-

摘要:

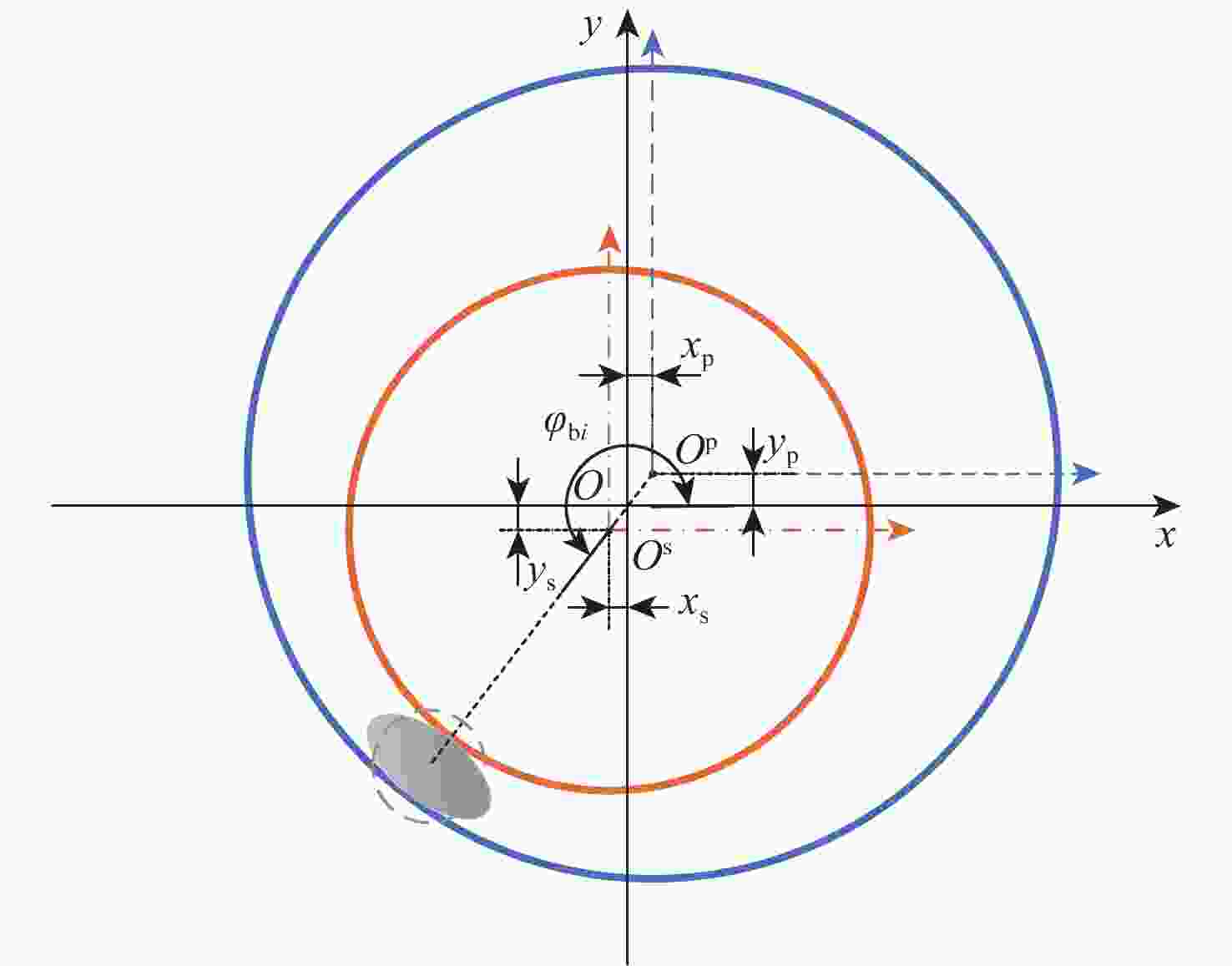

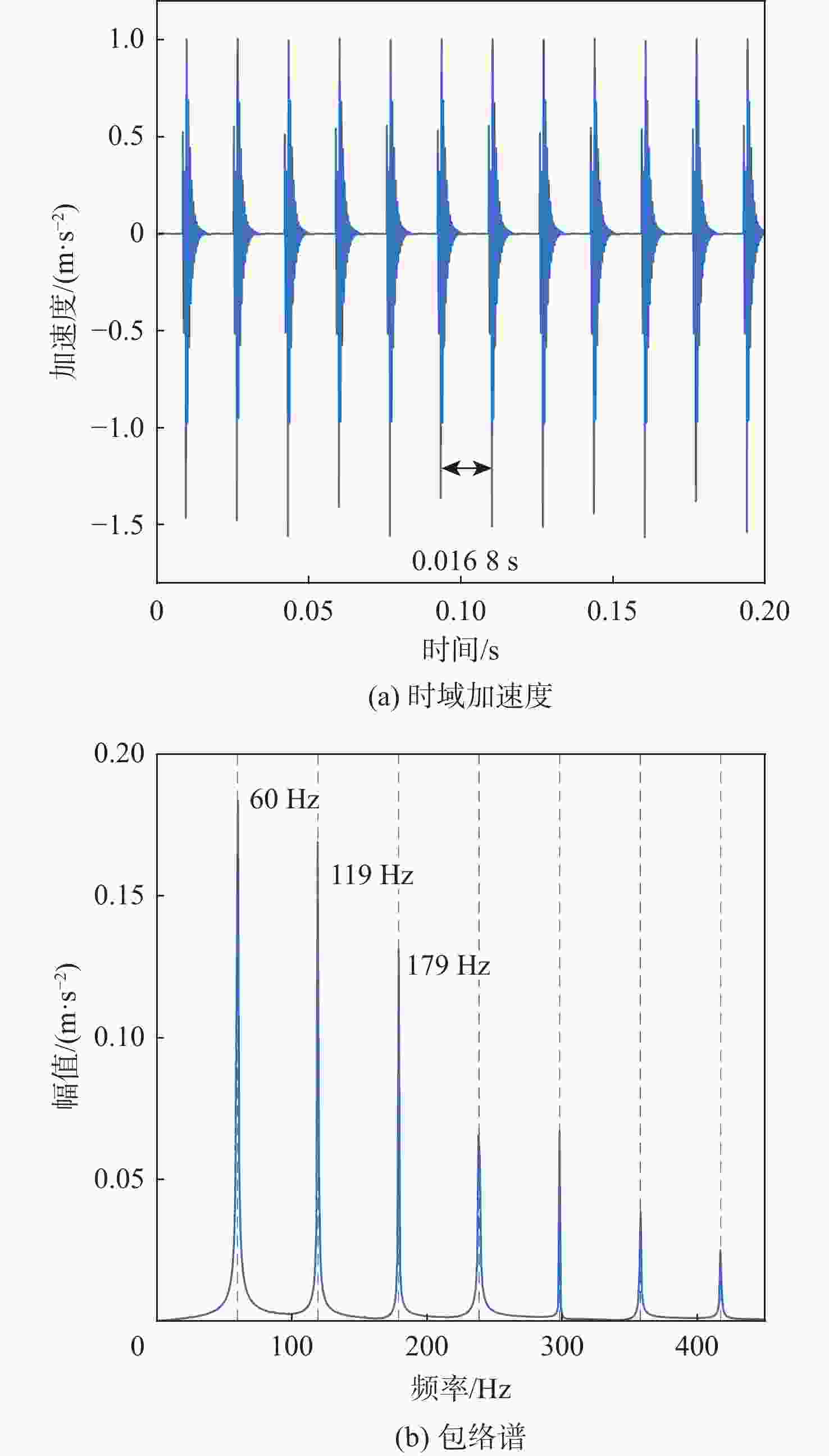

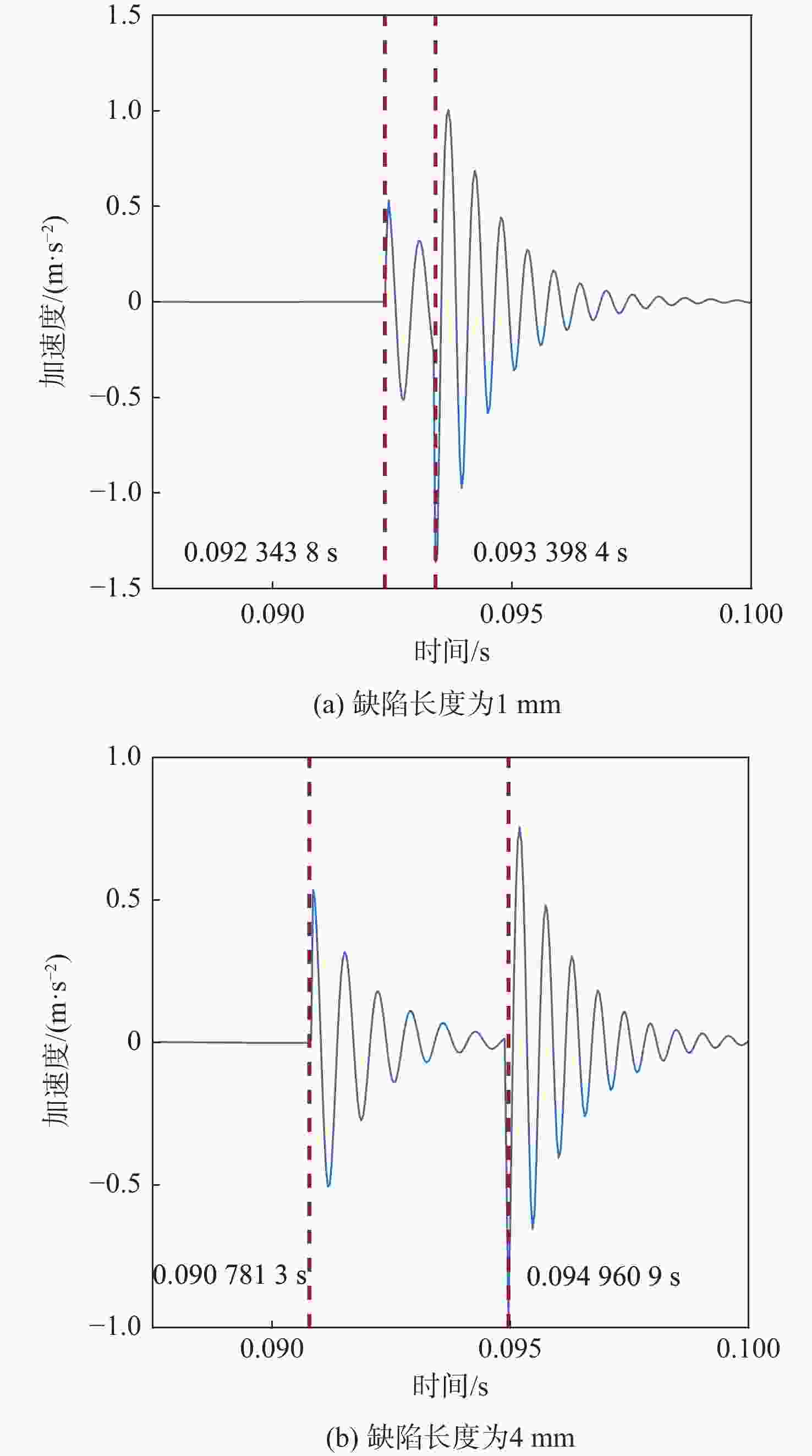

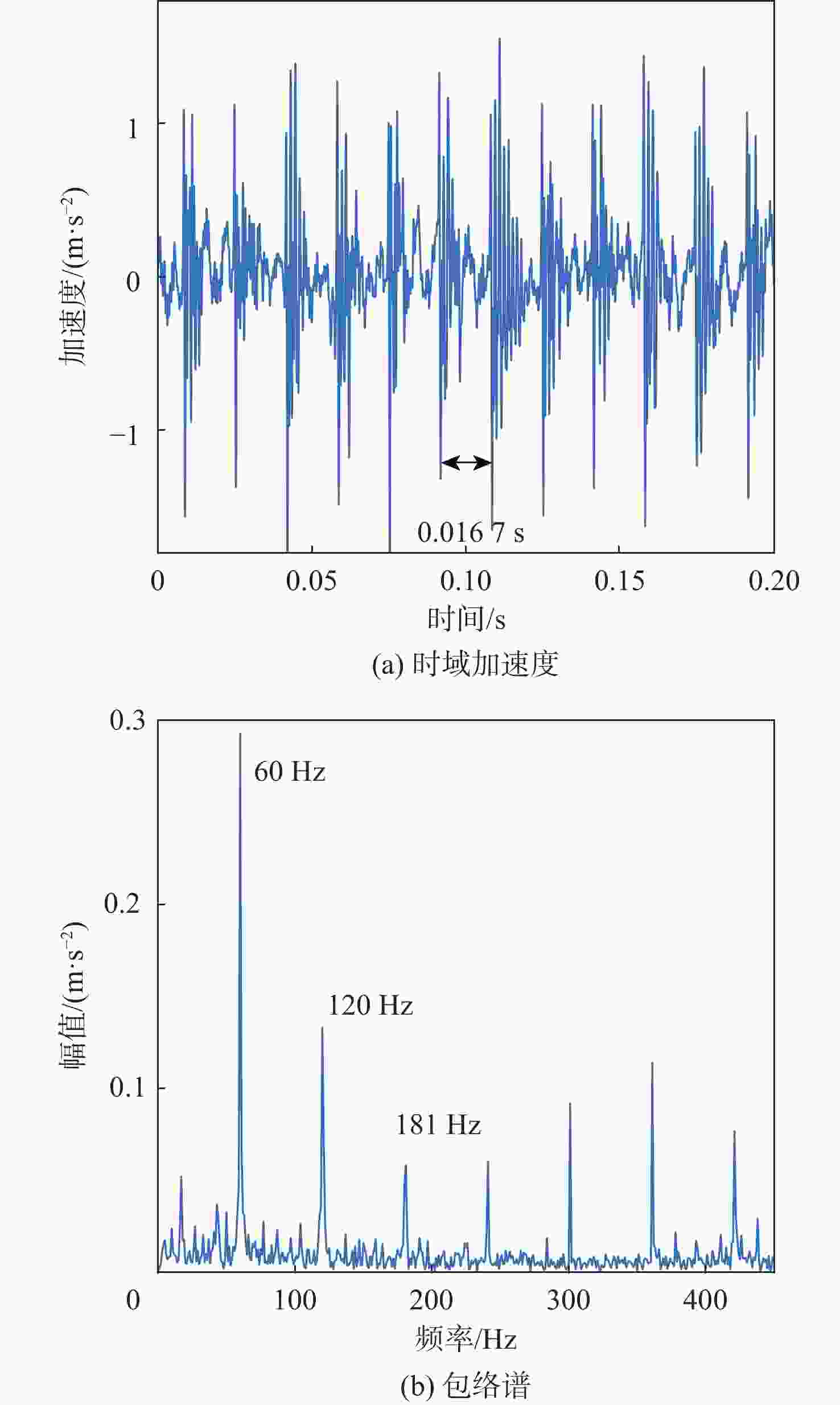

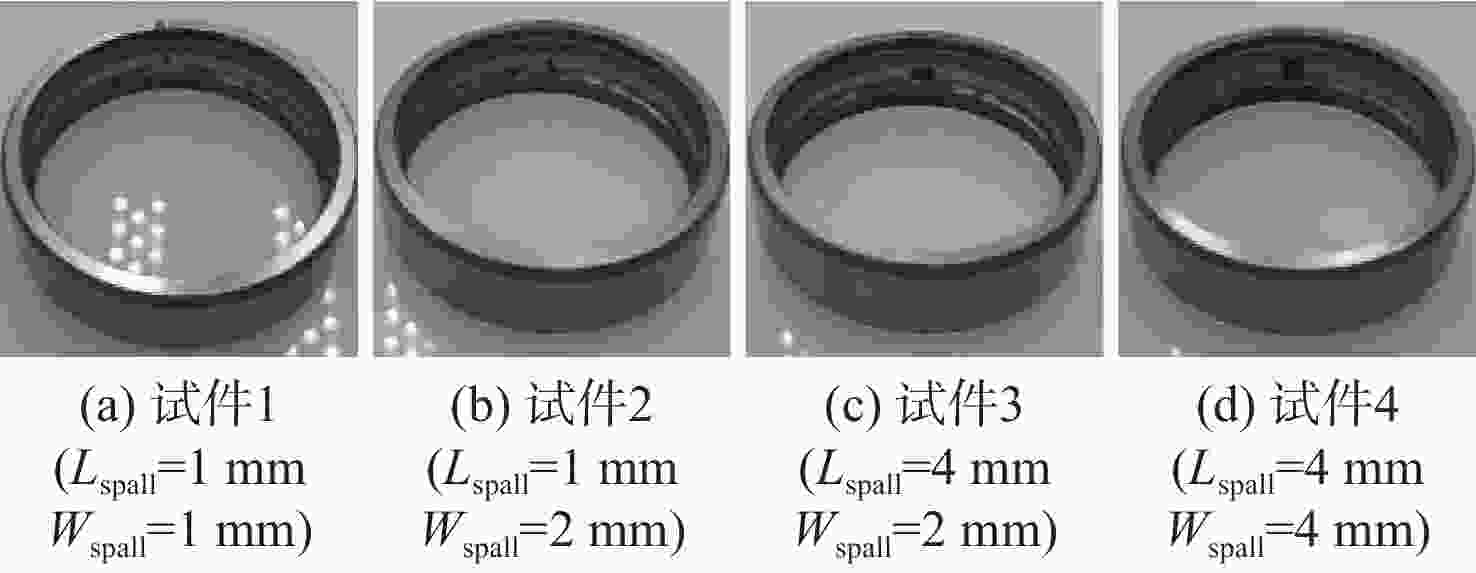

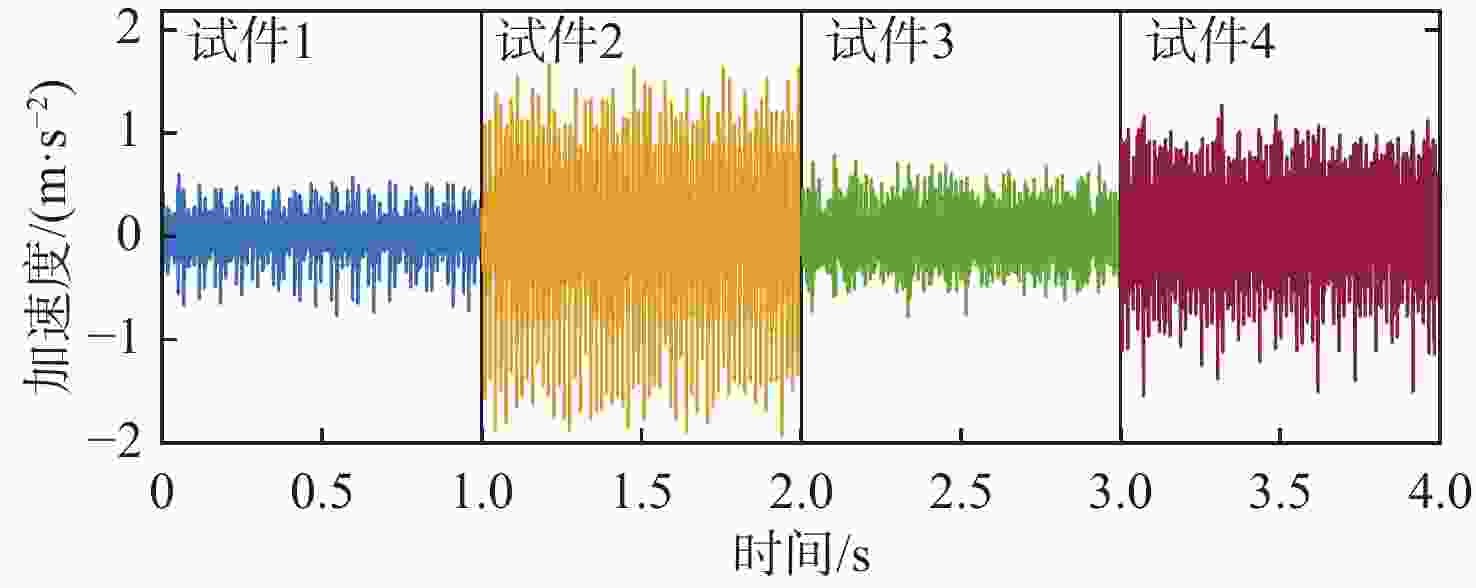

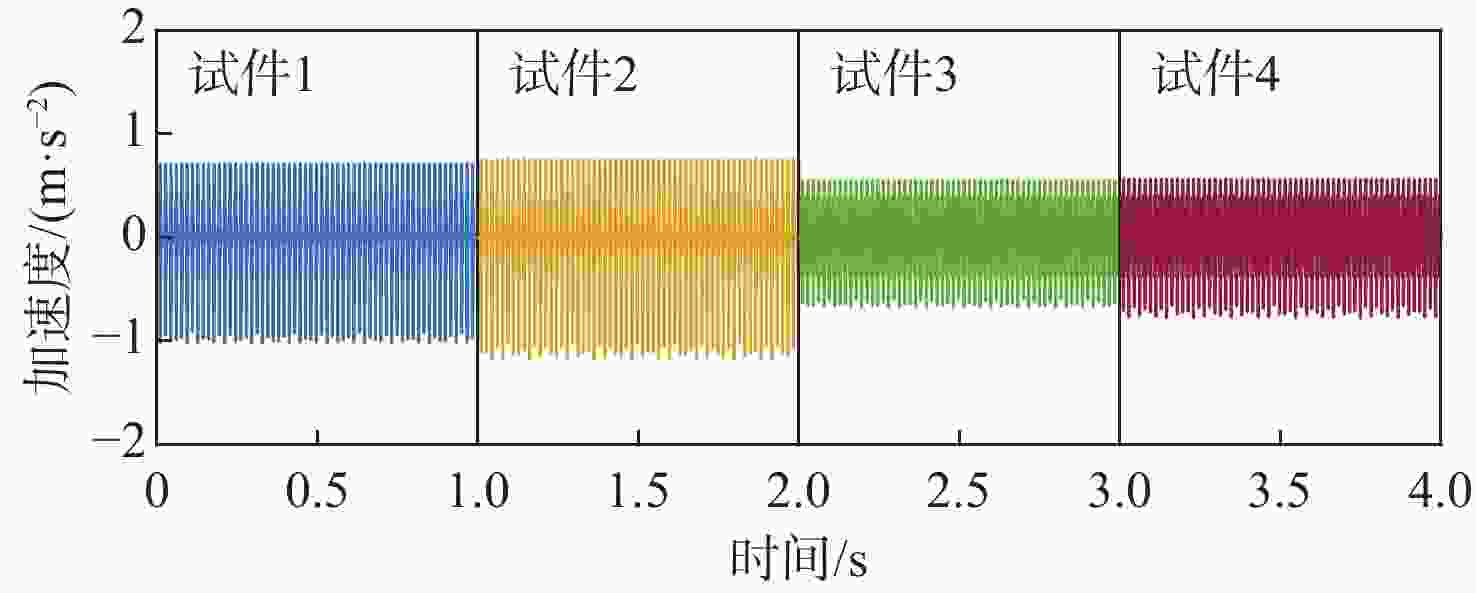

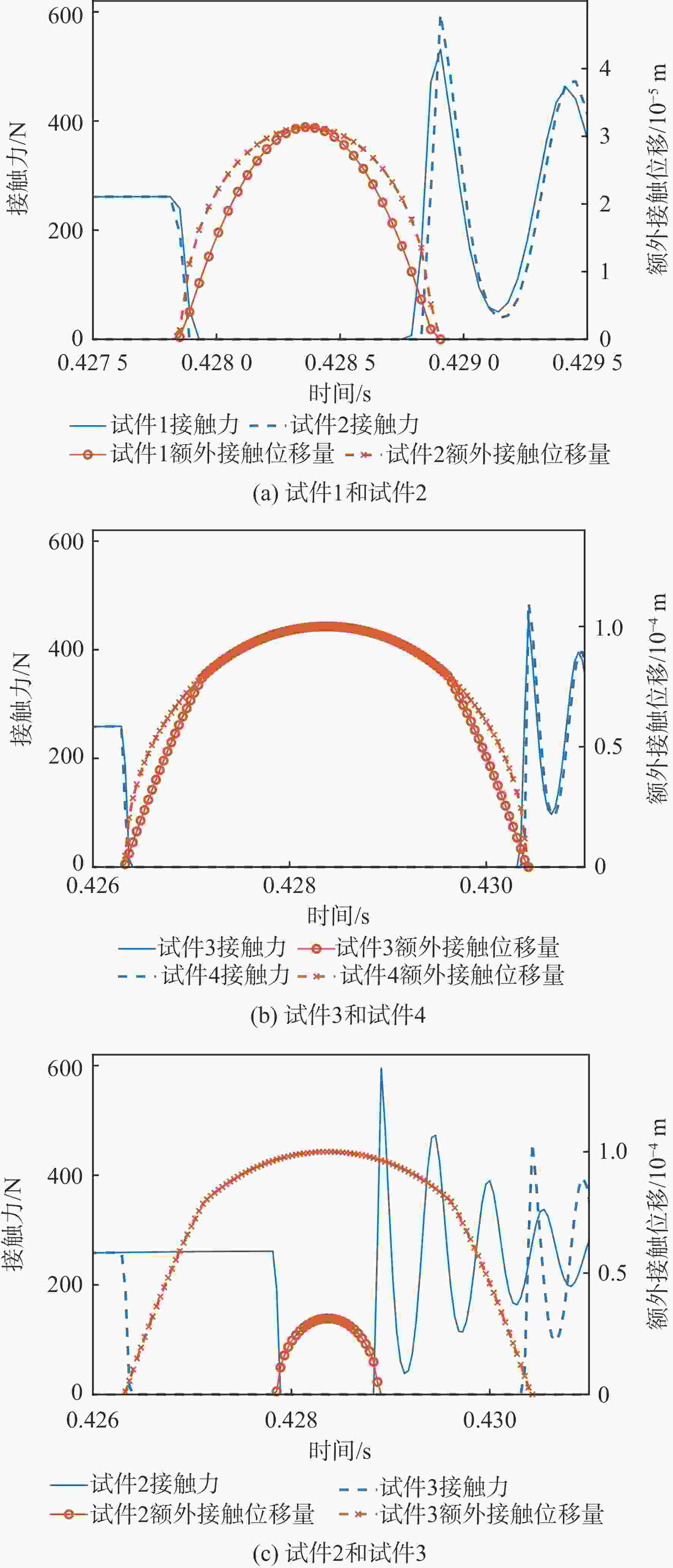

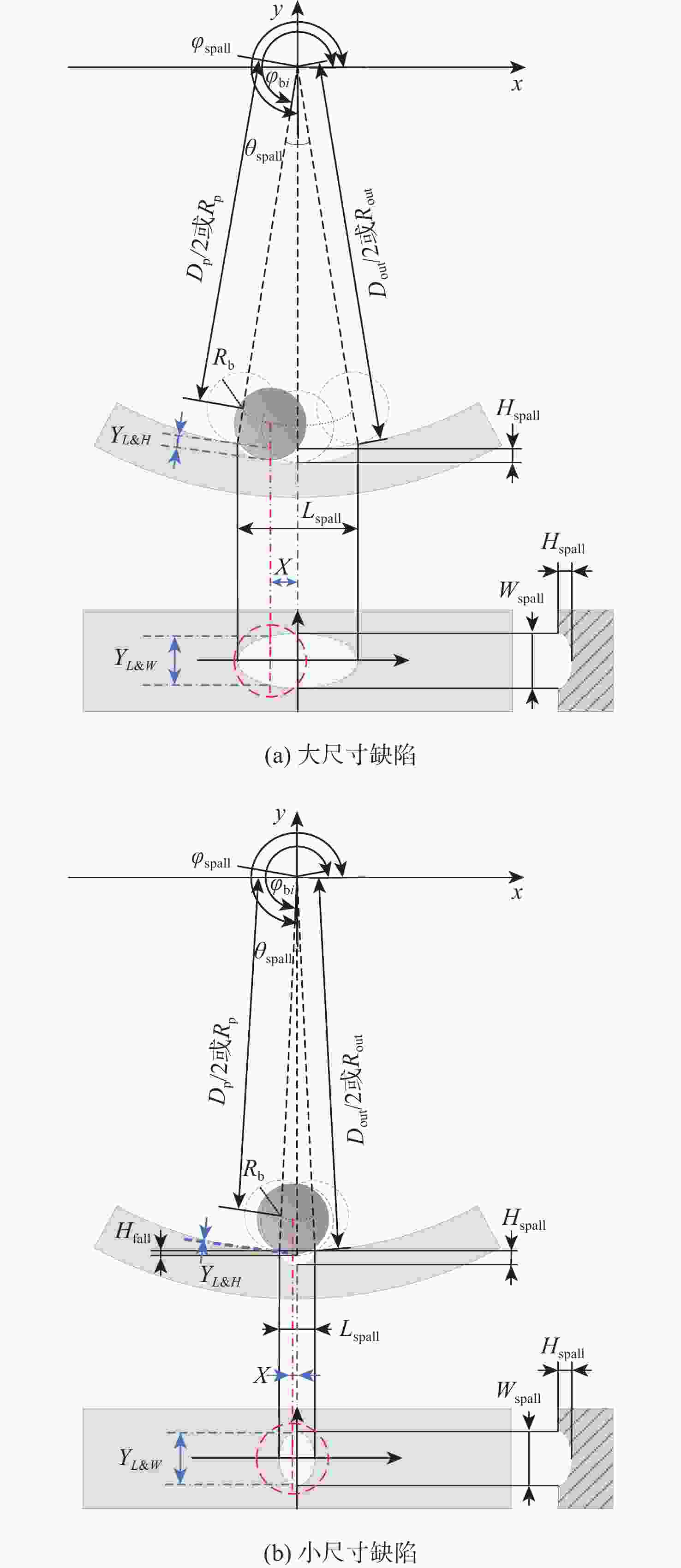

为了深入分析轴承滚道剥落缺陷引发冲击性振动响应的机理,动力学模型的构建成为必要且有效的手段。针对现有轴承动力学模型中的缺陷激励函数难以准确刻画实际剥落缺陷的问题,提出一种考虑缺陷三维尺寸的激励函数来构建含滚道剥落缺陷的轴承动力学模型。以椭圆形状模拟缺陷三维形貌,在此基础上构建缺陷激励函数,并将其融入动力学模型。分析滚动体通过不同尺寸缺陷过程中产生的额外接触位移量的变化情况。通过仿真和实验验证模型的正确性,并深入探究缺陷尺寸与振动响应间的关系。与矩形激励函数模型对比,证明所提模型的有效性和适用性。实验结果表明:所构建的模型与理论、实测信号误差均在±5%以内;缺陷尺寸的变化将引起额外接触位移的改变,进而使轴承产生不同的振动响应;相比矩形激励函数模型,所提模型可有效模拟滚动轴承在不同尺寸剥落缺陷下的振动响应。相关研究结果可为轴承故障诊断及性能评估提供理论支持。

Abstract:In order to deeply analyze the mechanism of impact vibration response triggered by bearing raceway spalling defects, the construction of dynamic models becomes a necessary and effective means. The dynamic model of a bearing with a raceway spalling defect is constructed by taking into account the three-dimensional size of the defect. This is done in order to address the issue that the defect excitation function in the current bearing dynamic model finds it challenging to accurately describe the actual spalling defect. Firstly, the three-dimensional morphology of the defect is simulated in an elliptical shape. On this basis, the defect excitation function is constructed and integrated into the dynamic model. Secondly, the variation of the additional contact displacement generated during the passage of the rolling element through the defects of different sizes is analyzed. Then, the correctness of the model is verified by simulation and actual experiments, and the relationship between defect size and vibration response is investigated in depth. Finally, the validity and applicability of the proposed model are demonstrated by comparing it with the rectangular excitation function model. The experimental results show that the error between the model, the theory and the measured signal is within ±5%. The change in defect size will cause the change of additional contact displacement, which will lead to a different vibration response of the bearing. The suggested model is capable of accurately simulating the vibration response of rolling bearings with varying sizes of spalling flaws as compared to the rectangular excitation function model. The relevant research results can provide theoretical support for bearing fault diagnosis and performance evaluation.

-

Key words:

- rolling bearings /

- raceway spalling /

- defect size /

- dynamic modeling /

- vibration response analysis

-

表 1 轴承几何参数

Table 1. Geometric parameter of bearing

参数 数值 内滚道直径Din/mm 47.0 外滚道直径Dout/mm 31.0 节圆直径Dp/mm 39.0 滚动体直径Db/mm 8 滚动体个数Nball 9 接触角α/(°) 0 表 2 动力学模型参数

Table 2. Parameters of dynamic model

参数 数值 内圈及转轴质量ms/kg 1.2 单元谐振器质量mr/kg 1 外圈及底座刚度kp/(N·m−1) 15.1056 ×106内圈及转轴阻尼cs/(N·s·m−1) 2376.8 单元谐振器阻尼cr/(N·s·m−1) 9424.8 外圈及底座质量mp/kg 7.2 内圈及转轴刚度ks/(N·m−1) 4.241×104 单元谐振器刚度kr/(N·m−1) 8.8826 ×109外圈及底座阻尼cp/(N·s·m−1) 2210.7 等效接触刚度Kb/(N·m−1.5) 1.8978 ×1010表 3 双冲击定量评估结果

Table 3. Quantitative evaluation results based on dual-impulse

编号 1 mm缺陷

评估值/mm4 mm缺陷

评估值/mm评估值与实际

误差(1 mm)/%评估值与实际

误差(4 mm) /%模型与评估值

误差(1 mm) /%模型与评估值

误差(4 mm) /%1 0.88 4.01 −12.00 0.25 17.05 1.75 2 1.03 3.85 3.00 −3.75 0 5.97 3 1.03 3.89 3.00 −2.75 0 4.88 4 1.07 3.97 7.00 −0.75 −3.74 2.77 5 0.95 3.82 −5.00 −4.50 8.42 6.81 6 0.95 4.20 −5.00 5.00 8.42 −2.86 7 0.99 3.82 −1.00 −4.50 4.04 6.81 8 0.92 3.86 −8.00 −3.50 11.96 5.70 9 0.96 4.01 −4.00 0.25 7.29 1.75 10 1.07 4.01 7.00 0.25 −3.74 1.75 注:1 mm缺陷评估值、4 mm缺陷评估值、评估值与实际误差(1 mm)、评估值与实际误差(4 mm) 、模型与评估值误差(1 mm)和模型与评估值误差(4 mm)的平均值分别为0.985 mm、3.944 mm、-1.50%、-1.40%、4.97%和3.53%。 -

[1] 王凡, 马军, 王晓东, 等. 一种改进的TVD电机轴承故障特征提取方法[J]. 振动与冲击, 2023, 42(10): 203-214.WANG F, MA J, WANG X D, et al. An improved TVD fault feature extraction method for motor bearing[J]. Journal of Vibration and Shock, 2023, 42(10): 203-214(in Chinese). [2] ZHANG H C, BORGHESANI P, RANDALL R B, et al. A benchmark of measurement approaches to track the natural evolution of spall severity in rolling element bearings[J]. Mechanical Systems and Signal Processing, 2022, 166: 108466. doi: 10.1016/j.ymssp.2021.108466 [3] EPPS I K. An investigation into vibrations excited by discrete faults in rolling element bearings[D]. Christchurch: University of Canterbury, 1991. [4] SAWALHI N, RANDALL R B. Simulating gear and bearing interactions in the presence of faults Part I. The combined gear bearing dynamic model and the simulation of localised bearing faults[J]. Mechanical Systems and Signal Processing, 2008, 22(8): 1924-1951. doi: 10.1016/j.ymssp.2007.12.001 [5] 胡爱军, 许莎, 向玲, 等. 滚动轴承外圈多点故障特征分析[J]. 机械工程学报, 2020, 56(21): 110-120. doi: 10.3901/JME.2020.21.110HU A J, XU S, XIANG L, et al. Characteristic analysis of multi-point faults on the outer race of rolling element bearing[J]. Journal of Mechanical Engineering, 2020, 56(21): 110-120(in Chinese). doi: 10.3901/JME.2020.21.110 [6] CUI L L, WANG X, WANG H Q, et al. Remaining useful life prediction of rolling element bearings based on simulated performance degradation dictionary[J]. Mechanism and Machine Theory, 2020, 153: 103967. doi: 10.1016/j.mechmachtheory.2020.103967 [7] 张耀强, 陈建军, 唐六丁, 等. 考虑外圈局部缺陷的滚动轴承非线性动力特性[J]. 航空学报, 2009, 30(4): 751-756. doi: 10.3321/j.issn:1000-6893.2009.04.028ZHANG Y Q, CHEN J J, TANG L D, et al. Nonlinear dynamic characteristics of rolling element bearing with localized defect on outer ring[J]. Acta Aeronautica et Astronautica Sinica, 2009, 30(4): 751-756(in Chinese). doi: 10.3321/j.issn:1000-6893.2009.04.028 [8] WU R Q, WANG X F, NI Z X, et al. Dual-impulse behavior analysis and quantitative diagnosis of the raceway fault of rolling bearing[J]. Mechanical Systems and Signal Processing, 2022, 169: 108734. doi: 10.1016/j.ymssp.2021.108734 [9] ZHANG F L, ZHANG Y W, GUAN J Y, et al. Fault dynamic modeling and characteristic parameter simulation of rolling bearing with inner ring local defects[J]. Shock and Vibration, 2021: 5077366. [10] 胡爱军, 吉新星, 向玲, 等. 滚动轴承非线性时变参数动力学模型与故障机理研究[J]. 机械工程学报, 2022, 58(19): 139-147. doi: 10.3901/JME.2022.19.139HU A J, JI X X, XIANG L, et al. Nonlinear time-varying parameter dynamic model of rolling bearing and failure mechanism research[J]. Journal of Mechanical Engineering, 2022, 58(19): 139-147(in Chinese). doi: 10.3901/JME.2022.19.139 [11] 常斌全, 剡昌锋, 苑浩, 等. 多事件激励的滚动轴承动力学建模[J]. 振动与冲击, 2018, 37(17): 16-24.CHANG B Q, YAN C F, YUAN H, et al. Dynamic modeling for rolling bearings under multi-event excitation[J]. Journal of Vibration and Shock, 2018, 37(17): 16-24(in Chinese). [12] 李志农, 李云龙, 任帅, 等. 局部点蚀故障滚动体的滚动轴承动力学模型研究[J]. 振动工程学报, 2020, 33(3): 597-603.LI Z N, LI Y L, REN S, et al. Research on dynamic model of rolling bearing with local pitting fault in rolling bearing element[J]. Journal of Vibration Engineering, 2020, 33(3): 597-603(in Chinese). [13] 李昊泽, 贺雅, 冯坤, 等. 考虑时变激励的滚动轴承局部故障动力学建模[J]. 航空学报, 2022, 43(8): 625176. doi: 10.7527/j.issn.1000-6893.2022.8.hkxb202208007LI H Z, HE Y, FENG K, et al. Dynamic modeling of rolling bearing local fault considering time-varying excitation[J]. Acta Aeronautica et Astronautica Sinica, 2022, 43(8): 625176(in Chinese). doi: 10.7527/j.issn.1000-6893.2022.8.hkxb202208007 [14] SAWALHI N, RANDALL R B. Simulating gear and bearing interactions in the presence of faults. Part Ⅱ: Simulation of the vibrations produced by extended bearing faults[J]. Mechanical Systems and Signal Processing, 2008, 22(8): 1952-1966. doi: 10.1016/j.ymssp.2007.12.002 [15] 王震, 杨正伟, 何浩浩, 等. 非规则轴承故障的动力学建模与仿真[J]. 北京麻豆精品秘 国产传媒学报, 2021, 47(8): 1580-1593.WANG Z, YANG Z W, HE H H, et al. Dynamic modeling and simulation of irregular bearing failure[J]. Journal of Beijing University of Aeronautics and Astronautics, 2021, 47(8): 1580-1593(in Chinese). [16] 雷春丽, 宋瑞哲, 樊高峰, 等. 含局部缺陷的角接触球轴承时变位移激励及动力学建模[J]. 北京麻豆精品秘 国产传媒学报, 2025, 51(3): 753-762.LEI C L, SONG R Z, FAN G F, et al. Study on time-varying displacement excitation and dynamic modeling of local defects in angular contact ball bearings[J]. Journal of Beijing University of Aeronautics and Astronautics, 2025, 51(3): 753-762(in Chinese). [17] 吴兴国. 数模联合驱动的全寿命滚动轴承数字孪生模型研究[D]. 重庆: 重庆大学, 2022: 12-22.WU X G. Research on digital twin model of full-life rolling bearing driven by digital-analog combination[D]. Chongqing: Chongqing University, 2022: 12-22(in Chinese). [18] 罗茂林, 郭瑜, 伍星. 考虑冲击力的球轴承外圈剥落缺陷双冲击现象动力学建模[J]. 振动与冲击, 2019, 38(14): 48-54.LUO M L, GUO Y, WU X. Dynamic modeling of the dual-impulse behavior produced by a spall on the outer race of a ball bearing considering impact forces[J]. Journal of Vibration and Shock, 2019, 38(14): 48-54(in Chinese). [19] 丁东升, 刘永强, 杨绍普. 外圈滚道剥离故障对滚动轴承动力学响应的影响分析[J]. 振动与冲击, 2022, 41(8): 141-148.DING D S, LIU Y Q, YANG S P. Analysis of the influence of outer ring raceway peeling fault on the dynamic response of a rolling bearing[J]. Journal of Vibration and Shock, 2022, 41(8): 141-148(in Chinese). [20] SAWALHI N, RANDALL R B. Vibration response of spalled rolling element bearings: observations, simulations and signal processing techniques to track the spall size[J]. Mechanical Systems and Signal Processing, 2011, 25(3): 846-870. doi: 10.1016/j.ymssp.2010.09.009 [21] HARRIS T A, KOTZALAS M N. Rolling bearing analysis: advanced concepts of bearing technology[M]. 5th ed. New York: Taylor and Francis, 2007: 1-7. [22] LIU L B, LIANG X H, ZUO M J. Vibration signal modeling of a planetary gear set with transmission path effect analysis[J]. Measurement, 2016, 85: 20-31. doi: 10.1016/j.measurement.2016.02.006 [23] 雷春丽, 宋瑞哲, 樊高峰, 等. 考虑冲击激励的局部缺陷角接触球轴承振动特性[J]. 航空动力学报, 2025, 40(2): 208-218.LEI C L, SONG R Z, FAN G F, et al. Vibration characteristics of angular contact ball bearing with local defect considering impact excitation[J]. Journal of Aerospace Power, 2025, 40(2): 208-218(in Chinese). [24] LI X, MA J, WANG X D, et al. An improved local mean decomposition method based on improved composite interpolation envelope and its application in bearing fault feature extraction[J]. ISA Transactions, 2020, 97: 365-383. doi: 10.1016/j.isatra.2019.07.027 [25] CUI L L, ZHANG Y, ZHANG F B, et al. Vibration response mechanism of faulty outer race rolling element bearings for quantitative analysis[J]. Journal of Sound and Vibration, 2016, 364: 67-76. doi: 10.1016/j.jsv.2015.10.015 -

下载:

下载: