Research on oxygen consumption based inerting monolithic catalyst reactor performance

-

摘要:

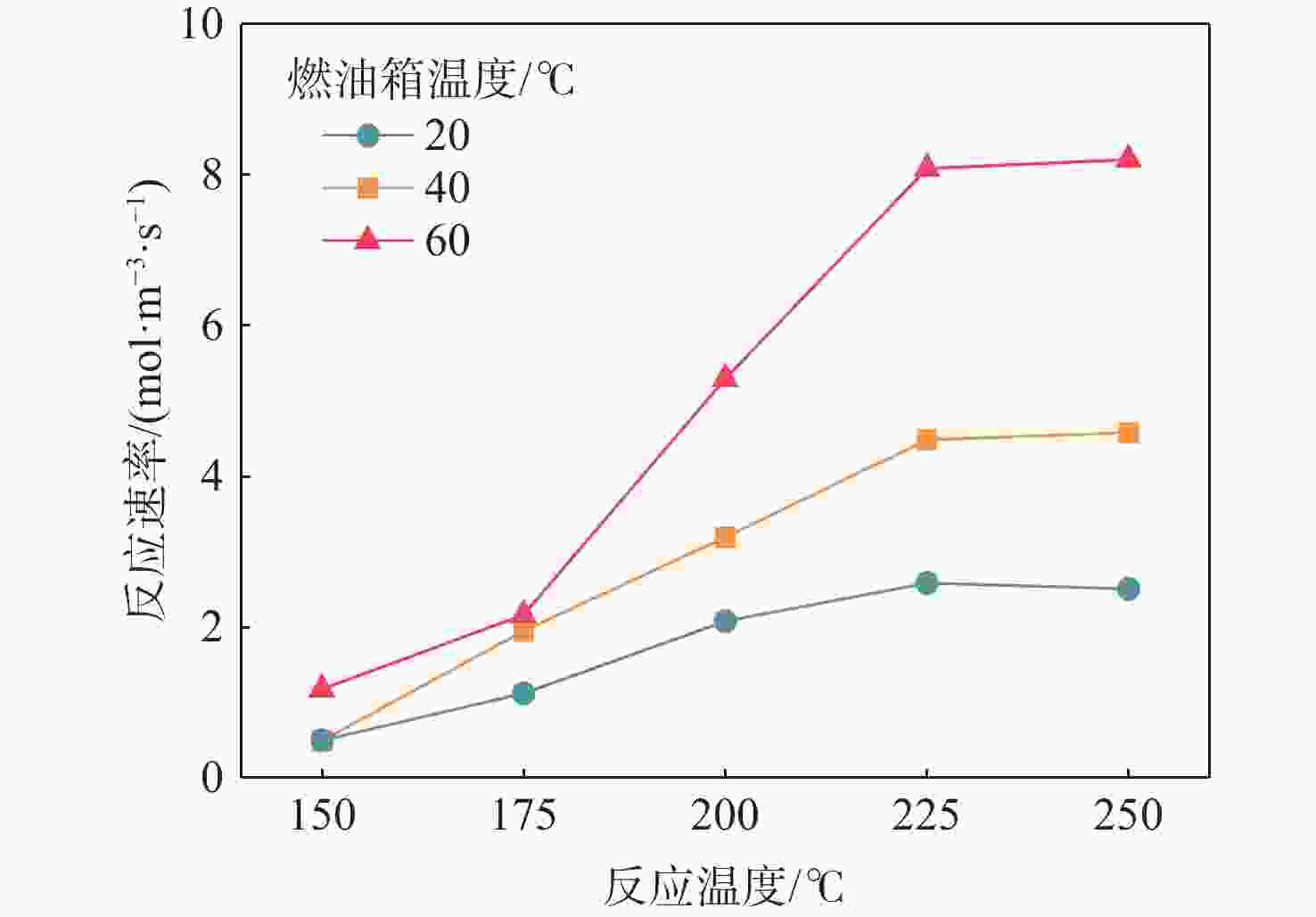

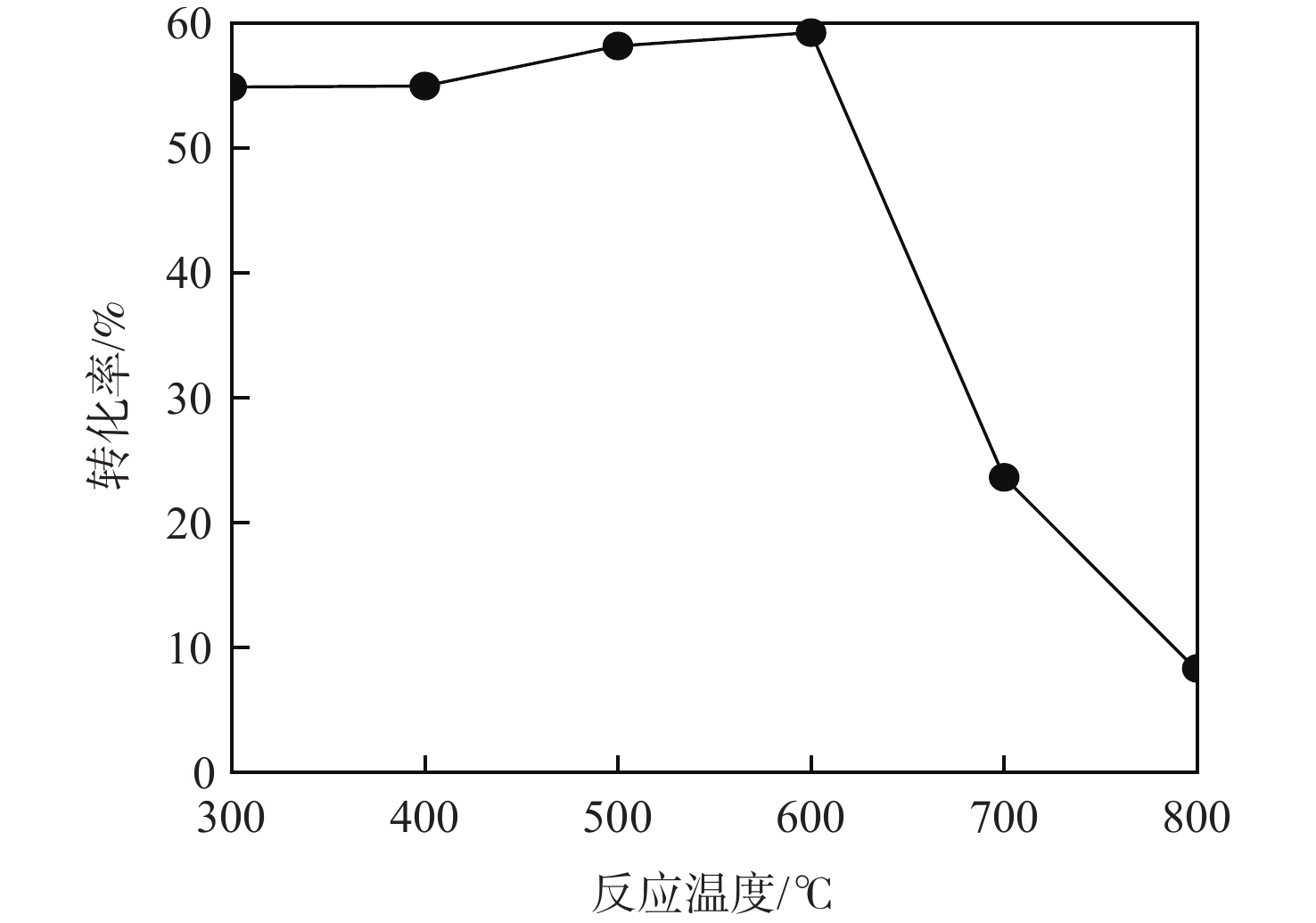

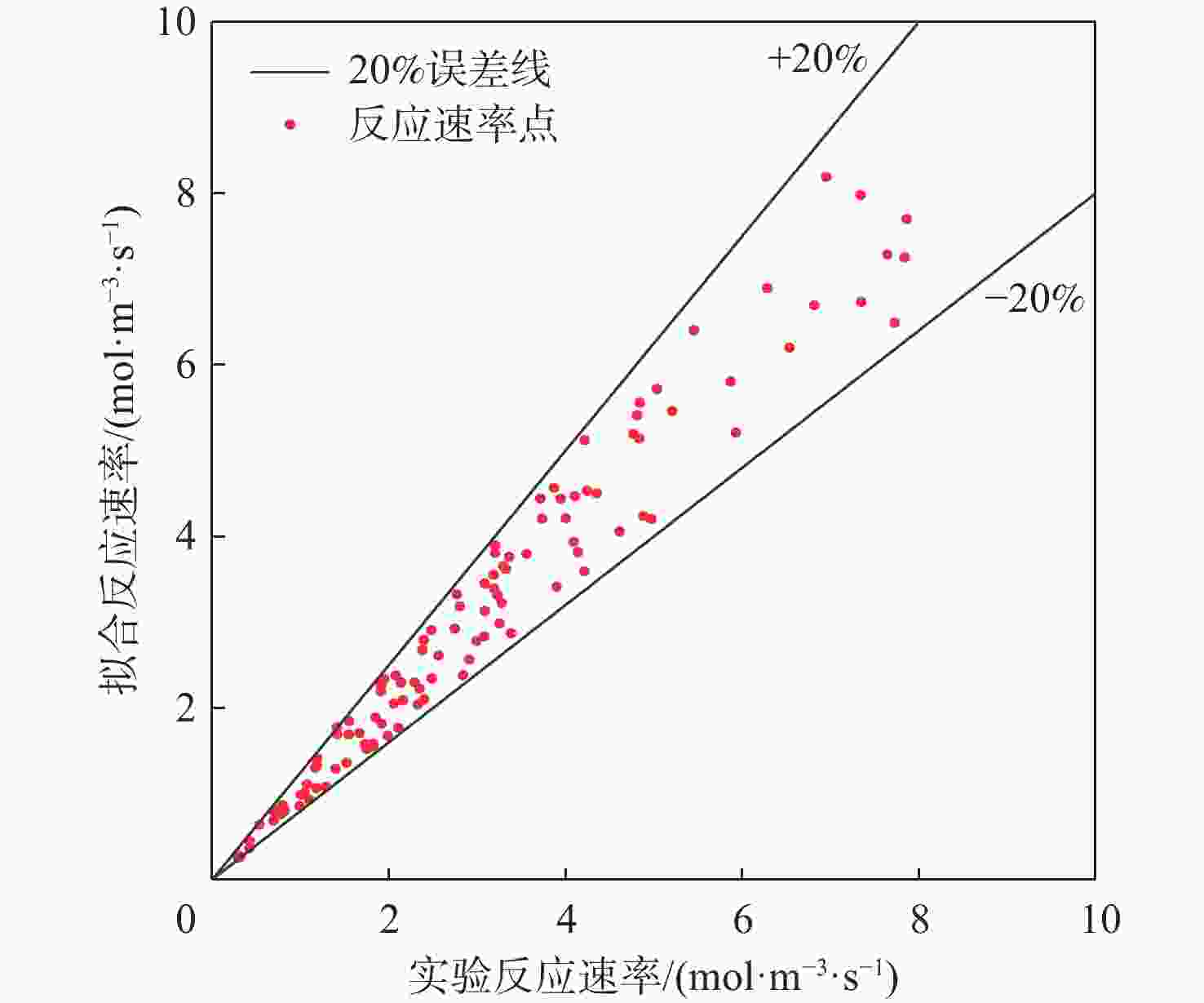

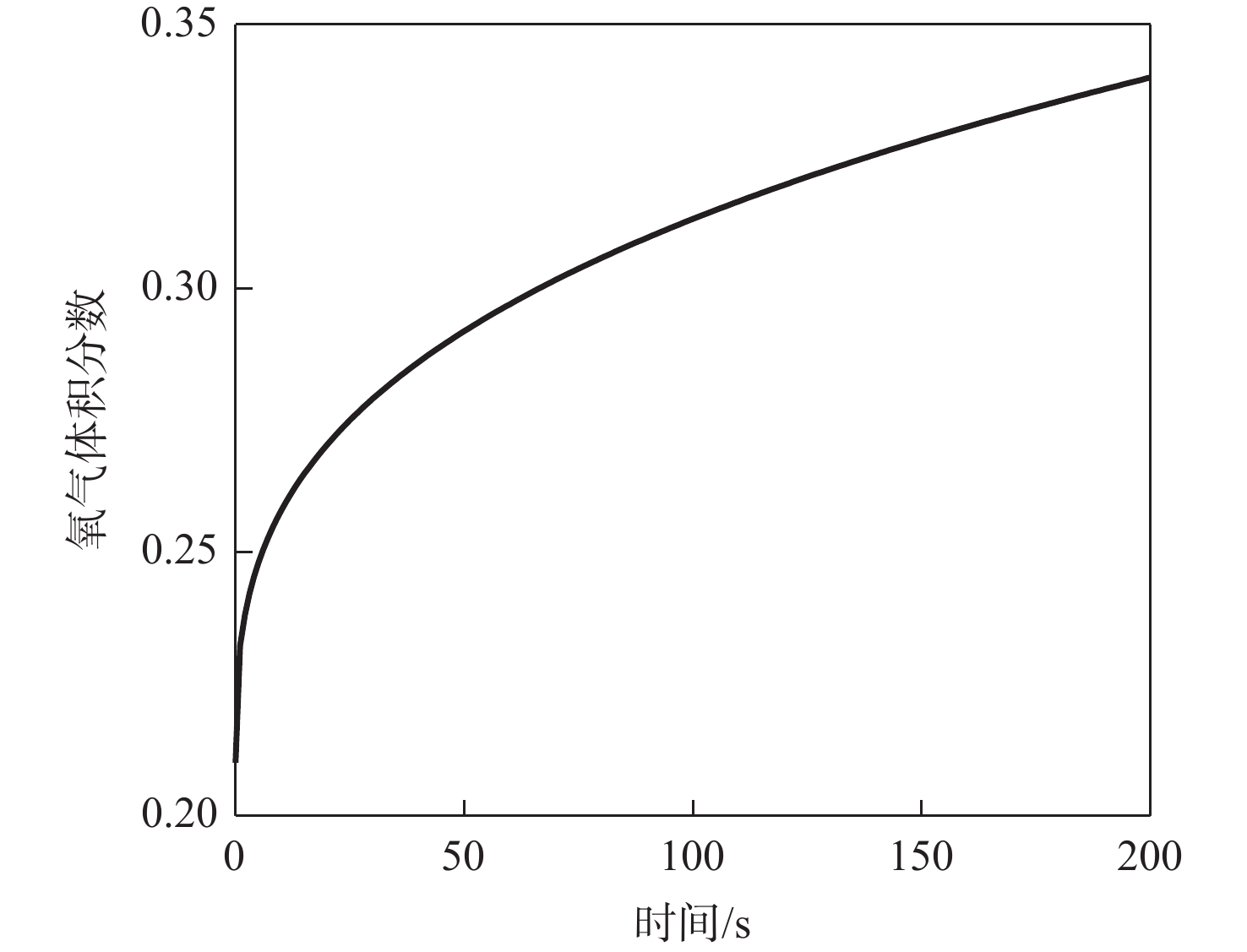

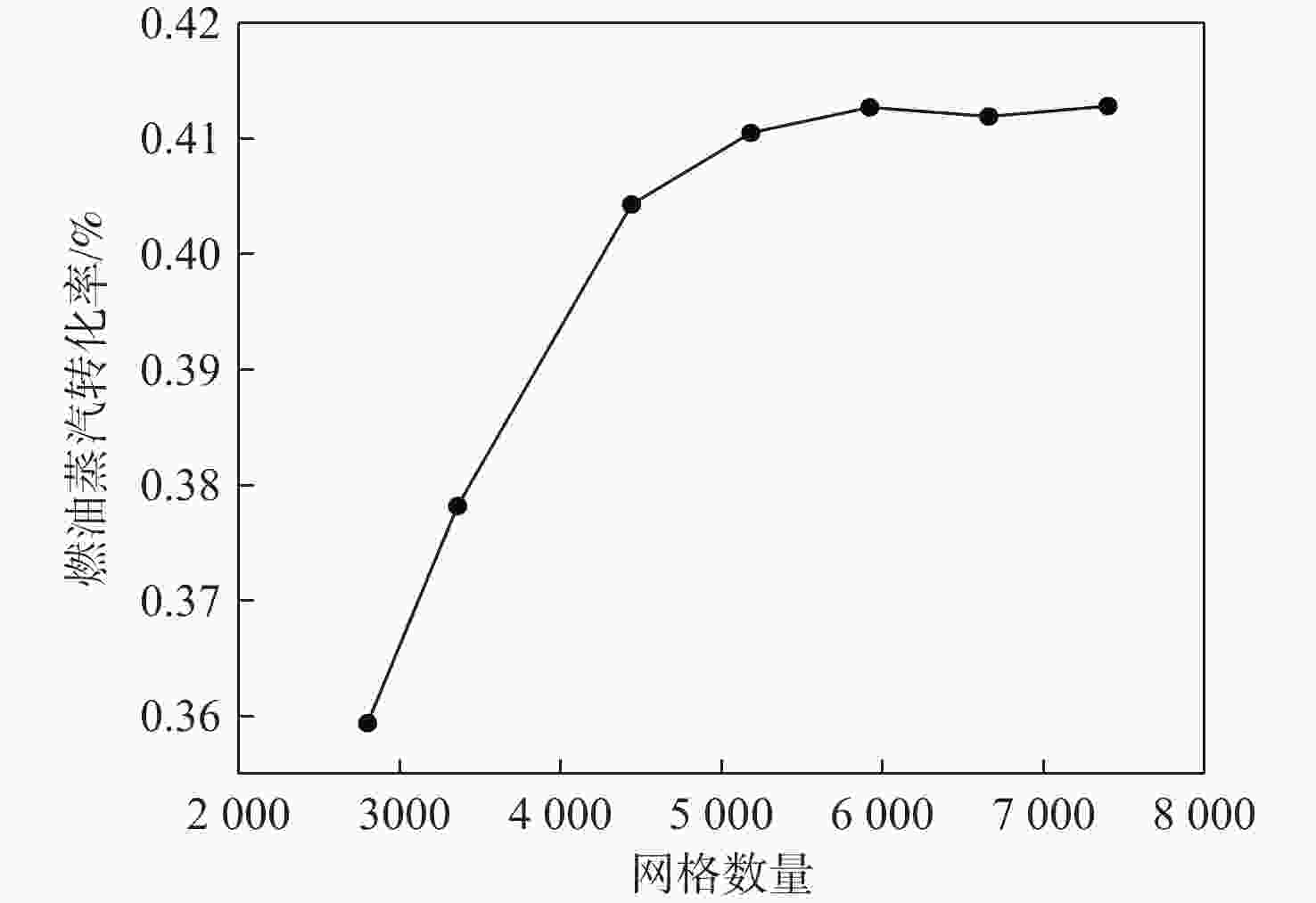

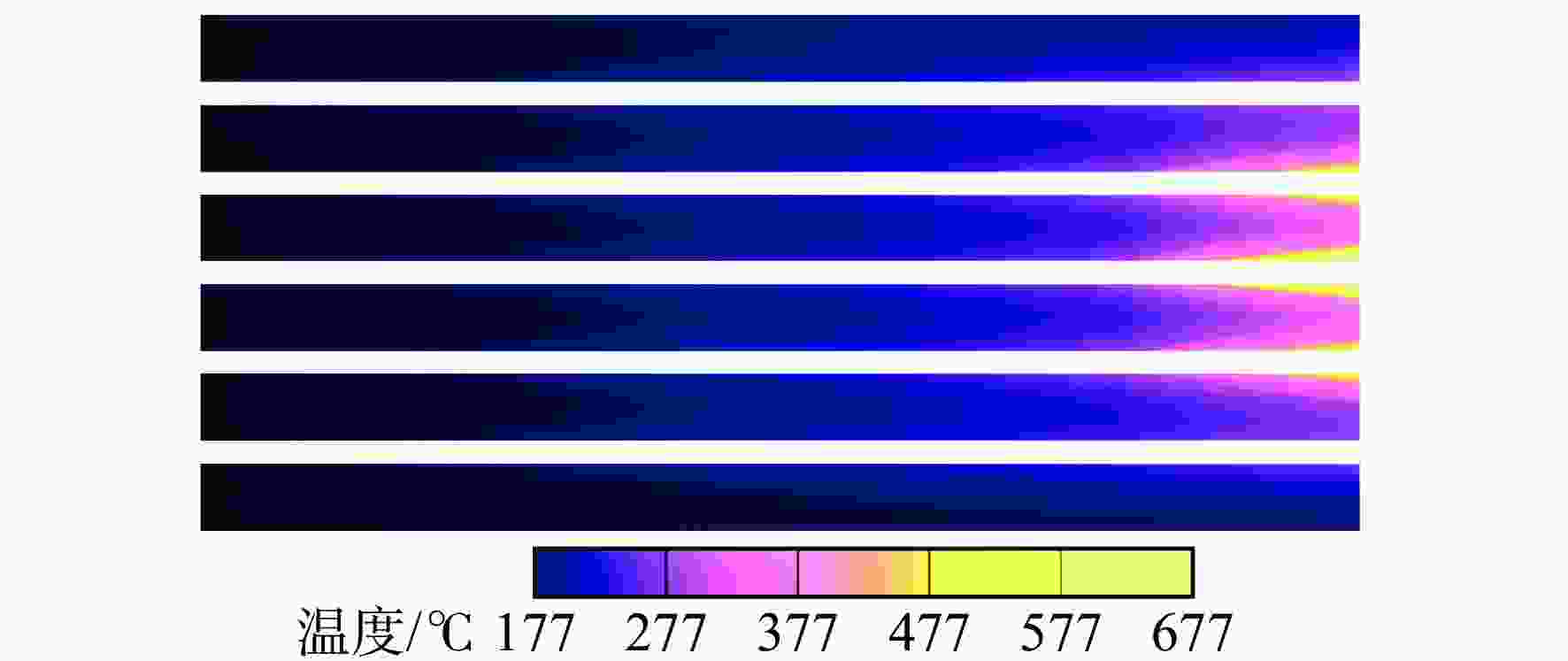

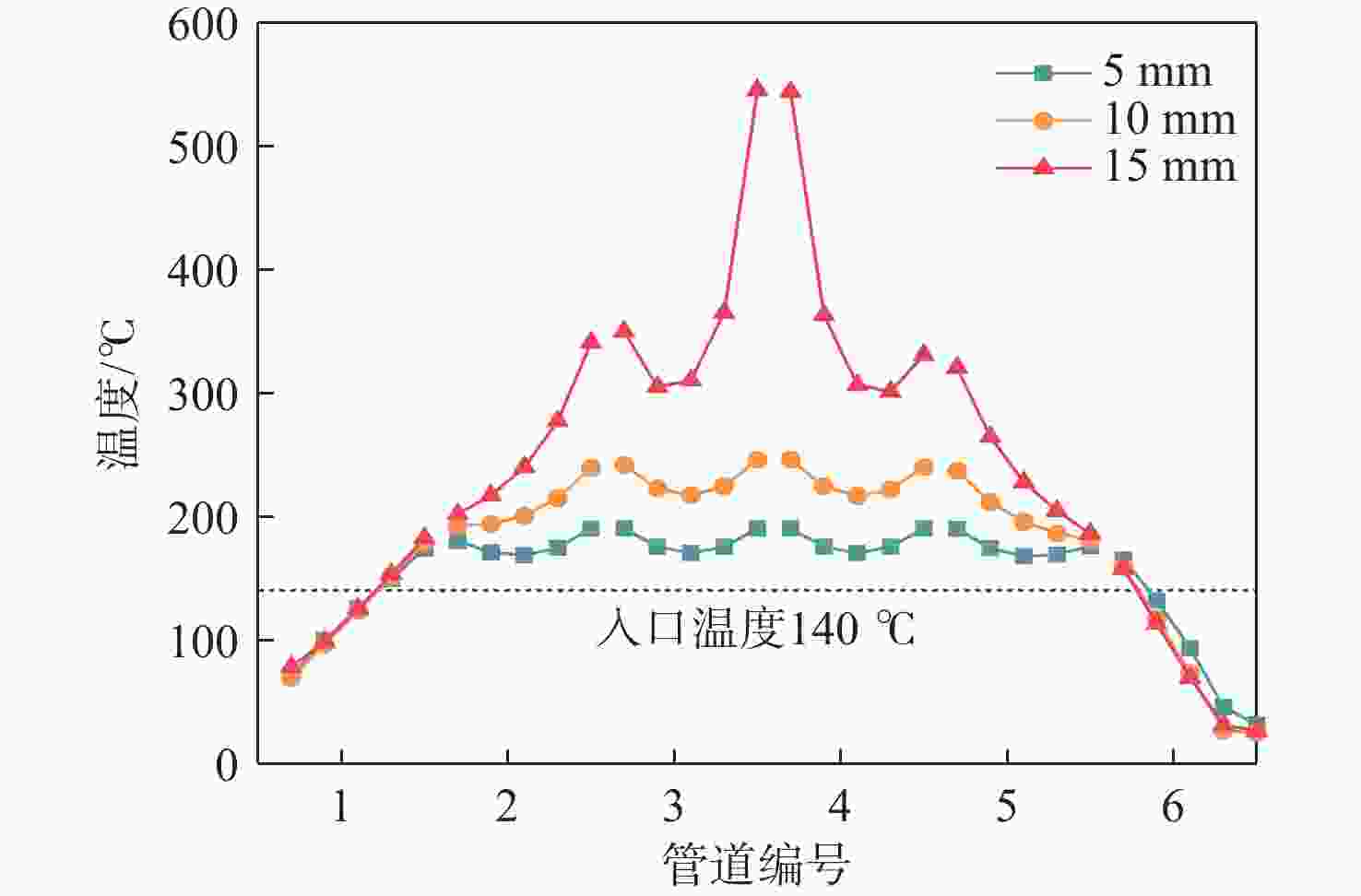

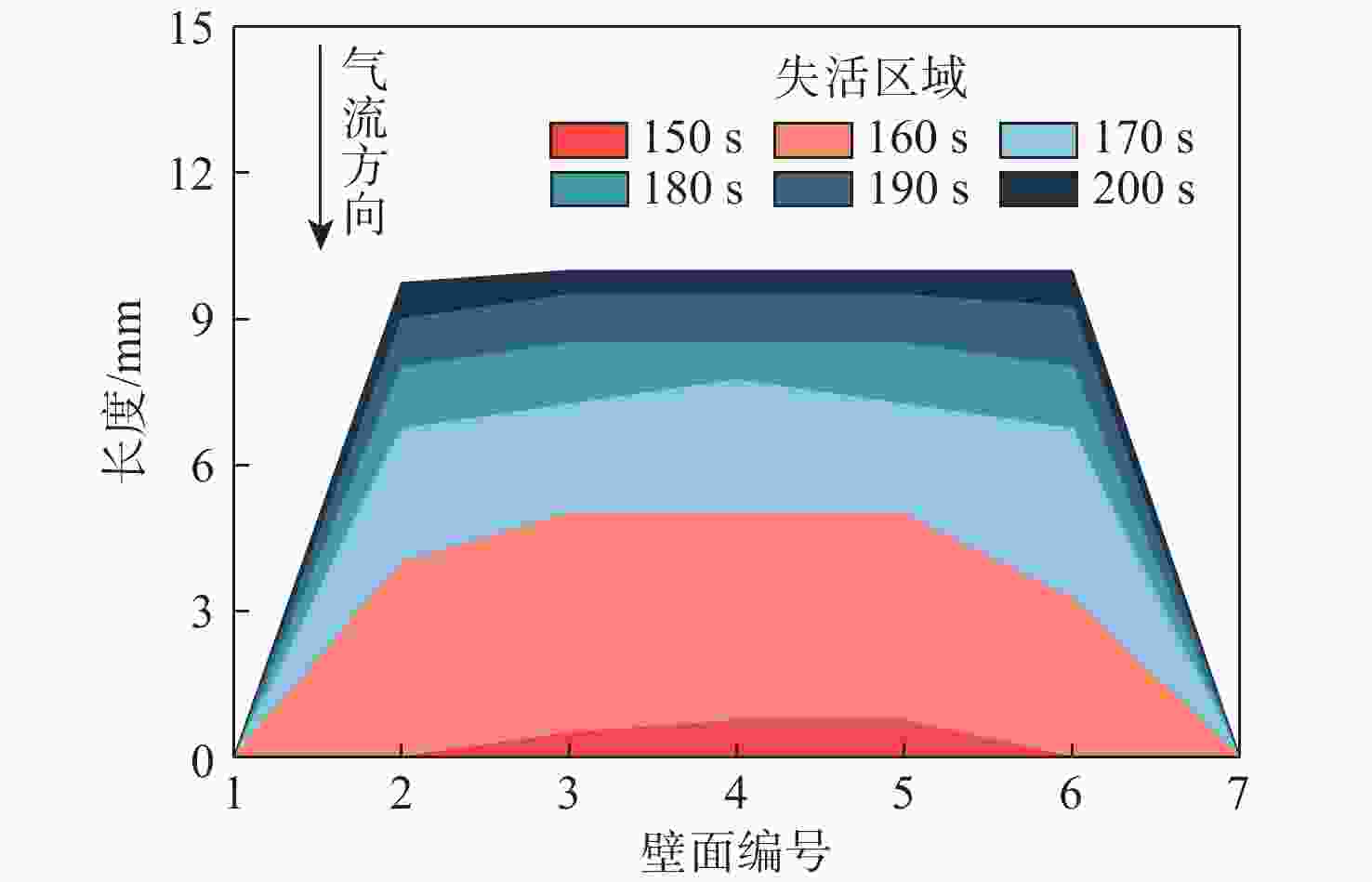

对Pd/γ-Al2O3催化剂进行了实验测量,拟合得到了其反应动力学方程,建立了整体式反应器二维瞬态模型,并采用Modelica语言编程求解,开展动态性能仿真,分析了耗氧型惰化系统中飞温和催化剂高温失活现象对整体式反应器性能的影响,研究了飞行过程中氧气体积分数变化对反应器的影响。研究结果表明:壁面冷却可有效降低飞温现象,但同时会降低反应器催化效率。飞温现象导致的催化剂涂层不可逆失活发生在反应最剧烈的反应器出口侧壁面上,小面积的失活会导致催化效率降低80%。飞机爬升阶段油箱内的氧浓度增加可有效提升反应器内的燃油蒸汽转化率,但也需要避免高氧浓度对反应器涂层加速失活的影响。

Abstract:An experiment of Pd/γ-Al2O3 performance is carried out to get its reaction dynamics function. A two-dimensional monolithic catalyst transient model is established and solved with Modelica. Catalyst transition performance has been studied by simulation. The influence of high temperature and catalyst deactivation on a monolithic catalyst is researched. It was investigated how the reactor was affected by the oxygen content while in flight. The result shows that wall cooling can reduce high temperatures and reactor efficiency at the same time. The catalyst deactivation due to high temperature occurs on the surface near the outlet of the reactor, where the sharpest reaction takes place. Deactivation in Less than half of the catalyst surface area cuts down the efficiency by 80%. The conversion rate of fuel steam can be effectively increased by the increase in oxygen concentration brought on by the loss of pressure during aircraft ascent; however, precautions should be taken to prevent the acceleration of catalyst deactivation caused by high oxygen concentration.

-

Key words:

- catalytic combustion /

- monolithic catalyst /

- fuel system /

- inerting system /

- catalyst inactivation

-

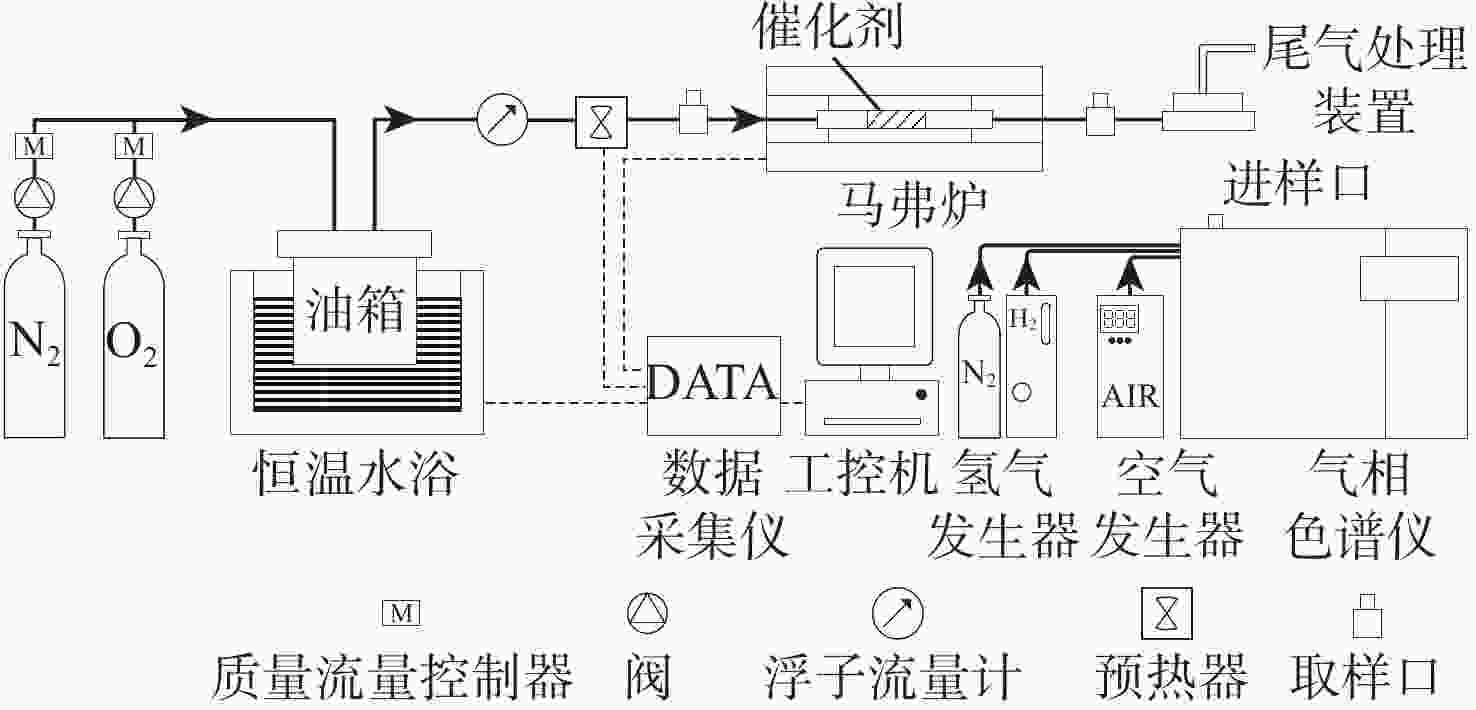

表 1 实验台使用的设备型号及性能参数

Table 1. Equipment model and performance parameters in the experiment used in the laboratory bench

设备 型号 工作范围 精度范围 浮子流量计 6~60 mL/min ±4% 注射泵 SP-1000 0.1~999.9 mL ±3% 马弗炉 SK2-2-13单管 功率2 kW 气相色谱仪 GC9790 总烃 ±0.1% 反应器 非标定制 温控表 HKDN 0~5 V ±0.5%F.S. 数据采集仪 LR-8400-21 DC±100 V 500 mV 表 2 参数拟合结果

Table 2. Parameter fitting result

氧气体积分数 指前因子k0/

(m3(mol·s)−1)活化能E/

(J·mol)−1m n <0.1(低) 13 370.72 23 422.56 0.319 0.659 ≥0.1(高) 25 027.53 28 285.78 0.798 0 表 3 反应器物理参数

Table 3. Reactor physics parameter

物理参数 数值 管壁密度/(kg·m−3) 2100 管壁比热容/(J·kg−1·K−1) 520 管壁导热系数/(W·m−1·K−1) 17.6 -

[1] 王明波, 邵垒, 潘俊, 等. 耗氧型燃油箱惰化技术历史和现状[J]. 航空科学技术, 2016, 27(7): 1-7.WANG M B, SHAO L, PAN J, et al. History and current status of oxygen consumption based fuel tank inerting technology[J]. Aeronautical Science & Technology, 2016, 27(7): 1-7 (in Chinese). [2] 刘卫华, 冯诗愚. 飞机燃油箱惰化技术[M]. 北京: 科学出版社, 2018: 2-3.LIU W H, FENG S Y. Aircraft fuel tank inerting technology[M]. Beijing: Science Press, 2018: 2-3. (in Chinese). [3] 王衡, 王昌红. 近几年整体式催化剂的开发与应用[J]. 工业催化, 2019, 27(10): 15-21. doi: 10.3969/j.issn.1008-1143.2019.10.003WANG H, WANG C H. Development and application of monolithic catalyst in recent years[J]. Industrial Catalysis, 2019, 27(10): 15-21. doi: 10.3969/j.issn.1008-1143.2019.10.003 [4] JOHNSON R W, ZAKI R, YATES S F. Advanced carbon dioxide fuel tank inerting system: US7905259 [P]. 2011-03-15. [5] 冯诗愚, 刘冠男, 江荣杰, 等. 飞机燃油箱机载惰化技术研究现状与发展趋势[J]. 航空动力学报, 2021, 36(3): 616-625.FENG S Y, LIU G N, JIANG R J, et al. Research status and development trend of aircraft fuel tank on-board inerting technology[J]. Journal of Aerospace Power, 2021, 36(3): 616-625 (in Chinese). [6] 彭孝天, 冯诗愚, 周利彪, 等. 温度对耗氧型惰化系统产水性能影响[J]. 航空动力学报, 2020, 35(8): 1622-1627.PENG X T, FENG S Y, ZHOU L B, et al. Effect of temperature on water production performance of oxygen-consuming inerting system[J]. Journal of Aerospace Power, 2020, 35(8): 1622-1627 (in Chinese). [7] 李乃珍. 焦炉煤气加氢脱硫FeMo/Al2O3催化剂积碳失活与性能优化研究[D]. 太原: 太原理工大学, 2022.LI N Z. Study on carbon deposit deactivation and performance optimization of FeMo/Al2O3 hydrodesulfurization catalyst in coke oven gas[D]. Taiyuan: Taiyuan University of Technology, 2022 (in Chinese). [8] WALKER S, JUNG W, ROBERTSON S. Demonstration of a novel catalyst based green on board inert gas generation system (GOBIGGS) for fuel tank inerting[C]//Proceedings of the American Helicopter Society 69th Annual Forum. Fairfax: American Helicopter Society, 2013, 69(1): 550-559. [9] 孙浩程, 赵朝成, 陈亚男, 等. 催化燃烧法处理挥发性有机物的研究进展[J]. 现代化工, 2015, 35(6): 57-61.SUN H C, ZHAO C C, CHEN Y N, et al. Research progress in catalytic combustion of volatile organic compounds[J]. Modern Chemical Industry, 2015, 35(6): 57-61. [10] 卢泽湘, 范立委. 金属基整体式催化剂的研究进展[J]. 广州化工, 2010, 38(6): 9-12.LU Z X, FAN L W. Research progress of metallic monolithic catalysts[J]. Guangzhou Chemical Industry, 2010, 38(6): 9-12 (in Chinese). [11] WANKER R, BERG M, RAUPENSTRAUCH H, et al. Numerical simulation of monolithic catalysts with a heterogeneous model and comparison with experimental results from a wood-fired domestic boiler[J]. Chemical Engineering & Technology, 2000, 23(6): 535-542. [12] DEPCIK C, SRINIVASAN A. One + one-dimensional modeling of monolithic catalytic converters[J]. Chemical Engineering & Technology, 2011, 34(12): 1949-1965. [13] GUO W Y, WU W Z, LUO M, et al. Modeling of diffusion and reaction in monolithic catalysts for the methanol-to-propylene process[J]. Fuel Processing Technology, 2013, 108: 133-138. doi: 10.1016/j.fuproc.2012.06.005 [14] PENG X T, WANG H M, HUANG L, et al. Performance of an oxygen-consuming inerting system for an aircraft fuel tank with RP-3 aviation fuel in flight[J]. Areospace Science and Technology, 2022, 123: 107446. [15] Peng X , Feng S , Chaoyue L I , et al. Effect of fuel type on the performance of an aircraft fuel tank oxygen-consuming inerting system[J]. Chinese Journal of Aeronautics, 2021, 34(3): 82-93. [16] 郑婷婷, 何俊俊, 吴乐刚, 等. 汽车尾气三效催化剂的失活 [C]//第八届全国工业催化技术及应用年会论文集. 西安: 工业催化, 2011: 11-14.ZHENG T T. HE J J. WU L G, et al. Deactivation of automobile exhaust three-way catalyst[C]// Proceedings of the 8th National Annual Conference on Industrial Catalysis Technology and Application. Xi’an: Industrial Catalysis, 2011: 11-14 (in Chinese). [17] 闫红敏. 军用飞机燃油箱的氮气惰化特性研究[D]. 沈阳: 沈阳航空工业学院, 2006.YAN H M. Study on nitrogen inerting characteristic of military aircraft fuel tank[D]. Shenyang: Shenyang Institute of Aeronautics Engineering, 2006 (in Chinese). [18] 黄敬敬, 贾志刚, 刘翻艳. Ce改性Pd基整体式催化剂的结构特征及其甲烷催化燃烧性能[J]. 工业催化, 2013, 21(5): 23-29. doi: 10.3969/j.issn.1008-1143.2013.05.005HUANG J J, JIA Z G, LIU F Y. Catalytic combustion of lean methane over Pd/γ-Al2O3/Cord monolith catalysts modified by Ce[J]. Industrial Catalysis, 2013, 21(5): 23-29 (in Chinese). doi: 10.3969/j.issn.1008-1143.2013.05.005 -

下载:

下载: