-

摘要:

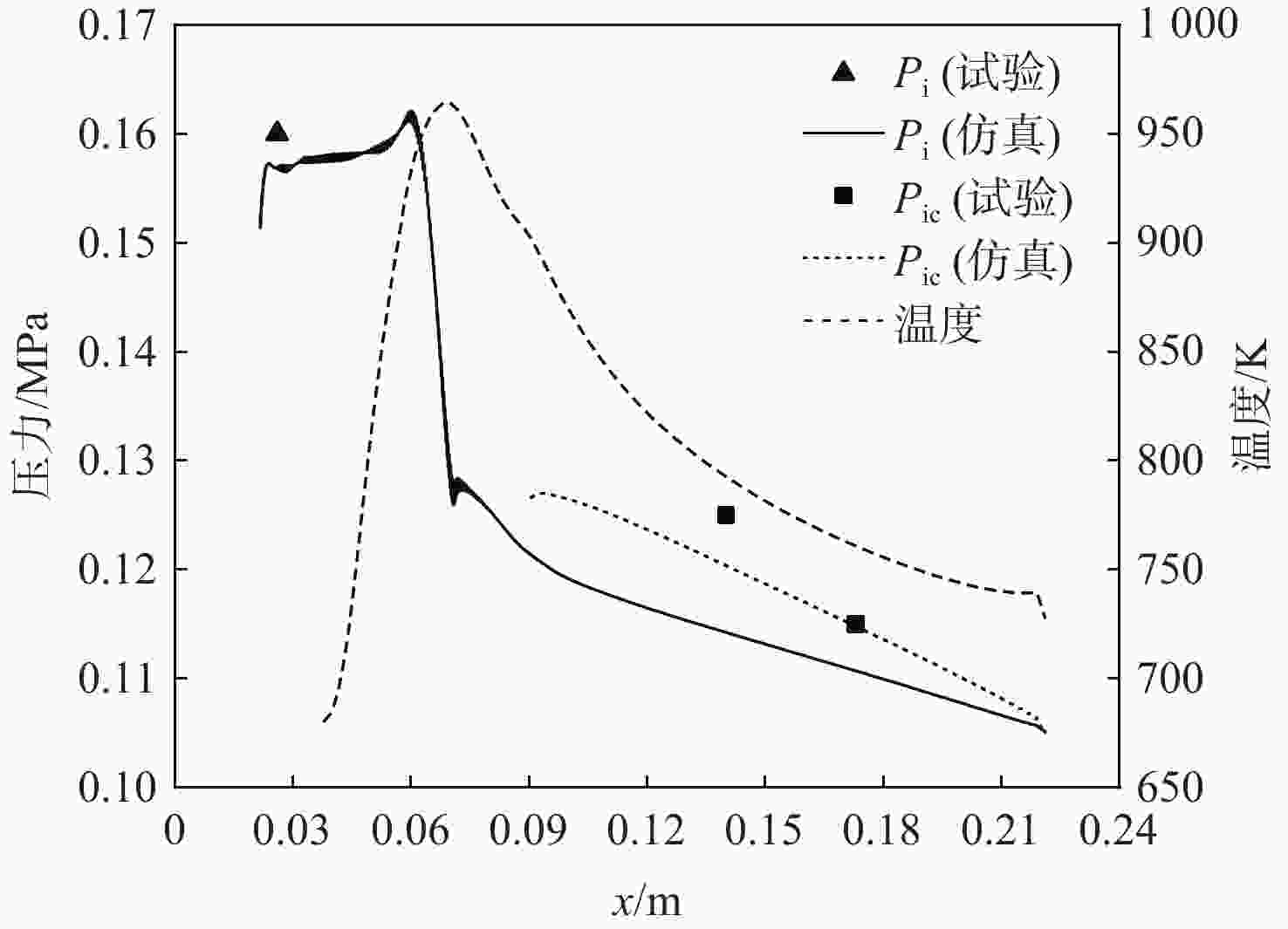

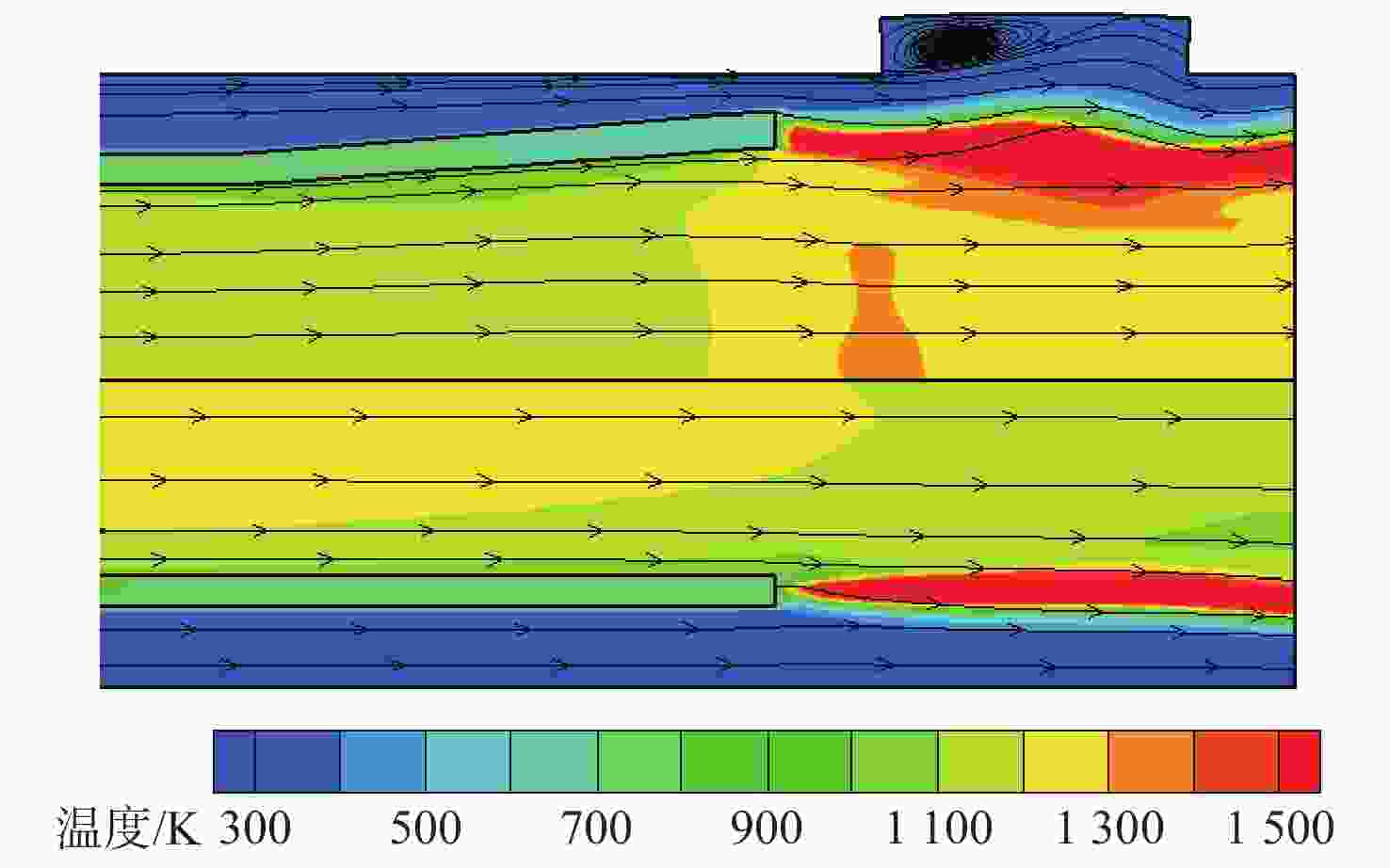

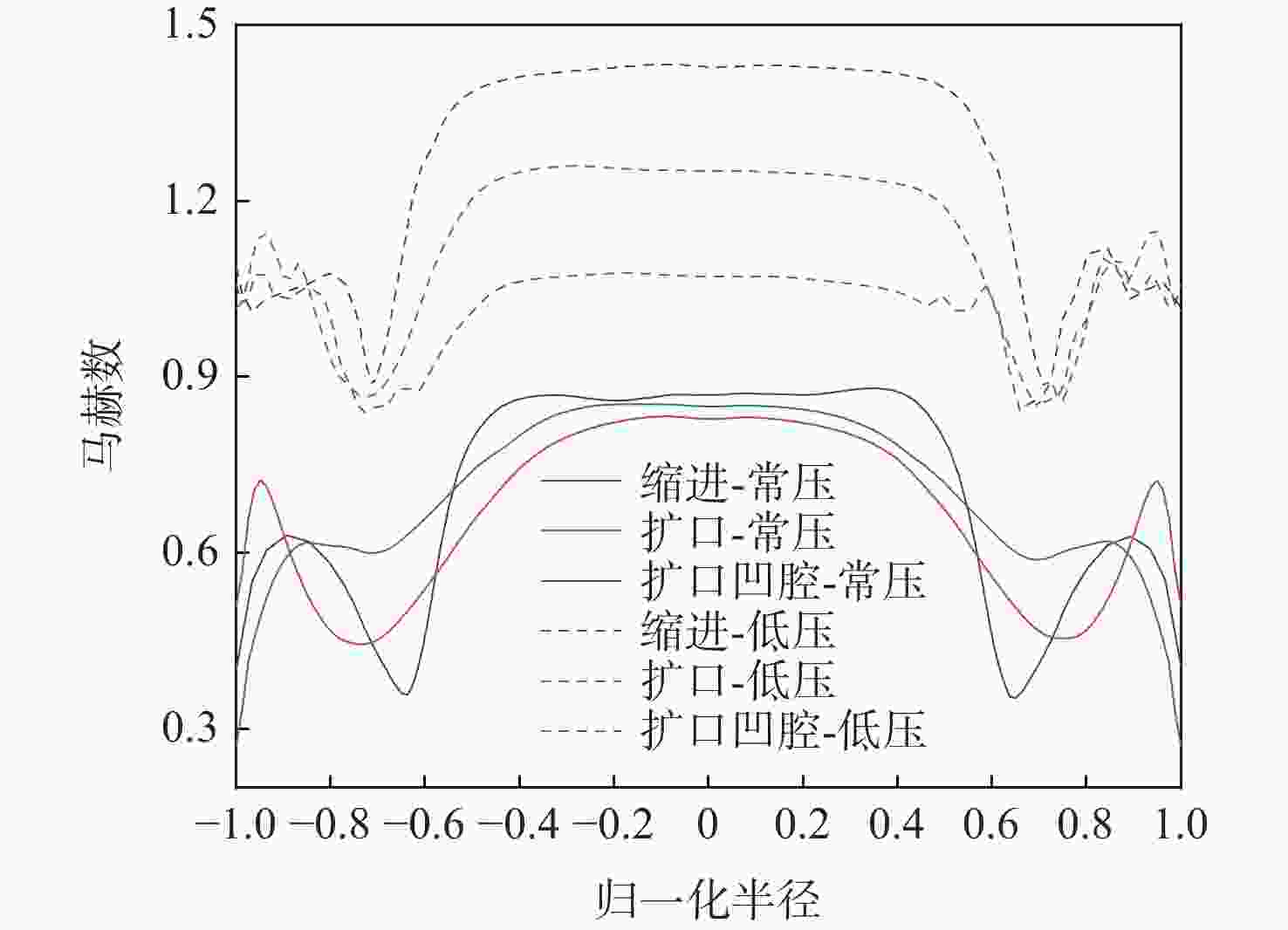

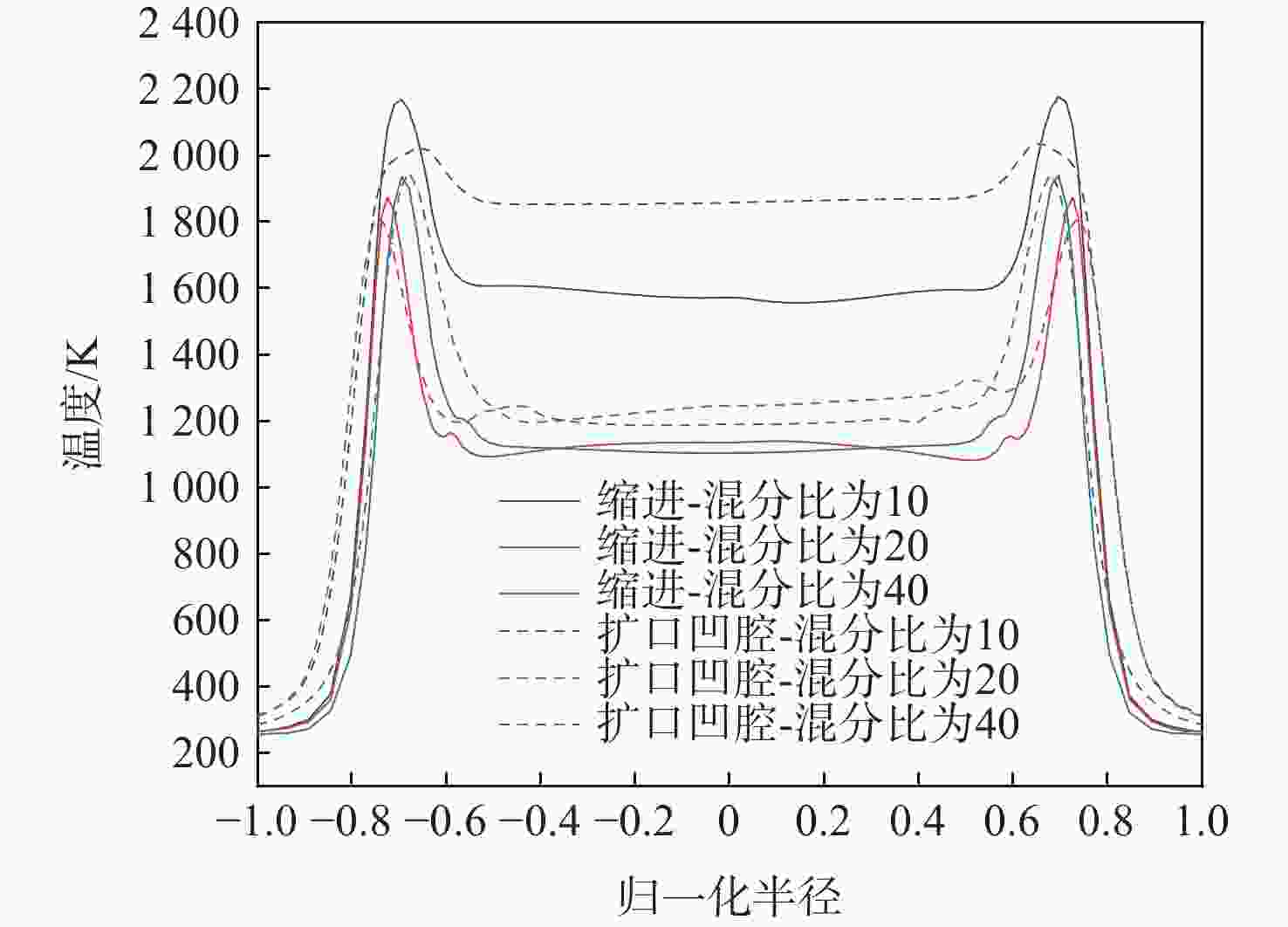

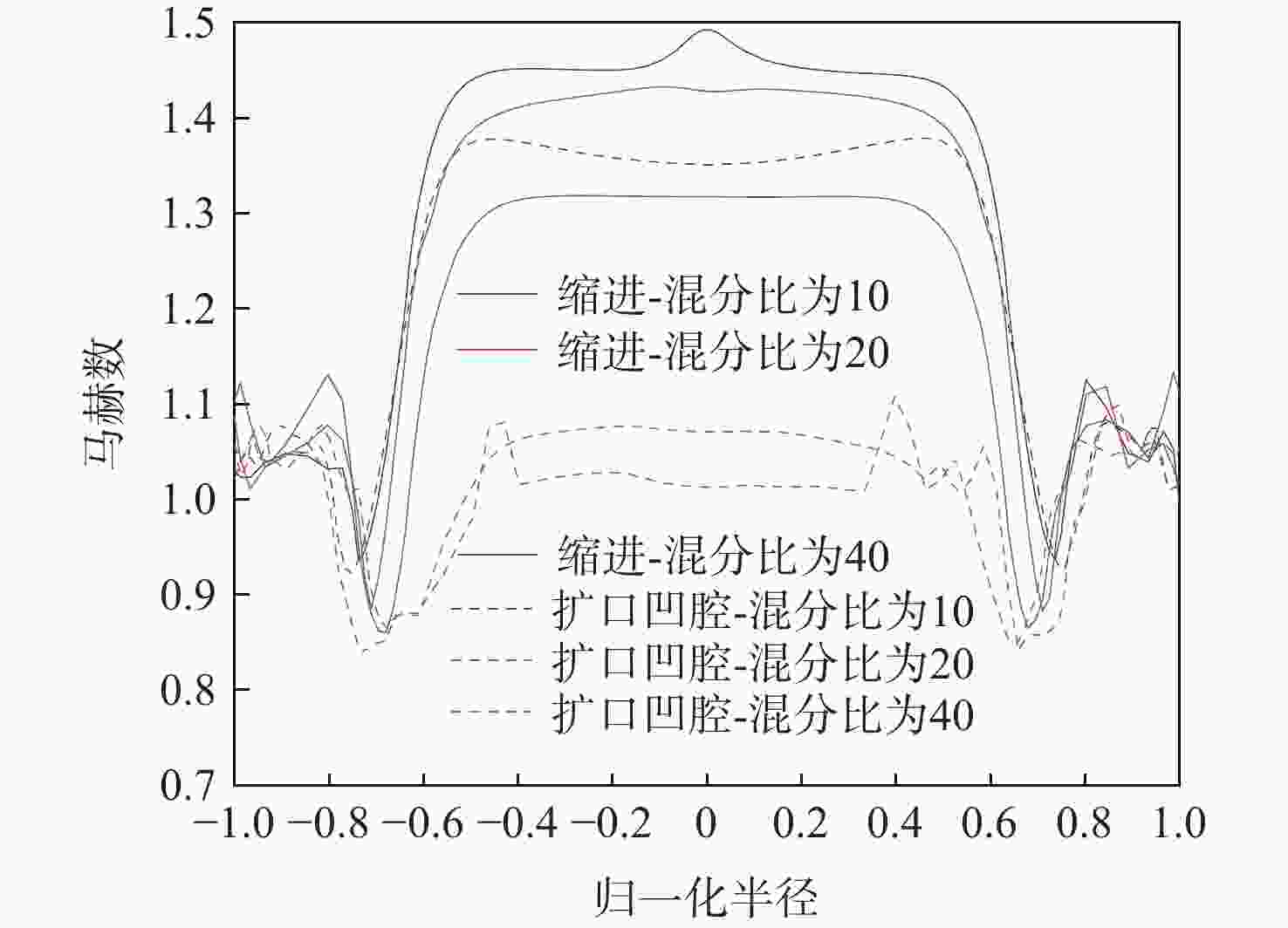

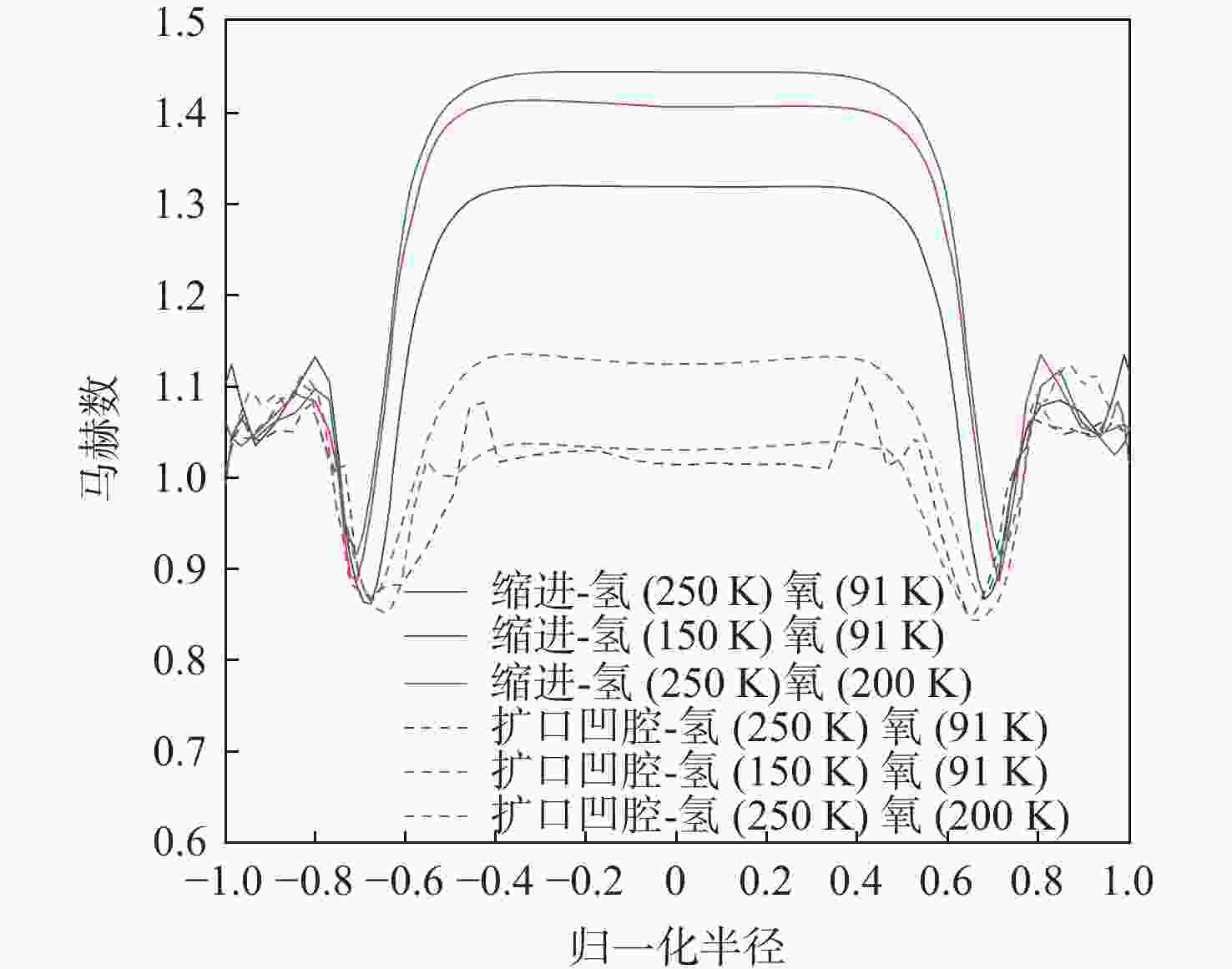

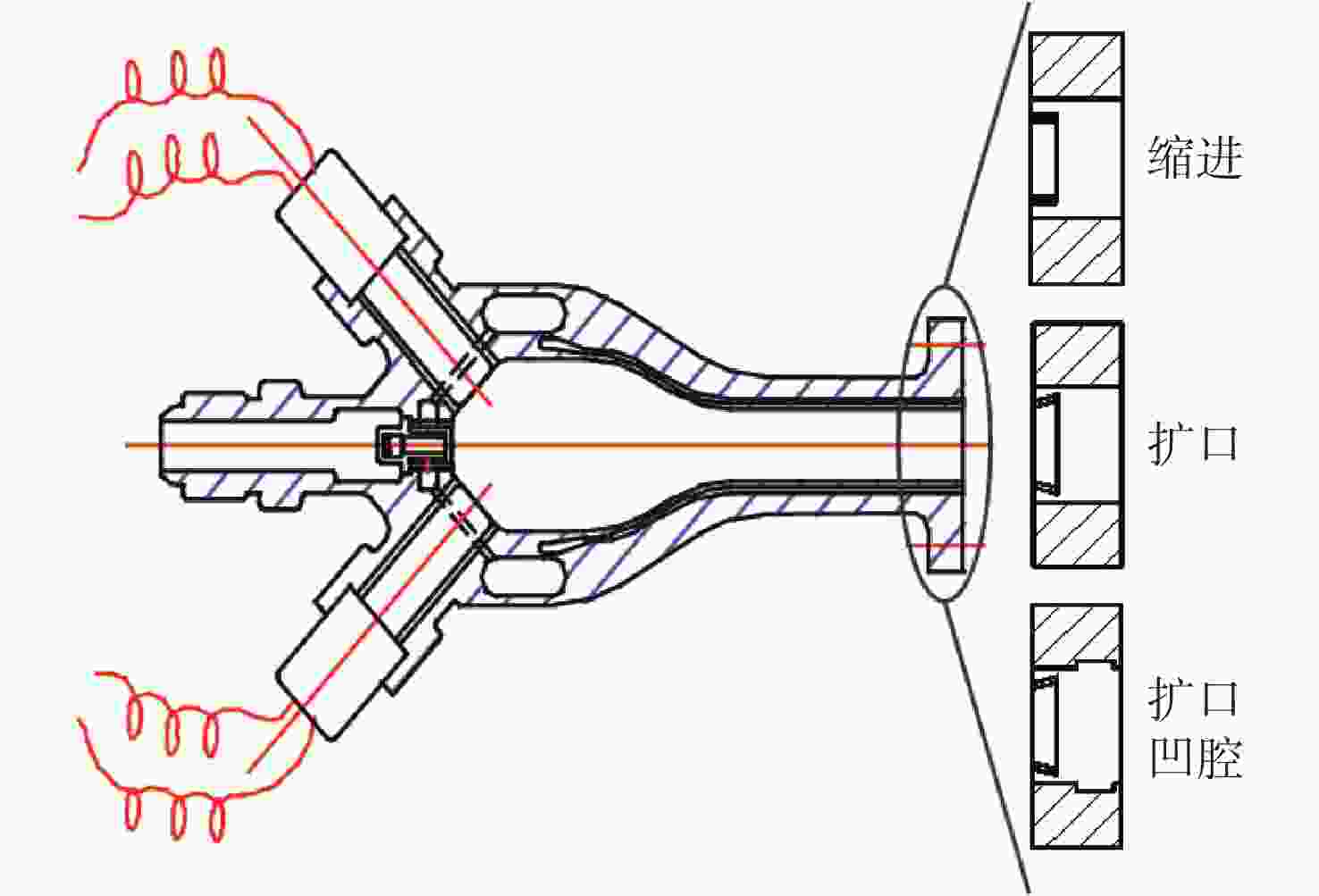

富氧火炬式电点火器在低压、宽工况及推进剂入口温度大幅变化等极限工况下存在燃气温度偏低、不均匀及出口流速过快等火焰不稳定性现象。基于此,采用试验仿真方法研究了富氧火炬式电点火器缩进、扩口、扩口凹腔3种火焰稳定结构对出口火焰稳定性的影响。扩口凹腔结构将中心燃气向壁面引流,降低掺混区内流速延长燃气停留时间,并在凹腔结构内形成回流区促进补燃。极限工况下,相较于缩进结构,扩口凹腔结构火焰出口中心燃气温度下限由1 000 K提升至1 200 K,与设计工况温度差由高于100 K降至50 K以内,出口马赫数由1.4降至声速,有效提升了点火器的出口火焰稳定性。

Abstract:Flame instability appeared under wide extreme sub-atmospheric conditions with varied inlet propellant temperatures, manifested as inadequate ignition energy, uneven gas temperatures, and excessive gas velocity. This paper investigated three flame stability methods: recess, flared outlet and flared cavity, through experiments and simulations. The flared cavity directs the central gas to mix and react with the cooling hydrogen, which also slows down the mixture and enhances reburning in the recirculation zone. Compared to the recess igniter under extreme conditions, the center gas temperature of the flared cavity increases from

1000 K to1200 K. The temperature difference from the design point decreases from 100 K to 50 K, and the outlet Mach number decelerates from 1.4 to sonic. The flared cavity significantly improves the flame stability of the oxygen-rich torch igniter.-

Key words:

- igniter /

- extreme condition /

- flame stability /

- recess /

- flared outlet /

- flared cavity outlet

-

[1] VAN LERBERGHE W M, EMDEE J L, FOUST R R. Enhanced reliability features of the RL10E-1 engine[J]. Acta Astronautica, 1997, 41(4-10): 197-207. doi: 10.1016/S0094-5765(98)00077-0 [2] LIANG P Y. Modeling of SSME fuel preburner ASI[C]//Proceedings of the 10th Workshop for Computational Fluid Dynamic Applications in Rocket Propulsion. Washington, D. C. : NASA, 1992: 1013-1031. [3] FUKUSHIMA Y, LMOTO T. Lessons learned in the development of the LE-5 and LE-7[C]//Proceedings of the 30th Joint Propulsion Conference and Exhibit. Reston: AIAA, 1994. [4] 吴宏斌. 国外氢氧火箭发动机的火药点火器和电点火器[J]. 导弹与航天运载技术, 1994(5): 32-42.WU H B. Pyrotechnic igniters and electrical spark igniters for LOX/LH2 rocket engines[J]. Missiles and Space Vehicles, 1994(5): 32-42(in Chinese). [5] 郑大勇, 陶瑞峰, 胡骏. 氢氧发动机真空点火及高空模拟试验[J]. 导弹与航天运载技术, 2014(5): 38-43.ZHENG D Y, TAO R F, HU J. Vacuum ignition characteristics and altitude simulation testing of the cryogenic LOX/LH2 rocket engine[J]. Missiles and Space Vehicles, 2014(5): 38-43(in Chinese). [6] WANG Y, YANG J H, CAI G B, et al. Effects of injection distance and droplet size on an LH2/LOX torch igniter[J]. Aerospace Science and Technology, 2022, 121: 107334. doi: 10.1016/j.ast.2022.107334 [7] 杨进慧, 王朝晖, 左安军, 等. 氢氧火炬式电点火器燃烧流动分析[J]. 导弹与航天运载技术, 2019(3): 45-48.YANG J H, WANG Z H, ZUO A J, et al. Combustion flow analysis of the hydrogen-oxygen torch igniter[J]. Missiles and Space Vehicles, 2019(3): 45-48(in Chinese). [8] 王铁岩, 郑孟伟, 蔡振宇. 气氧甲烷火炬式点火器稳态仿真分析[J]. 导弹与航天运载技术, 2016(4): 63-66.WANG T Y, ZHENG M W, CAI Z Y. Steady-state simulation of GOX/methane spark torch igniter[J]. Missiles and Space Vehicles, 2016(4): 63-66(in Chinese). [9] 张锋, 于涵, 尚帅, 等. 气氧/气甲烷火炬式电点火器燃烧仿真与热试[J]. 火箭推进, 2022, 48(4): 36-42. doi: 10.3969/j.issn.1672-9374.2022.04.005ZHANG F, YU H, SHANG S, et al. Combustion simulation and hot-fire test of GOX/GCH4 spark torch igniter[J]. Journal of Rocket Propulsion, 2022, 48(4): 36-42(in Chinese). doi: 10.3969/j.issn.1672-9374.2022.04.005 [10] 孙纪国, 王珏. 高混合比火炬式电点火器试验研究[J]. 推进技术, 2000, 21(1): 33-35. doi: 10.3321/j.issn:1001-4055.2000.01.010SUN J G, WANG J. Experimental study on high mixture ratio torch ignitor[J]. Journal of Propulsion Technology, 2000, 21(1): 33-35(in Chinese). doi: 10.3321/j.issn:1001-4055.2000.01.010 [11] WU H, CHEN Q, SHAO W W, et al. Combustion of hydrogen in an experimental trapped vortex combustor[J]. Journal of Thermal Science, 2009, 18(3): 256-261. doi: 10.1007/s11630-009-0256-5 [12] CHEN S, ZHAO D. Numerical study of non-reacting flowfields of a swirling trapped vortex ramjet combustor[J]. Aerospace Science and Technology, 2018, 74: 81-92. doi: 10.1016/j.ast.2018.01.006 [13] LI M Y, HE X M, ZHAO Y L, et al. Effect of strut length on combustion performance of a trapped vortex combustor[J]. Aerospace Science and Technology, 2018, 76: 204-216. doi: 10.1016/j.ast.2018.02.019 [14] CAI Z, WANG T Y, SUN M B. Review of cavity ignition in supersonic flows[J]. Acta Astronautica, 2019, 165: 268-286. doi: 10.1016/j.actaastro.2019.09.016 [15] 马文杰, 孙明波, 邵文清, 等. 基于Driscoll凹腔稳焰模型的超声速燃烧火焰稳定尺度效应研究[J]. 推进技术, 2021, 42(8): 1865-1875.MA W J, SUN M B, SHAO W Q, et al. Scaling effect of supersonic combustion flame stabilization based on driscoll cavity blowout limits model[J]. Journal of Propulsion Technology, 2021, 42(8): 1865-1875(in Chinese). [16] 陈兴良, 景婷婷, 朱韶华, 等. 支板/凹腔组合稳焰器耦合机制研究[J]. 推进技术, 2022, 43(11): 198-207.CHEN X L, JING T T, ZHU S H, et al. Coupling mechanism of strut/cavity combined flame stabilizer[J]. Journal of Propulsion Technology, 2022, 43(11): 198-207(in Chinese). [17] SHI L, YANG X, YANG Y Y, et al. Experimental study on rocket jet-driven ignition and scramjet combustion in a kerosene-fueled RBCC combustor[J]. Aerospace Science and Technology, 2022, 126: 107643. doi: 10.1016/j.ast.2022.107643 [18] 杨揖心. 后缘突扩型凹腔超声速流动模式与稳焰机理研究[D]. 长沙: 国防科技大学, 2018.YANG Y X. Study on supersonic flow pattern and flame stabilization mechanism of cavity with sudden expansion of trailing edge[D]. Changsha: National University of Defense Technology, 2018(in Chinese). [19] 丁猛. 基于凹腔的超声速燃烧火焰稳定技术研究[D]. 长沙: 国防科学技术大学, 2005.DING M. Study on flame stabilization technology of supersonic combustion based on concave cavity[D]. Changsha: National University of Defense Technology, 2005(in Chinese). -

下载:

下载: