-

摘要:

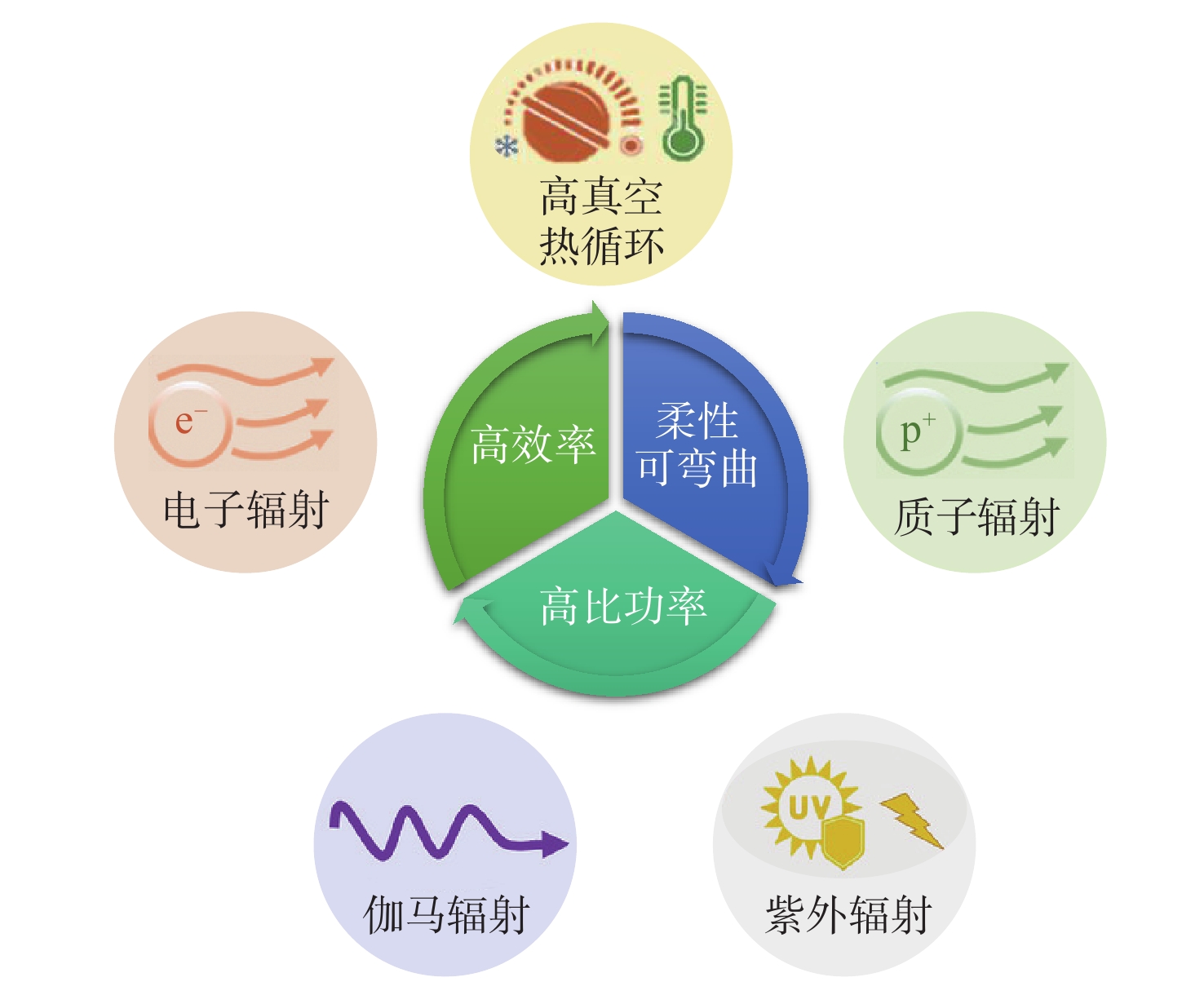

有机太阳能电池(OSC)因低成本、轻质柔性及可印刷制备特性,被视为空间领域新型光伏器件的潜在选择,其小面积单结器件能量转换效率(PCE)已突破19%,比功率显著高于传统硅基及Ⅲ-Ⅴ族电池,且可折叠特性可节省运输空间,但大面积组件化面临能量转换效率损失、结构设计与长期工作稳定性等瓶颈。基于此,聚焦柔性有机太阳能电池在空间应用中的核心问题,系统分析溶液印刷技术在大面积制备中的工艺优化路径,总结面积放大导致的能量转换效率损失因素。同时,回顾有机太阳能电池在模拟超高真空、极端温差及辐射环境中的稳定性验证。结合当前研究进展,提出未来需通过分子结构优化、叠层设计及器件工艺改进,实现器件能量转换效率突破20%,并提高器件长期工作稳定性,为柔性有机太阳能电池在空间飞行器电力系统中的应用提供理论与技术参考。

Abstract:Organic solar cells (OSCs) are emerging as a promising candidate for space applications due to their low cost, lightweight flexibility, and printable fabrication. Small-area single-junction OSCs have achieved power conversion efficiency (PCE) exceeding 19%, demonstrating a specific power significantly higher than traditional silicon-based and Ⅲ-Ⅴ-based photovoltaics. Their foldable design further reduces transportation volume, making them ideal for aerospace systems. However, large-area module fabrication still faces challenges such as efficiency loss, structural design limitations, and long-term operational stability. This study focuses on the key issues of flexible OSCs in space environments, systematically analyzing the optimization of solution-printing techniques for scalable production and summarizing the factors contributing to efficiency degradation during upscaling. Additionally, the stability of OSCs under simulated extreme conditions, including ultra-high vacuum, wide temperature ranges, and radiation exposure, is reviewed. Based on recent advances, the study proposes future directions, including molecular structure optimization, tandem device design, and process improvements, to push PCE beyond 20% and enhance long-term stability. These efforts aim to establish a theoretical and technical foundation for the application of flexible OSCs in spacecraft power systems.

-

Key words:

- organic solar cell /

- flexible electronics /

- space application /

- large-area device /

- coating technique

-

-

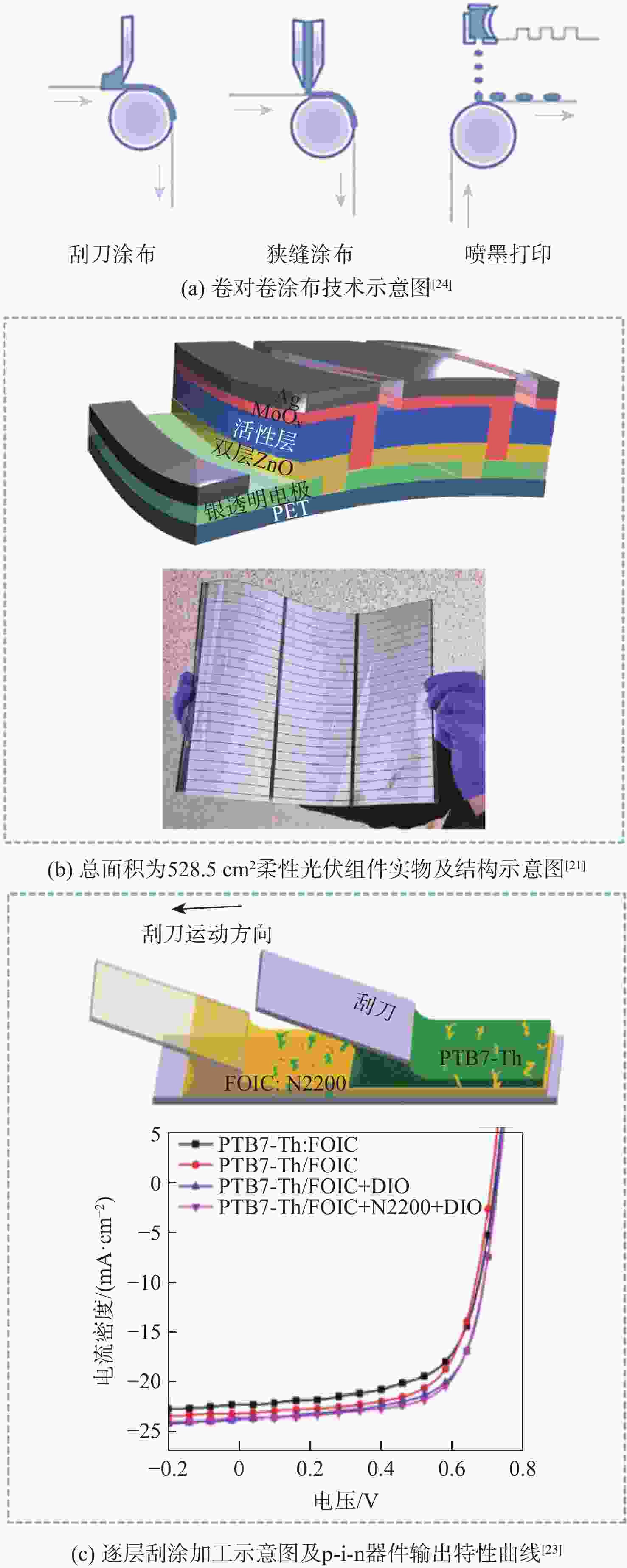

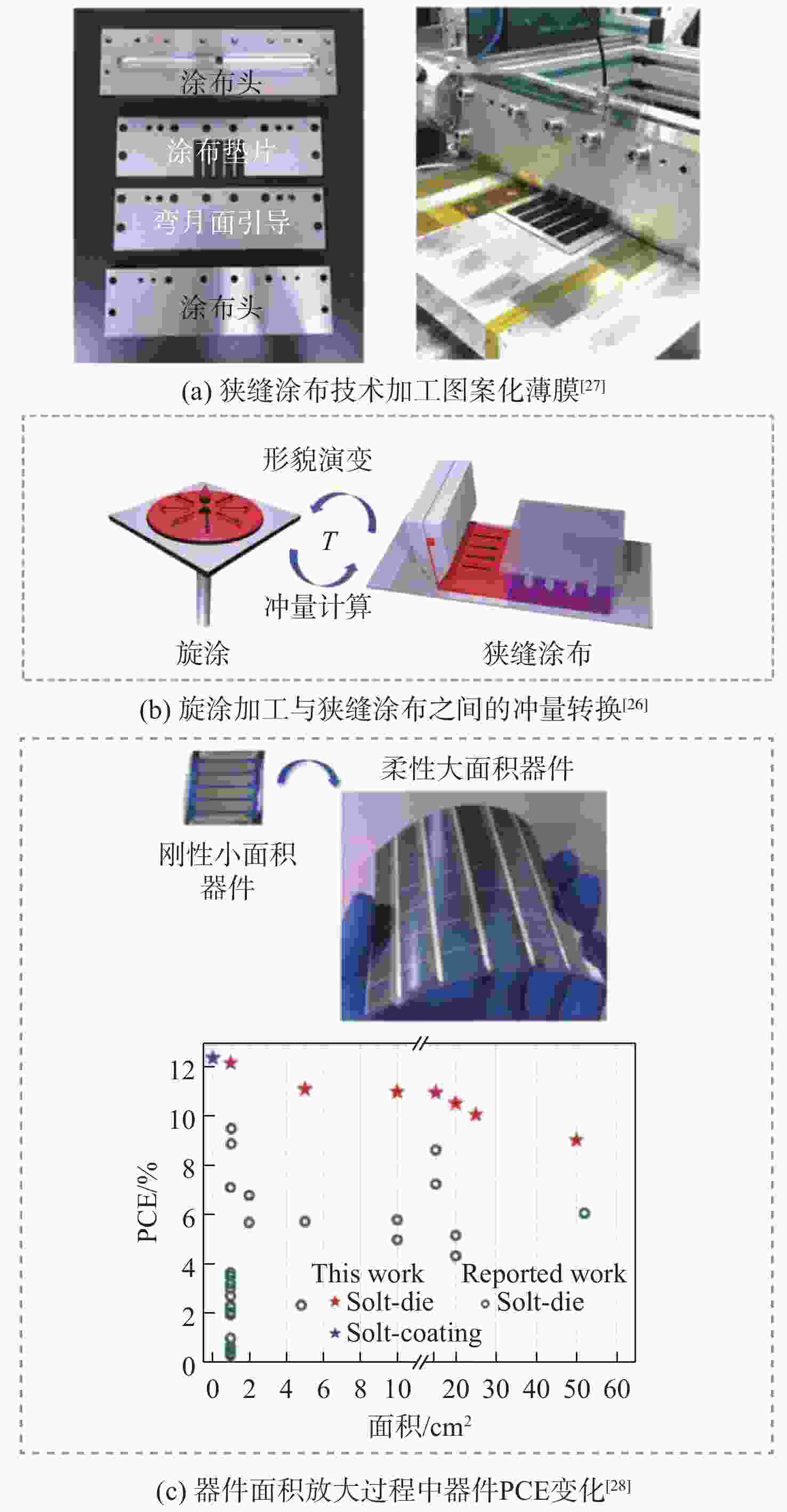

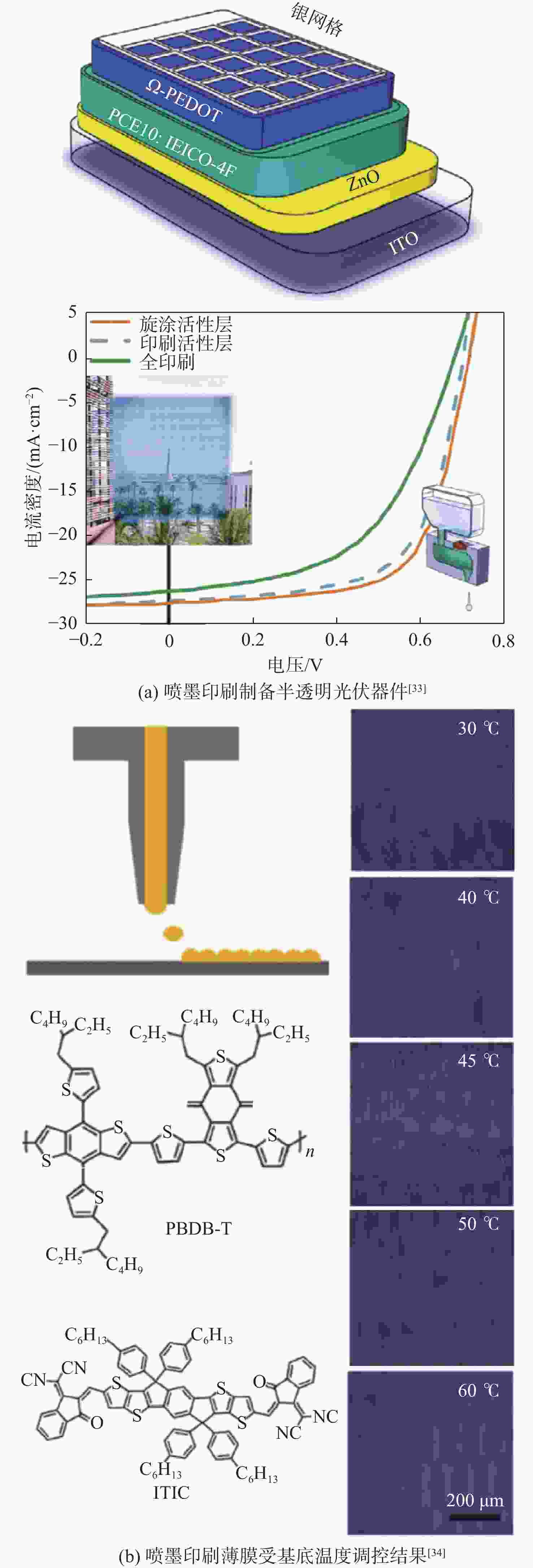

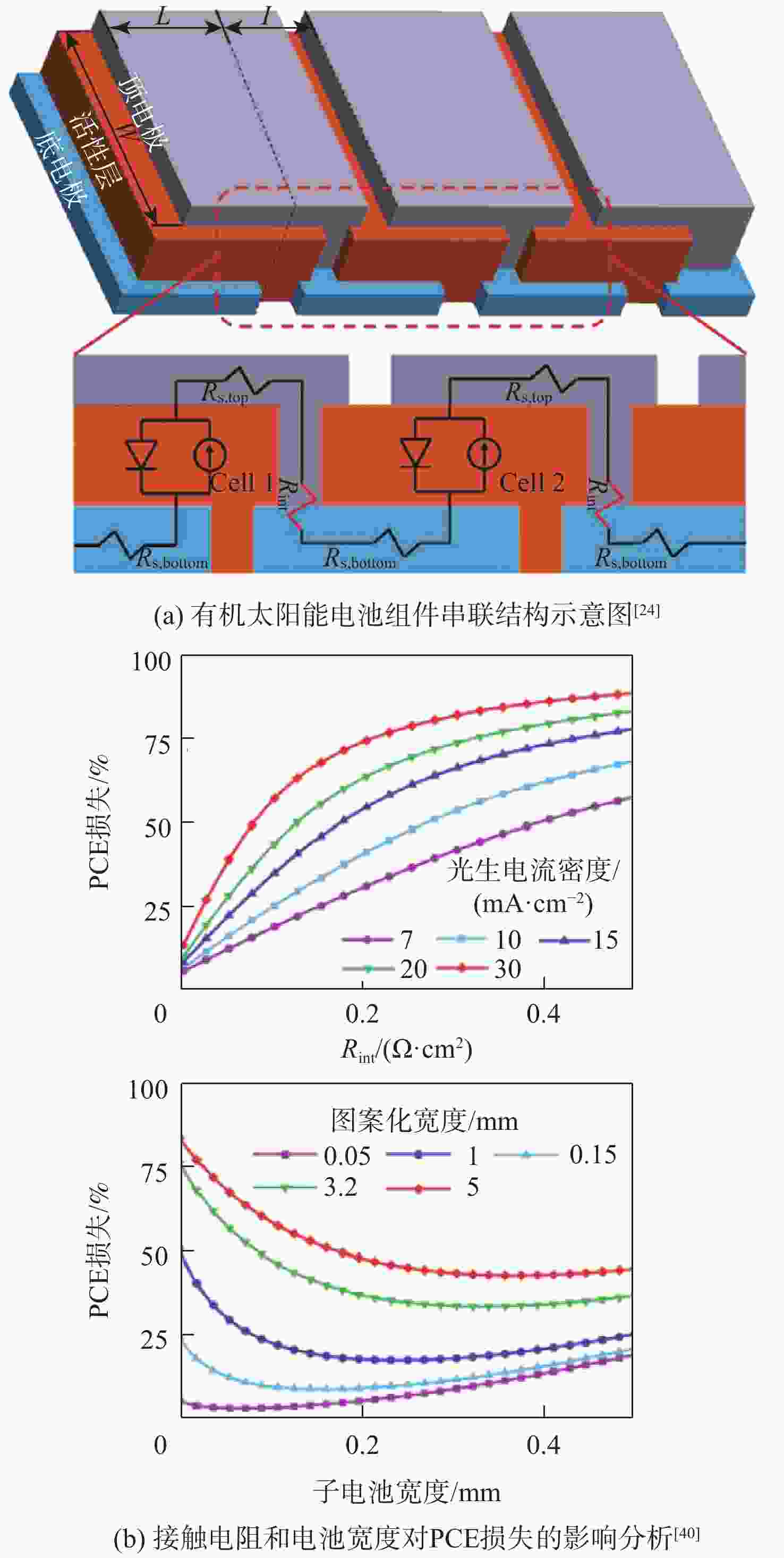

[1] PARK S, HEO S W, LEE W, et al. Self-powered ultra-flexible electronics via nano-grating-patterned organic photovoltaics[J]. Nature, 2018, 561(7724): 516-521. doi: 10.1038/s41586-018-0536-x [2] LIU Y H, LIU B W, MA C Q, et al. Recent progress in organic solar cells (Part I. Material science)[J]. Science China Chemistry, 2022, 65(2): 224-268. doi: 10.1007/s11426-021-1180-6 [3] ZHU L, ZHANG M, XU J Q, et al. Single-junction organic solar cells with over 19% efficiency enabled by a refined double-fibril network morphology[J]. Nature Materials, 2022, 21(6): 656-663. doi: 10.1038/s41563-022-01244-y [4] CHE X Z, LI Y X, QU Y, et al. High fabrication yield organic tandem photovoltaics combining vacuum- and solution-processed subcells with 15% efficiency[J]. Nature Energy, 2018, 3: 422-427. [5] FILIPIČ M, LÖPER P, NIESEN B, et al. CH3NH3PbI3 perovskite/silicon tandem solar cells: characterization based optical simulations[J]. Optics Express, 2015, 23(7): A263-A278. [6] THIRSK R, KUIPERS A, MUKAI C, et al. The space-flight environment: the international space station and beyond[J]. Journal de L’Association Medicale Canadienne, 2009, 180(12): 1216-1220. [7] TU Y G, WU J, XU G N, et al. Perovskite solar cells for space applications: progress and challenges[J]. Advanced Materials, 2021, 33(21): 2006545. doi: 10.1002/adma.202006545 [8] MOHR N J, SCHERMER J J, HUIJBREGTS M A J, et al. Life cycle assessment of thin-film GaAs and GaInP/GaAs solar modules[J]. Progress in Photovoltaics: Research and Applications, 2007, 15(2): 163-179. doi: 10.1002/pip.735 [9] KALTENBRUNNER M, WHITE M S, GŁOWACKI E D, et al. Ultrathin and lightweight organic solar cells with high flexibility[J]. Nature Communications, 2012, 3: 770. doi: 10.1038/ncomms1772 [10] CARDINALETTI I, VANGERVEN T, NAGELS S, et al. Organic and perovskite solar cells for space applications[J]. Solar Energy Materials and Solar Cells, 2018, 182: 121-127. doi: 10.1016/j.solmat.2018.03.024 [11] WANG Q, XIE Y, SOLTANI-KORDSHULI F, et al. Progress in emerging solution-processed thin film solar cells–Part I: Polymer solar cells[J]. Renewable and Sustainable Energy Reviews, 2016, 56: 347-361. doi: 10.1016/j.rser.2015.11.063 [12] NORRMAN K, GHANBARI-SIAHKALI A, LARSEN N B. Studies of spin-coated polymer films[J]. Annual Reports Section “C” (Physical Chemistry), 2005, 101(0): 174-201. [13] KUMAR P. Organic solar cells: device physics, processing, degradation, and prevention[M]. Boca Raton: CRC Press, 2016. [14] YANG F, HUANG Y T, LI Y W, et al. Large-area flexible organic solar cells[J]. NPJ Flexible Electronics, 2021, 5: 30. doi: 10.1038/s41528-021-00128-6 [15] BLAKE T D. The physics of moving wetting lines[J]. Journal of Colloid and Interface Science, 2006, 299(1): 1-13. doi: 10.1016/j.jcis.2006.03.051 [16] GU X D, SHAW L, GU K, et al. The meniscus-guided deposition of semiconducting polymers[J]. Nature Communications, 2018, 9: 534. doi: 10.1038/s41467-018-02833-9 [17] LE BERRE M, CHEN Y, BAIGL D. From convective assembly to Landau-Levich deposition of multilayered phospholipid films of controlled thickness[J]. Langmuir, 2009, 25(5): 2554-2557. doi: 10.1021/la803646e [18] FAUSTINI M, LOUIS B, ALBOUY P A, et al. Preparation of Sol-Gel films by dip-coating in extreme conditions[J]. The Journal of Physical Chemistry C, 2010, 114(17): 7637-7645. doi: 10.1021/jp9114755 [19] LIAO C Y, CHEN Y, LEE C C, et al. Processing strategies for an organic photovoltaic module with over 10% efficiency[J]. Joule, 2020, 4(1): 189-206. [20] KANG H, JUNG S, JEONG S, et al. Polymer-metal hybrid transparent electrodes for flexible electronics[J]. Nature Communications, 2015, 6: 6503. [21] KWON H C, JEONG W, LEE Y S, et al. Overcoming the low-surface-energy-induced wettability problem of flexible and transparent electrodes for large-area organic photovoltaic modules over 500 cm2[J]. Advanced Energy Materials, 2022, 12(21): 2200023. doi: 10.1002/aenm.202200023 [22] HAN Y F, HU Z S, ZHA W S, et al. 12.42% monolithic 25.42 cm2 flexible organic solar cells enabled by an amorphous ITO-modified metal grid electrode[J]. Advanced Materials, 2022, 34(17): 2110276. doi: 10.1002/adma.202110276 [23] WANG Y L, ZHU Q L, NAVEED H B, et al. Sequential blade-coated acceptor and donor enables simultaneous enhancement of efficiency, stability, and mechanical properties for organic solar cells[J]. Advanced Energy Materials, 2020, 10(7): 1903609. doi: 10.1002/aenm.201903609 [24] WANG G D, ADIL M A, ZHANG J Q, et al. Large-area organic solar cells: material requirements, modular designs, and printing methods[J]. Advanced Materials, 2019, 31(45): 1805089. doi: 10.1002/adma.201805089 [25] XUE P Y, CHENG P, HAN R P S, et al. Printing fabrication of large-area non-fullerene organic solar cells[J]. Materials Horizons, 2022, 9(1): 194-219. doi: 10.1039/D1MH01317C [26] MENG X C, ZHANG L, XIE Y P, et al. A general approach for lab-to-manufacturing translation on flexible organic solar cells[J]. Advanced Materials, 2019, 31(41): 1903649. doi: 10.1002/adma.201903649 [27] HAN Y W, JEON S J, LEE H S, et al. Evaporation-free nonfullerene flexible organic solar cell modules manufactured by an all-solution process[J]. Advanced Energy Materials, 2019, 9(42): 1902065. doi: 10.1002/aenm.201902065 [28] WANG G D, ZHANG J Q, YANG C, et al. Synergistic optimization enables large-area flexible organic solar cells to maintain over 98% PCE of the small-area rigid devices[J]. Advanced Materials, 2020, 32(49): 2005153. doi: 10.1002/adma.202005153 [29] SHEN Y F, ZHANG H, ZHANG J Q, et al. In situ absorption characterization guided slot-die-coated high-performance large-area flexible organic solar cells and modules[J]. Advanced Materials, 2023, 35(10): 2209030. doi: 10.1002/adma.202209030 [30] WU Q, GUO J, SUN R, et al. Slot-die printed non-fullerene organic solar cells with the highest efficiency of 12.9% for low-cost PV-driven water splitting[J]. Nano Energy, 2019, 61: 559-566. doi: 10.1016/j.nanoen.2019.04.091 [31] KREBS F C. Fabrication and processing of polymer solar cells: a review of printing and coating techniques[J]. Solar Energy Materials and Solar Cells, 2009, 93(4): 394-412. doi: 10.1016/j.solmat.2008.10.004 [32] BURGUÉS-CEBALLOS I, STELLA M, LACHARMOISE P, et al. Towards industrialization of polymer solar cells: material processing for upscaling[J]. Journal of Materials Chemistry A, 2014, 2(42): 17711-17722. doi: 10.1039/C4TA03780D [33] CORZO D, BIHAR E, ALEXANDRE E B, et al. Ink engineering of transport layers for 9.5% efficient all-printed semitransparent nonfullerene solar cells[J]. Advanced Functional Materials, 2021, 31(7): 2005763. doi: 10.1002/adfm.202005763 [34] CHEN X Z, HUANG R, HAN Y F, et al. Balancing the molecular aggregation and vertical phase separation in the polymer: nonfullerene blend films enables 13.09% efficiency of organic solar cells with inkjet-printed active layer[J]. Advanced Energy Materials, 2022, 12(12): 2200044. doi: 10.1002/aenm.202200044 [35] KOPOLA P, AERNOUTS T, SLIZ R, et al. Gravure printed flexible organic photovoltaic modules[J]. Solar Energy Materials and Solar Cells, 2011, 95(5): 1344-1347. doi: 10.1016/j.solmat.2010.12.020 [36] GALAGAN Y, RUBINGH J J M, ANDRIESSEN R, et al. ITO-free flexible organic solar cells with printed current collecting grids[J]. Solar Energy Materials and Solar Cells, 2011, 95(5): 1339-1343. doi: 10.1016/j.solmat.2010.08.011 [37] KOPOLA P, AERNOUTS T, GUILLEREZ S, et al. High efficient plastic solar cells fabricated with a high-throughput gravure printing method[J]. Solar Energy Materials and Solar Cells, 2010, 94(10): 1673-1680. doi: 10.1016/j.solmat.2010.05.027 [38] KOIDIS C, LOGOTHETIDIS S, KASSAVETIS S, et al. Effect of process parameters on the morphology and nanostructure of roll-to-roll printed P3HT: PCBM thin films for organic photovoltaics[J]. Solar Energy Materials and Solar Cells, 2013, 112: 36-46. doi: 10.1016/j.solmat.2012.12.044 [39] KAPNOPOULOS C, MEKERIDIS E D, TZOUNIS L, et al. Fully gravure printed organic photovoltaic modules: a straightforward process with a high potential for large scale production[J]. Solar Energy Materials and Solar Cells, 2016, 144: 724-731. doi: 10.1016/j.solmat.2015.10.021 [40] LUCERA L, KUBIS P, FECHER F W, et al. Guidelines for closing the efficiency gap between hero solar cells and roll-to-roll printed modules[J]. Energy Technology, 2015, 3(4): 373-384. doi: 10.1002/ente.201402192 [41] HEO Y J, JUNG Y S, HWANG K, et al. Small-molecule organic photovoltaic modules fabricated via halogen-free solvent system with roll-to-roll compatible scalable printing method[J]. ACS Applied Materials & Interfaces, 2017, 9(45): 39519-39525. [42] STROHM S, MACHUI F, LANGNER S, et al. P3HT: non-fullerene acceptor based large area, semi-transparent PV modules with power conversion efficiencies of 5%, processed by industrially scalable methods[J]. Energy & Environmental Science, 2018, 11(8): 2225-2234. [43] CHANG K, LI Y X, DU G X, et al. Efficient non-fullerene organic photovoltaics printed by electrospray via solvent engineering[J]. ACS Applied Materials & Interfaces, 2020, 12(24): 27405-27415. [44] ZHANG L, LIN B J, HU B, et al. Blade-cast nonfullerene organic solar cells in air with excellent morphology, efficiency, and stability[J]. Advanced Materials, 2018, 30(22): 1800343. doi: 10.1002/adma.201800343 [45] GUO S, BRANDT C, ANDREEV T, et al. First step into space: performance and morphological evolution of P3HT: PCBM bulk heterojunction solar cells under AM0 illumination[J]. ACS Applied Materials & Interfaces, 2014, 6(20): 17902-17910. [46] KREBS F C, NORRMAN K. Analysis of the failure mechanism for a stable organic photovoltaic during 10 000 h of testing[J]. Progress in Photovoltaics: Research and Applications, 2007, 15(8): 697-712. doi: 10.1002/pip.794 [47] CLASSEN A, HEUMUELLER T, WABRA I, et al. Revealing hidden UV instabilities in organic solar cells by correlating device and material stability[J]. Advanced Energy Materials, 2019, 9(39): 1902124. doi: 10.1002/aenm.201902124 [48] RYU M S, CHA H J, JANG J. Improvement of operation lifetime for conjugated polymer: fullerene organic solar cells by introducing a UV absorbing film[J]. Solar Energy Materials and Solar Cells, 2010, 94(2): 152-156. doi: 10.1016/j.solmat.2009.08.011 [49] KIMURA H, FUKUDA K, JINNO H, et al. High operation stability of ultraflexible organic solar cells with ultraviolet-filtering substrates[J]. Advanced Materials, 2019, 31(19): 1808033. doi: 10.1002/adma.201808033 [50] PATERNÒ G M, ROBBIANO V, FRASER K J, et al. Neutron radiation tolerance of two benchmark thiophene-based conjugated polymers: the importance of crystallinity for organic avionics[J]. Scientific Reports, 2017, 7: 41013. doi: 10.1038/srep41013 [51] MARTYNOV I V, AKKURATOV A V, LUCHKIN S Y, et al. Impressive radiation stability of organic solar cells based on fullerene derivatives and carbazole-containing conjugated polymers[J]. ACS Applied Materials & Interfaces, 2019, 11(24): 21741-21748. [52] YANG W Y, LUO Z H, SUN R, et al. Simultaneous enhanced efficiency and thermal stability in organic solar cells from a polymer acceptor additive[J]. Nature Communications, 2020, 11: 1218. doi: 10.1038/s41467-020-14926-5 [53] TU Y G, XU G N, YANG X Y, et al. Mixed-cation perovskite solar cells in space[J]. Science China Physics, Mechanics & Astronomy, 2019, 62(7): 974221. [54] WANG H, JIANG X, CAO Y X, et al. The first record of diurnal performance evolution of perovskite solar cells in near space[J]. Advanced Energy Materials, 2023, 13(2): 2202643. doi: 10.1002/aenm.202202643 [55] REB L K, BÖHMER M, PREDESCHLY B, et al. Perovskite and organic solar cells on a rocket flight[J]. Joule, 2020, 4(9): 1880-1892. doi: 10.1016/j.joule.2020.07.004 [56] BAILEY S, RAFFAELLE R. Space solar cells and arrays[M]//LUQUE A, HEGEDUS S. Handbook of photovoltaic science and engineering. New York: Wiley, 2011: 369-373. [57] O’NEILL M, HOWELL J, FIKES J, et al. Stretched lens array SquareRigger (SLASR): a new space array for high-power missions[C]//Proceedings of the IEEE 4th World Conference on Photovoltaic Energy Conference. Piscataway: IEEE Press, 2006: 2006-2009. -

下载:

下载: