle[J]. Chinese Journal of Power Sources, 2016, 40(8): 1722-1725(in Chinese). doi: 10.3969/j.issn.1002-087X.2016.08.059 [7] STROBL G F X, EBEL L, FUHRMANN D, et al. Development of lightweight space solar cells with 30% efficiency at end-of-life[C]//Proceedings of the IEEE 40th Photovoltaic Specialist Conference. Piscataway: IEEE Press, 2014: 3595-3600. [8] 邹帅, 吴成坤, 徐磊, 等. 全角度陷光的微-纳复合绒面单晶PERC太阳电池[J]. 太阳能学报, 2022, 43(7): 134-139.ZOU S, WU C K, XU L, et al. All-angled light-trapped micro-nano hybrid textured mono-Si perc solar cells[J]. Acta Energiae Solaris Sinica, 2022, 43(7): 134-139(in Chinese). [9] RAZZAQ A, ALLEN T G, LIU W Z, et al. Silicon heterojunction solar cells: techno-economic assessment and opportunities[J]. Joule, 2022, 6(3): 514-542. doi: 10.1016/j.joule.2022.02.009 [10] 仇恒抗, 姜德鹏, 杨琴, 等. 32%效率三结砷化镓太阳电池设计与在轨应用[J]. 电源技术, 2022, 46(5): 545-548. doi: 10.3969/j.issn.1002-087X.2022.05.019QIU H K, JIANG D P, YANG Q, et al. Design and application in orbit 32% efficiency triple junction GaAs solar cell[J]. Chinese Journal of Power Sources, 2022, 46(5): 545-548(in Chinese). doi: 10.3969/j.issn.1002-087X.2022.05.019 [11] GEISZ J F, FRIEDMAN D J, WARD J S, et al. 40.8% efficient inverted triple-junction solar cell with two independently metamorphic junctions[J]. Applied Physics Letters, 2008, 93(12): 123505. doi: 10.1063/1.2988497 [12] 铁剑锐, 李晓东, 孙希鹏. 高效超薄空间用三结砷化镓太阳电池研制[J]. 电源技术, 2018, 42(8): 1174-1176. doi: 10.3969/j.issn.1002-087X.2018.08.025TIE J R, LI X D, SUN X P. High-efficiency and ultra-thin triple-junction space solar cell[J]. Chinese Journal of Power Sources, 2018, 42(8): 1174-1176(in Chinese). doi: 10.3969/j.issn.1002-087X.2018.08.025 [13] YAMAGUCHI M, DIMROTH F, EKINS-DAUKES N J, et al. Overview and loss analysis of III–V single-junction and multi-junction solar cells[J]. EPJ Photovoltaics, 2022, 13: 22. doi: 10.1051/epjpv/2022020 [14] DENG W W, CHEN D M, XIONG Z, et al. 20.8% PERC solar cell on 156 mm × 156 mm P-type multicrystalline silicon substrate[J]. IEEE Journal of Photovoltaics, 2016, 6(1): 3-9. doi: 10.1109/JPHOTOV.2015.2489881 [15] SONG L H, HU Z C, LIN D H, et al. Progress of hydrogenation engineering in crystalline silicon solar cells: a review[J]. Journal of Physics D Applied Physics, 2022, 55(45): 453002. doi: 10.1088/1361-6463/ac9066 [16] WANG P, LI G F, WANG M, et al. Numerical study of mono-crystalline silicon solar cells with passivated emitter and rear contact configuration for the efficiency beyond 24% based on mass production technology[J]. Journal of Semiconductors, 2020, 41(6): 062701. doi: 10.1088/1674-4926/41/6/062701 [17] TAGUCHI M, KAWAMOTO K, TSUGE S, et al. HITTM cells: high-efficiency crystalline Si cells with novel structure[J]. Progress in Photovoltaics: Research and Applications, 2000, 8(5): 503-513. doi: 10.1002/1099-159X(200009/10)8:5<503::AID-PIP347>3.0.CO;2-G [18] MASUKO K, SHIGEMATSU M, HASHIGUCHI T, et al. Achievement of more than 25% conversion efficiency with crystalline silicon heterojunction solar cell[J]. IEEE Journal of Photovoltaics, 2014, 4(6): 1433-1435. doi: 10.1109/JPHOTOV.2014.2352151 [19] PARK H, LEE Y J, PARK J, et al. Front and back TCO research review of a-Si/c-Si heterojunction with intrinsic thin layer (HIT) solar cell[J]. Transactions on Electrical and Electronic Materials, 2018, 19(3): 165-172. doi: 10.1007/s42341-018-0026-8 [20] DU J L, MENG F Y, FU H X, et al. Selective rounding for pyramid peaks and valleys improves the performance of SHJ solar cells[J]. Energy Science & Engineering, 2021, 9(9): 1306-1312. [21] HUANG W, SHI J H, LIU Y Y, et al. High-performance Ti and W Co-doped indium oxide films for silicon heterojunction solar cells prepared by reactive plasma deposition[J]. Journal of Power Sources, 2021, 506: 230101. [22] MENG F Y, SHI J H, LIU Z X, et al. High mobility transparent conductive W-doped In2O3 thin films prepared at low substrate temperature and its application to solar cells[J]. Solar Energy Materials and Solar Cells, 2014, 122: 70-74. doi: 10.1016/j.solmat.2013.11.030 [23] VYGRANENKO Y, KHOSROPOUR A, YANG R, et al. Lightweight amorphous silicon photovoltaic modules on flexible plastic substrate[J]. Canadian Journal of Physics, 2014, 92(7/8): 871-874. doi: 10.1139/cjp-2013-0566 [24] MAYVILLE P, PATIL N V, PEARCE J M. Distributed manufacturing of after market flexible floating photovoltaic modules[J]. Sustainable Energy Technologies and Assessments, 2020, 42: 100830. doi: 10.1016/j.seta.2020.100830 [25] KEMPE M. Overview of scientific issues involved in selection of polymers for PV applications[C]//Proceedings of the 37th IEEE Photovoltaic Specialists Conference. Piscataway: IEEE Press, 2011: 85-90. [26] JORGENSEN G J, MCMAHON T J. Accelerated and outdoor aging effects on photovoltaic module interfacial adhesion properties[J]. Progress in Photovoltaics: Research and Applications, 2008, 16(6): 519-527. doi: 10.1002/pip.826 [27] POLVERINI D, FIELD M, DUNLOP E, et al. Polycrystalline silicon PV modules performance and degradation over 20 years[J]. Progress in Photovoltaics: Research and Applications, 2013, 21(5): 1004-1015. doi: 10.1002/pip.2197 [28] SÁNCHEZ-FRIERA P, PILIOUGINE M, PELÁEZ J, et al. Analysis of degradation mechanisms of crystalline silicon PV modules after 12 years of operation in Southern Europe[J]. Progress in Photovoltaics: Research and Applications, 2011, 19(6): 658-666. doi: 10.1002/pip.1083 [29] KOEHL M, HECK M, WIESMEIER S. Modelling of conditions for accelerated lifetime testing of Humidity impact on PV-modules based on monitoring of climatic data[J]. Solar Energy Materials and Solar Cells, 2012, 99: 282-291. doi: 10.1016/j.solmat.2011.12.011 [30] KAWAI S, TANAHASHI T, FUKUMOTO Y, et al. Causes of degradation identified by the extended thermal cycling test on commercially available crystalline silicon photovoltaic modules[J]. IEEE Journal of Photovoltaics, 2017, 7(6): 1511-1518. doi: 10.1109/JPHOTOV.2017.2741102 [31] REPINS I L, KERSTEN F, HALLAM B, et al. Stabilization of light-induced effects in Si modules for IEC 61215 design qualification[J]. Solar Energy, 2020, 208: 894-904. doi: 10.1016/j.solener.2020.08.025 [32] KEMPE M D. Ultraviolet light test and evaluation methods for encapsulants of photovoltaic modules[J]. Solar Energy Materials and Solar Cells, 2010, 94(2): 246-253. doi: 10.1016/j.solmat.2009.09.009 [33] KÖNTGES M, KUNZE I, KAJARI-SCHRÖDER S, et al. The risk of power loss in crystalline silicon based photovoltaic modules due to micro-cracks[J]. Solar Energy Materials and Solar Cells, 2011, 95(4): 1131-1137. doi: 10.1016/j.solmat.2010.10.034 -

下载:

下载: