Ensemble-based prediction using multi-level degradation parameters for micro direct methanol fuel cells

-

摘要:

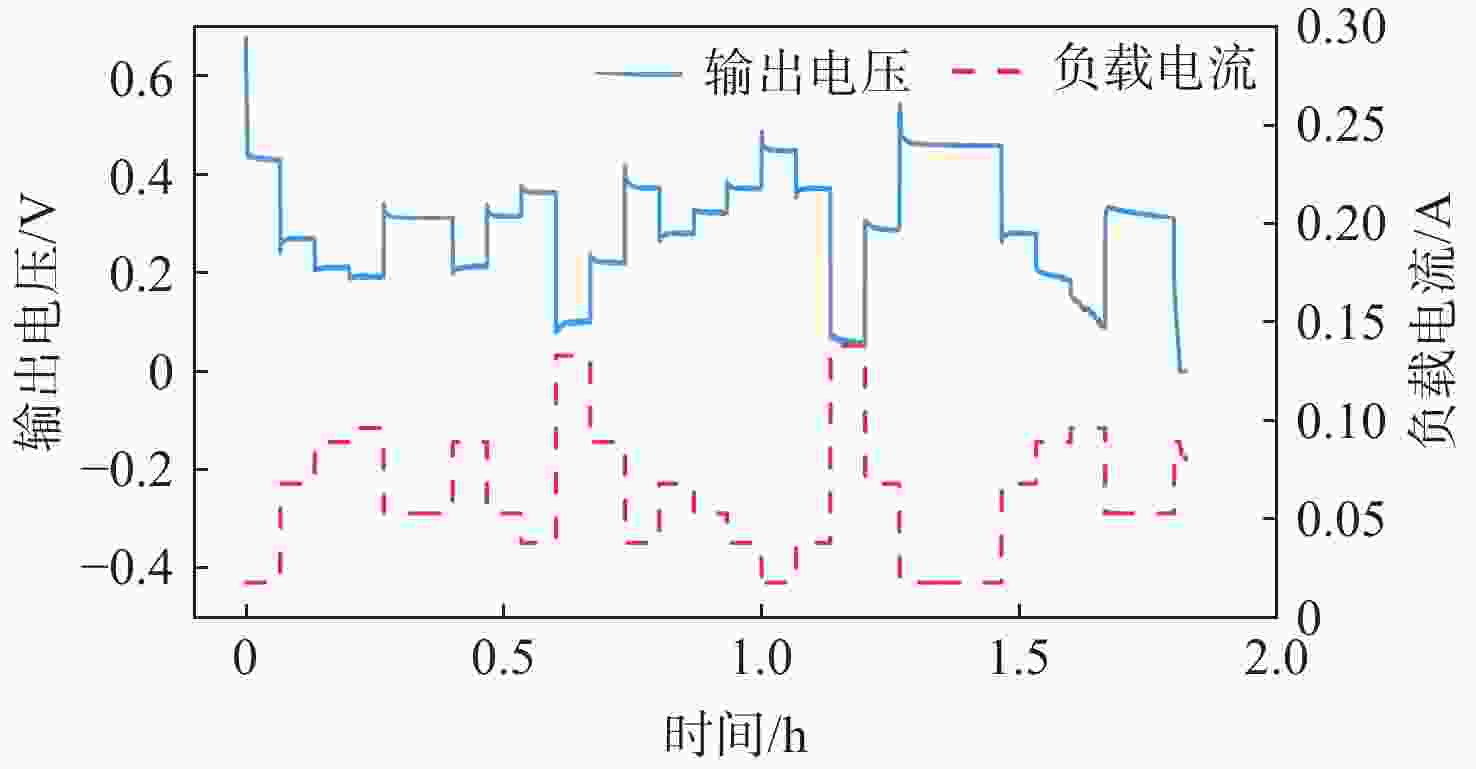

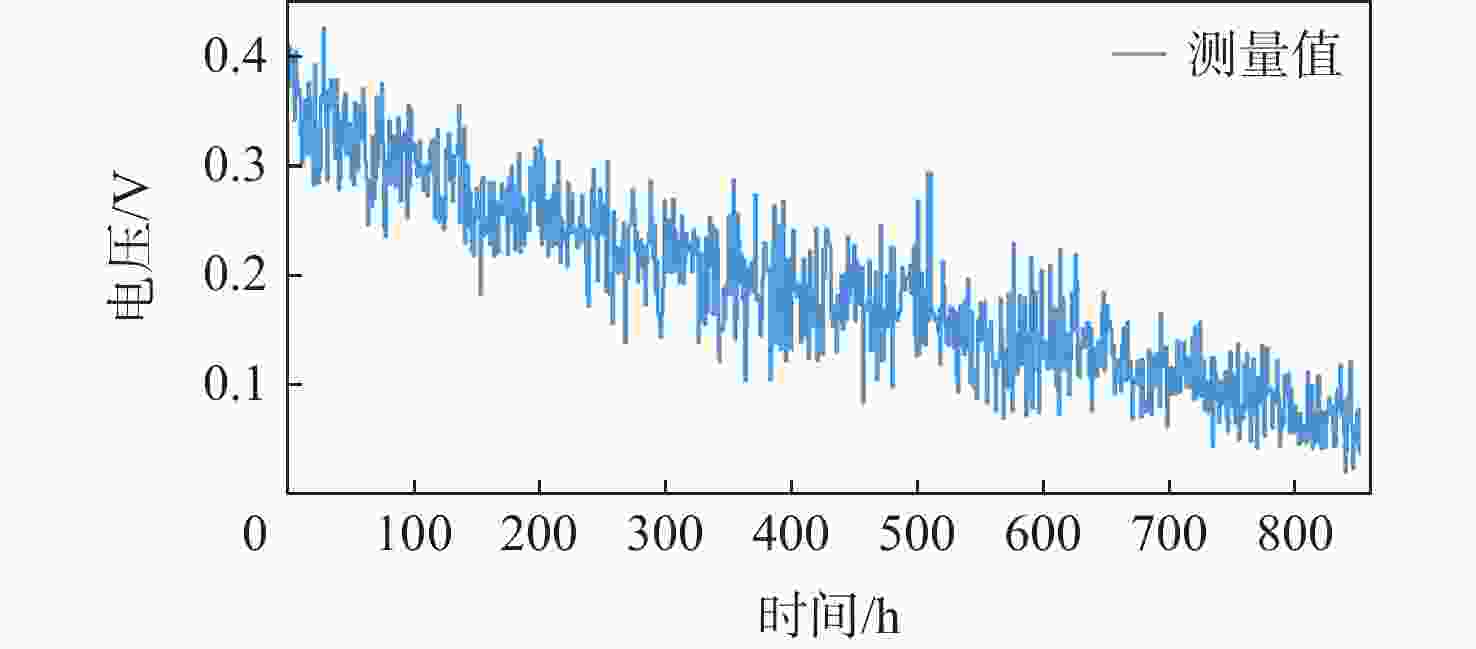

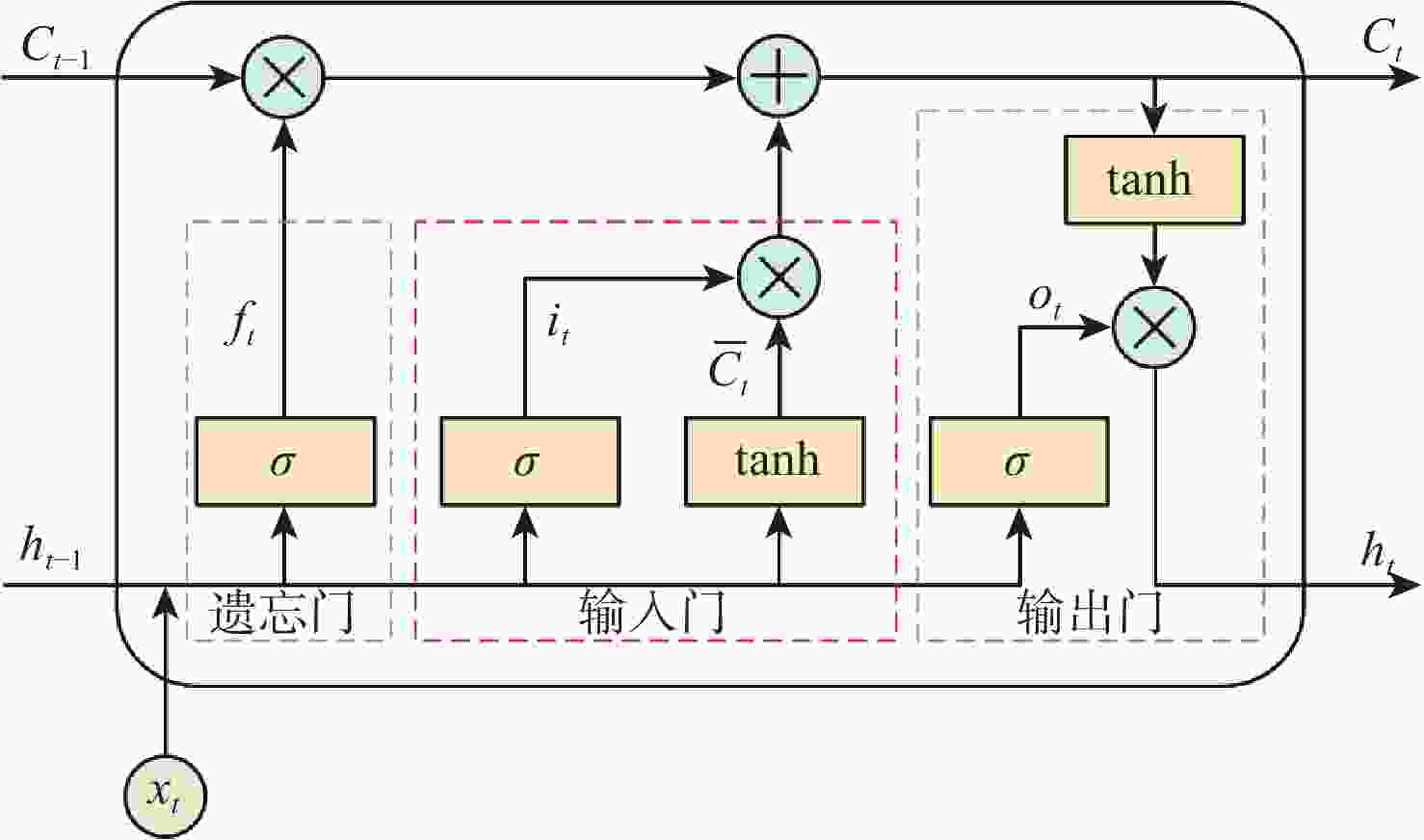

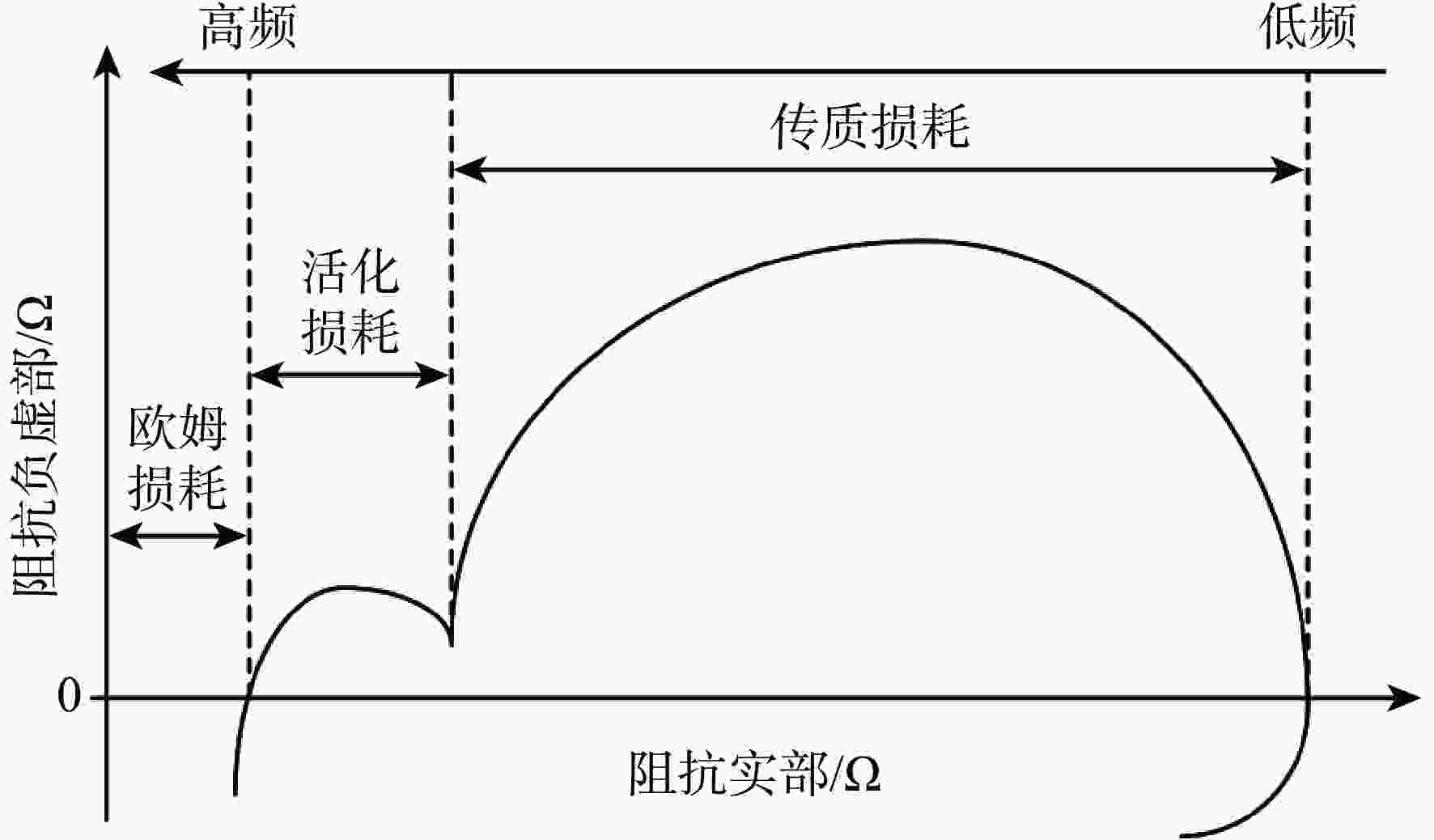

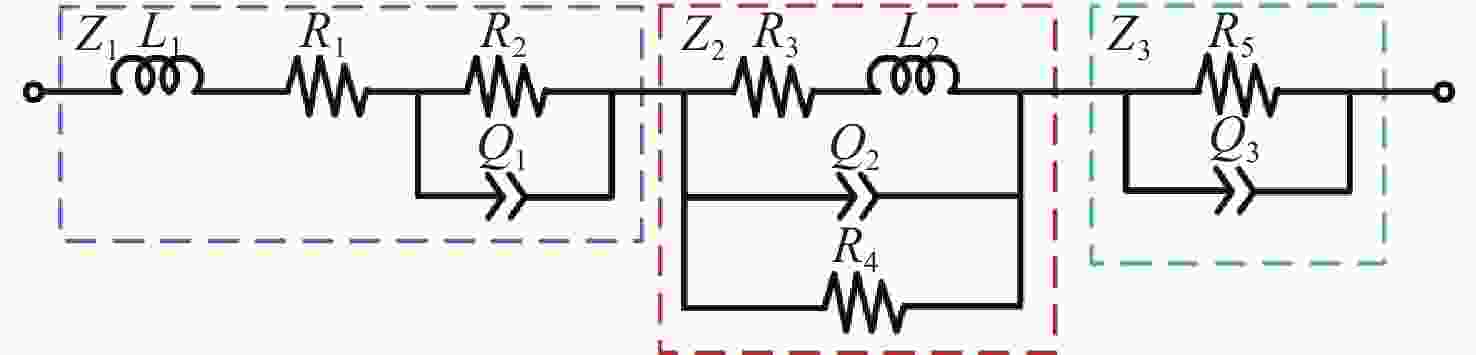

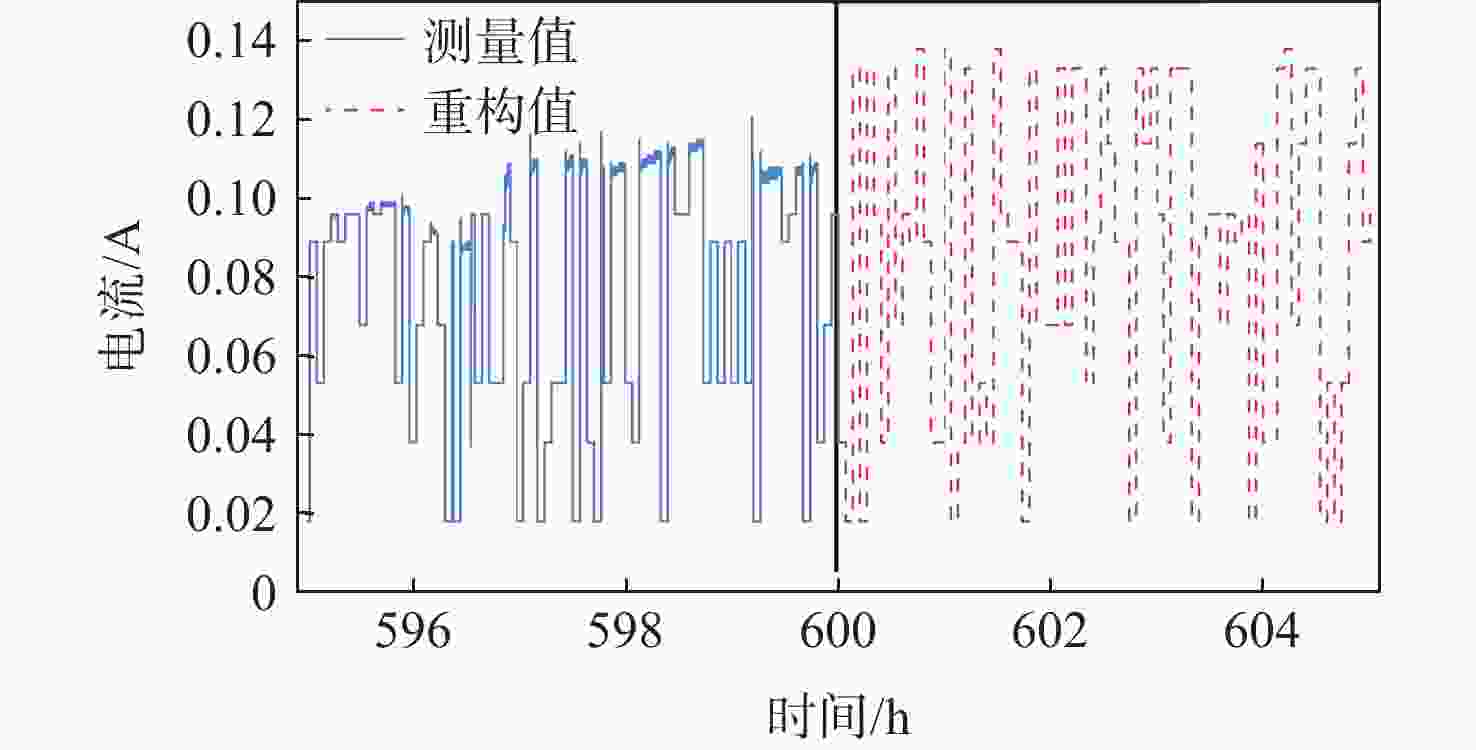

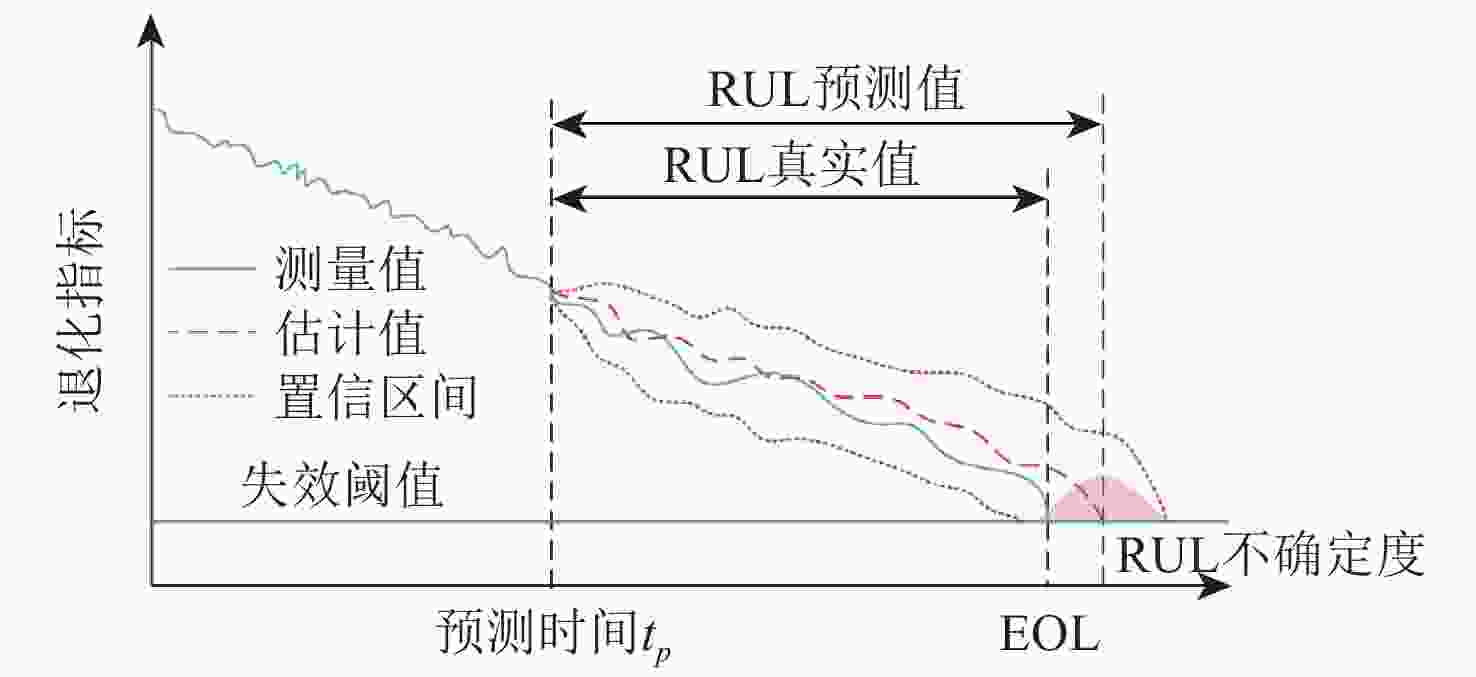

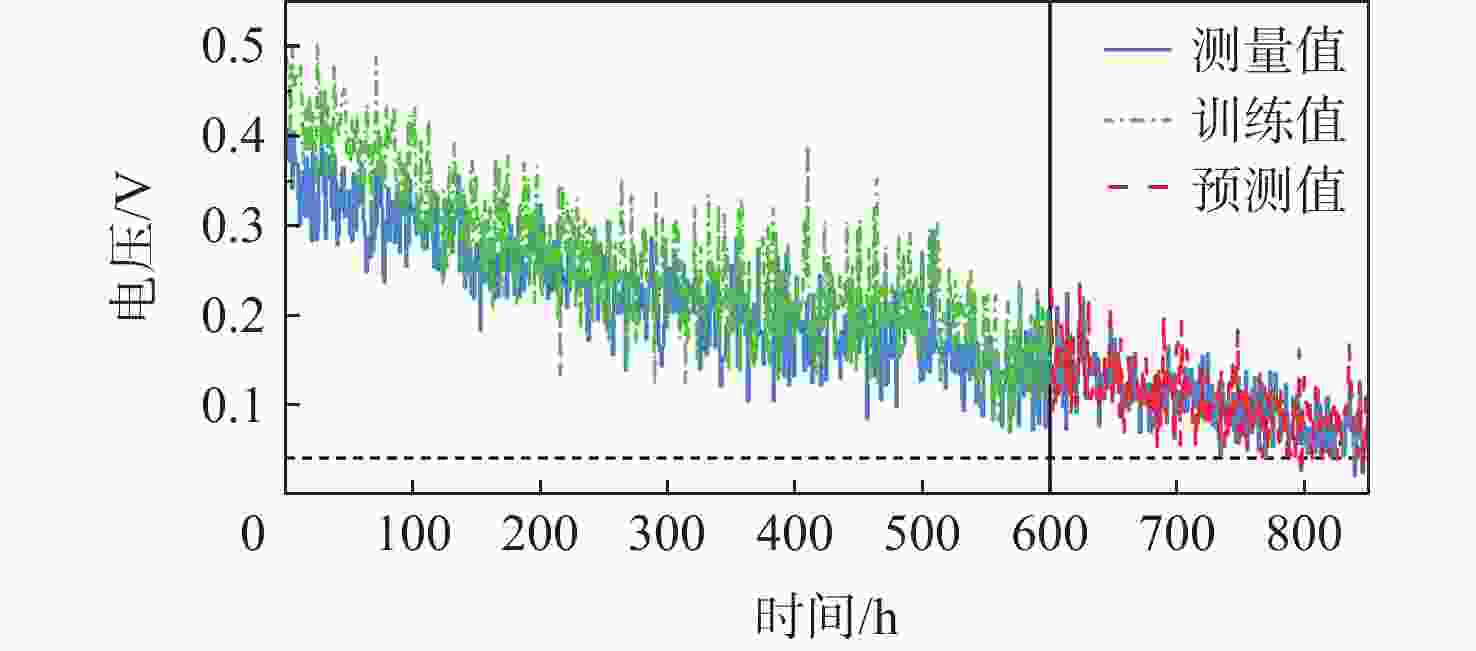

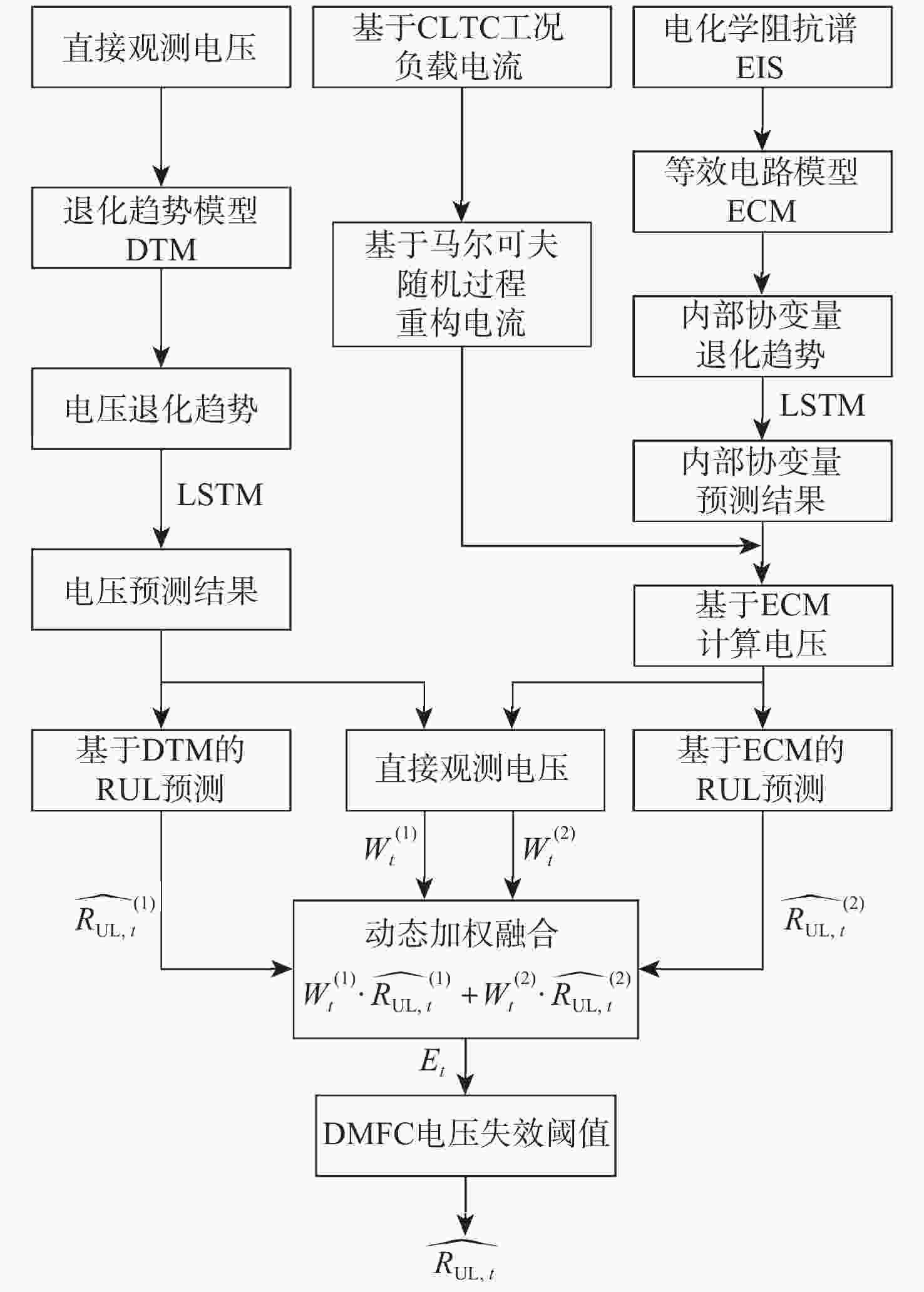

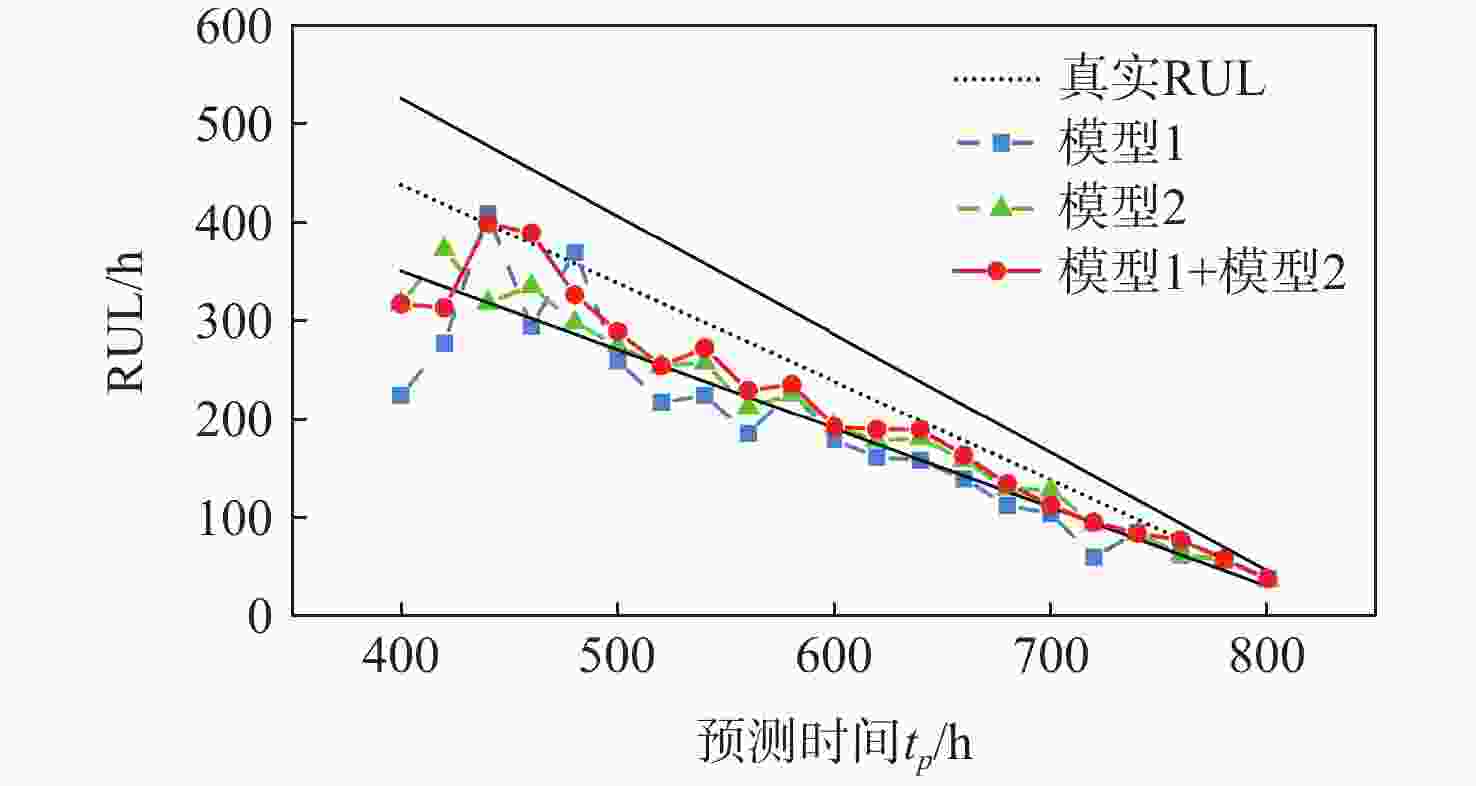

微型直接甲醇燃料电池(µDMFC)膜电极性能会随运行时间和工况衰退,影响其效率和使用寿命。准确的健康状态(SOH)估计与剩余使用寿命(RUL)预测可以确保µDMFC安全运行。输出电压的退化趋势受运行工况影响而波动,传统基于退化趋势回归的预测方法无法准确捕获这种随机变化。在数据驱动和机理模型相结合的思路下,提出基于输出电压和等效电路模型(ECM)的RUL融合预测方法。针对动态工况,引入负载电流这一退化协变量,利用随机过程重构了未来时刻的负载变化,结合ECM参量的退化趋势,实现对输出电压的准确估计和RUL预测,并在中国轻型汽车测试工况(CLTC)下进行验证。实验结果表明:基于多级退化参量的融合预测方法能更好地适应变工况,RUL预测精度、准确度分别为88.18%和85.71%,高于单一退化模型最优值3.27%和14.28%。

-

关键词:

- 微型直接甲醇燃料电池 /

- 动态工况 /

- 剩余使用寿命 /

- 多级退化参量 /

- 融合预测

Abstract:The deterioration of the membrane electrode assembly in micro direct methanol fuel cells (µDMFC) limits cell efficiency and lifespan. Accurate prediction of the state of health (SOH) and remaining useful life (RUL) is essential for ensuring the safe and reliable operation of µDMFCs in industrial applications. The degradation trend of the output voltage fluctuates depending on the operating conditions. Traditional trend regression methods, however, are inadequate for capturing such stochastic fluctuations. Therefore, an RUL ensemble-based prediction method based on the output voltage and equivalent circuit model (ECM) was proposed under a combination of data-driven and mechanistic models. The degradation covariate of load current was introduced to account for dynamic operating conditions. The load changes in the future were reconstructed using a random process, and combined with the degradation trend of ECM parameters, the accurate estimation of the output voltage and RUL prediction were achieved. The proposed approach was validated using accelerated aging tests under the China light vehicle test cycle (CLTC). Experimental results show that the ensemble-based method can adapt to varying operating conditions. RUL prediction accuracy and precision are 88.18% and 85.71%, respectively, outperforming the best individual model by 3.27% and 14.28%.

-

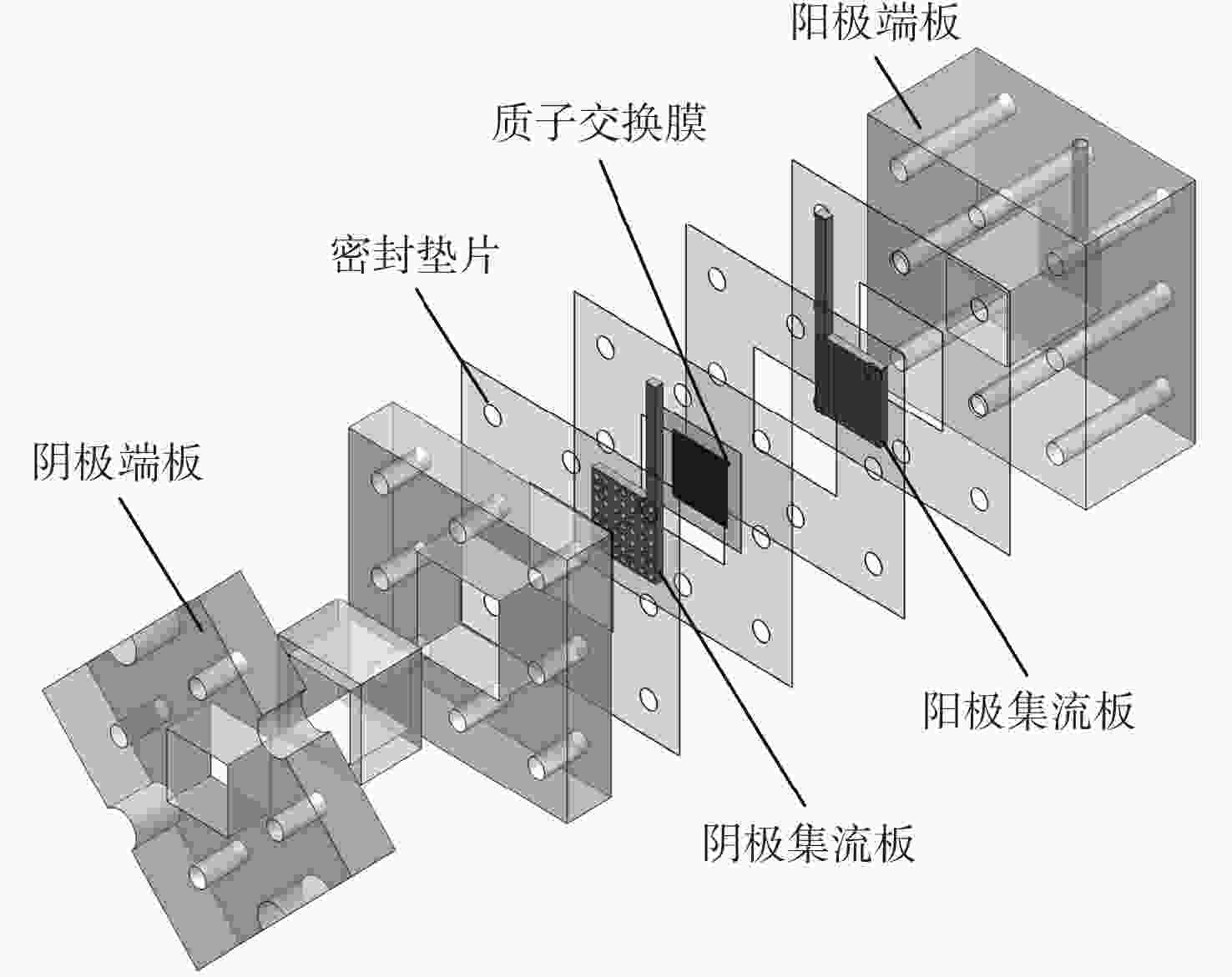

表 1 基于CLTC工况的负载电流设置

Table 1. Load current settings based on CLTC operating conditions

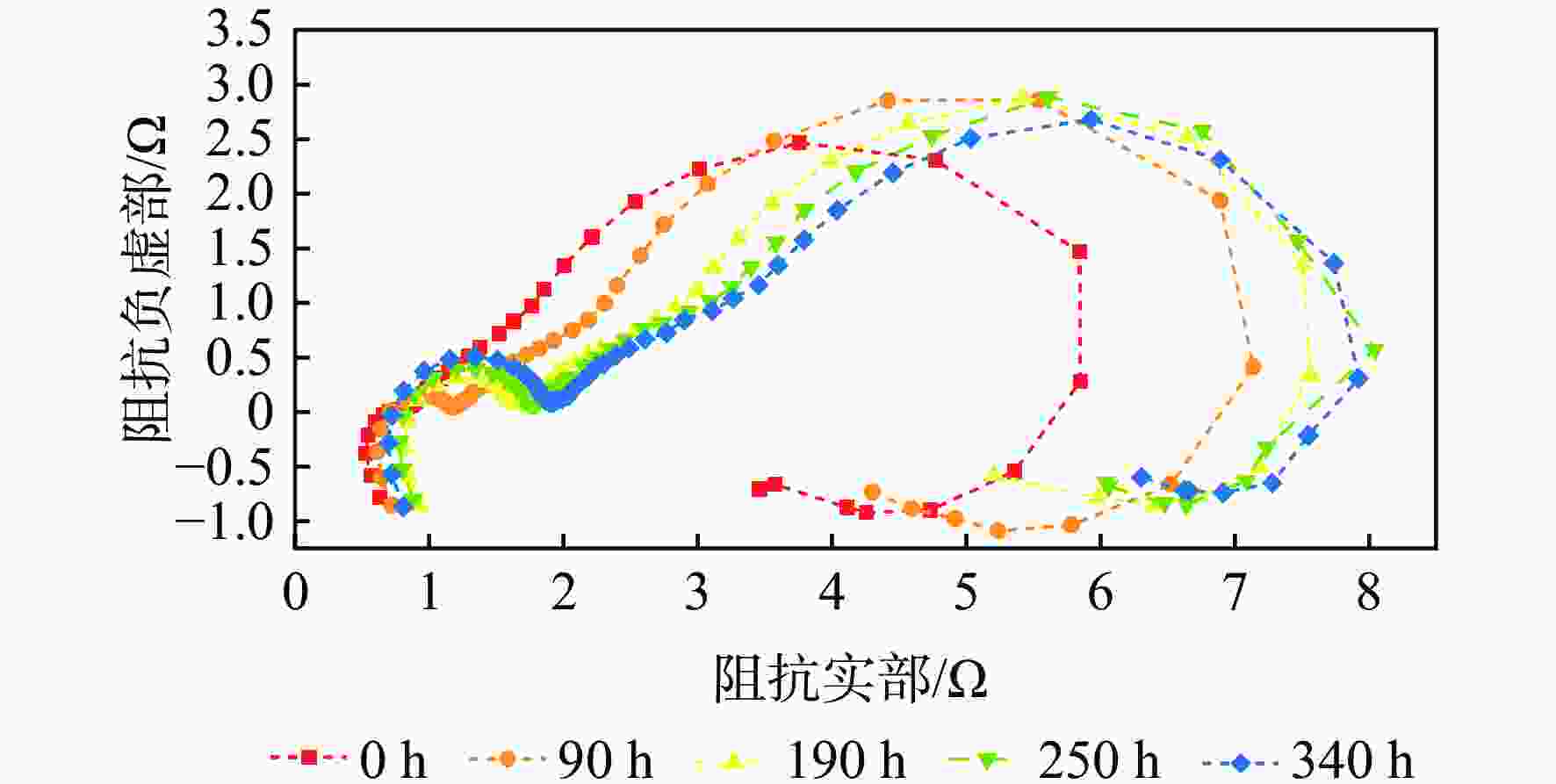

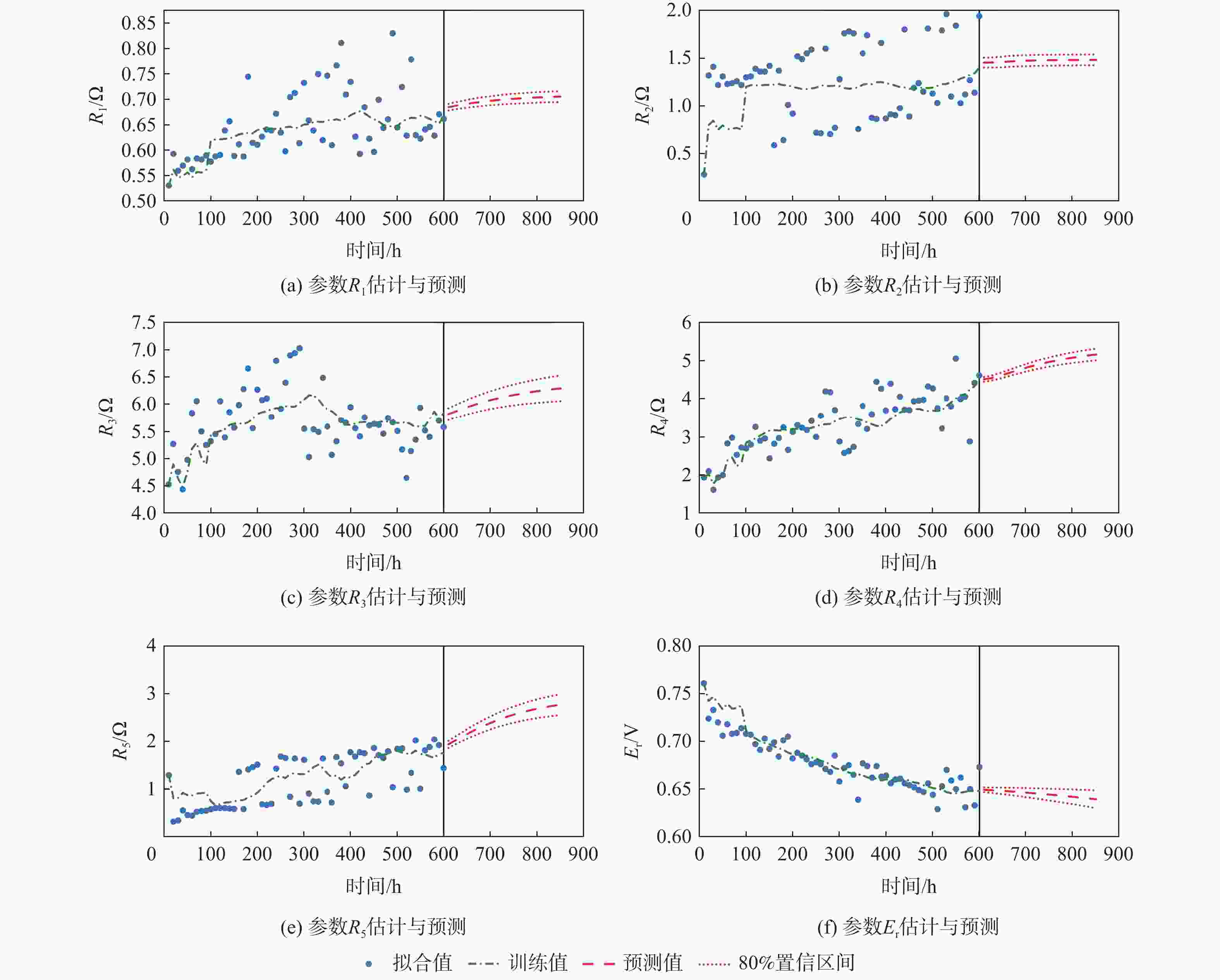

速度区间 运行状态 占比/% 平均车速/(km·h−1) 实验负载电流/A 低速 减速 23.67 11.85 0.018 匀速 21.36 24.91 0.038 加速 22.18 35.02 0.053 怠速 32.79 0 0 中速 减速 26.67 44.52 0.068 匀速 28.29 55.53 0.089 加速 27.32 62.49 0.096 怠速 17.72 0 0 高速 减速 19.56 75.13 0.114 匀速 57.11 87.71 0.133 加速 19.78 90.92 0.138 怠速 3.56 0 0 表 2 不同时间的 ECM 模型参数识别结果示例

Table 2. ECM parameters identification results at different time

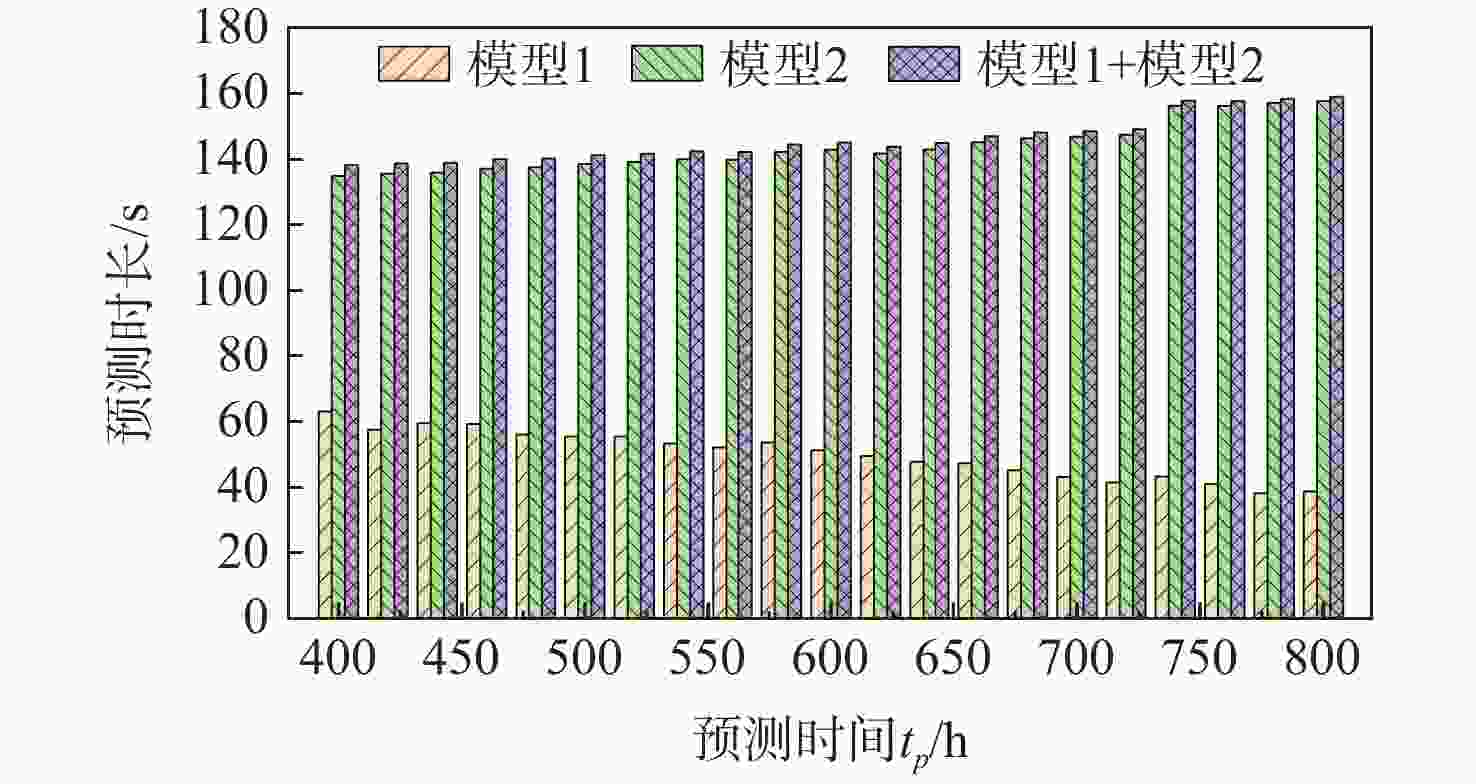

时间/h Er/V R1/Ω R2/Ω R3/Ω R4/Ω R5/Ω 0 0.724 0.531 0.280 4.530 1.940 1.290 90 0.717 0.590 1.220 5.250 2.720 0.551 190 0.705 0.615 1.010 5.560 2.660 1.460 250 0.678 0.635 0.719 5.920 3.000 1.680 340 0.639 0.620 1.550 6.490 3.340 1.770 表 3 各模型 RUL 预测性能评价结果

Table 3. Prognostic performance evaluation for different models

模型 Acc/% $\alpha_ {A_{\mathrm{c}} } $/% 平均预测时长/s 模型1 77.87 33.33 50.20 模型2 84.91 71.43 143.91 模型1与模型2融合 88.18 85.71 146.11 -

[1] JIAO K, XUAN J, DU Q, et al. Designing the next generation of proton-exchange membrane fuel cells[J]. Nature, 2021, 595(7867): 361-369. doi: 10.1038/s41586-021-03482-7 [2] MARAPPAN M, PALANISWAMY K, VELUMANI T, et al. Performance studies of proton exchange membrane fuel cells with different flow field designs–review[J]. The Chemical Record, 2021, 21(4): 663-714. doi: 10.1002/tcr.202000138 [3] ESMAEILI N, GRAY E M, WEBB C J. Non‐fluorinated polymer composite proton exchange membranes for fuel cell applications: a review[J]. ChemPhysChem, 2019, 20(16): 2016-2053. doi: 10.1002/cphc.201900191 [4] LEE J, WU F J, ZHAO W Y, et al. Prognostics and health management design for rotary machinery systems: reviews, methodology and applications[J]. Mechanical Systems and Signal Processing, 2014, 42(1-2): 314-334. doi: 10.1016/j.ymssp.2013.06.004 [5] LI X, ZHANG W, DING Q. Deep learning-based remaining useful life estimation of bearings using multi-scale feature extraction[J]. Reliability Engineering & System Safety, 2019, 182: 208-218. [6] 刘浩. 质子交换膜燃料电池的寿命预测研究[D]. 杭州: 浙江大学, 2019: 1-14.LIU H. Study on life prediction of proton exchange membrane fuel cell[D]. Hangzhou: Zhejiang University, 2019: 1-14 (in Chinese). [7] ZHANG D, CADET C, BÉRENGUER C, et al. Some improvements of particle filtering based prognosis for PEM fuel cells[J]. IFAC-PapersOnLine, 2016, 49(28): 162-167. doi: 10.1016/j.ifacol.2016.11.028 [8] FUTTER G A, LATZ A, JAHNKE T. Physical modeling of chemical membrane degradation in polymer electrolyte membrane fuel cells: influence of pressure, relative humidity and cell voltage[J]. Journal of Power Sources, 2019, 410: 78-90. [9] JOUIN M, GOURIVEAU R, HISSEL D, et al. Prognostics of PEM fuel cell in a particle filtering framework[J]. International Journal of Hydrogen Energy, 2014, 39(1): 481-494. doi: 10.1016/j.ijhydene.2013.10.054 [10] VICHARD L, HAREL F, RAVEY A, et al. Degradation prediction of PEM fuel cell based on artificial intelligence[J]. International Journal of Hydrogen Energy, 2020, 45(29): 14953-14963. doi: 10.1016/j.ijhydene.2020.03.209 [11] DONG H C, JIN X N, LOU Y B, et al. Lithium-ion battery state of health monitoring and remaining useful life prediction based on support vector regression-particle filter[J]. Journal of Power Sources, 2014, 271: 114-123. doi: 10.1016/j.jpowsour.2014.07.176 [12] ZHANG D, BARALDI P, CADET C, et al. An ensemble of models for integrating dependent sources of information for the prognosis of the remaining useful life of proton exchange membrane fuel cells[J]. Mechanical Systems and Signal Processing, 2019, 124: 479-501. doi: 10.1016/j.ymssp.2019.01.060 [13] ZHAO Z G, ZHANG F, ZHANG Y H, et al. Performance optimization of μDMFC with foamed stainless steel cathode current collector[J]. Energies, 2021, 14(20): 6608. doi: 10.3390/en14206608 [14] 薛瑞. 微型直接甲醇燃料电池高浓度传质阻挡层技术研究[D]. 哈尔滨: 哈尔滨工业大学, 2019: 46-62.XUE R. Research on the mass transfer barrier layer of concentrated direct methanol fuel cell[D]. Harbin: Harbin Institute of Technology, 2019: 46-62(in Chinese). [15] LIU Y, WU Z X, ZHOU H, et al. Development of China light-duty vehicle test cycle[J]. International Journal of Automotive Technology, 2020, 21(5): 1233-1246. doi: 10.1007/s12239-020-0117-5 [16] 王鑫, 吴际, 刘超, 等. 基于LSTM循环神经网络的故障时间序列预测[J]. 北京麻豆精品秘 国产传媒学报, 2018, 44(4): 772-784.WANG X, WU J, LIU C, et al. Exploring LSTM based recurrent neural network for failure time series prediction[J]. Journal of Beijing University of Aeronautics and Astronautics, 2018, 44(4): 772-784(in Chinese). [17] PASTOR-FERNÁNDEZ C, DHAMMIKA WIDANAGE W, MARCO J, et al. Identification and quantification of ageing mechanisms in Lithium-ion batteries using the EIS technique[C]//Proceedings of the 2016 IEEE Transportation Electrification Conference and Expo. Piscataway: IEEE Press, 2016: 1-6. [18] YUAN T, ZOU Z Q, CHEN M, et al. New anodic diffusive layer for passive micro-direct methanol fuel cell[J]. Journal of Power Sources, 2009, 192(2): 423-428. doi: 10.1016/j.jpowsour.2009.03.032 [19] SØRENSEN T S, KJELSTRUP S. A simple Maxwell-Wagner-Butler-Volmer approach to the impedance of the hydrogen electrode in a Nafion fuel cell[J]. Journal of Colloid and Interface Science, 2002, 248(2): 355-375. doi: 10.1006/jcis.2001.8210 [20] ZHU Y L, GAO L, LI J Y. A novel button-type micro direct methanol fuel cell with graphene diffusion layer[J]. Micromachines, 2019, 10(10): 658. doi: 10.3390/mi10100658 [21] YUAN T, YANG J, WANG Y L, et al. Anodic diffusion layer with graphene-carbon nanotubes composite material for passive direct methanol fuel cell[J]. Electrochimica Acta, 2014, 147: 265-270. doi: 10.1016/j.electacta.2014.09.124 [22] JIANWEI G, ZONGQIANG M, JINGMING X. Studies on the electrochemical behavior of polymer electrolyte membrane fuel cell (PEMFC) by AC impedance method[J]. Chemical Journal of Chinese Universities, 2003, 24(8): 1477-1481. [23] KIM T, KIM H, HA J, et al. A degenerated equivalent circuit model and hybrid prediction for state-of-health (SOH) of PEM fuel cell[C]//Proceedings of the 2014 International Conference on Prognostics and Health Management. Piscataway: IEEE Press, 2014: 1-7. [24] 苏雨临, 连冠, 张大骋. 等效电路模型法预测动态工况下微型直接甲醇燃料电池剩余使用寿命[J]. 上海交通大学学报, 2024, 58(10): 1525-1532.SU Y L, LIAN G, ZHANG D C. Equivalent circuit model-based prognostics for micro direct methanol fuel cell under dynamic operating conditions[J]. Journal of Shanghai Jiao Tong University, 2024, 58(10): 1525-1532(in Chinese). -

下载:

下载: