-

摘要:

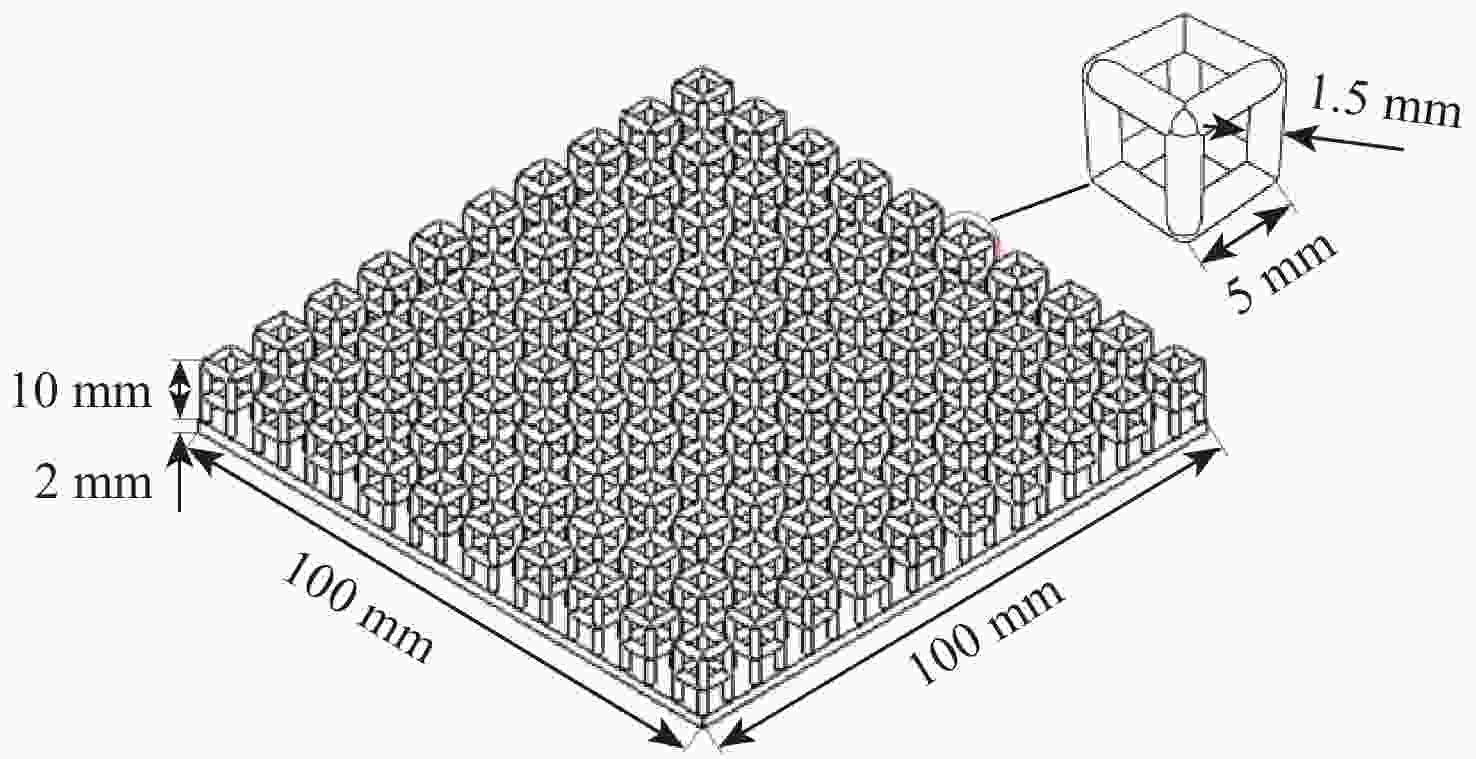

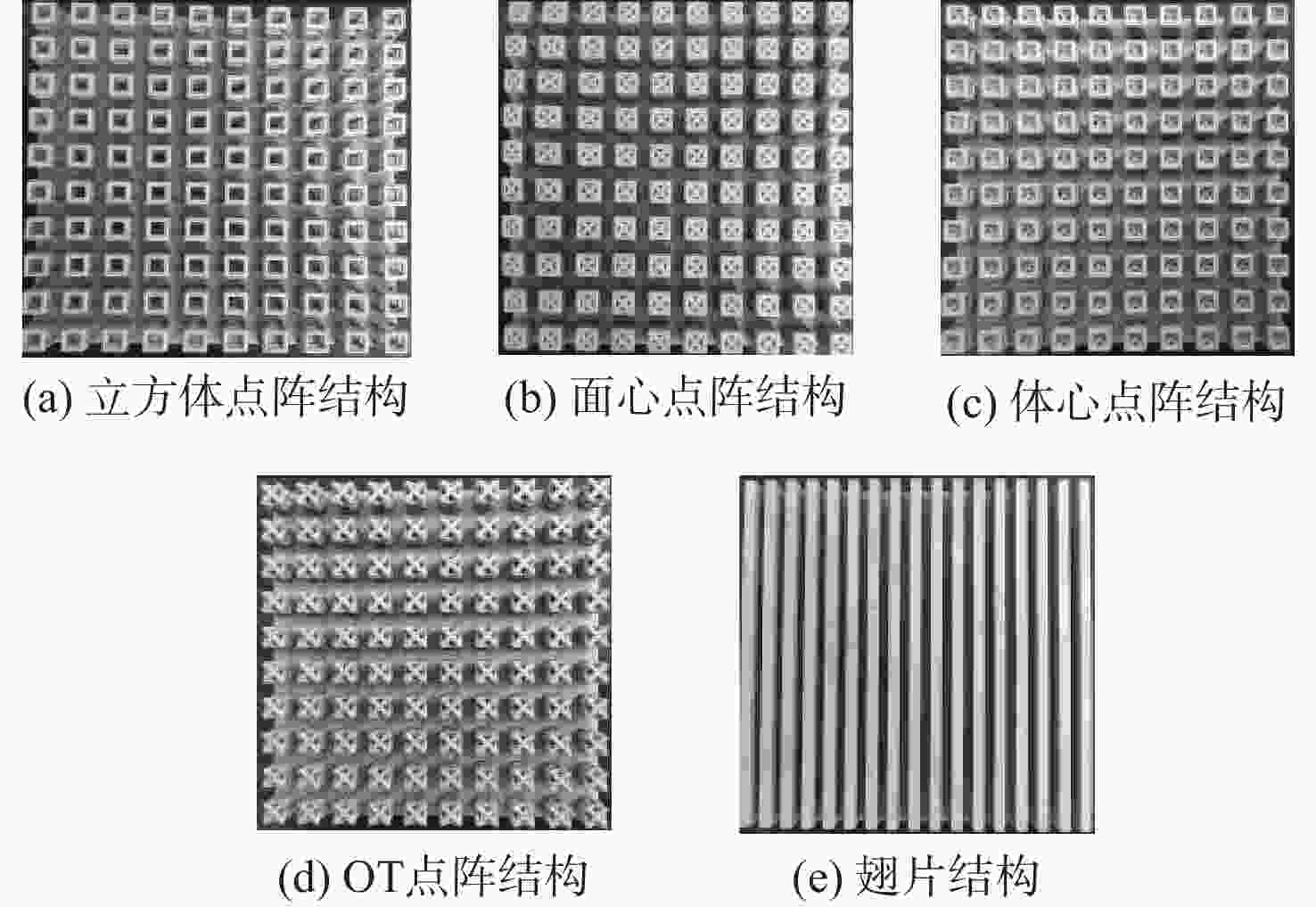

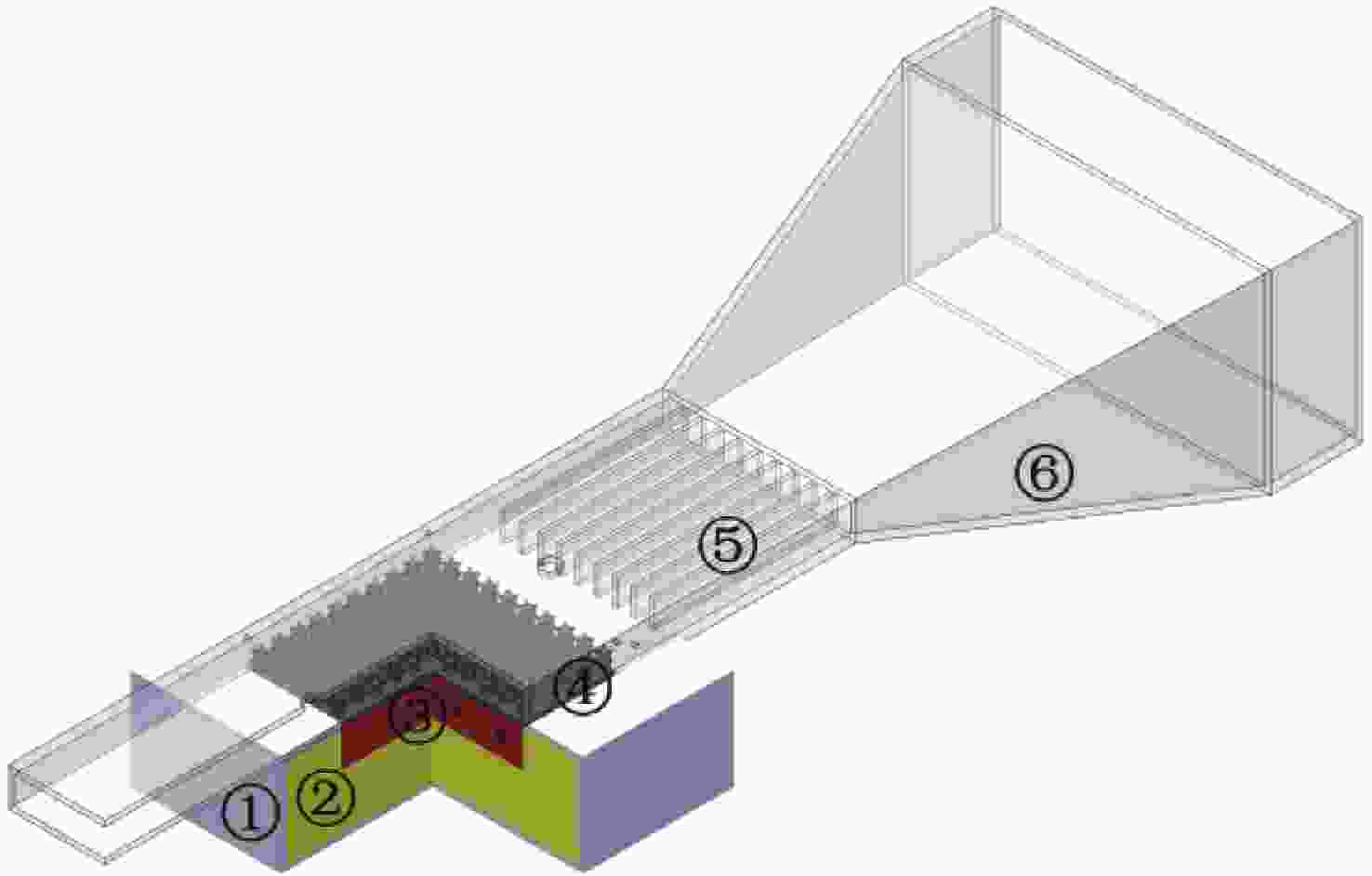

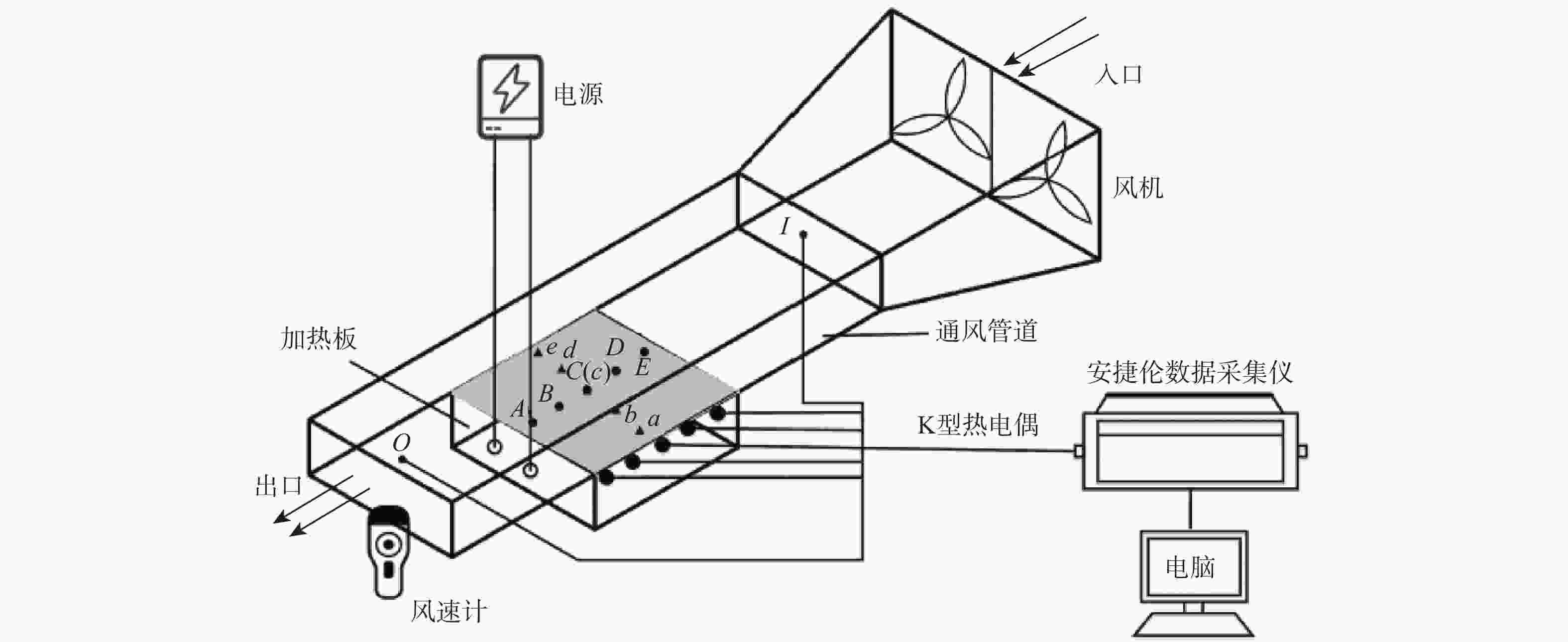

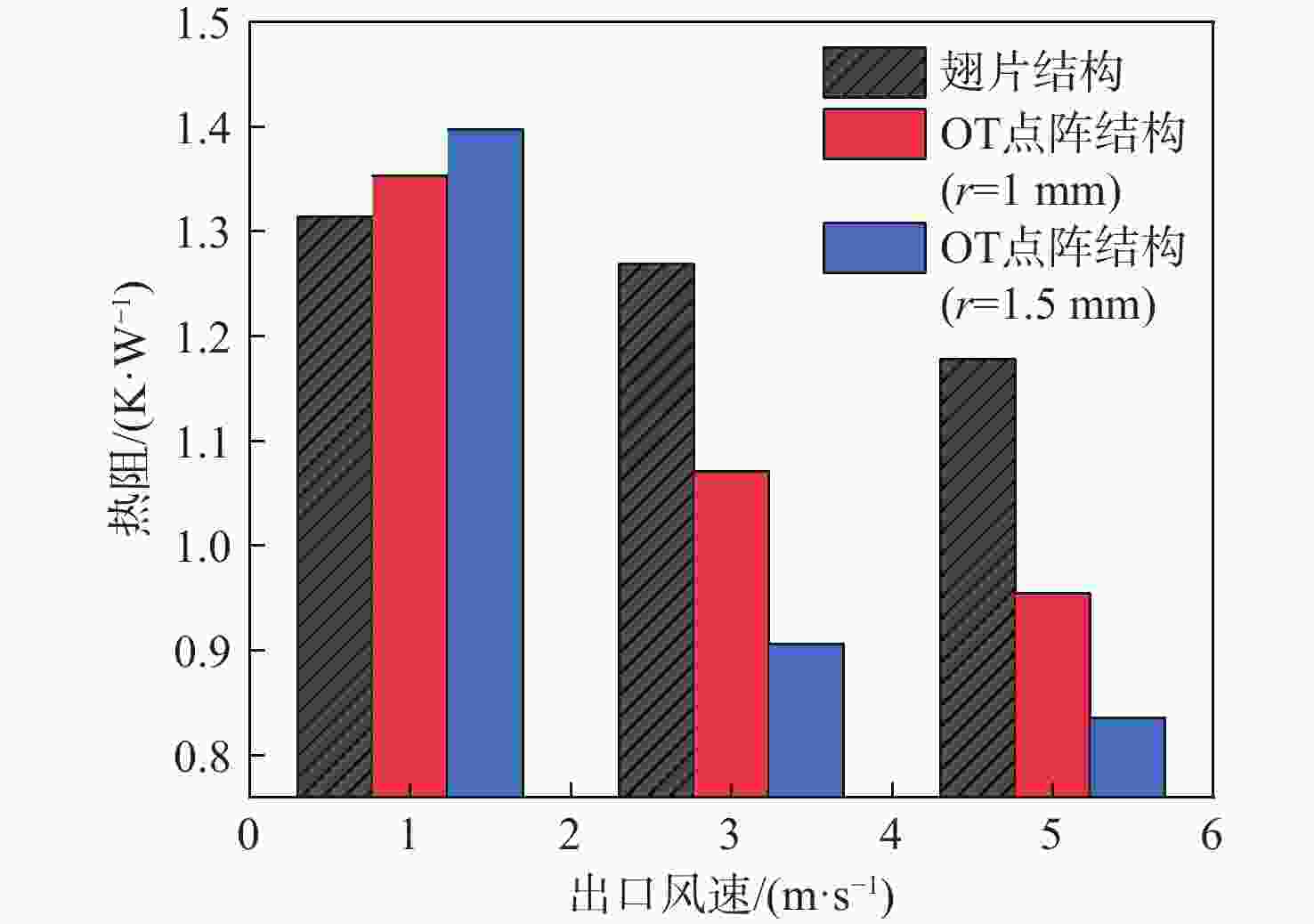

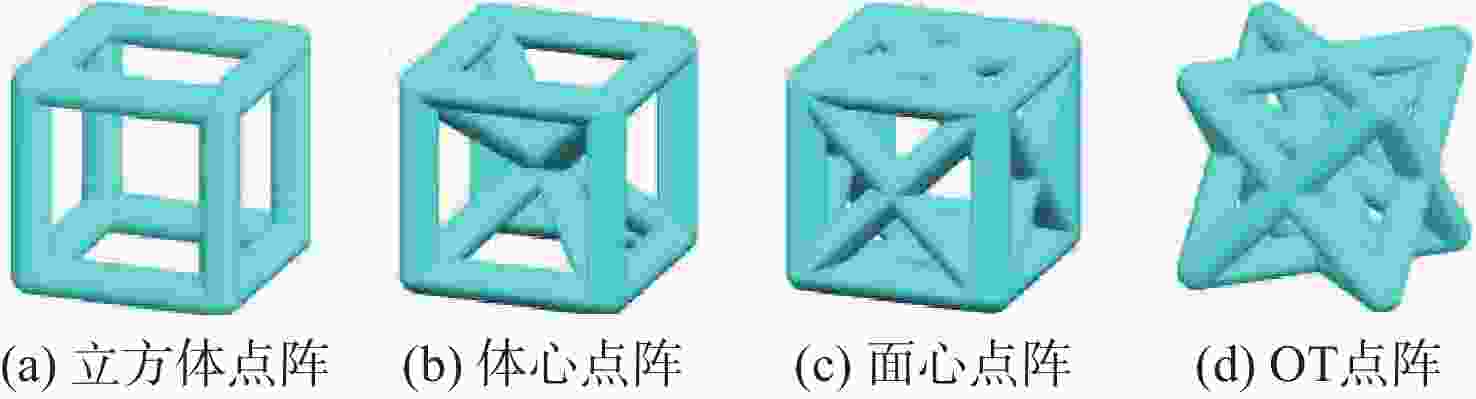

航空电静液驱动执行器(EHA)作为航空舵面控制的核心部件,对高功重比的追求要求对其部件进行高效散热与轻量化综合设计。基于此,通过实验方法对4种典型轻量化点阵结构的散热特性进行研究,得到了不同点阵散热模块的温度分布特性,为点阵结构散热与轻量化性能评价提供可靠数据。针对点阵结构散热特性,提出点阵结构散热轻量化系数评价指标,用以定量评估不同散热点阵结构的轻量化特性。根据构建的评价指标对4种点阵结构进行评价,结果表明:OT点阵结构散热性能与轻量化综合特性最优。与翅片结构相比,OT点阵结构散热系数为翅片的1.2倍,但其散热轻量化系数仅约为翅片的1/3。研究结果为综合考虑散热和轻量化要求的点阵结构筛取提供了参考。

Abstract:As the core component of aviation rudder control, the pursuit of a high power-to-weight ratio for an electro-hydrostatic actuator (EHA) requires efficient heat dissipation and a lightweight integrated design for its components. Reliable data for assessing lattice structure heat dissipation and lightweight performance is provided by this paper’s experimental study of the heat dissipation properties of four common lightweight lattice structures and the temperature distribution properties of various lattice heat dissipation modules. Based on the heat dissipation characteristics of lattice structures, an evaluation index of the heat dissipation lightweight coefficient of lattice structures is proposed to quantitatively evaluate the lightweight characteristics of different heat dissipation lattice structures. The four types of lattice structures are assessed using the evaluation index developed in this research, and the findings indicate that the OT lattice structure has the best combined lightweight and heat dissipation performance. Compared with the fin structure, the heat dissipation coefficient of the OT lattice structure is 1.2 times that of the fin, but its heat dissipation lightweight coefficient is only about 1/3 of that of the fin. This study provides a theoretical basis for the screening of the lattice structure considering both heat dissipation and lightweight.

-

Key words:

- lattice structure /

- heat dissipation /

- lightweight /

- experimental research /

- evluation

-

表 1 点阵结构散热性能实验工况

Table 1. Working condition of lattice structure heat dissipation characteristic experiment

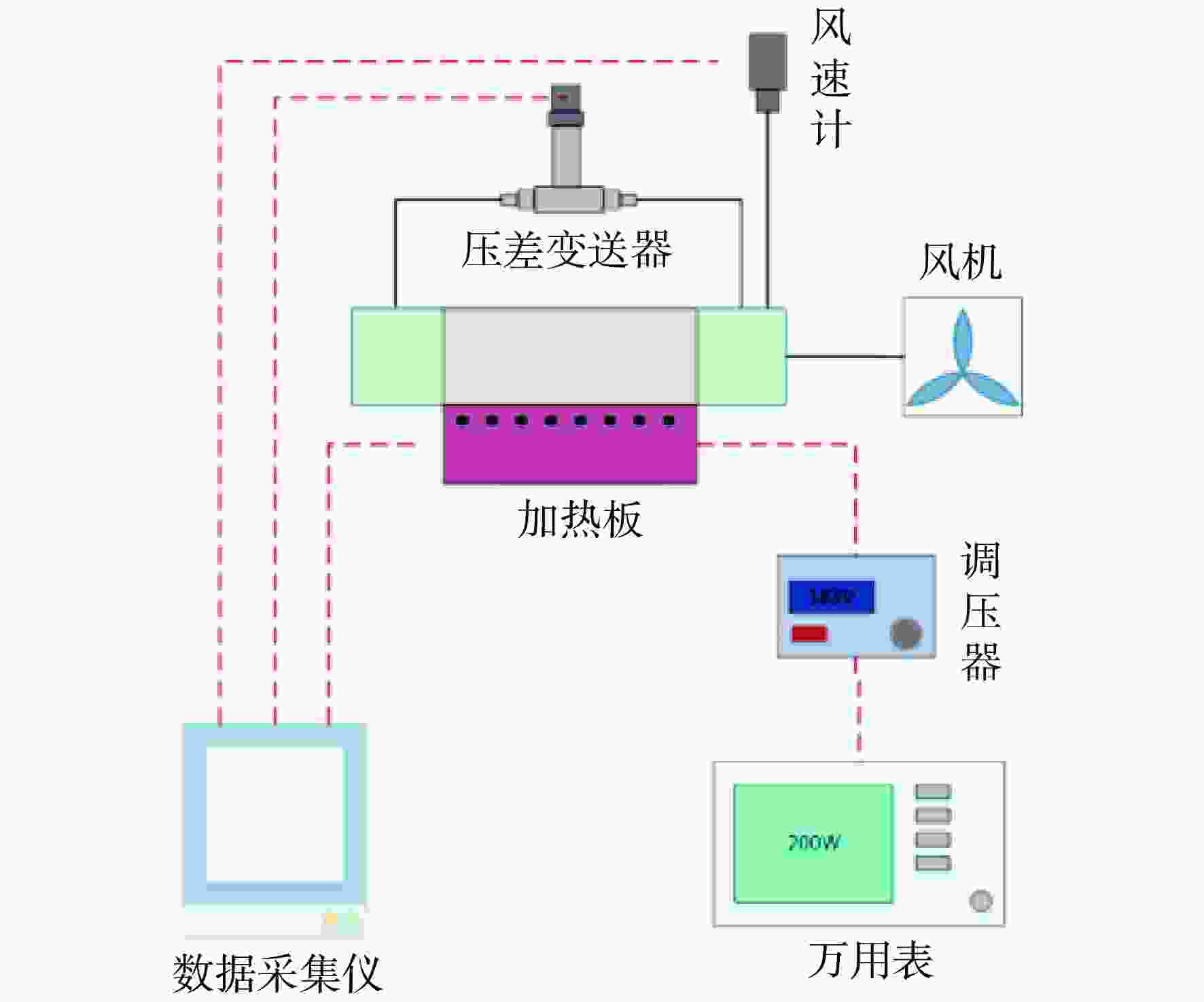

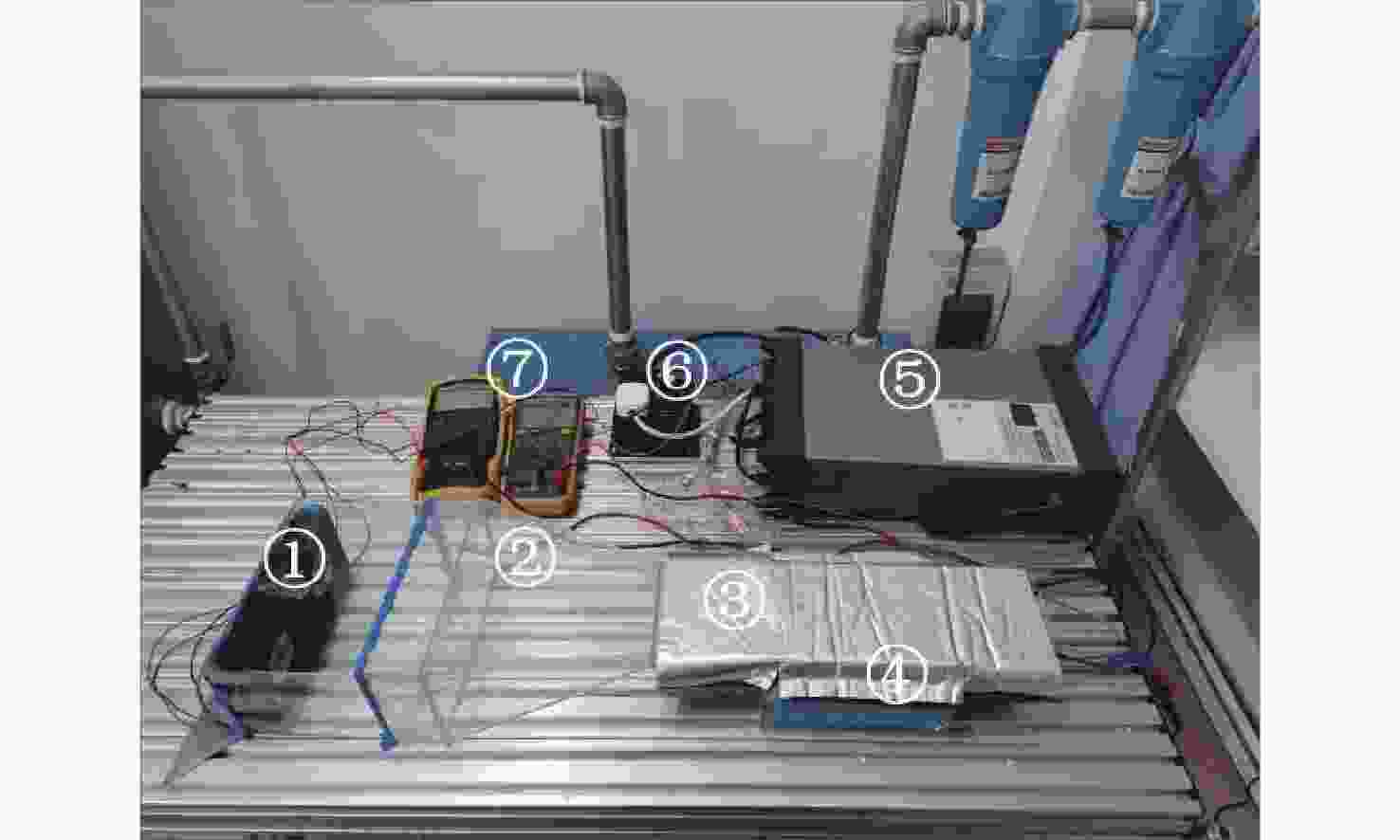

分组 出口风速/(m·s−1) 加热功率/W 杆径/mm 点阵类型 第1组 5 35 1.5 立方体点阵 5 35 1.5 体心点阵 5 35 1.5 面心点阵 5 35 1.5 OT点阵 5 35 3(翅厚) 翅片 第2组 5 35 0.5 OT点阵 5 35 1 OT点阵 5 35 1.5 OT点阵 第3组 1 35 1.5 OT点阵 3 35 1.5 OT点阵 5 35 1.5 OT点阵 表 2 测量仪器型号及参数

Table 2. Measuring instrument model and parameters

设备 型号 参数 安捷伦数据采集仪 34972A 精度:0.004% 欧米伽热线风速计 HHF-SD1 工作温度0~50 ℃;分辨率:0.1 ℃;精度:0.8 ℃ 数字万用表 Fluke 101 精度:±(1%+1) 热电偶 K-Type 测温范围:−200~260 ℃;精度:0.75% -

[1] 许巍, 赵俊伟, 袁本立, 等. 飞行器热防护与利用一体化系统实验与模拟[J]. 航空动力学报, 2022, 37(3): 555-563.XU W, ZHAO J W, YUAN B L, et al. Experiment and simulation on aircraft thermal protection and utilization integrated system[J]. Journal of Aerospace Power, 2022, 37(3): 555-563(in Chinese). [2] 朱喜华, 李颖晖, 刘聪, 等. 基于自适应核主元分析的EHA系统传感器故障检测[J]. 推进技术, 2014, 35(6): 838-845.ZHU X H, LI Y H, LIU C, et al. Sensor fault detection for EHA system based on adaptive kernel principal component analysis[J]. Journal of Propulsion Technology, 2014, 35(6): 838-845(in Chinese). [3] 李永欣, 郭长春, 李凯伦, 等. SLM制备的小长径比四棱锥点阵填充轻量化研究[J]. 机械工程学报, 2021, 57(24): 132-138. doi: 10.3901/JME.2021.24.132LI Y X, GUO C C, LI K L, et al. Filling lightweight research on pyramid lattice with small slenderness ratio fabricated by SLM[J]. Journal of Mechanical Engineering, 2021, 57(24): 132-138(in Chinese). doi: 10.3901/JME.2021.24.132 [4] 王伟, 袁雷, 王晓巍. 飞机增材制造制件的宏观结构轻量化分析[J]. 飞机设计, 2015, 35(3): 24-28.WANG W, YUAN L, WANG X W. Macro-structural lightweight analysis for aircraft parts made by additive manufacturing technology[J]. Aircraft Design, 2015, 35(3): 24-28(in Chinese). [5] LIAN W L, NIU W J, LIN L J. A passive cooling design for an aircraft electromechanical actuator by using heat pipes[J]. Applied Thermal Engineering, 2021, 184: 116248. doi: 10.1016/j.applthermaleng.2020.116248 [6] OENLER C D. Fluid flow and heat transfer simulation of an electro hydraulic actuator[D]. Delft: Delft University of Technology, 2016. [7] 白晓辉, 刘存良, 孟宪龙, 等. 八面体桁架结构在内冷通道中的流动传热特性研究[J]. 推进技术, 2022, 43(7): 286-295.BAI X H, LIU C L, MENG X L, et al. Flow and heat transfer characteristics of octet truss structure in internal cooling channel[J]. Journal of Propulsion Technology, 2022, 43(7): 286-295(in Chinese). [8] 邓昊宇, 王春洁. 三维点阵结构等效热分析与优化方法[J]. 北京麻豆精品秘 国产传媒学报, 2019, 45(6): 1122-1128.DENG H Y, WANG C J. Equivalent thermal analysis and optimization method for three-dimensional lattice structure[J]. Journal of Beijing University of Aeronautics and Astronautics, 2019, 45(6): 1122-1128(in Chinese). [9] EKADE P, KRISHNAN S. Fluid flow and heat transfer characteristics of octet truss lattice geometry[J]. International Journal of Thermal Sciences, 2019, 137: 253-261. doi: 10.1016/j.ijthermalsci.2018.11.031 [10] 易长炎, 柏龙, 陈晓红, 等. 金属三维点阵结构拓扑构型研究及应用现状综述[J]. 功能材料, 2017, 48(10): 10055-10065.YI C Y, BAI L, CHEN X H, et al. Review on the metal three-dimensional lattice topology configurations research and application status[J]. Journal of Functional Materials, 2017, 48(10): 10055-10065(in Chinese). [11] KHADERI S N, DESHPANDE V S, FLECK N A. The stiffness and strength of the gyroid lattice[J]. International Journal of Solids and Structures, 2014, 51(23-24): 3866-3877. doi: 10.1016/j.ijsolstr.2014.06.024 [12] SHEN B B, LI Y, YAN H B, et al. Heat transfer enhancement of wedge-shaped channels by replacing pin fins with Kagome lattice structures[J]. International Journal of Heat and Mass Transfer, 2019, 141: 88-101. doi: 10.1016/j.ijheatmasstransfer.2019.06.059 [13] SON K N, WEIBEL J A, KUMARESAN V, et al. Design of multifunctional lattice-frame materials for compact heat exchangers[J]. International Journal of Heat and Mass Transfer, 2017, 115: 619-629. doi: 10.1016/j.ijheatmasstransfer.2017.07.073 [14] LIANG D, CHEN W, JU Y C, et al. Comparing endwall heat transfer among staggered pin fin, Kagome and body centered cubic arrays[J]. Applied Thermal Engineering, 2021, 185: 116306. doi: 10.1016/j.applthermaleng.2020.116306 [15] TAKEZAWA A, KOBASHI M, KOIZUMI Y, et al. Porous metal produced by selective laser melting with effective isotropic thermal conductivity close to the Hashin-Shtrikman bound[J]. International Journal of Heat and Mass Transfer, 2017, 105: 564-572. doi: 10.1016/j.ijheatmasstransfer.2016.10.006 [16] VAISSIER B, PERNOT J P, CHOUGRANI L, et al. Parametric design of graded truss lattice structures for enhanced thermal dissipation[J]. Computer-Aided Design, 2019, 115: 1-12. doi: 10.1016/j.cad.2019.05.022 [17] CHENG L, LIU J K, LIANG X, et al. Coupling lattice structure topology optimization with design-dependent feature evolution for additive manufactured heat conduction design[J]. Computer Methods in Applied Mechanics and Engineering, 2018, 332: 408-439. doi: 10.1016/j.cma.2017.12.024 [18] 张龙, 李昂, 赵云鹏, 等. 一种全封闭蒙皮点阵支撑结构的优化设计与试验验证[J]. 机械工程学报, 2021, 57(22): 35-42. doi: 10.3901/JME.2021.22.035ZHANG L, LI A, ZHAO Y P, et al. Optimal design and experimental verification of an enclosed skin lattice support structure[J]. Journal of Mechanical Engineering, 2021, 57(22): 35-42(in Chinese). doi: 10.3901/JME.2021.22.035 [19] VALDEVIT L, HUTCHINSON J W, EVANS A G. Structurally optimized sandwich panels with prismatic cores[J]. International Journal of Solids and Structures, 2004, 41(18-19): 5105-5124. doi: 10.1016/j.ijsolstr.2004.04.027 [20] MOON S K, TAN Y E, HWANG J, et al. Application of 3D printing technology for designing light-weight unmanned aerial vehicle wing structures[J]. International Journal of Precision Engineering and Manufacturing-Green Technology, 2014, 1(3): 223-228. doi: 10.1007/s40684-014-0028-x [21] XU X , JIANG Y, LEE H P. Engineering optimization multi-objective optimal design of sandwich panels using a genetic algorithm multi-objective optimal design of sandwich panels using a genetic algorithm[J]. Engineering Optimization, 2017, 49(10): 1665-1684. [22] 侯伟, 陈静, 储松林, 等. 选区激光熔化成形AlSi10Mg组织与拉伸性能的各向异性研究[J]. 中国激光, 2018, 45(7): 67-77.HOU W, CHEN J, CHU S L, et al. Anisotropy of microstructure and tensile properties of AlSi10Mg formed by selective laser melting[J]. Chinese Journal of Lasers, 2018, 45(7): 67-77(in Chinese). [23] 姚再起, 马芳武, 刘强, 等. 汽车轻量化评价方法研究[J]. 中国工程科学, 2014, 16(1): 36-39. doi: 10.3969/j.issn.1009-1742.2014.01.004YAO Z Q, MA F W, LIU Q, et al. Evaluation methods of vehicle lightweight[J]. Engineering Sciences, 2014, 16(1): 36-39(in Chinese). doi: 10.3969/j.issn.1009-1742.2014.01.004 -

下载:

下载: