Contamination lock characteristics analysis of fuel metering unit based on OMEGA theory

-

摘要:

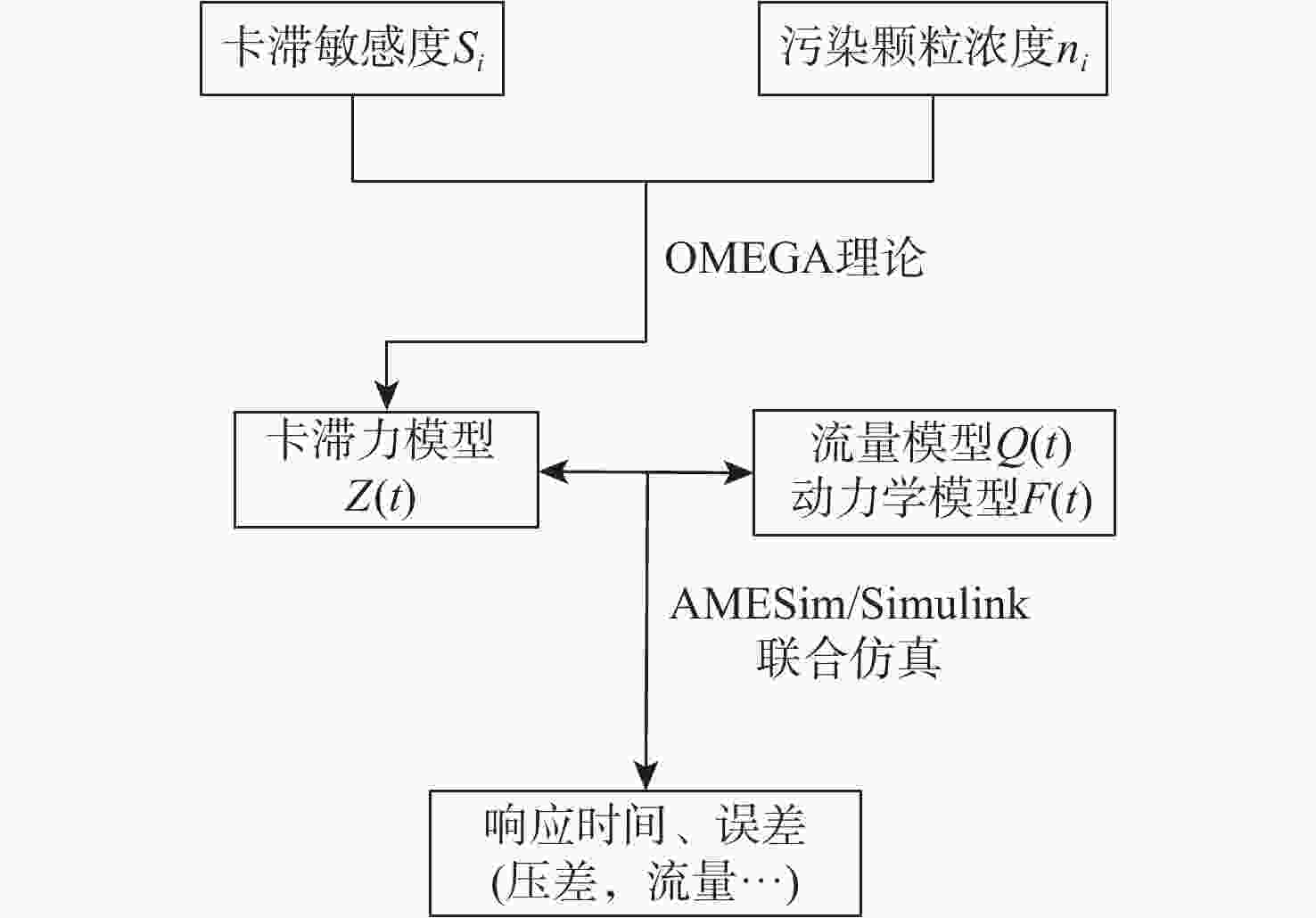

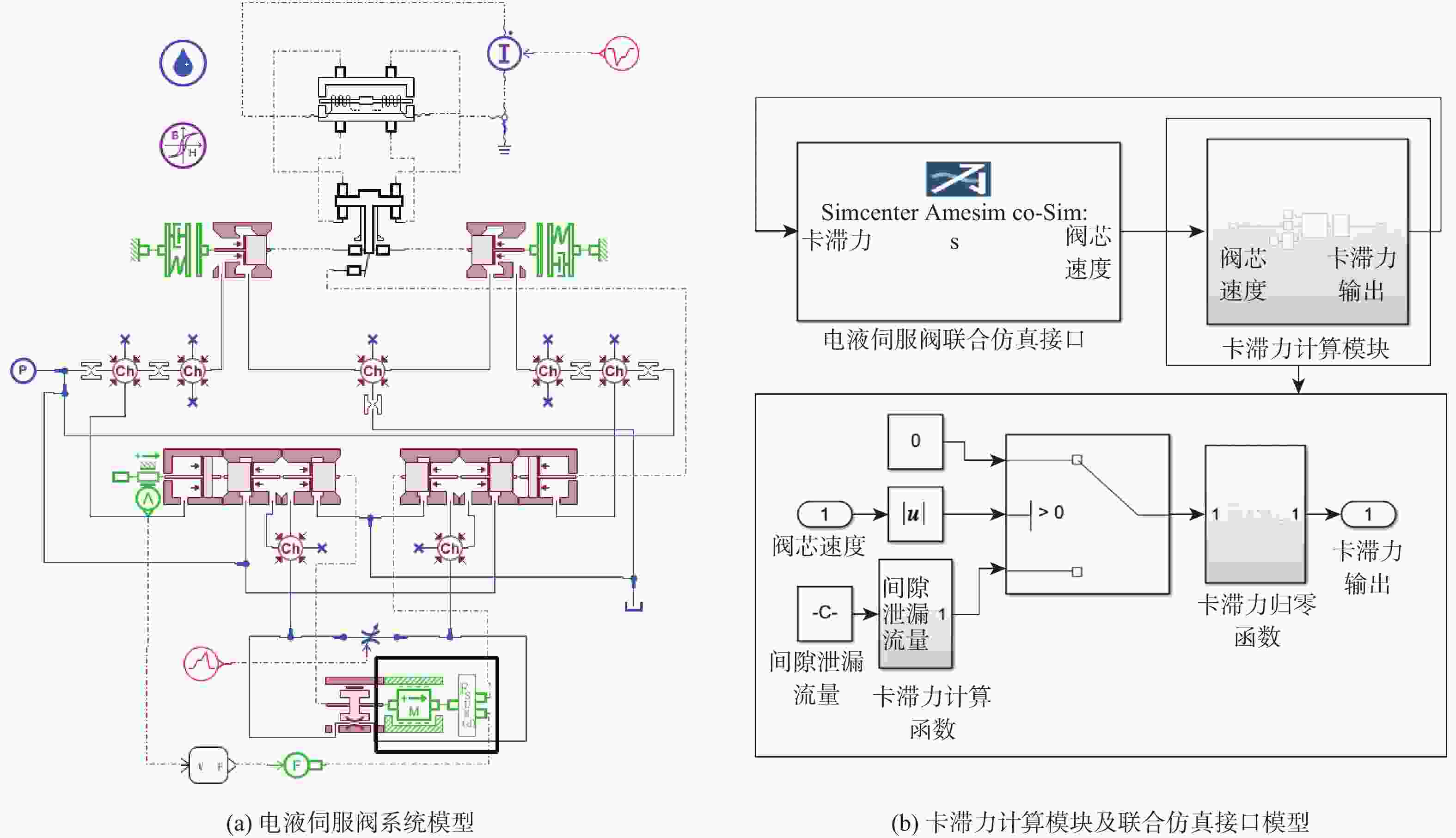

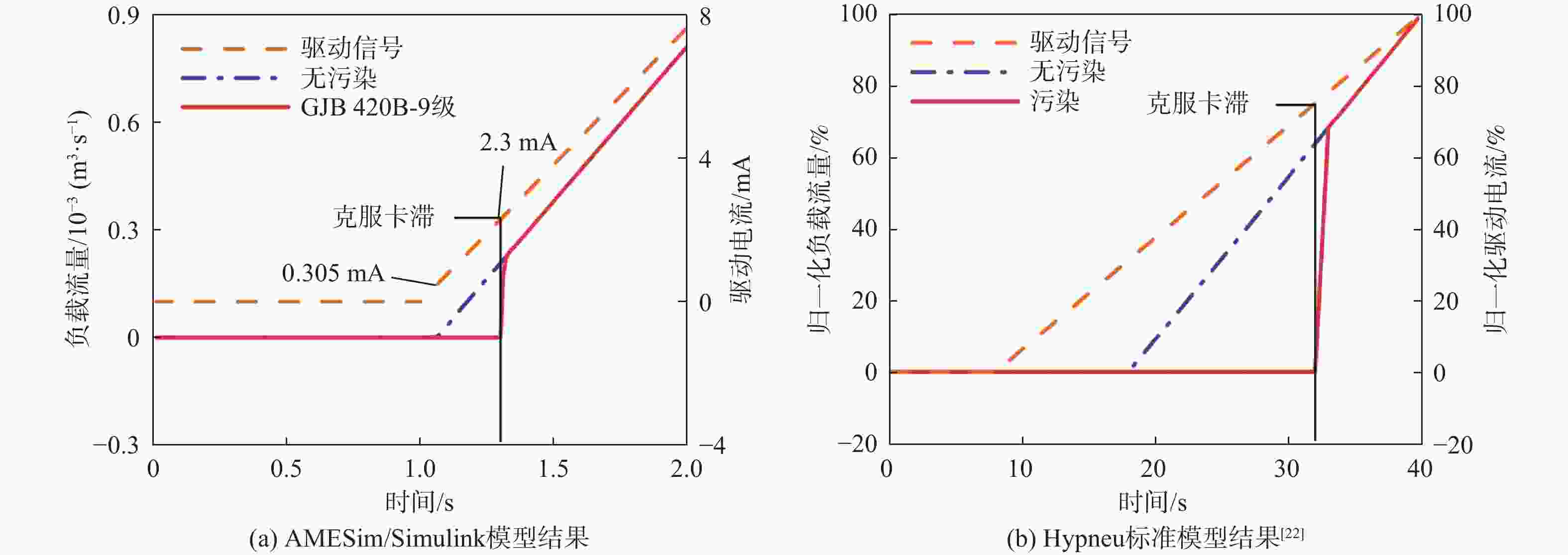

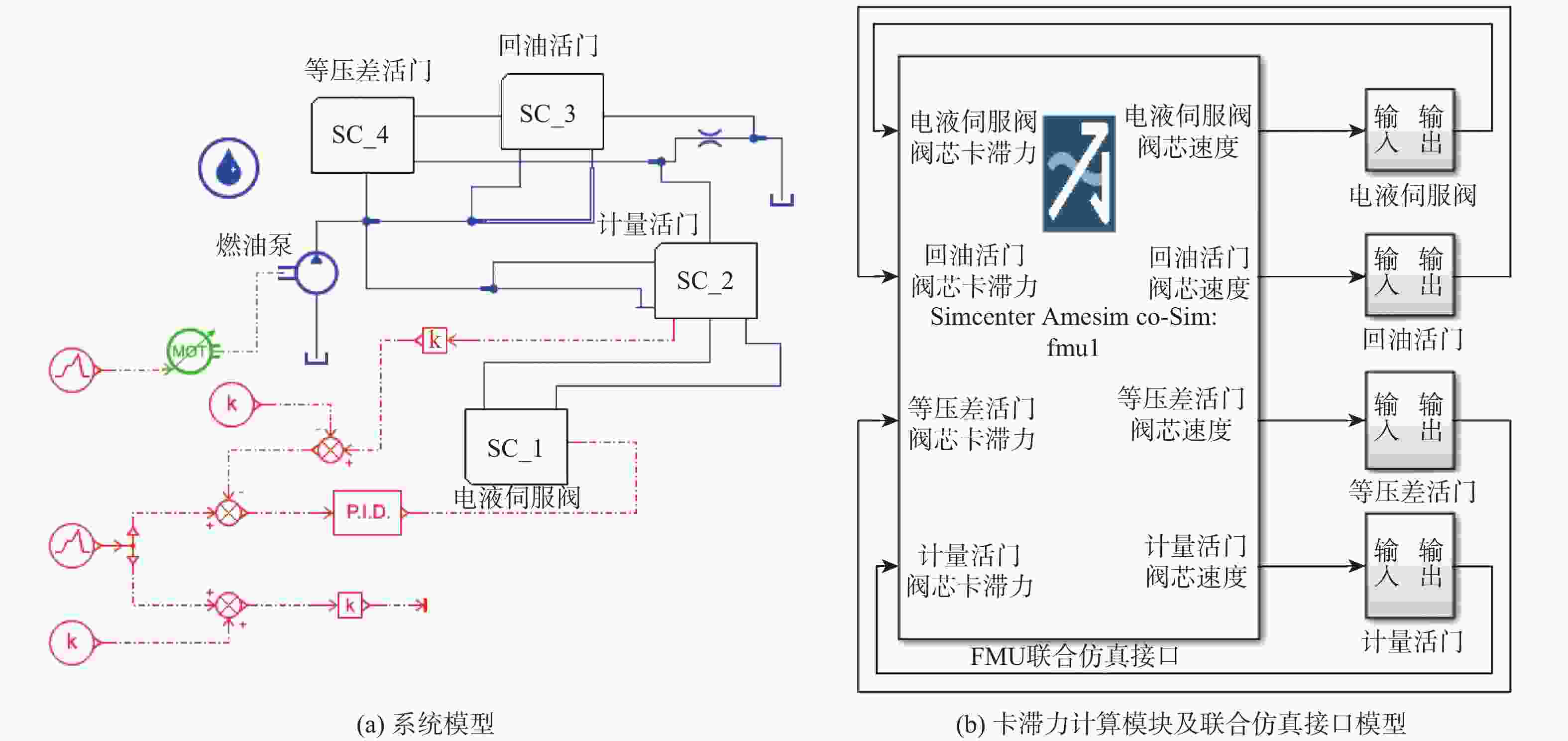

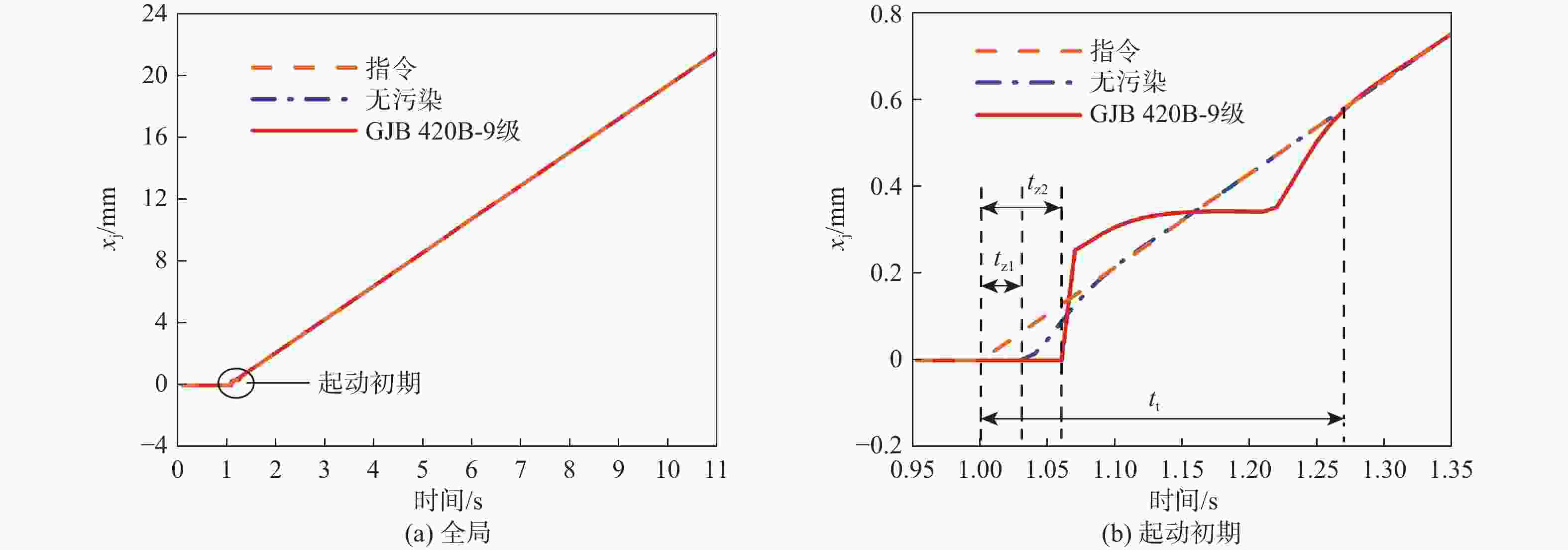

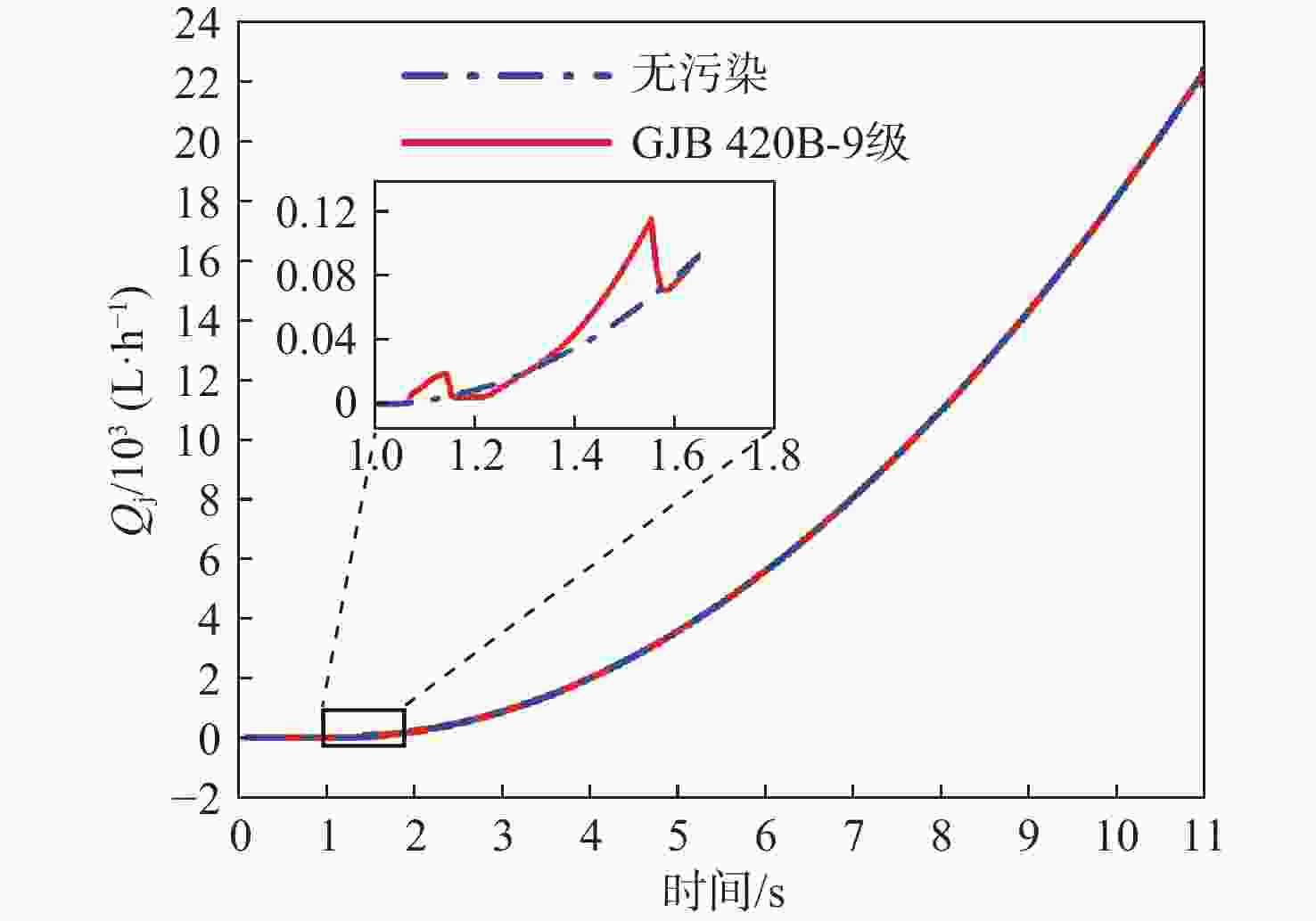

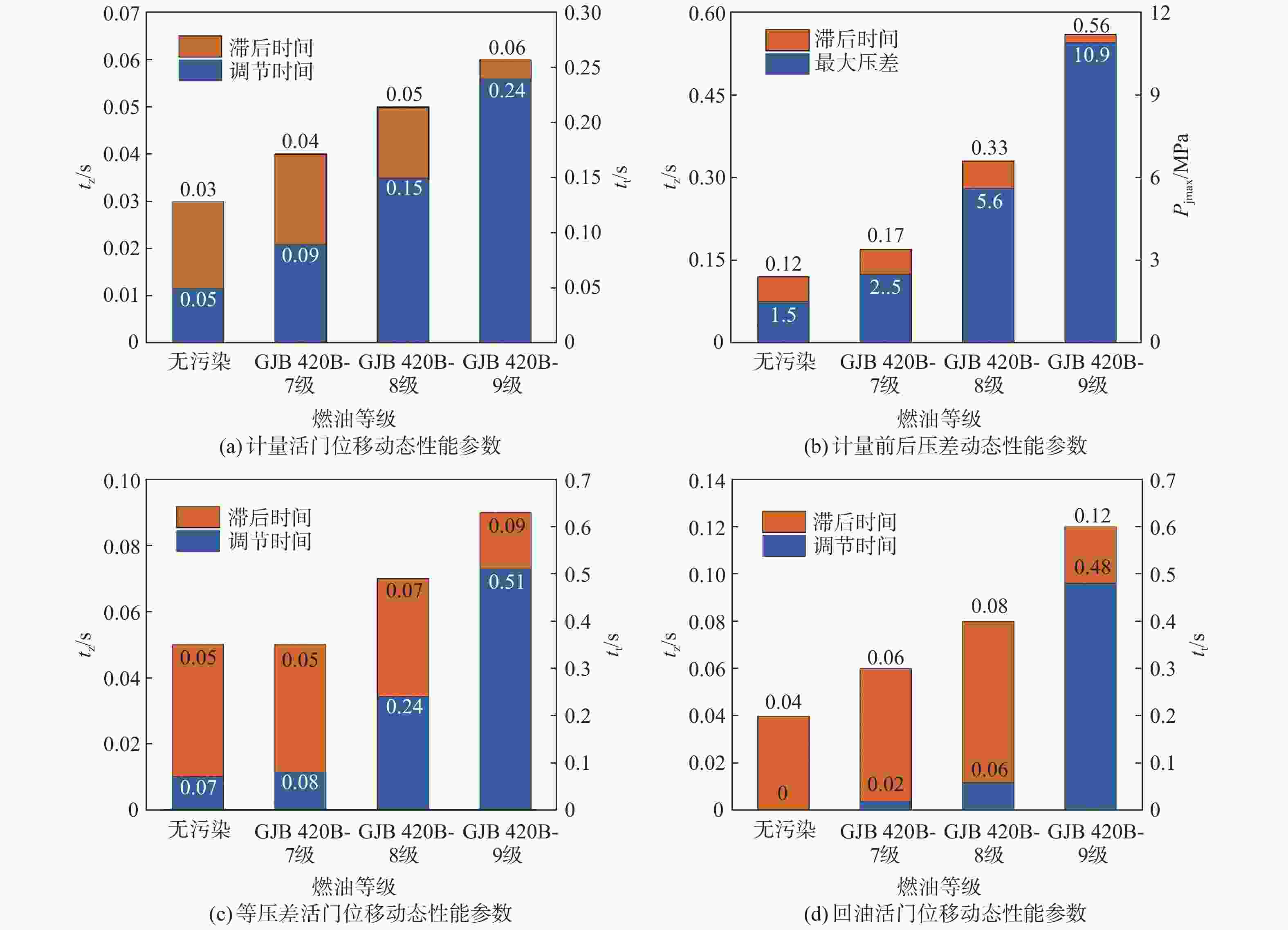

为获得燃油中污染颗粒对燃油计量装置(FMU)工作特性影响的定量规律,并探索一种面向非标燃油部件污染卡滞特性的分析方法,基于OMEGA理论将污染颗粒对燃油部件的作用转化为卡滞力,建立了燃油污染工况下燃油部件和装置的动力学模型。开展了固体污染度等级为GJB 420B-7/8/9级时FMU的工作特性仿真,获得了各等级燃油对其关键部件性能的影响规律。结果表明:所建电液伺服阀污染卡滞模型获得的负载流量响应与标准电液伺服阀污染卡滞模型的结果基本吻合,GJB 420B-9级燃油中计量活门最大卡滞力约140 N,响应时间为无污染时的2倍以上,计量流量最大相对误差增加4倍以上。所提方法可为非标燃油部件和系统的污染卡滞建模提供参考。

Abstract:To quantify the impact of contamination particles on the operational characteristics of a fuel metering unit (FMU) and to explore an analytical method for the contamination lock characteristics of non-standard fuel components, OMEGA theory was applied to translate the effect of these particles into lock forces on fuel components. A dynamic model for the components and units under fuel contamination conditions was developed. The operational characteristics of an FMU using class GJB 420B-7/8/9 fuel were simulated, and the effects of each fuel class on key components were analyzed. The results show that the load flow response from the servo-valve contamination lock model aligns closely with the standard servo-valve lock model. The maximum lock force of the metering valve reaches 140 N for class GJB 420B-9 fuel. The response time is more than twice as long as that under non-contaminated conditions, and the maximum relative error in the metered fuel increases by a factor of more than four. The method proposed in this paper provides a valuable reference for modeling contamination lock effects in non-standard fuel components and systems.

-

Key words:

- OMEGA theory /

- fuel metering unit /

- lock force /

- operational characteristic /

- fuel class

-

表 1 GJB 420B-7/8/9级燃油污染颗粒浓度

Table 1. Particle concentration of pollutants in class GJB 420B-7/8/9 fuel

污染颗粒

尺度/μm污染颗粒浓度/(个·(100 mL)−1) GJB 420B-7 GJB 420B-8 GJB 420B-9 >1 100000 200000 400000 >5 38900 77900 156000 >15 6920 13900 27700 >25 1200 2450 4900 >50 212 424 848 >100 32 64 128 表 2 污染卡滞敏感度

Table 2. Contamination lock sensitivity

污染颗粒尺度/μm 卡滞敏感度/(N·粒−1) 0~5 4.56486 ×10−85~10 1.27656 ×10−710~20 3.30282 ×10−720~30 1.22369 ×10−530~40 1.15079 ×10−540~50 1.50553 ×10−650~60 3.33644 ×10−660~70 0 70~80 0 -

[1] 杨文举, 邵垒, 刘卫华, 等. 飞机燃油箱水污染物数值建模[J]. 北京麻豆精品秘 国产传媒学报, 2024, 50(11): 3578-3586.YANG W J, SHAO L, LIU W H, et al. Numerical modeling of water contaminants in aircraft fuel tank[J]. Journal of Beijing University of Aeronautics and Astronautics, 2024, 50(11): 3578-3586(in Chinese). [2] 赵维义, 李岩, 王占勇, 等. 飞机液压系统油液的污染与控制[J]. 机床与液压, 2012, 40(10): 157-159. doi: 10.3969/j.issn.1001-3881.2012.10.050ZHAO W Y, LI Y, WANG Z Y, et al. Pollution and control of oil in hydraulic system of aircraft[J]. Machine Tool & Hydraulics, 2012, 40(10): 157-159(in Chinese). doi: 10.3969/j.issn.1001-3881.2012.10.050 [3] 李志强. 高效精油过滤器的设计及在线检测和监控[D]. 南京: 南京理工大学, 2016: 6-9.LI Z Q. Design and on-line detection and monitoring of high-efficiency essential oil filter[D]. Nanjing: Nanjing University of Science and Technology, 2016: 6-9(in Chinese). [4] 郭善新, 陈达贵, 张禹, 等. 高压齿轮泵污染磨损的寿命模型研究与验证[J]. 流体机械, 2018, 46(5): 13-17. doi: 10.3969/j.issn.1005-0329.2018.05.003GUO S X, CHEN D G, ZHANG Y, et al. Research and verification of life model for pollution wear of high pressure gear pump[J]. Fluid Machinery, 2018, 46(5): 13-17(in Chinese). doi: 10.3969/j.issn.1005-0329.2018.05.003 [5] 罗宇轩, 林振浩, 母娟, 等. 阀芯卡滞的研究进展[J]. 机电工程, 2022, 39(7): 865-876. doi: 10.3969/j.issn.1001-4551.2022.07.001LUO Y X, LIN Z H, MU J, et al. Research progress of valve core clamping[J]. Journal of Mechanical & Electrical Engineering, 2022, 39(7): 865-876(in Chinese). doi: 10.3969/j.issn.1001-4551.2022.07.001 [6] 郑帅可. 液压元件污染敏感度分析及测试系统研制[D]. 杭州: 浙江大学, 2020.ZHENG S K. Analysis of contamination sensitivity of hydraulic components and development of testing system[D]. Hangzhou: Zhejiang University, 2020(in Chinese). [7] 卢继霞, 郭瑞宇, 王成, 等. 基于固体颗粒尺寸分布的微孔滤膜堵塞机理分析[J]. 机械工程学报, 2018, 54(20): 145-151. doi: 10.3901/JME.2018.20.145LU J X, GUO R Y, WANG C, et al. Fouling mechanism analysis on micro-pore filter membrane based on the solid particle size distribution[J]. Journal of Mechanical Engineering, 2018, 54(20): 145-151(in Chinese). doi: 10.3901/JME.2018.20.145 [8] 刘阁, 张梅菊, 王文瑾, 等. 光阻法油液污染度检测传感器的设计与实现[J]. 测控技术, 2022, 41(3): 18-25.LIU G, ZHANG M J, WANG W J, et al. Design and implementation of oil contamination detection sensor based on photoresist method[J]. Measurement & Control Technology, 2022, 41(3): 18-25(in Chinese). [9] SRIDHAR V, CHANA K S, SINGH D. Computational and experimental study of a platinum thin-film based oil condition and contamination sensor[C]//Proceedings of the ASME Turbo Expo 2017 Turbomachinery Technical Conference and Exposition. New York: ASME, 2017: 1-7. [10] 姚金勇, 李娇, 张坤, 等. 液压系统污染性能仿真与优化设计[J]. 液压与气动, 2014, 38(3): 48-53.YAO J Y, LI J, ZHANG K, et al. Pollution performance simulation and optimization design for hydraulic system[J]. Chinese Hydraulics & Pneumatics, 2014, 38(3): 48-53(in Chinese). [11] 张人才. 主动控制油液污染来提高航空液压系统的可靠性及寿命[D]. 北京: 中国地质大学(北京), 2017: 47-53.ZHANG R C. Actively control oil pollution to improve the reliability and life of aviation hydraulic system[D]. Beijing: China University of Geosciences (Beijing), 2017: 47-53(in Chinese). [12] JI H, NIE S L, BAI X R. Simulation on mechanism of contamination mitigation through Higee and hydrocyclone techniques in fluid power system[J]. Proceedings of the Institution of Mechanical Engineers, Part E: Journal of Process Mechanical Engineering, 2018, 232(1): 77-93. doi: 10.1177/0954408916684161 [13] 张育洋. 基于污染磨损试验的液压柱塞泵寿命评估技术研究[D]. 西安: 西安电子科技大学, 2019.ZHANG Y Y. Research on life assessment technology of hydraulic piston pump based on pollution wear test[D]. Xi’an: Xidian University, 2019(in Chinese). [14] 刘勇, 马彪, 张赛飞, 等. 油液污染颗粒引起的齿轮泵劣化失效研究[J]. 农业机械学报, 2015, 46(2): 316-321. doi: 10.6041/j.issn.1000-1298.2015.02.047LIU Y, MA B, ZHANG S F, et al. Failure analysis of degradation induced by contaminant particles in gear pump[J]. Transactions of the Chinese Society for Agricultural Machinery, 2015, 46(2): 316-321(in Chinese). doi: 10.6041/j.issn.1000-1298.2015.02.047 [15] 王洪波, 黄智鹏, 张向英, 等. 基于加速寿命试验方法的伺服阀污染卡滞寿命分析[J]. 液压与气动, 2022, 46(7): 131-135. doi: 10.11832/j.issn.1000-4858.2022.07.017WANG H B, HUANG Z P, ZHANG X Y, et al. Analysis of fouling and sticking life of servo valve based on accelerated life test method[J]. Chinese Hydraulics & Pneumatics, 2022, 46(7): 131-135(in Chinese). doi: 10.11832/j.issn.1000-4858.2022.07.017 [16] 郑长松, 葛鹏飞, 李芸辉, 等. 液压滑阀污染卡紧及滤饼形成机制研究[J]. 润滑与密封, 2014, 39(8): 14-19. doi: 10.3969/j.issn.0254-0150.2014.08.003ZHENG C S, GE P F, LI Y H, et al. Contaminant lock force and filter cake forming mechanism of hydraulic spool valves[J]. Lubrication Engineering, 2014, 39(8): 14-19(in Chinese). doi: 10.3969/j.issn.0254-0150.2014.08.003 [17] 中国航空工业第二集团. 航空工作液固体污染度分级: GJB 420B—2015[S]. 北京: 总装备部军标出版发行部, 2016: 1-3.The Second Group of China Aviation Industry. Solid particle contamination classes for fluid of aviation: GJB 420B—2015[S]. Beijing: Military Standard Publishing and Distribution Department of General Equipment Department, 2016: 1-3(in Chinese). [18] ZHANG Y, WANG S P, SHI J, et al. Evaluation of thermal effects on temperature-sensitive operating force of flow servo valve for fuel metering unit[J]. Chinese Journal of Aeronautics, 2020, 33(6): 1812-1823. doi: 10.1016/j.cja.2019.09.011 [19] 来晨阳, 郭迎清, 于华锋. 基于RF-SVR的燃油计量装置性能衰退检测和剩余寿命估计方法[J]. 航空动力学报, 2019, 34(7): 1624-1632.LAI C Y, GUO Y Q, YU H F. Fuel metering unit performance degradation detection and remaining useful life estimation method based on RF-SVR[J]. Journal of Aerospace Power, 2019, 34(7): 1624-1632(in Chinese). [20] 陆亮, 夏飞燕, 訚耀保, 等. 小球式旋转直驱压力伺服阀卡滞机理研究[J]. 浙江大学学报(工学版), 2019, 53(7): 1265-1273.LU L, XIA F Y, YIN Y B, et al. Spool stuck mechanism of ball-type rotary direct drive pressure servo valve[J]. Journal of Zhejiang University (Engineering Science), 2019, 53(7): 1265-1273(in Chinese). [21] 朴英, 张绍基. 某涡扇发动机加力供油系统排故试验及仿真研究[J]. 航空动力学报, 1995, 10(4): 354-356.PIAO Y, ZHANG S J. Troubleshooting tests and simulation for a reheat fuel system of a turbofan engine[J]. Journal of Aerospace Power, 1995, 10(4): 354-356(in Chinese). [22] WANG X H, YAN Y J, LI Q X. Contaminant lock life prediction of double flapper-nozzle servo valve[J]. Advanced Materials Research, 2014, 933: 953-958. doi: 10.4028/www.scientific.net/AMR.933.953 [23] 中国人民解放军驻113厂军事代表室, 中国一航第113厂. 航空发动机燃油系统附件污染度要求: GJB 7078—2010[S]. 北京: 总装备部军标出版发行部, 2010: 1-2.Military Representative Office of the Chinese People’s Liberation Army Stationed at Factory 113, No.113 Factory of Aviation Industry Corporation of China. Fuel systems, components, aero-engine, requirements for contamination: GJB 7078—2010[S]. Beijing: Military Standard Publishing and Distribution Department of General Equipment Department, 2010: 1-2(in Chinese). -

下载:

下载: