-

摘要:

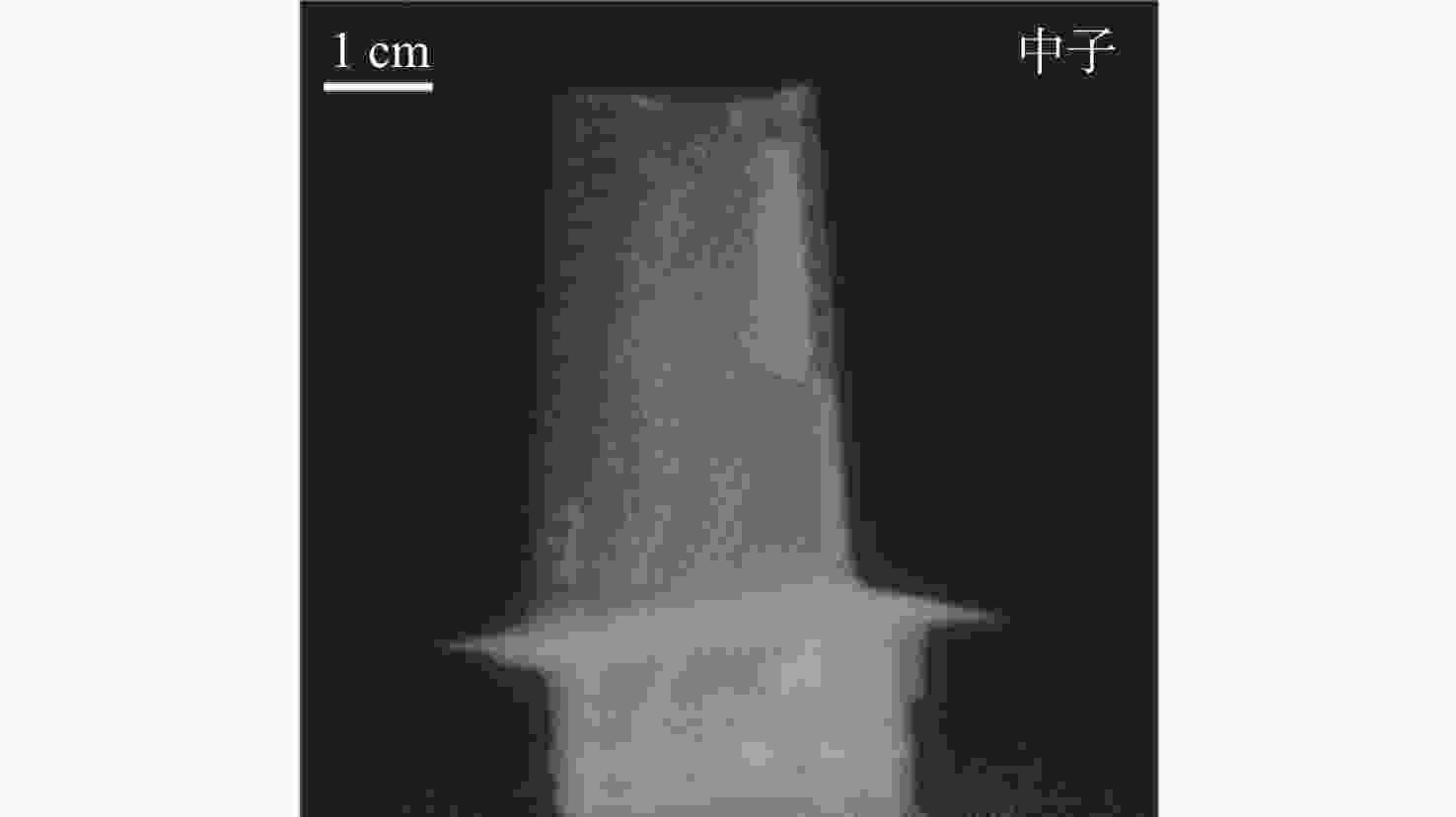

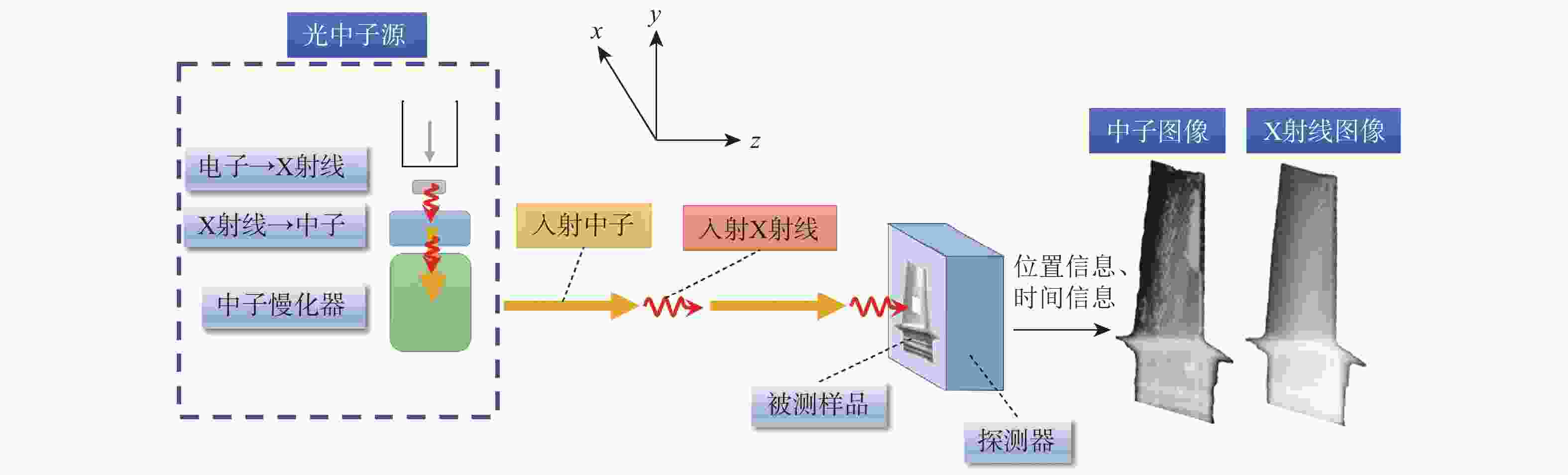

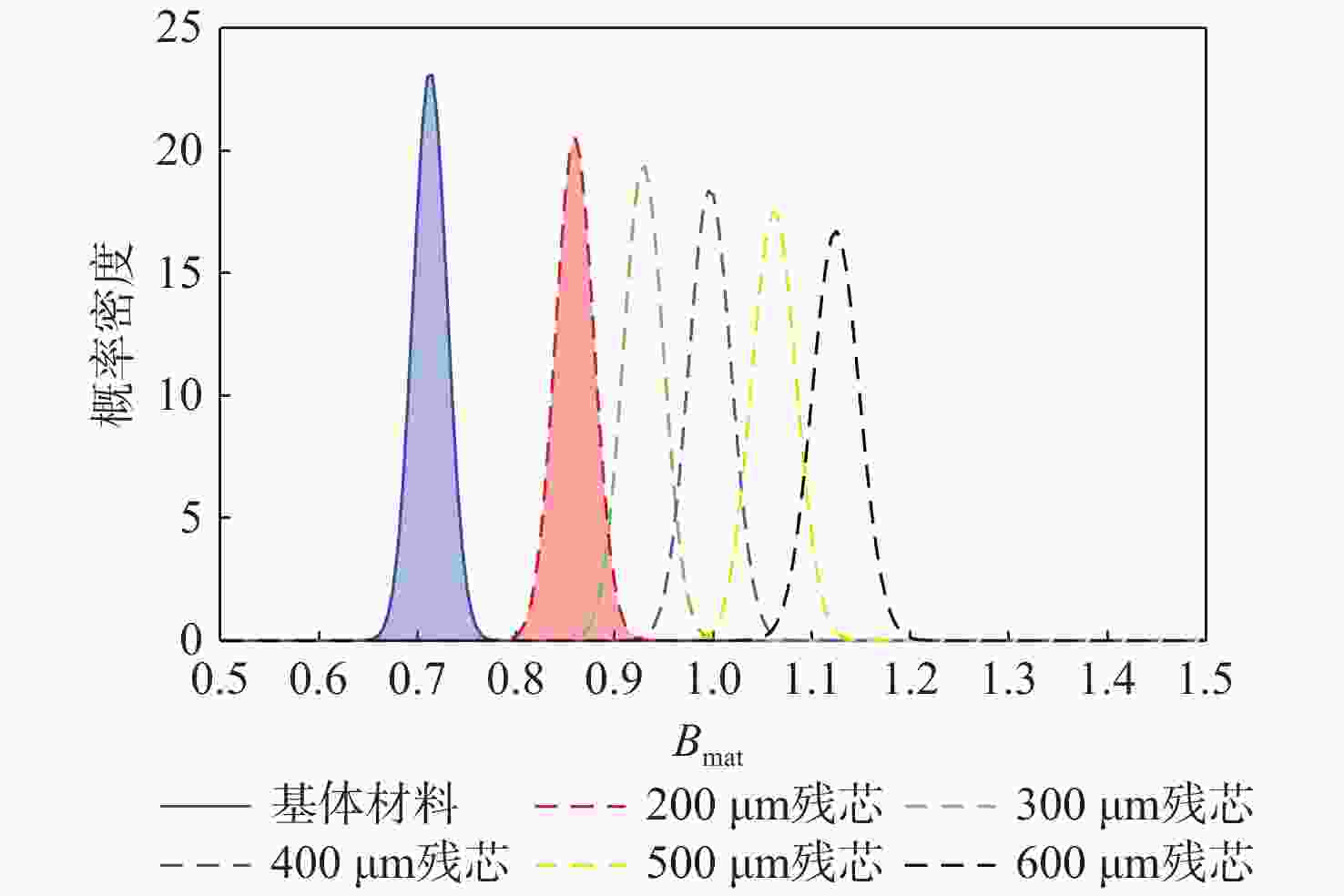

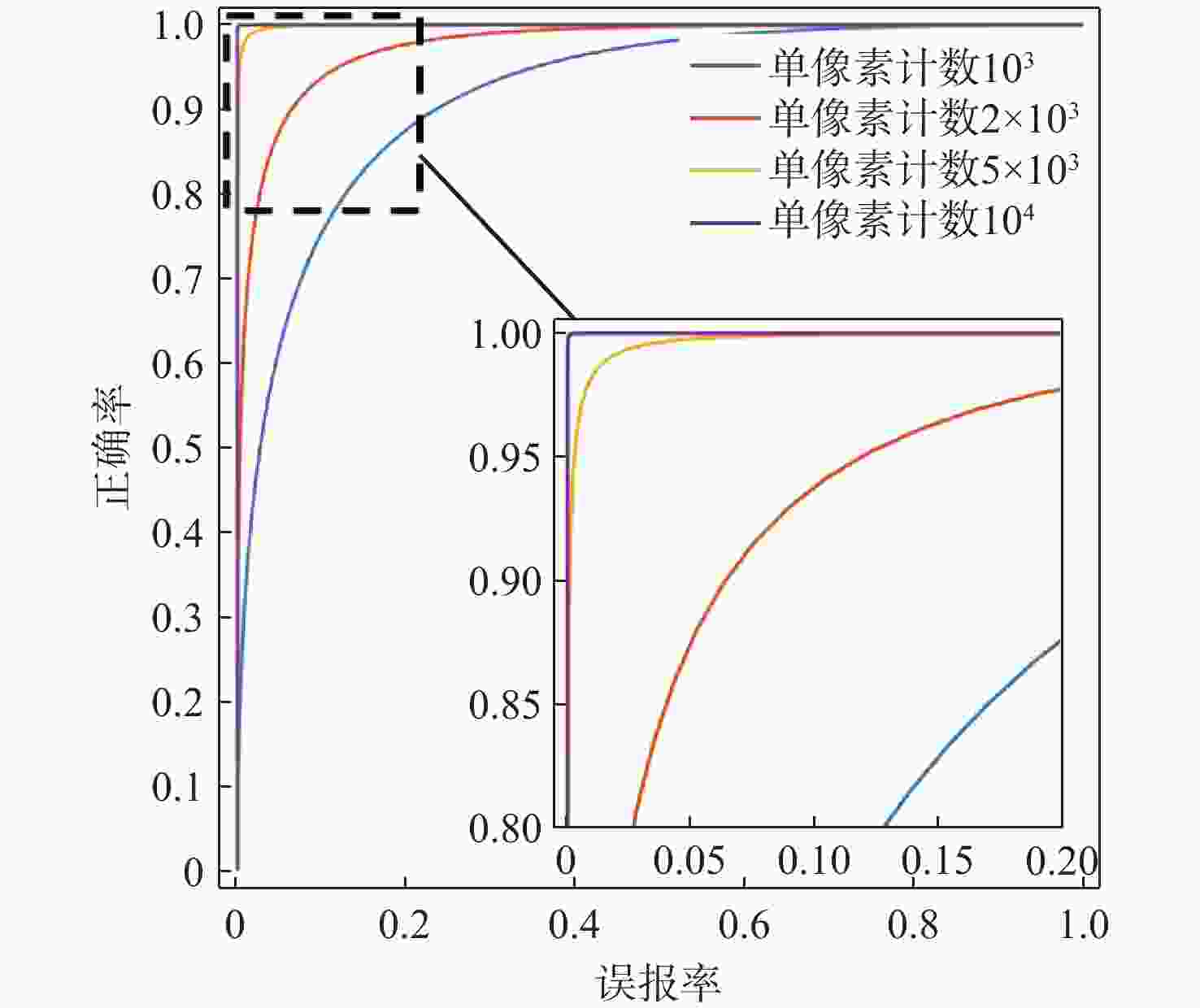

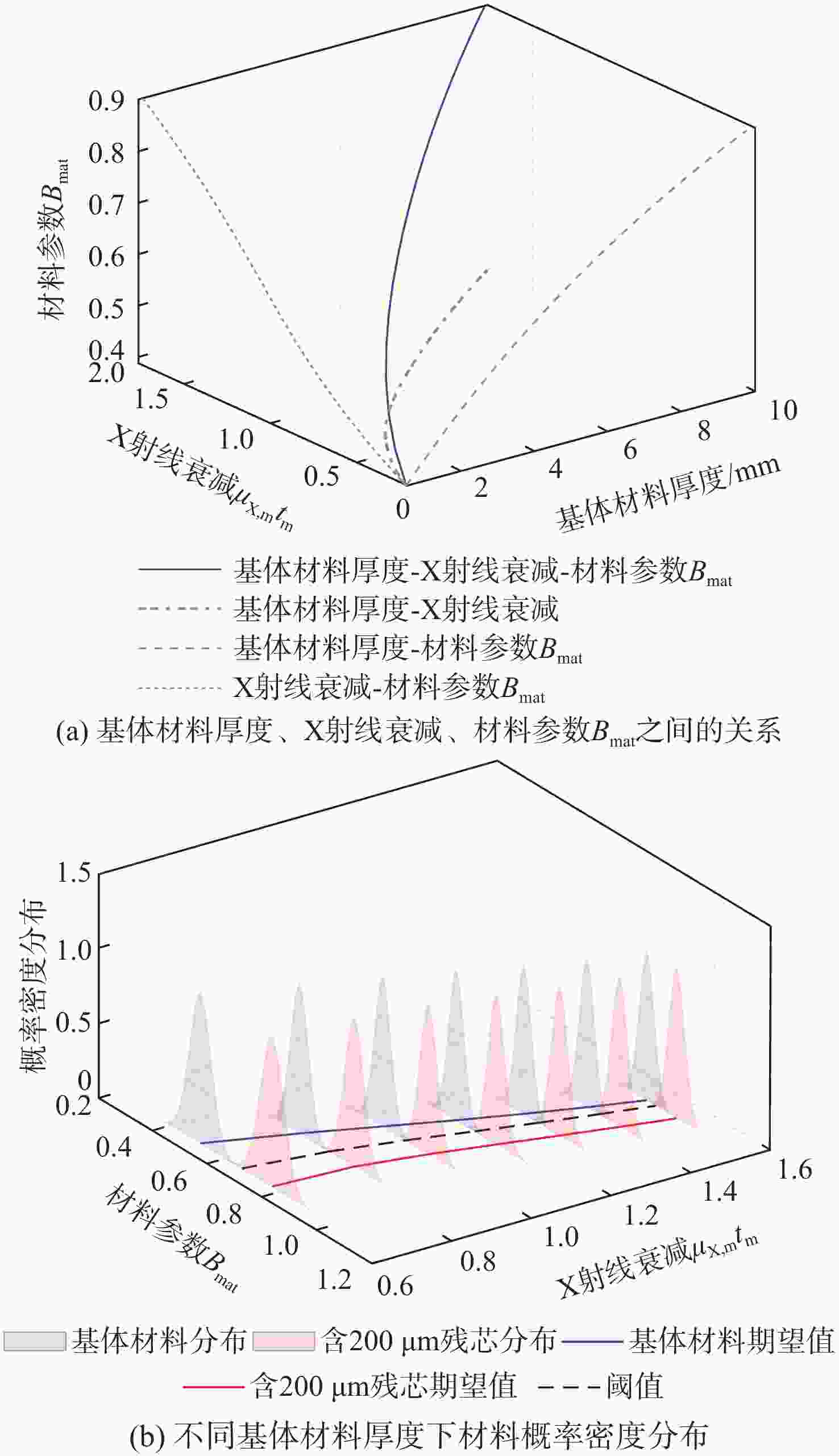

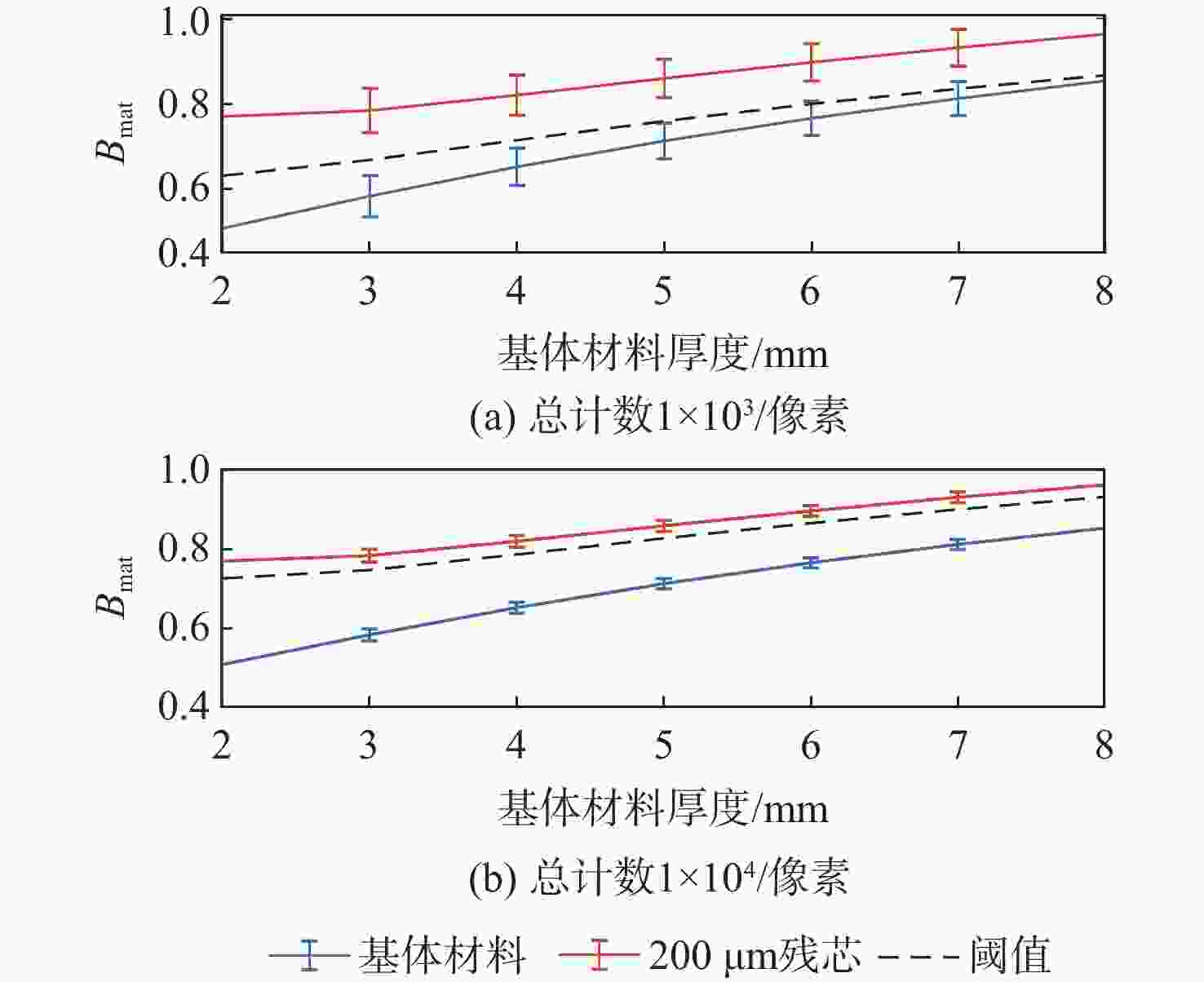

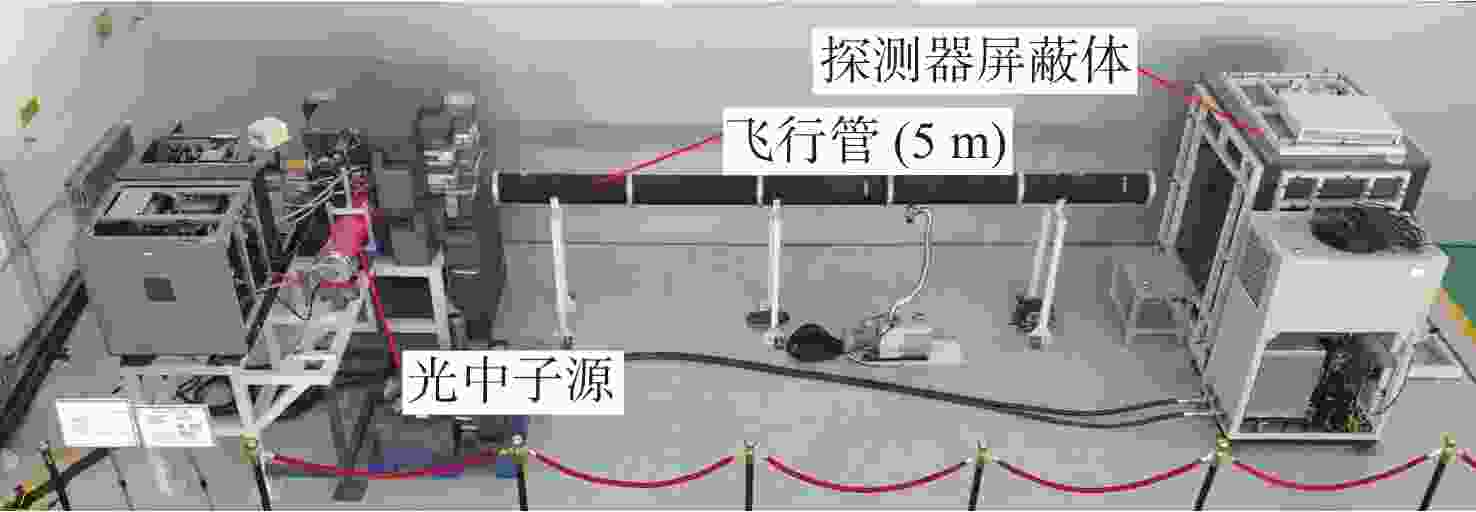

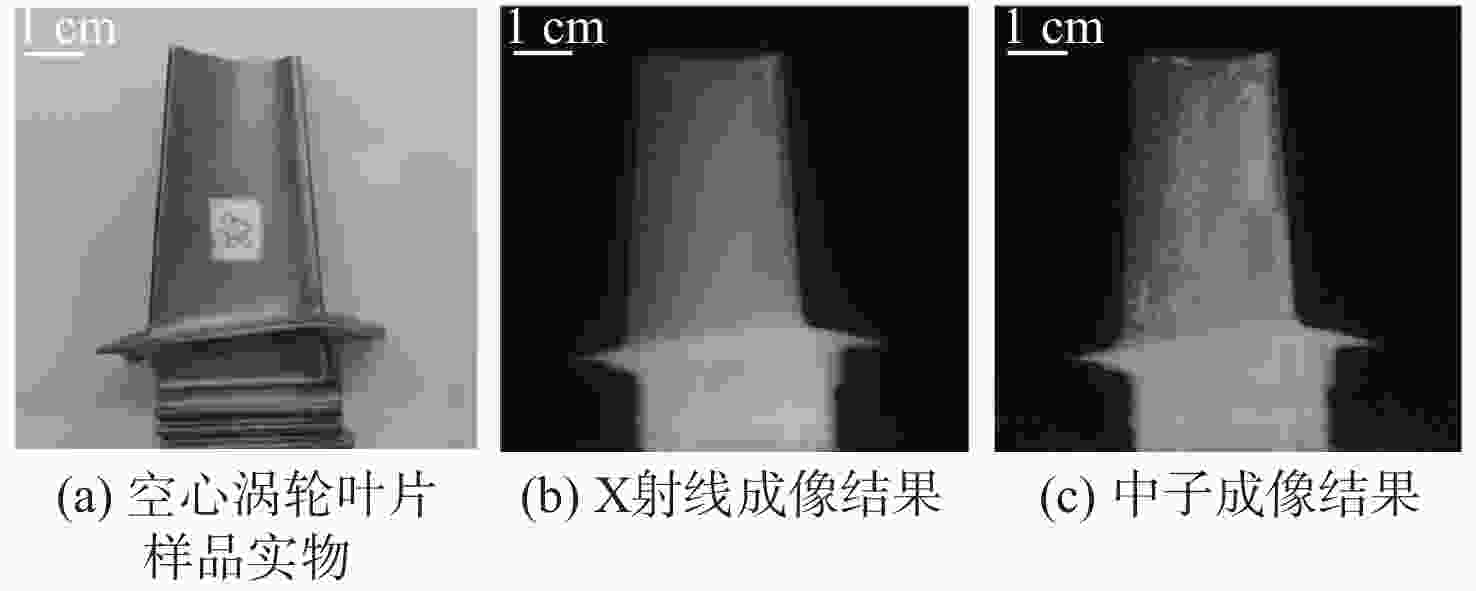

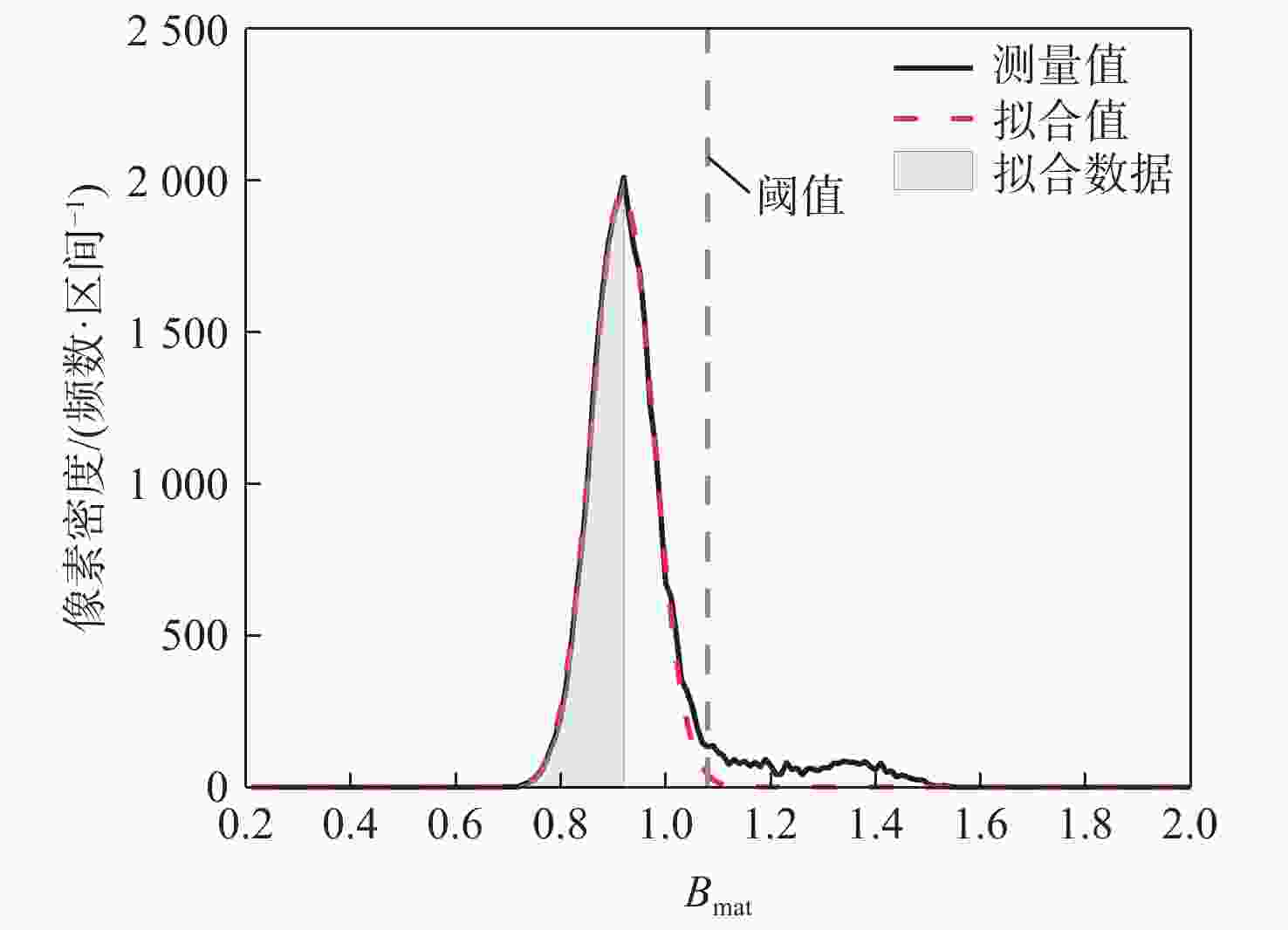

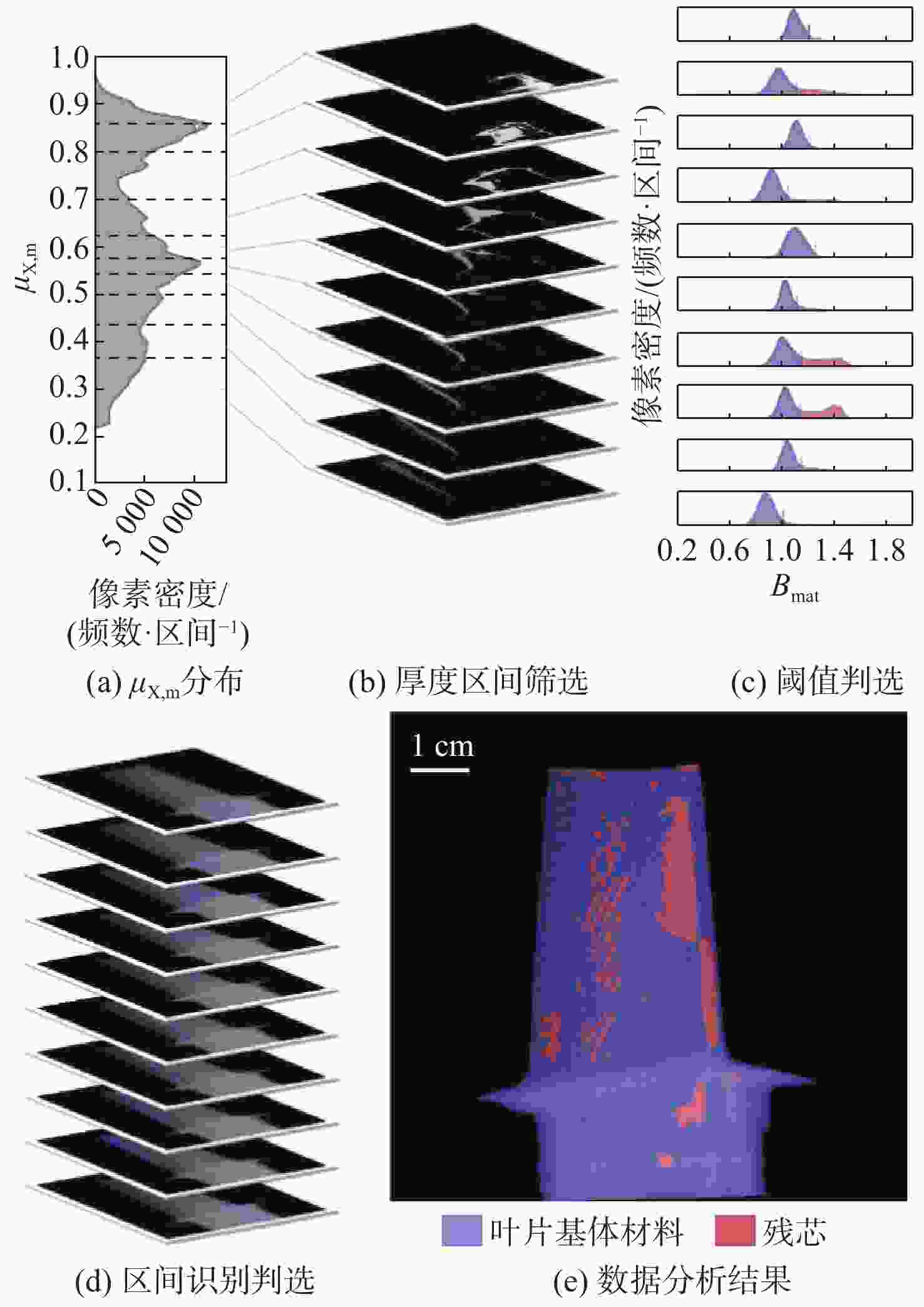

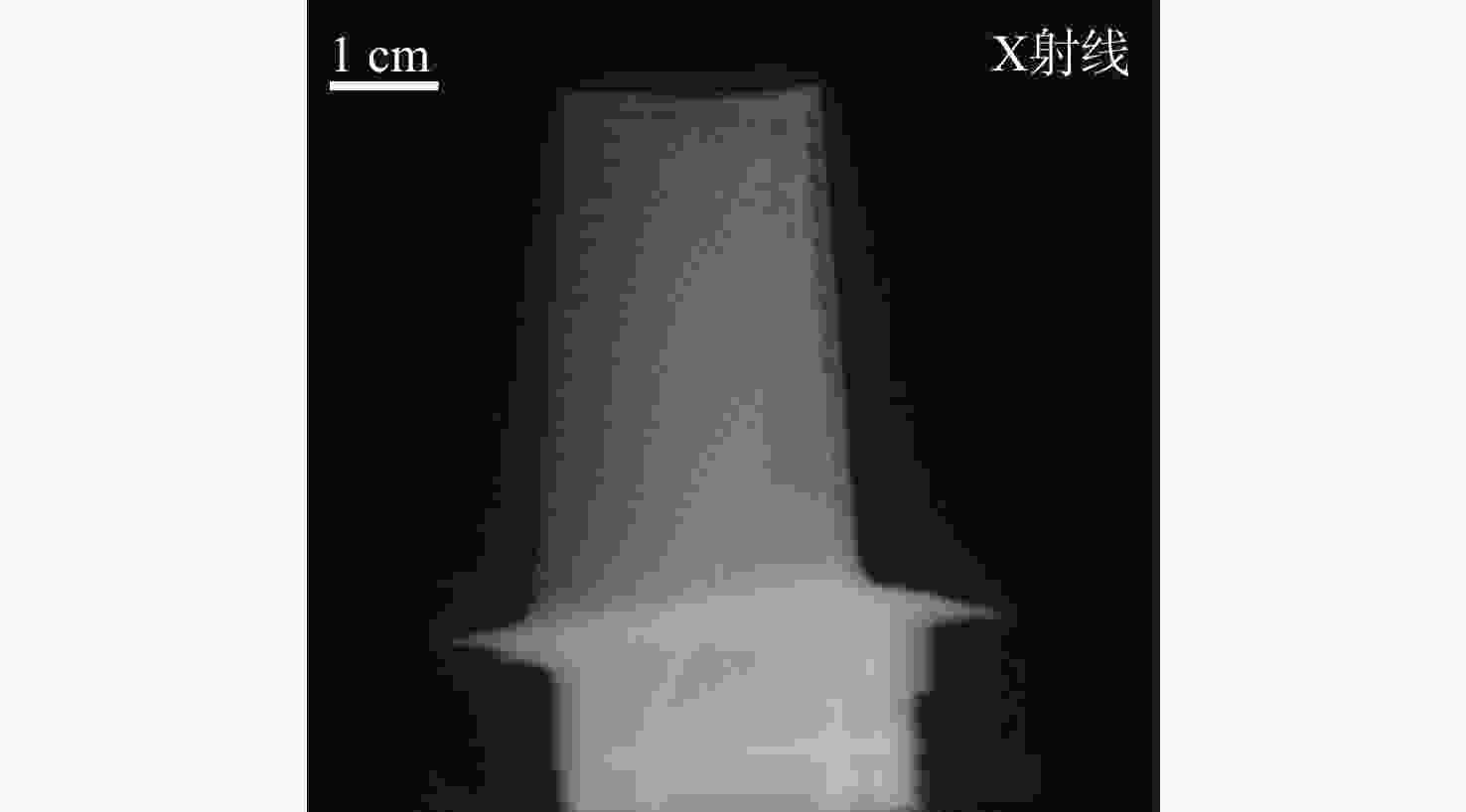

空心涡轮叶片的残芯检测对于航空发动机的生产制造具有重要价值。目前,基于电子加速器的双模成像方法已经实现了中子与X射线的同光路融合成像,可以从材料属性角度对叶片的基体材料与残芯材料进行分辨。针对双模成像中的射线能谱硬化问题,采用自动分段阈值设定的方法,实现了无需了解叶片几何构造先验知识和人工参与判断,直接检测出叶片中残芯存在区域的自动化无损检测新方法。当单个像素的中子计数不低于104时,双模成像方法对残芯识别的误差不超过1%。

Abstract:Residual core inspection is crucial in the production of hollow turbine blades. The e-LINAC-based bi-modal imaging method combines neutron and X-ray imaging along the same optical path, enabling fusion analysis to differentiate between base and core materials based on their properties. This study addresses the beam hardening issue in bi-modal imaging by developing an automatic segmental threshold setting method, which enables a novel automated non-destructive testing approach that does not require prior knowledge of blade geometry or manual intervention, and directly identifies the residual core regions within the blade. When the neutron count per pixel is no less than 104, the error in residual core identification using the bi-modal imaging method does not exceed 1%.

-

Key words:

- bi-modal imaging /

- neutron imaging /

- non-destructive testing /

- residual core /

- hollow turbine blade

-

表 1 利用X射线或中子进行残芯检测时的质量衰减系数、质量厚度和射线衰减数据

Table 1. Mass attenuation coefficient, mass thickness, and attenuation data for residual core inspection using X-rays and neutrons

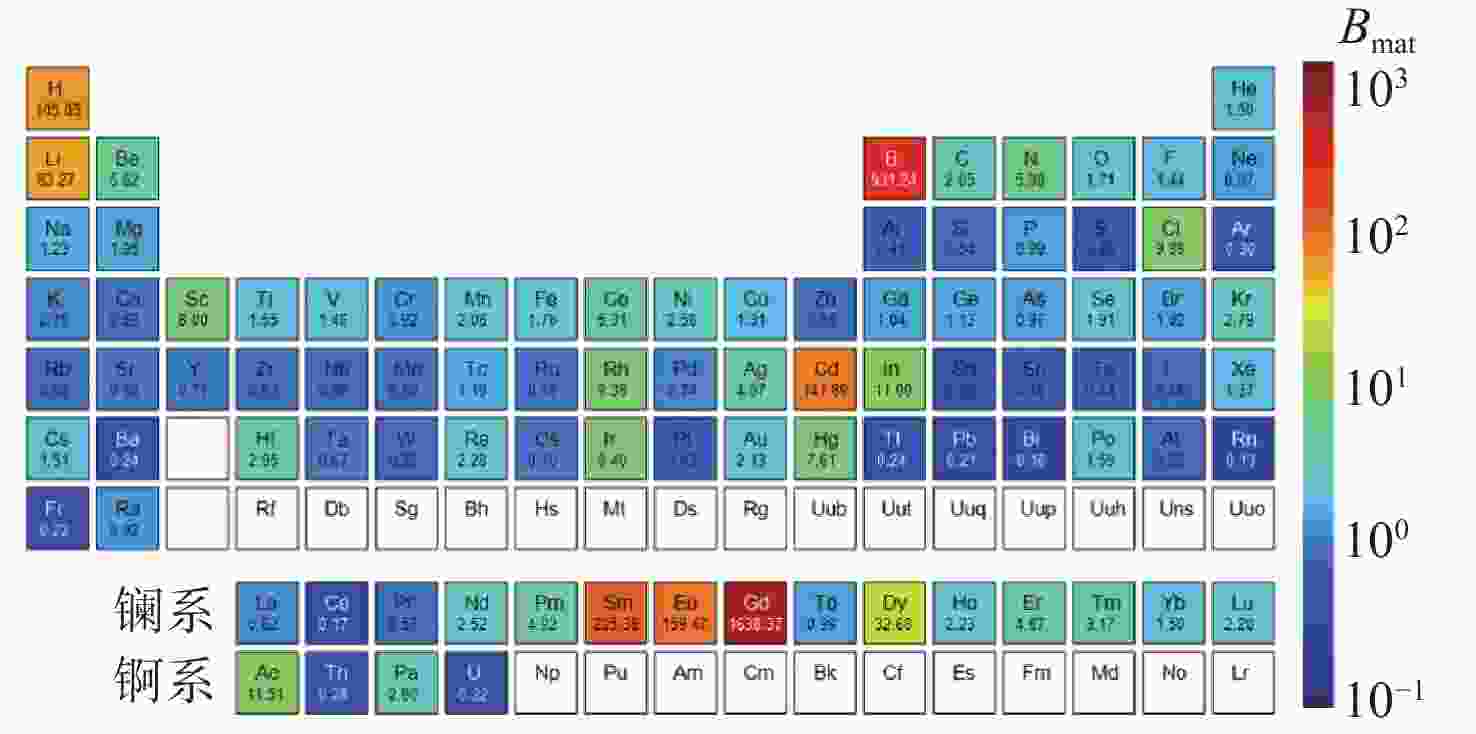

射线种类 质量衰减系数/(cm2·g−1) 典型质量厚度/(g·cm−2) 射线衰减 残芯衰减占比/% 基体材料 残芯 基体材料 残芯 基体材料 残芯 X射线 0.262 0.156 4.39 0.0540 1.156 0.0084 0.73 中子 0.188 3.320 4.39 0.0540 1.004 0.1800 17.9 注:表中X射线与中子的质量衰减系数根据清华大学9 MeV双模成像系统的能谱与ENDF/B-Ⅷ数据共同计算得到,其中,典型的基体材料厚度设定为5 mm,残芯厚度设定为200 μm。 表 2 双模成像装置参数

Table 2. Parameters of bi-modal imaging system

电子加速器参数 数值 成像探测器参数 数值 电子能量/MeV 9 探测器类型 nMCP 重复频率/Hz 100 灵敏区尺寸/

(mm×mm)95×95 中子总产额/(n·s−1) 2×1011 分辨率/μm < 200 中子通量(10 m飞行距离)/

(cm−2·s−1)2500 读出方式 sCMOS 光子通量(10 m飞行距离)/

(cm−2·s−1)1.03×106 像素尺寸/μm ~50 准直比 100/1 像素数/(像素×像素) 2160 ×2560 -

[1] BARTON J P, FARNY G, PERSON J L, et al. Neutron radiography: proceedings of the second world conference Paris, France, June16-20, 1986[M]. Berlin: Springer, 1986: 16-20. [2] 李彪, 祝强, 金磊, 等. 空心涡轮叶片内腔残留型芯的检测技术[C]//2020中国铸造活动周论文集. 北京: 中国机械工程学会, 2020: 158-166.LI B, ZHU Q, JIN L, et al. Detection technologies for residual ceramic cores in hollow turbine blades[C]//Proceedings of the 2020 China Foundry Week. Beijing: Chinese Mechanical Engineering Society, 2020: 158-166(in Chinese). [3] 王婵, 李泽, 罗辅全, 等. 涡轮叶片内腔滞留物射线检测[C]//陕西省第十届无损检测年会论文集. 西安: 陕西省机械工程学会, 2006: 111-121.WANG C, LI Z, LUO F Q, et al. Turbine blade inner cavity stagnant material radiographic inspection[C]//Proceedings of the 10th Annual NDT Conference in Shaanxi Province. Xi’an: The Shaanxi Provincial Institute of Mechanical Engineering, 2006: 111-121(in Chinese). [4] 高祥熙, 尹伟, 顾国红, 等. 基于钆掺杂法的空心涡轮叶片残芯冷中子照相检测[J]. 无损检测, 2021, 43(6): 1-5.GAO X X, YIN W, GU G H, et al. Cold neutron radiography testing of residual core in hollow turbine blade based on gadolinium doping method[J]. Nondestructive Testing Technologying, 2021, 43(6): 1-5(in Chinese). [5] 王倩妮, 郭广平, 顾国红, 等. 航空发动机叶片残余型芯中子照相检测[J]. 失效分析与预防, 2021, 16(1): 76-82.WANG Q N, GUO G P, GU G H, et al. Neutron radiography detection of residual core in turbine blades[J]. Failure Analysis and Prevention, 2021, 16(1): 76-82(in Chinese). [6] GARBE U, AHUJA Y, IBRAHIM R, et al. Industrial application experiments on the neutron imaging instrument DINGO[J]. Physics Procedia, 2017, 88: 13-18. doi: 10.1016/j.phpro.2017.06.001 [7] MARTZ H E, LOGAN C M, SCHNEBERK D J, et al. X-ray imaging: fundamentals, industrial techniques and applications[M]. Raton: CRC Press, 2016. [8] MAIER A, STEIDL S, CHRISTLEIN V, et al. Medical imaging systems: an introductory guide[M]. Beilin: Springer, 2018. [9] MCLEAN M. Nickel-base superalloys: current status and potential[J]. Philosophical Transactions of the Royal Society of London Series A: Physical and Engineering Sciences, 1995, 351(1697): 419-433. doi: 10.1098/rsta.1995.0044 [10] YIP S. Nuclear radiation interactions[M]. Singapore: World Scientific Publishing Company, 2014. [11] BROWN D A, CHADWICK M B, CAPOTE R, et al. ENDF/B-VIII. 0: the 8th major release of the nuclear reaction data library with CIELO-project cross sections, new standards and thermal scattering data[J]. Nuclear Data Sheets, 2018, 148: 1-142. doi: 10.1016/j.nds.2018.02.001 [12] LEHMANN E H, MANNES D, KAESTNER A P, et al. The XTRA option at the NEUTRA facility: more than 10 years of bi-modal neutron and X-ray imaging at PSI[J]. Applied Sciences, 2021, 11(9): 3825. doi: 10.3390/app11093825 [13] SINHA V, SRIVASTAVA A, LEE H K. A novel method for NDT applications using NXCT system at the Missouri University of Science & Technology[J]. Nuclear Instruments and Methods in Physics Research Section A: Accelerators, Spectrometers, Detectors and Associated Equipment, 2014, 750: 43-55. [14] TENGATTINI A, LENOIR N, ANDÒ E, et al. NeXT-Grenoble, the neutron and X-ray tomograph in Grenoble[J]. Nuclear Instruments and Methods in Physics Research Section A: Accelerators, Spectrometers, Detectors and Associated Equipment, 2020, 968: 163939. doi: 10.1016/j.nima.2020.163939 [15] LAMANNA J M, HUSSEY D S, BALTIC E, et al. Neutron and X-ray tomography (NeXT) system for simultaneous, dual modality tomography[J]. Review of Scientific Instruments, 2017, 88(11): 113702. doi: 10.1063/1.4989642 [16] 杨祎罡, 王学武, 张智, 等. 双模探测方法、控制器和系统: CN110779939B[P]. 2018-07-11.YANG Y G, WANG X W, ZHANG Z, et al. Bi-modal detection method, controller and system: CN110779939B[P]. 2018-07-11(in Chinese). [17] YU Y Y, ZHANG R Q, LU L, et al. The bimodal neutron and X-ray imaging driven by a single electron linear accelerator[J]. Applied Sciences, 2021, 11(13): 6050. doi: 10.3390/app11136050 [18] BROOKS R A, DI CHIRO G. Beam hardening in X-ray reconstructive tomography[J]. Physics in Medicine and Biology, 1976, 21(3): 390-398. doi: 10.1088/0031-9155/21/3/004 -

下载:

下载: