-

摘要:

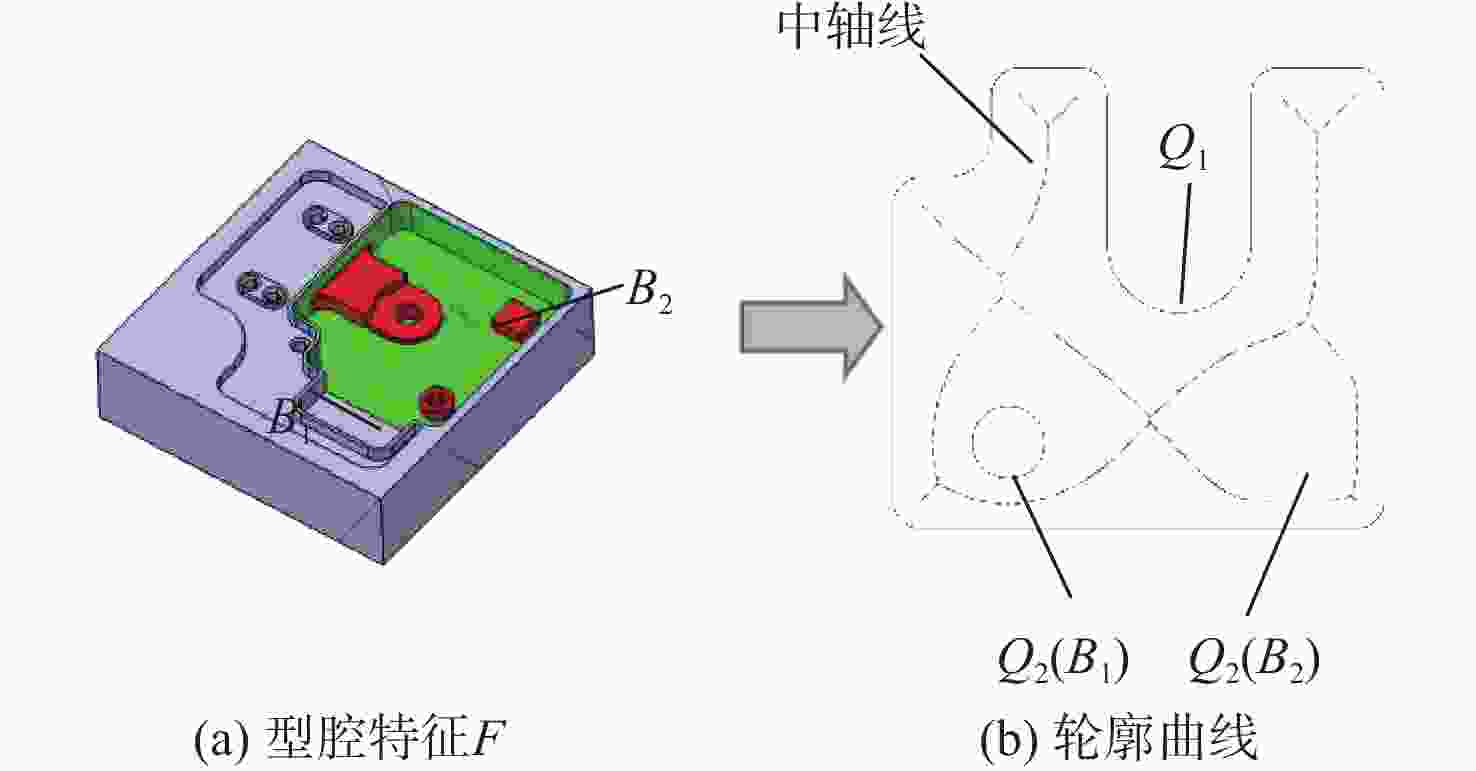

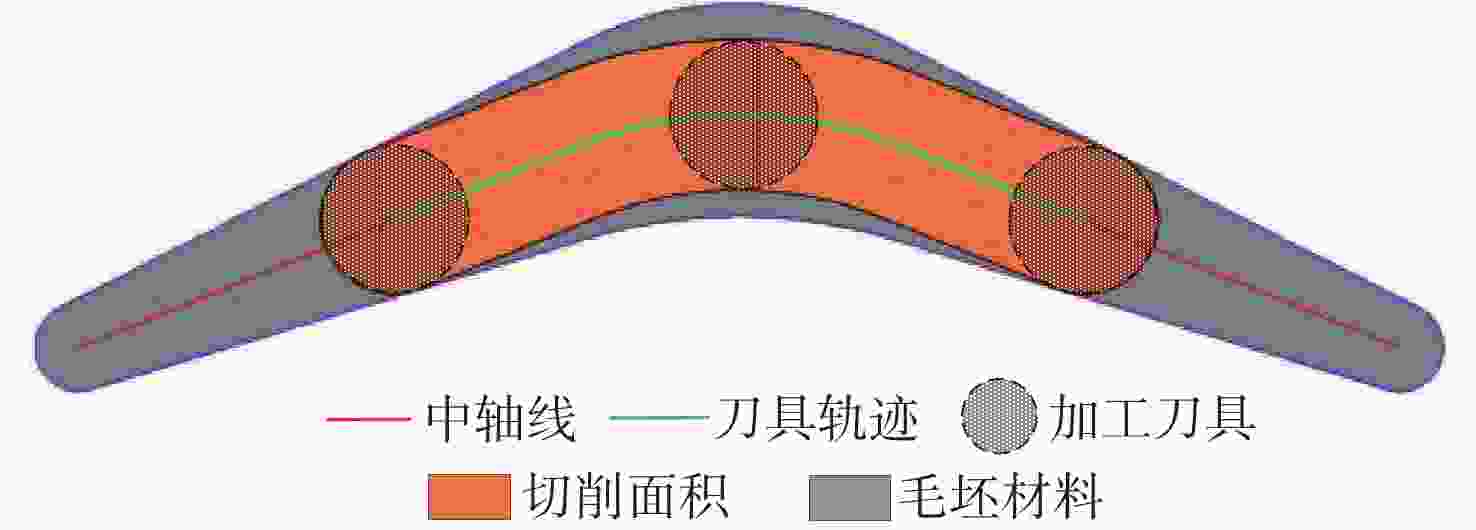

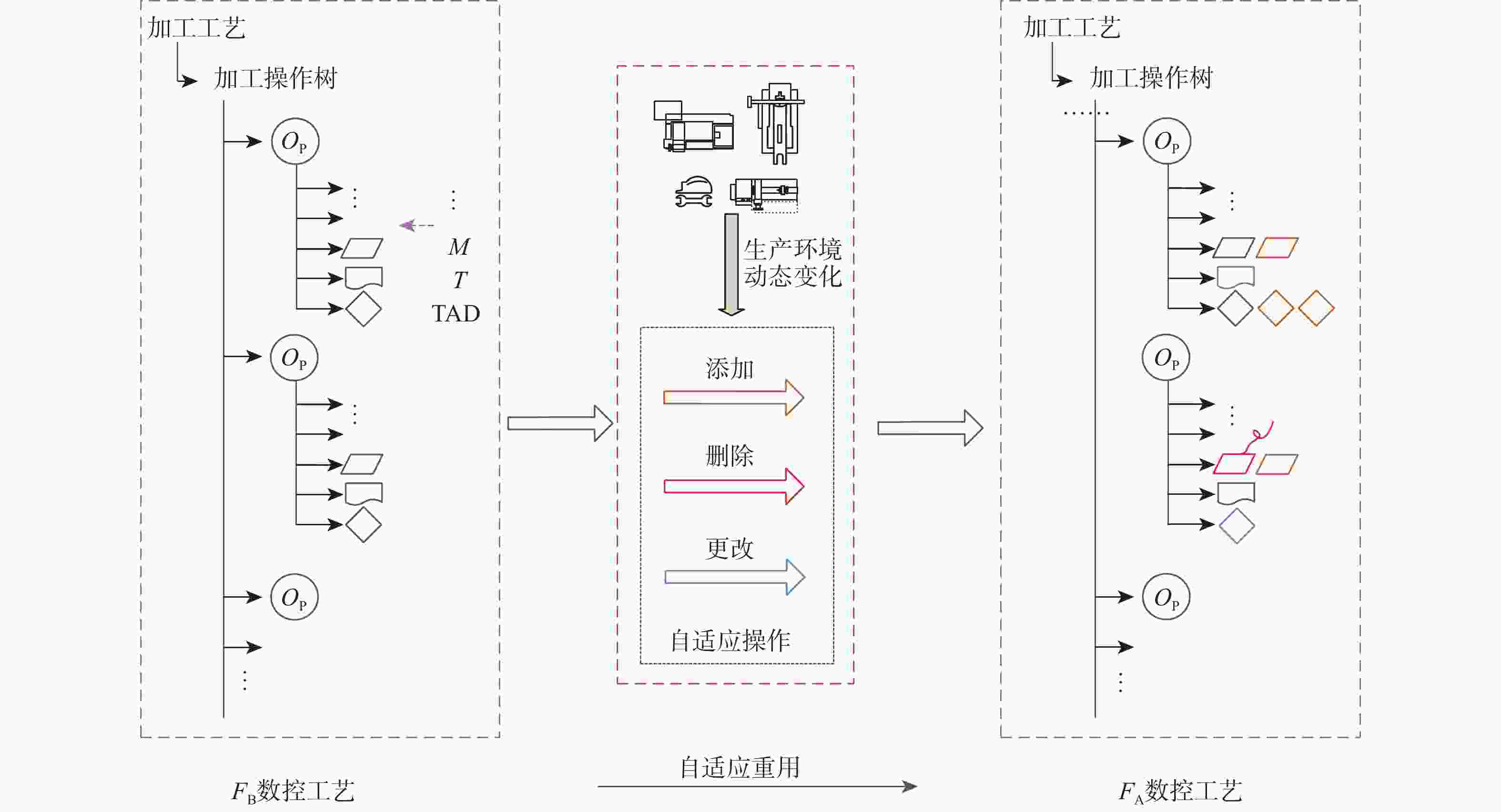

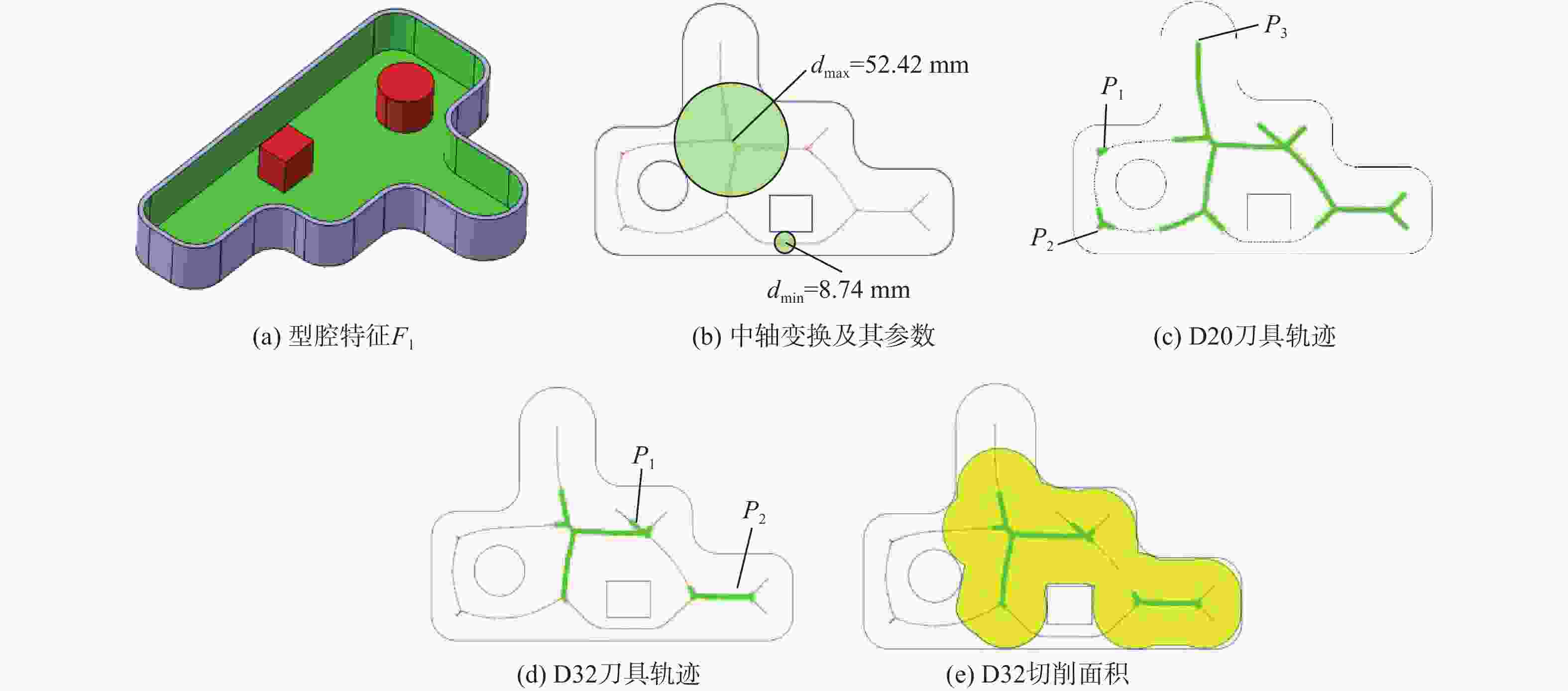

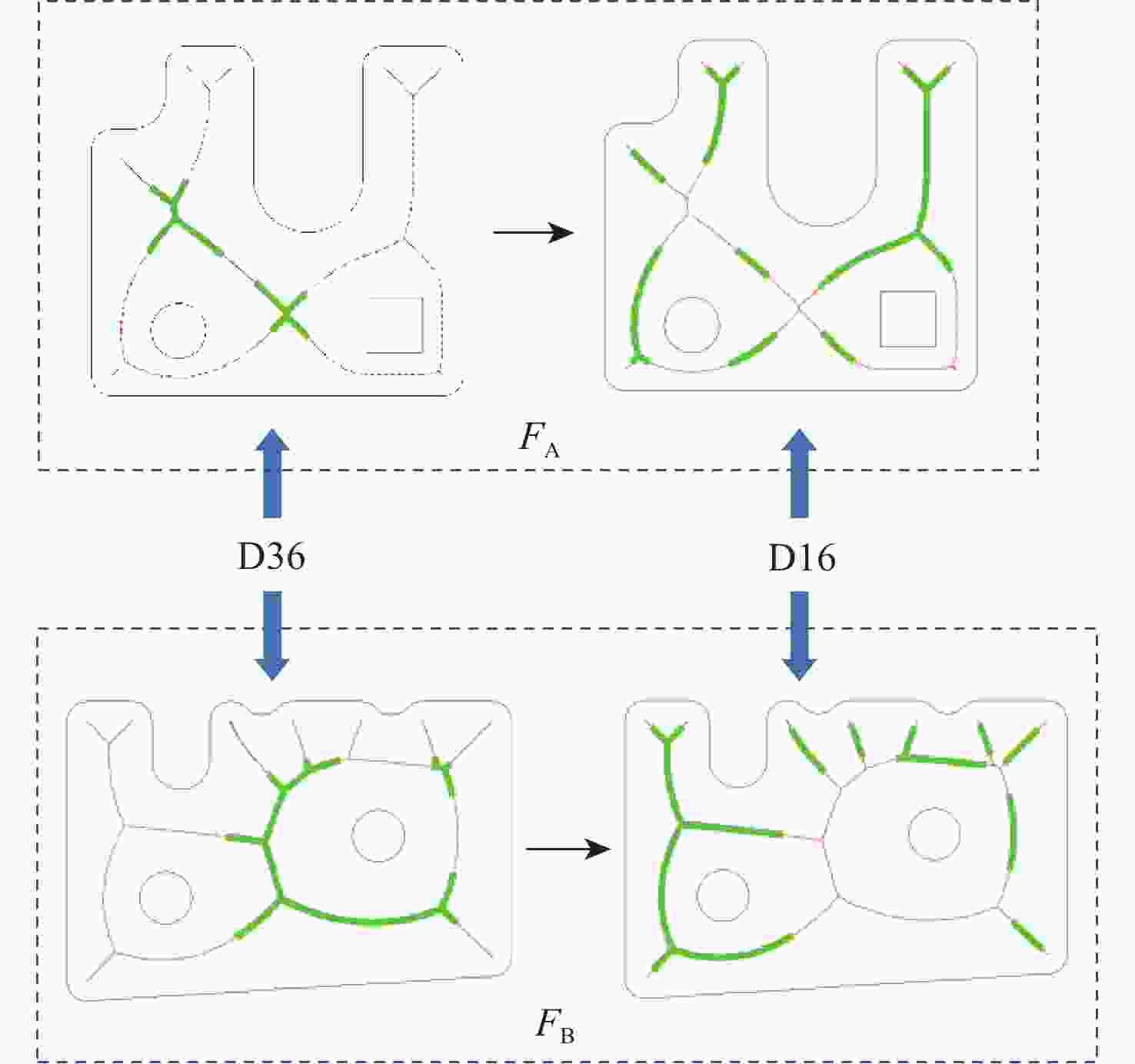

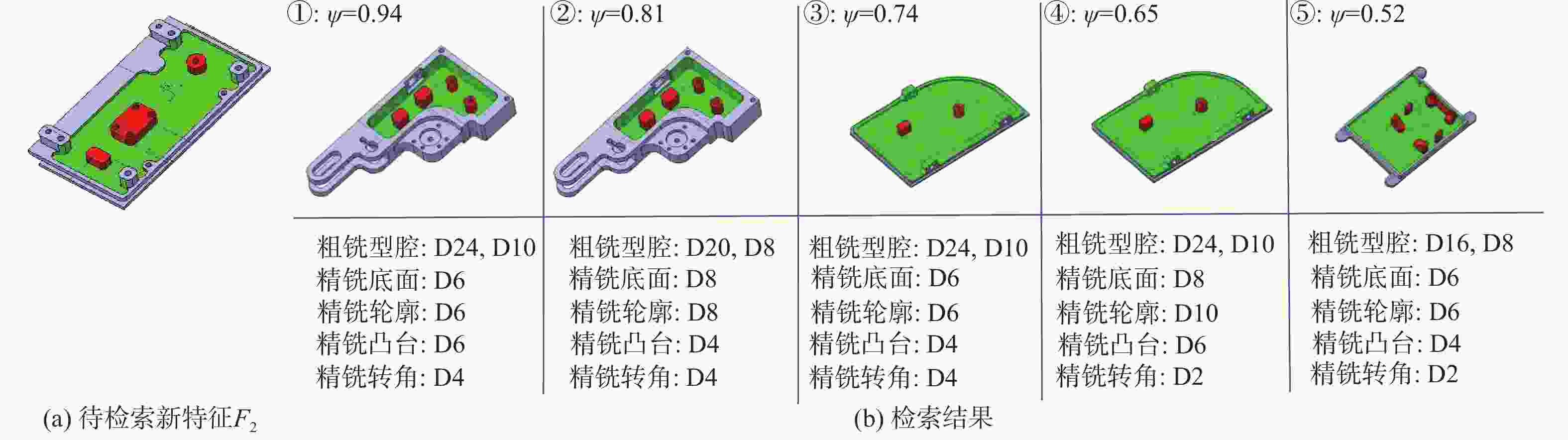

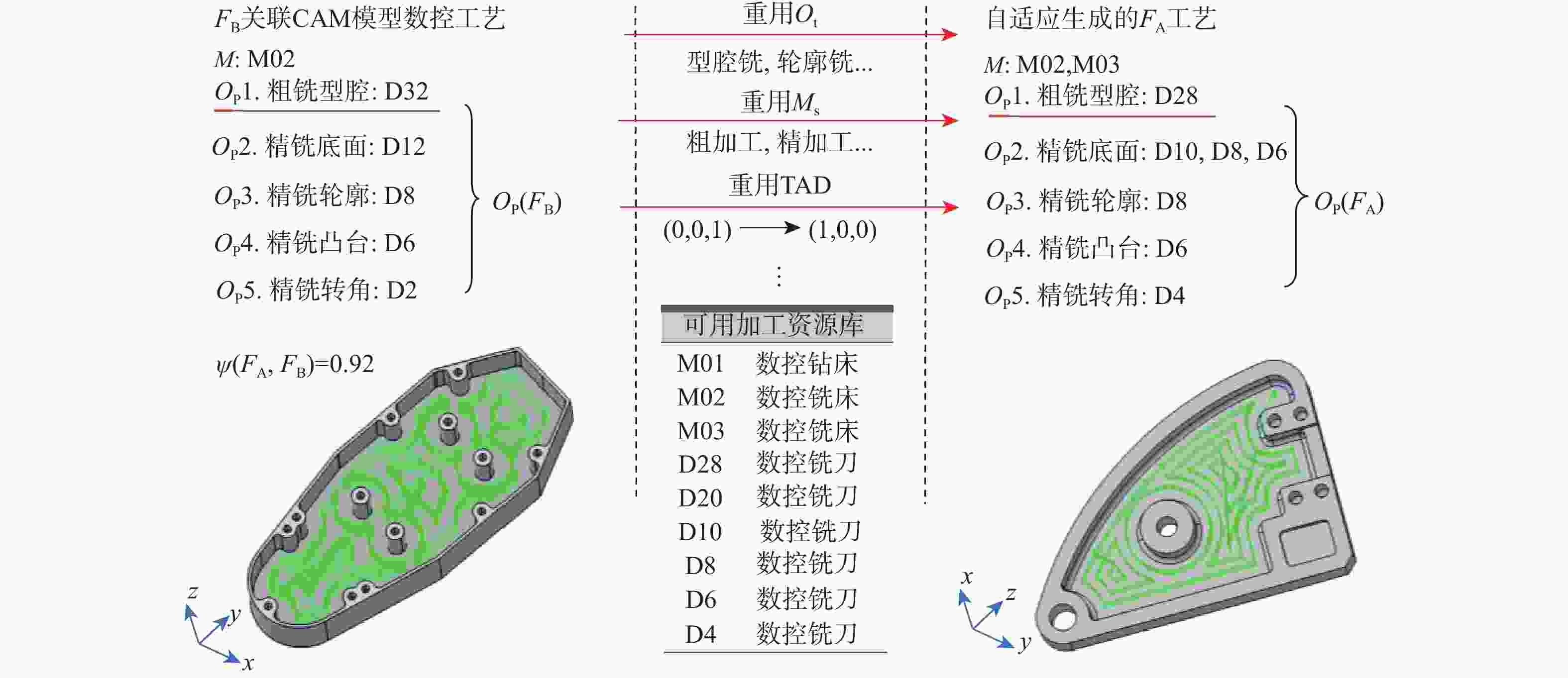

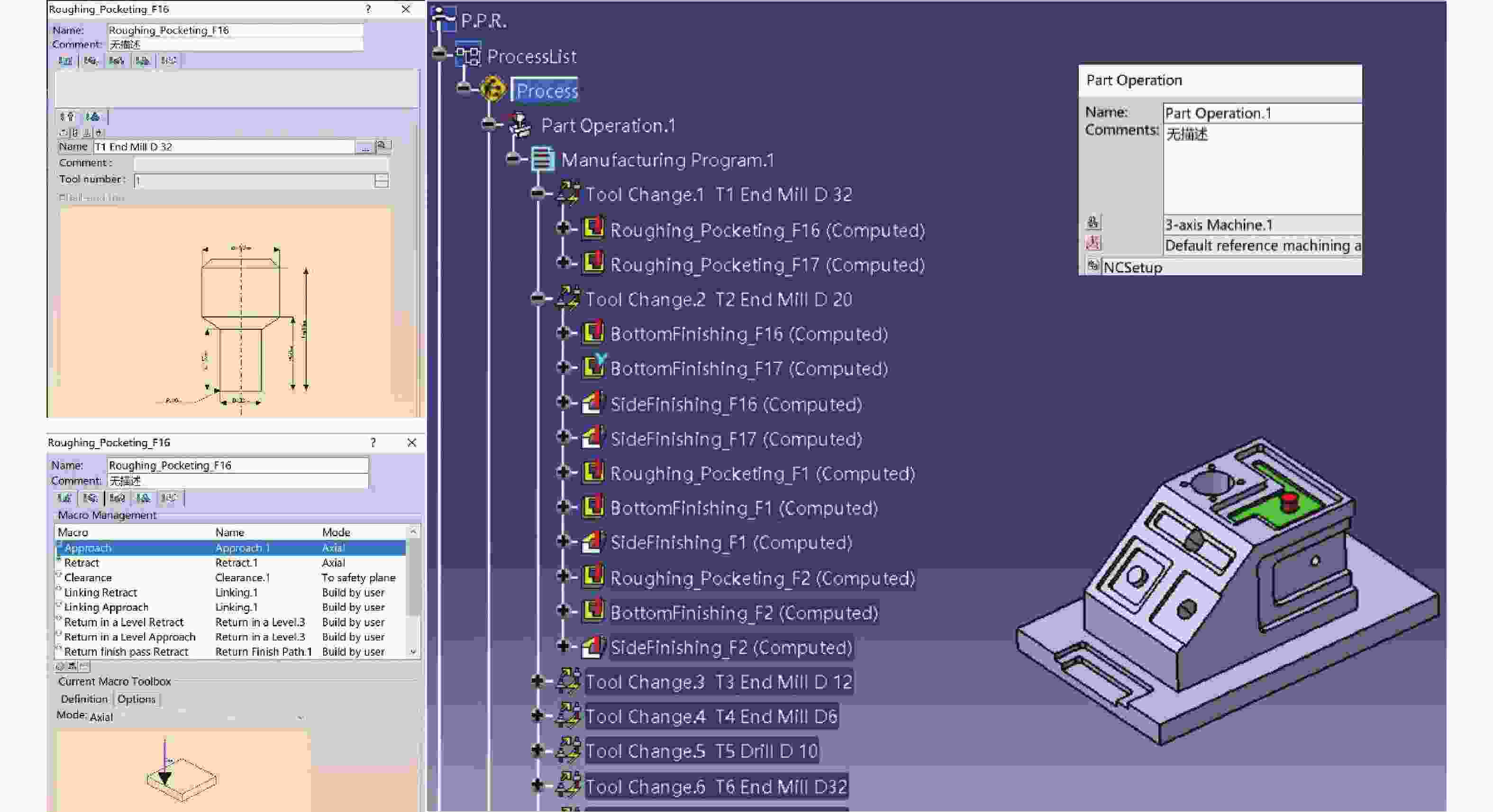

为实现对已有数控(NC)工艺设计成果的有效重用,提出一种计算机辅助设计/计算机辅助制造(CAD/CAM)模型驱动的型腔特征自适应数控工艺设计方法。基于中轴变换(MAT)提取型腔特征三维CAD模型中隐藏的高层次数控工艺信息,有效表征刀具切削过程;针对已有特征实例进行可重用性分析,构建一个融合多属性数控工艺要素的特征相似性评价模型;基于检索返回的相似特征实例,自适应重用其关联的CAM模型工艺参数生成新特征的数控工艺。实验结果表明:所提方法能够自动、高效地获得特征数控工艺,提升工艺设计效率85%以上,满足企业工艺设计智能化的工程需求。

Abstract:To realize the effective reuse of existing numerical control (NC) process, an adaptive NC processes planning approach for pocket features driven by computer aided design/computer aided manufacturing (CAD/CAM) models was presented. Firstly, using the medial axis transform (MAT), the deeper NC process information concealed in 3D CAD models was recovered to explain the tool cutting process. Finally, based on the returned similar feature case through retrieval, the corresponding process parameters of the associated CAM model were reused adaptively to generate the NC process for the query feature. According to experimental results, the proposed method could automatically and effectively get the NC process for features and boost the NC process planning's efficiency by over 85%, satisfying the requirements of intelligent NC process planning for entertainment.

-

Key words:

- numerical control process /

- reuse /

- pocket features /

- adaptive /

- similarity

-

表 1 可重用性分析因素

Table 1. Elements of reusability analysis

因素 内容 可重用要求 材料Material GGr15、45钢··· Material (FA) =Material (FB) 特征类型Feature 型腔、孔、凸台··· Feature (FA)= Feature (FB) 毛坯类型Blank 铸件、锻件、机加件··· Blank (FA)= Blank (FB) 精度要求 尺寸公差等级IT、

表面粗糙度RaIT(FB)≤IT(FA)∧

Ra(FB)≤Ra(FA)刀具要求 粗加工刀具序列、

候选刀具集TR(FB)$ \subseteq $FACTS 表 2 多属性数控工艺要素及其内涵

Table 2. Multi-attribute factors of NC process

信息层次 工艺要素 工艺相似性内涵 高层次 刀具轨迹 刀具切削运动 退刀次数 加工连续性 切削面积 材料去除量 低层次 精度要求 加工质量 表 3 相似度计算结果

Table 3. Result of similarity calculation

特征 L(D36)/mm L(D16)/mm R(D36) R(D16) S(D36)/mm2 S(D16)/mm2 IT Ra ψ FA 73.45 221.98 2 7 3 938.52 2 742.31 (12,11) 6.3 0.86 (12,11) FB 136.51 323.05 2 8 5 436.13 4 128.95 (13,12) 6.3 (14,12) 注:L(D36),L(D16)为θL=0.76, ωL=0.3时数值;R(D36),R(D16)为θR=0.97, ωR=0.3时数值;S(D36),S(D16)为θA=0.82, ωA=0.3时数值;IT和Ra为θP=0.98, ωP=0.1时数值。 表 4 数控工艺设计效率分析

Table 4. Efficiency analysis of NC process planning

方法 加工操作数量 人工交互次数 编程时间/min 交互式方法 5 ≥120 ≥20 本文方法 0 ≤15 ≤3 -

[1] 邓乐武, 黄玉璐, 王浩然, 等. 基于MBD的飞机测试工艺数字化定义方法[J]. 北京麻豆精品秘 国产传媒学报, 2021, 47(11): 2181-2188.DENG L W, HUANG Y L, WANG H R, et al. Digital definition method of aircraft test process based on MBD[J]. Journal of Beijing University of Aeronautics and Astronautics, 2021, 47(11): 2181-2188(in Chinese). [2] SONG I, HAN S. Implementation of the direct integration from CAM to CAE for the PCB simulation[J]. Computers in Industry, 2013, 64(8): 1014-1021. doi: 10.1016/j.compind.2013.06.014 [3] 黄波, 张树生, 黄瑞, 等. 面向宏观工艺重用的三维CAD模型检索方法[J]. 计算机集成制造系统, 2020, 26(12): 3386-3398.HUANG B, ZHANG S S, HUANG R, et al. Macro process reuse oriented 3D CAD model retrieval method[J]. Computer Integrated Manufacturing Systems, 2020, 26(12): 3386-3398(in Chinese). [4] ZHANG C, ZHOU G H, LU Q, et al. Graph-based knowledge reuse for supporting knowledge-driven decision-making in new product development[J]. International Journal of Production Research, 2017, 55(23): 7187-7203. doi: 10.1080/00207543.2017.1351643 [5] GAO Y, TANG J H, LI H J, et al. View-based 3D model retrieval with probabilistic graph model[J]. Neurocomputing, 2010, 73(10-12): 1900-1905. doi: 10.1016/j.neucom.2009.11.050 [6] HERZOG V, SUWELACK S. Bridging the gap between geometry and user intent: retrieval of CAD models via regions of interest[J]. Computer-Aided Design, 2023, 163: 103573. doi: 10.1016/j.cad.2023.103573 [7] 杜雨佳, 李海生, 姚春莲, 等. 基于三元组网络的单图三维模型检索[J]. 北京麻豆精品秘 国产传媒学报, 2020, 46(9): 1691-1700.DU Y J, LI H S, YAO C L, et al. Monocular image based 3D model retrieval using triplet network[J]. Journal of Beijing University of Aeronautics and Astronautics, 2020, 46(9): 1691-1700(in Chinese). [8] 于勇, 顾黎, 印璞, 等. MBD模型本体建模及检索技术研究与应用[J]. 北京麻豆精品秘 国产传媒学报, 2017, 43(2): 260-269.YU Y, GU L, YIN P, et al. Research and implementation of ontology modeling and retrieval technology of MBD model[J]. Journal of Beijing University of Aeronautics and Astronautics, 2017, 43(2): 260-269(in Chinese). [9] ZHANG R Z, ZHOU X H. Similarity assessment of mechanical parts based on integrated product information model[J]. Journal of Computing and Information Science in Engineering, 2011, 11(1): 1. [10] LI Z, ZHOU X H, LIU W, et al. A similarity-based reuse system for injection mold design in automotive interior industry[J]. The International Journal of Advanced Manufacturing Technology, 2016, 87(5): 1783-1795. [11] LI Z, ZHOU X H, LIU W. A geometric reasoning approach to hierarchical representation for B-rep model retrieval[J]. Computer-Aided Design, 2015, 62: 190-202. doi: 10.1016/j.cad.2014.05.008 [12] HONG T, LEE K, KIM S. Similarity comparison of mechanical parts to reuse existing designs[J]. Computer-Aided Design, 2006, 38(9): 973-984. doi: 10.1016/j.cad.2006.05.004 [13] HOU B K, PENG J H, HE S, et al. A similarity-based approach for the variant design of core-pulling mechanism in injection mold design[J]. The International Journal of Advanced Manufacturing Technology, 2021, 115(1): 329-344. [14] 花豹, 周彬, 顾星海, 等. 基于图神经网络的工艺表格语义相似性度量[J]. 计算机集成制造系统, 2022, 28(12): 3805-3821.HUA B, ZHOU B, GU X H, et al. Semantic similarity measurement of process table based on graph neural network[J]. Computer Integrated Manufacturing Systems, 2022, 28(12): 3805-3821(in Chinese). [15] 杨梦媛, 李迎光, 许可. 基于中轴变换的型腔高速铣削刀具轨迹生成方法[J]. 航空学报, 2021, 42(10): 524979.YANG M Y, LI Y G, XU K. An approach of tool path generation based on medial transformation for high-speed pocketing[J]. Acta Aeronautica et Astronautica Sinica, 2021, 42(10): 524979(in Chinese). [16] HUANG R, JIANG J F, HUANG B, et al. Multilevel structured NC machining process model based on dynamic machining feature for process reuse[J]. The International Journal of Advanced Manufacturing Technology, 2019, 104(5): 2045-2060. [17] ERBER M, ROSNITSCHEK T, HARTMANN C, et al. Geometry-based assurance of directional solidification for complex topology-optimized castings using the medial axis transform[J]. Computer-Aided Design, 2022, 152: 103394. doi: 10.1016/j.cad.2022.103394 [18] CHEN Z C, FU Q. An optimal approach to multiple tool selection and their numerical control path generation for aggressive rough machining of pockets with free-form boundaries[J]. Computer-Aided Design, 2011, 43(6): 651-663. doi: 10.1016/j.cad.2011.01.020 [19] QIAN B, FAN H R, ZHANG J R. Fast calculation algorithm for region recognition and model interference ratio in the STL model based on voxel mapping decoupling[J]. The International Journal of Advanced Manufacturing Technology, 2022, 119(3): 1553-1578. [20] RASOULZADEH S, SENK V, KÖNIGSBERGER M, et al. A novel integrative design framework combining 4D sketching, geometry reconstruction, micromechanics material modelling, and structural analysis[J]. Advanced Engineering Informatics, 2023, 57: 102074. doi: 10.1016/j.aei.2023.102074 [21] BAI J, GAO S M, TANG W H, et al. Design reuse oriented partial retrieval of CAD models[J]. Computer-Aided Design, 2010, 42(12): 1069-1084. doi: 10.1016/j.cad.2010.07.002 [22] BICKEL S, SCHLEICH B, WARTZACK S. A novel shape retrieval method for 3D mechanical components based on object projection, pre-trained deep learning models and autoencoder[J]. Computer-Aided Design, 2023, 154: 103417. doi: 10.1016/j.cad.2022.103417 [23] LUPINETTI K, GIANNINI F, MONTI M, et al. Content-based multi-criteria similarity assessment of CAD assembly models[J]. Computers in Industry, 2019, 112: 103111. doi: 10.1016/j.compind.2019.07.001 [24] LEE H, RYU K. Product and design feature-based similar process retrieval and modeling for mold manufacturing[J]. The International Journal of Advanced Manufacturing Technology, 2021, 115(3): 703-714. doi: 10.1007/s00170-020-06161-5 -

下载:

下载: